DIY generator autostart

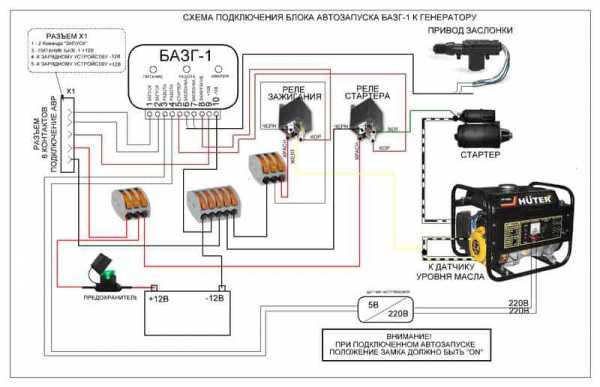

If you have certain skills in electrical engineering, you can independently assemble a circuit that can start a generator without human intervention when electricity goes out on the main line. The main condition is that this requires a generator model that starts and stops with a key, since automating the starter, which must be pulled by the cord, is obviously a thankless task.

To understand the principle of automatic start-up, you need to accurately imagine the entire procedure that will have to be done to turn on the generator:

1. After 1-2 minutes after the light goes out, open the engine choke and start it. A time delay is needed in case the light just blinked or went out for a few seconds.

2. After another 2 minutes, when the engine is warmed up, switch the load from the main line to the generator, then close the choke.

3. When electricity appears on the main line, after 30-60 seconds, turn off the engine and switch the load from the generator to the main line.

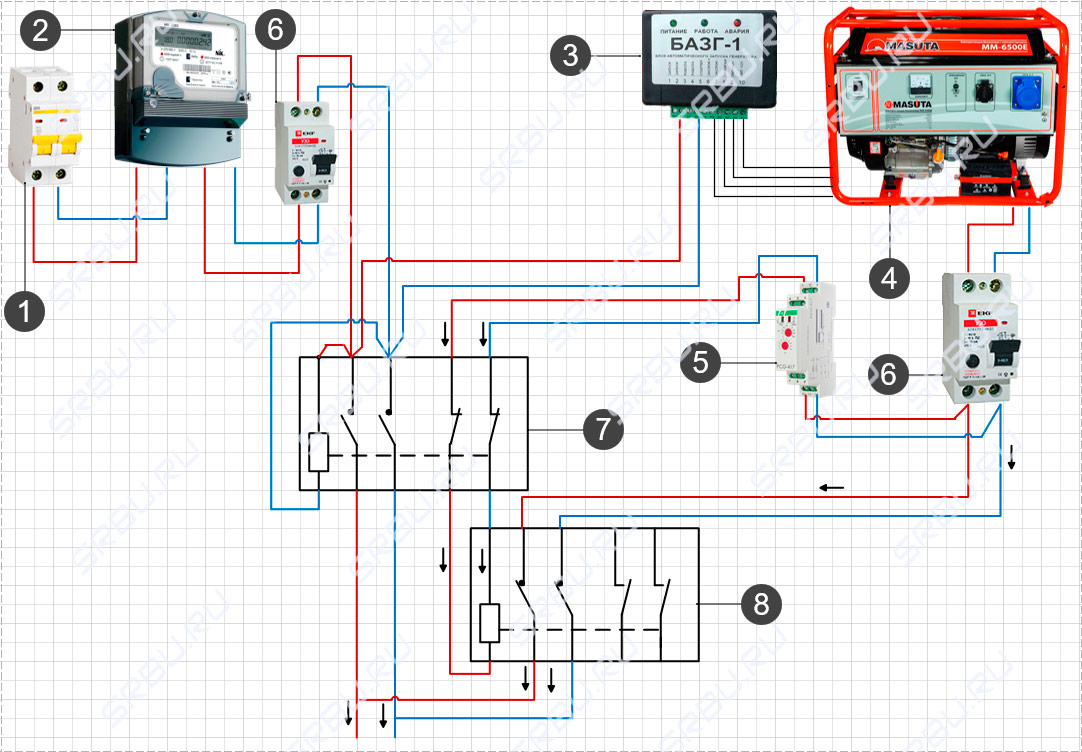

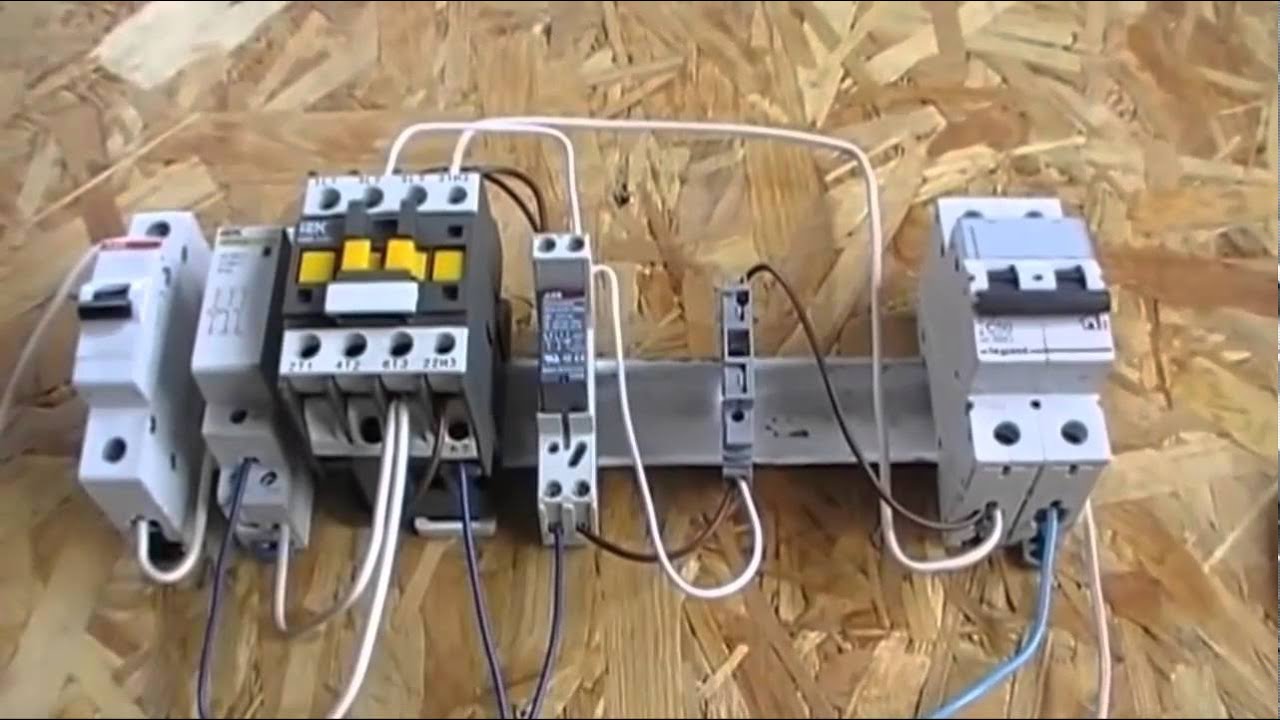

To implement this algorithm, you need four time relays, four electromagnetic starters and magnetic pushers with limit switches, like the servos used for the central locking of a car. A standard electromagnetic starter has a coil (KM), normally open power contacts (KMk), 2 normally open control contacts (KMnr1-2) and 2 normally closed control contacts (KMnz1-2).

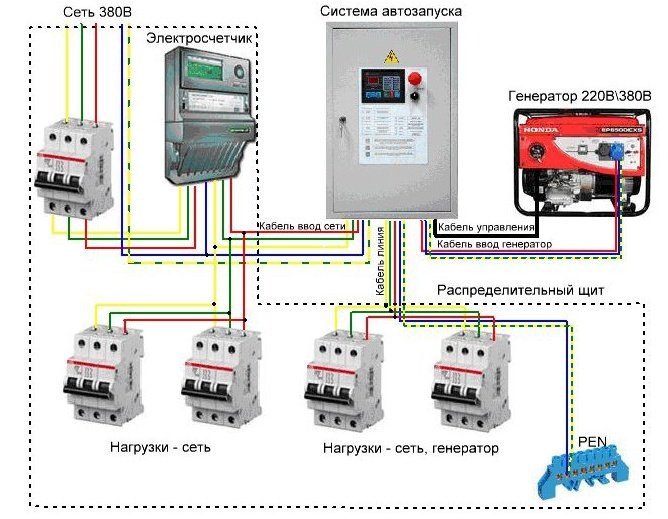

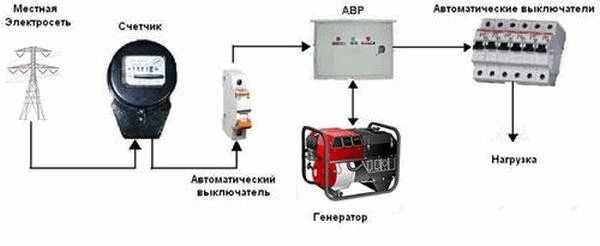

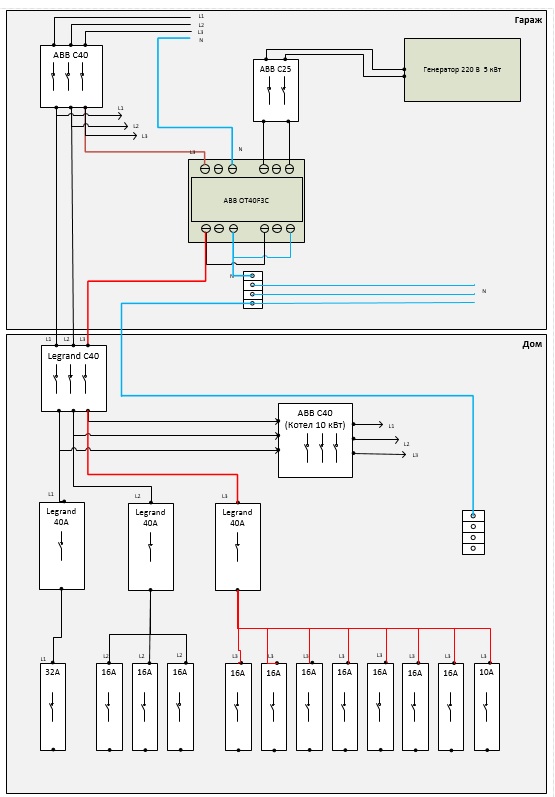

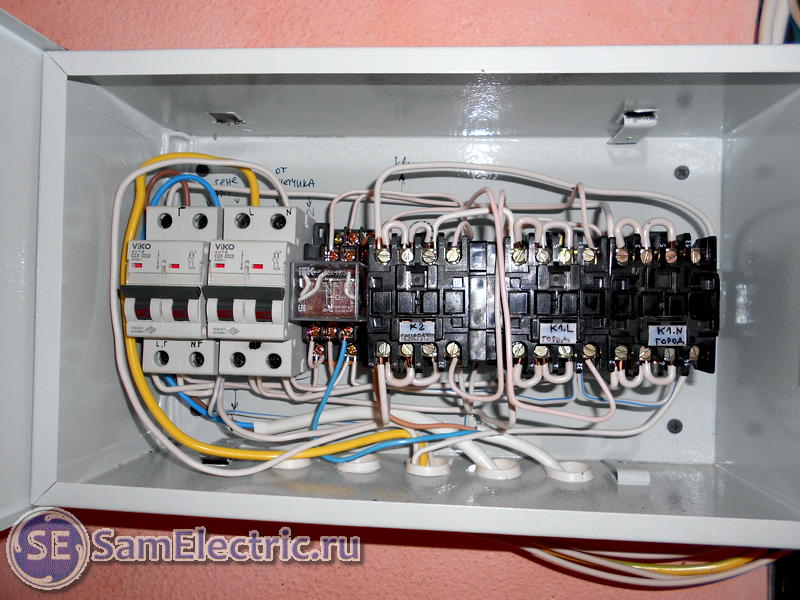

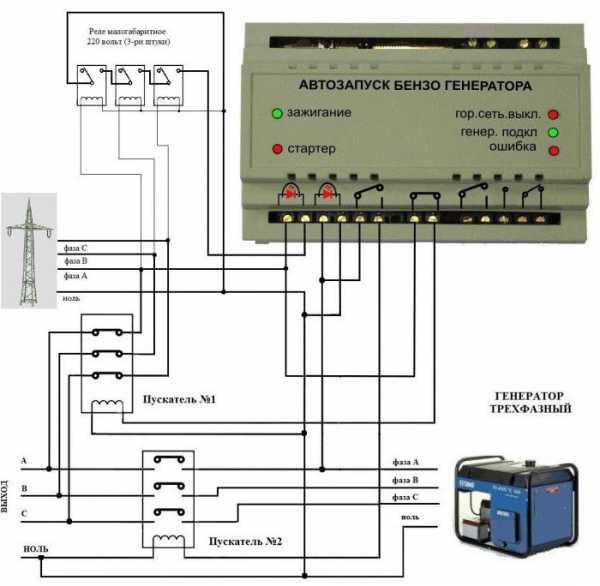

The figure shows a general diagram of connecting a generator to a home with auto start - the principle of its operation is as follows.

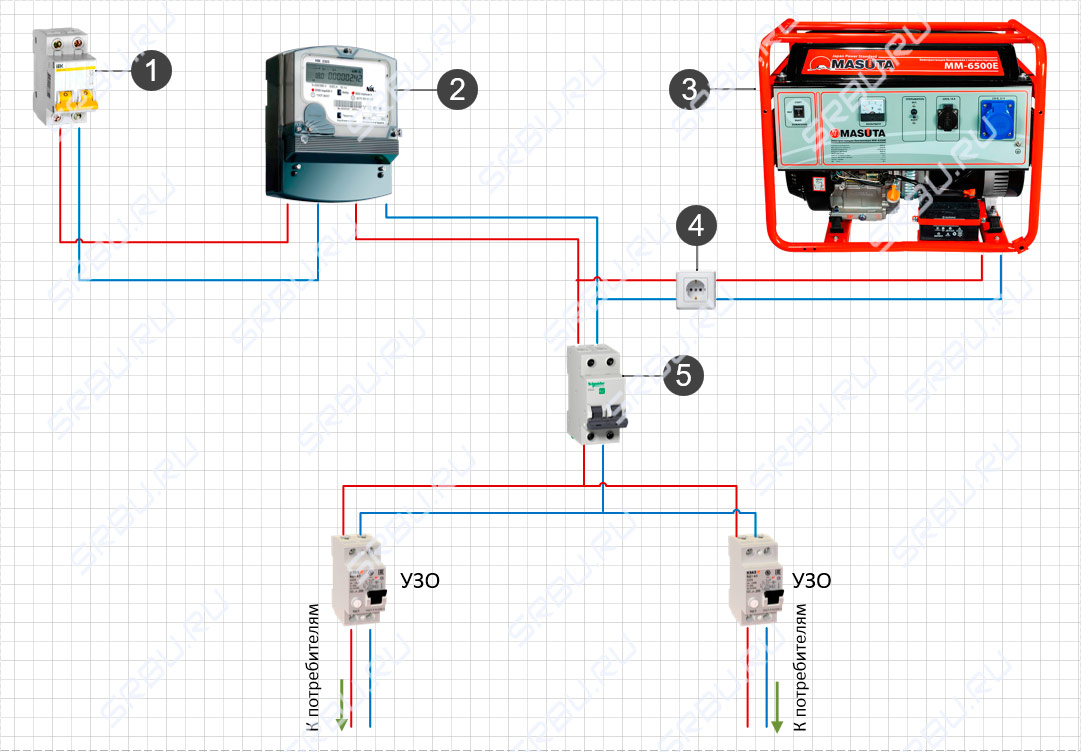

1. Introductory machine. 2. Electricity meter. 3. Generator. 4. Distribution machine. 5, 6. RCD.

When the electricity is turned off, the KM4 coil ceases to hold the KM4nz2 contacts in the open state, which turns on the ignition of the generator. Also, the KM1 coil ceases to hold the KMk1 contacts - they open and now the line is disconnected from the home network. Normally closed contacts KM1nz1 and KM1nz2 are closed in parallel. They start the servo that opens the air damper of the engine and give an impulse to start. Time relay 1 - after a minute, the key contact will close and the starter will start the engine.

The start of the generator triggers the KM3 coil, which opens the normally closed contacts KM3nz1 and KM3nz2, which stops the starter and de-energizes Servo-1. Parallel closure of the normally closed contact KM1nz2 gives a pulse to another time relay - after two minutes Servo-2 will start, closing the air damper, and the KM2 coil will operate, closing the KMk2 contacts, after which the current is supplied to the house from the generator.

To ensure the reverse switching, you first need to open the KM2 coil circuit in 1-2 minutes after the appearance of electricity and turn off the engine, for which the Time Relay 3 and the KM4 starter are used, when triggered, the normally closed KM4nz1 and KM4nz2 open. When the KM2 coil is disconnected, the normally closed contact KM2nz1 closes, which after two minutes, through Time Relay 4, turns on the KM1 coil - now the generator is de-energized and ready for the next start, and power is supplied to the house from the main line.

This is just one of the possible options for automating the launch. For example, if desired, the circuit can be simplified by removing the time relay and air damper servos from it.True, this can only be done if the engine starts well, and in general all its components are well debugged.

The main disadvantage of any such scheme is that it controls the generator's autostart, but it will not be able to react even to a minor emergency situation. For example, if the air damper is jammed, the engine will operate at increased speeds, and if the internal combustion engine itself fails - if it does not start - at best, the battery will run out.

Single-phase or three-phase generators

There are several very important points to consider here, the first of which is the cost of devices. Three-phase generators, like single-phase ones, are available with all types of engines - gasoline or diesel, but those devices that produce three phases are much more expensive than single-phase ones. At the same time, some buyers prefer to take a three-phase generator and use it to connect single-phase electrical appliances.

They are guided by the fact that three-phase gas generators are allegedly generally more reliable, and most importantly, they are universal - when three-phase equipment appears on the farm, there will be where to connect it.

In practice, everything is different - for the comfortable operation of a three-phase generator, the load on its phases must be evenly distributed and this is possible only when three-phase current consumers are connected to it or if single-phase devices are correctly phase-distributed. Few can competently do the latter, especially considering that all these devices must be turned on all the time - otherwise, there is a phase imbalance in the load and the generator will work for wear and tear.

This means that it will not give out the rated voltage, the generator winding will overheat, the engine will overspend on oil and fuel - if you force the gas generator to work in this mode for a long time, then it will fail quickly enough.

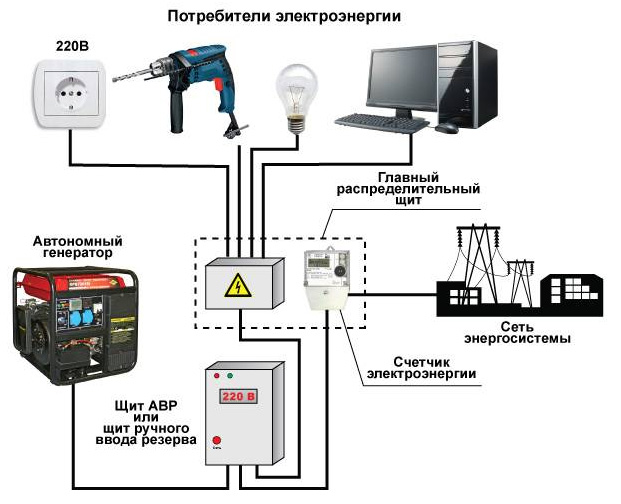

Connection with full use of the ATS

The next way to connect a gas generator involves the use of a full-fledged ATS. Automation checks the presence of voltage in the general network. If the voltage disappears, the ATS starts the installed generator, heats it up to operating temperature and transfers the load to it.

When the voltage appears in the main source, the load is switched from the gas generator to the general power grid, then the genset is turned off.

The latter method with fully automatic work is optimal. The main disadvantage is the high cost of ATS and installation work.

When carrying out work on the installation of ATS, knowledge and skills are needed to combine an electric generator and automation. For a fully automatic operation of a mini-power plant, it must be equipped with an electric starter.

Step-by-step connection of the gas generator to the house.

After the consumer has chosen the optimal connection option for himself, you can start directly to work.

The easiest way is when the appliances are connected to the generator outlet. Additional manipulations are not required in this option.

The electric unit is connected to consumers, regardless of the availability of centralized power supply. The generator is always connected to the wiring of electricity consumers.

It is necessary to ensure that the cross-section of the wires corresponds to the rated current of the gas generator.

This method does not require special manipulations - the plug of the powered appliance is connected to the generator directly or through an extension cord. Usually, a portable low-power generator is used here, which is subsequently removed.

Connecting powerful power plants.

When connecting more powerful stationary units, it is necessary to carry out a number of additional work.

Before connecting the generating set, remember to position it correctly.There are many factors to consider when choosing a location for installation, including increased noise from the unit and emissions. Usually, the unit is installed at some distance from the house or summer cottage.

Ideally, the generating set is housed in a separate, lockable room with good ventilation. Placed in a basement without access to cold air, the generator will constantly overheat, which will lead to its breakdown.

The base on which the gas generator is installed should not rigidly bond with the building. You can install the unit on special shock absorbers, or even on a rubber pad. This will help reduce the noise from the generator. Also, special soundproof enclosures will help to reduce the noise level.

The installation of a gas generator includes grounding. The grounding element can be a one and a half meter metal rod with a diameter of one and a half centimeters or a sheet of iron 500 * 1000mm in size. The earthing switch is immersed in the ground, then the ground wire using clamps connects it to the generator.

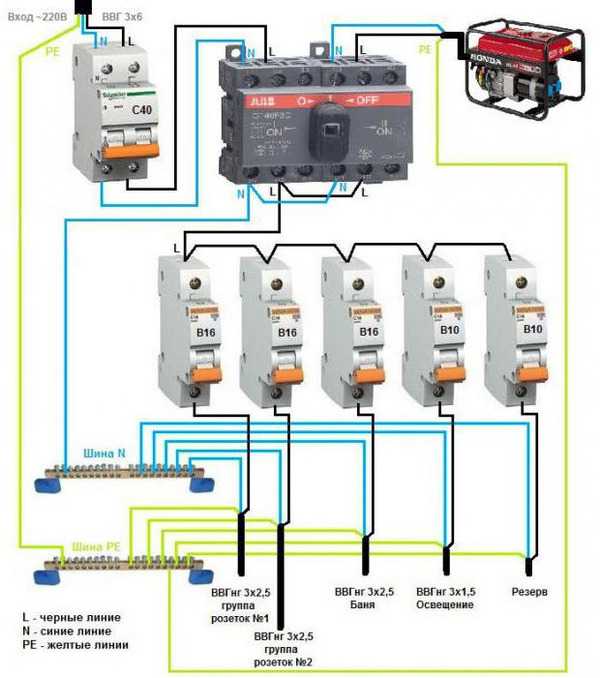

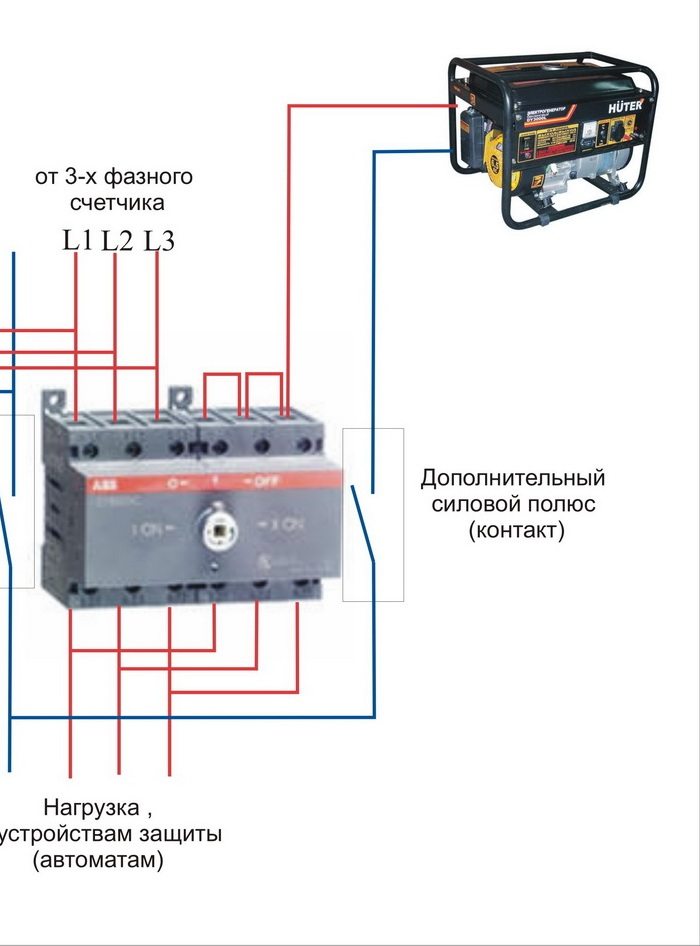

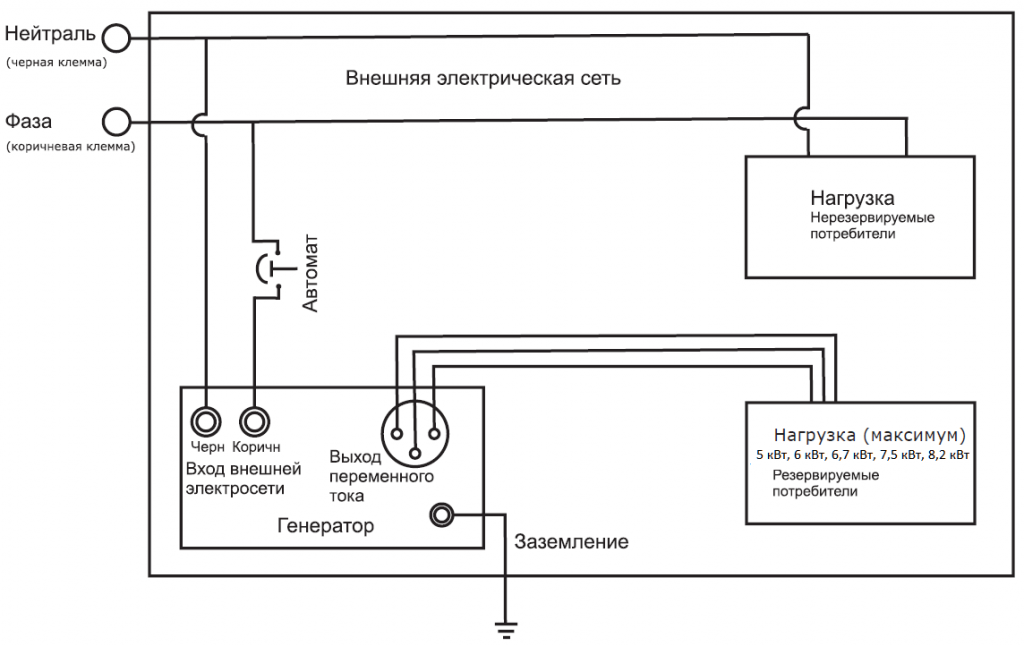

The connection diagram of a gasoline electric generator as a backup power supply has the modes "power grid" and "generator". Switching between modes can be carried out both manually and automatically using a switch. When connecting the generator, remember that the switch entry point is always located after the electricity meter, but in front of the protective device.

Useful Tips

There are several ways to incorrectly connect the gas generator. First of all, this is connecting the network from the unit to the general network and connecting the wiring from the generator to a standard consumer outlet.

These methods are not allowed. If the generator is connected to a regular outlet of the consumer network, with a heavy load, the outlet along with the electrical wiring will simply collapse, and a fire hazard will arise.

The fact is that the parameters of the outlet are not designed for the power of the generator. If the gas generator is connected to a common network, then when a centralized power supply appears, the unit may fail.

Before each switching on, the condition of all blocks and units of the generating set is carefully checked. If necessary, damaged units are repaired or replaced.

Choosing the best scheme option

If electricity is lost in the general network, then the contacts are discarded and a pair of contacts is closed, which activates other contacts responsible for the reserve.

It is enough to connect the main consumers: lighting and some household appliances.

The power is chosen depending on how much equipment will be powered by the generator. Changeover switch or contactors? Most often, models are equipped with air radiators.

The next step is to manually start the generator. It is connected according to the scheme indicated with the instructions. There is a separate 12 volt output for starting the respective consumers.

See also: Certificate of registration of the electrical laboratory in the bodies of Rostechnadzor

The operation algorithm of the device is quite simple: In the event of a city electricity failure, approach the generator and start it, if there is no electricity in the main network, the generator contactor will close

It is important to draw it up correctly and protect the generator itself and consumers from high load

Since you are dealing with combustible fuels, do not forget about this! The launch process takes place entirely in manual mode. As for the connection technology, it looks like this: Turn off the power in the house with the machines on the dashboard. According to the characteristics of such a wiring, it can withstand a power consumption of up to 3.5 kW.

Choosing a generator

Recommended entries. The features of using such a device include the following points: The switch can be in three positions: the extreme closes two circuits, the central one opens both.The cost of three-phase units is higher, and the generator itself must be evenly loaded across three loads evenly.

Features of control, connection and fuel filling. When refueling the generator, you need to turn it off, and carefully remove spilled traces of fuel!

How I connected the generator to the house

Determine the range of tasks to be solved

The first thing to do before choosing a gasoline generator is to decide on the tasks that will be solved with its help. It is clear that for a summer residence and a manufacturing enterprise, you need to purchase completely different devices, but which one is suitable in a particular case must be determined on the spot.

Even if you just buy a generator "like a neighbor's", it is not a fact that its needs will be the same, which means either an overpayment for excessive power, or the inability of the gas generator to cope with the load imposed on it.

Standby or permanent source of electricity

If the generator is installed in an area to which the power supply line is connected, then it will be used only in the event of a power outage. Often, a large reserve is not required - 3-4 hours of uninterrupted operation, for which gasoline generators are designed, will quite help to wait out the shutdown. Also, such devices can be used in places where there is no electricity at all, but the scope of work is small and does not require its constant availability.

When you need a constant source of electricity, even if you need to connect not very powerful electrical appliances, then you need to look towards diesel devices. Even low-power generators can be designed for long-term operation, and devices producing 15 kW or more are generally equipped with water cooling and can not be turned off around the clock.

Gas generator power and intensity of use

These two concepts are often incorrectly correlated with each other. Depending on the task, you can choose a gas generator that can work only an hour without interruption, but at the same time, during this time, it will provide the total amount of electricity to the device. power up to 10-15 kW.

On the other hand, you can choose a generator that will work for 4-5 hours, but in total it is possible to "hang" a load of no more than 5 kW on it.

The same applies to generators for uninterrupted operation - if there should be no questions here over time, then their power can be very different.

Operating conditions

Gas generators do not have to be used to carry out any work - there are a number of portable models that you can take with you when going out into the countryside: on a hike or fishing. The weight of such devices is about 15-25 kg and they are specially made in the form of a suitcase with a handle for easy portability. Also, such devices will be appreciated by specialists who may need electricity when carrying out field work.

For work on a construction site, more powerful gas generators are needed, but still have sufficient mobility to move them around the construction site. In this case, you need to choose frame-type generators - some of them are even equipped with wheels so that they can be moved by the forces of one person.

You also need to figure out in advance if there are any restrictions on the permissible noise level in the place of use of the device. If so, then it is better to select gasoline models. Also, such generators will show themselves better in the cold season, while diesel ones will have to be additionally warmed up before starting.

It is also worth paying attention to the level of dust and moisture resistance of the case - the gas generator case is responsible for this. The standard marking applies here - from IP24 to IP54

Generator power

One of the most important the characteristics of the unit is its capacity. According to this parameter, stations are divided into the following categories:

- up to 1 kW - for going outdoors;

- from 2 to 5 kW - gas generators for a summer residence with a small area;

- from 6 to 10 kW - for a medium-sized house;

- from 11 to 15 kW - for a modern cottage with heavy loads.

Before choosing a gasoline generator for your home, you need to calculate the maximum energy consumption of electrical appliances during the period of autonomous supply of the house. To correctly determine the load, one should be guided by the power values of all electricity consumers and their current ratios.

They look like this:

| Device type | Power consumption level, kW | Current factor |

|---|---|---|

| Fridge | 0.25 | 3.5 |

| Air conditioning | 1 | 3.5 |

| Washer | 1.5 | 3.5 |

| A computer | 0.3 | 2 |

| Electric pump | 0.7 | 3 |

| Microwave | 1 | 2 |

| Television | 0.08 | 1 |

| Lighting devices in the amount of 6 units | 0.36 | 1 |

The calculation of the maximum load on a power plant involves multiplying the indicators of power consumption by current factors and then adding them together. In the example of the table above, the power value is 14.76 kW. For a cottage with a high level of consumption, it is necessary to choose a professional-level gas generator with a two-cylinder engine, the power of which reaches 10-15 kW. Installations such as HONDA EM 1000 KP and SDMO TECHNIC 20000 TE AVR C can act as worthy options.

- In the event that the house is equipped with an electric heating boiler, a high-performance diesel generator will need to be used to maintain the life of this device.

- To power the electronics of a gas boiler, a small power generator is required. We wrote about generators to ensure uninterrupted power supply to a gas boiler in a separate article.

It should be noted that during the operation of the generator, the load on the power plant must be at least 30%. For example, if you connect only a 100 W device to the network by means of a 1 kW generator, the device will not be able to achieve the required thermal regime and will function for wear and tear. Such actions should not be allowed, since in this case the station may deafen, work intermittently or fail.

What to consider when choosing?

For the successful selection of a gasoline generator, you need to pay close attention to a number of issues, among which it is worth highlighting the following

The required power of the device. Make sure that the station will be able to cope with the supply of power to all devices. Each person will be able to make calculations, because for this it is enough to summarize the power of all devices that will be simultaneously connected to the network. It should be noted that some people mistakenly believe that it is more profitable to take the most powerful device, and then use it only half, as a result of which they overpay.

Voltage, which is determined depending on what kind of devices or tools will be used.

Unit use frequency

Based on this parameter, you need to pay attention to the station resource. It should be borne in mind that generators, which have a small resource of work, can boast of minimal weight and mobility.

But they are not able to work more than a couple of hours.

The starting method, which can be manual or automatic, is also important. The first option is convenient in cases where the generator is rarely turned on; to start, it will be enough just to pull the cord

The main advantage of such models is their affordable cost. Electric start gas generators, on the other hand, are more expensive, but they will become the preferred option for permanent use.

If you live in an area where blackouts are a constant phenomenon, then it is better to look at models with automatic start. They start their work as soon as the power is lost in the network.

When choosing a gasoline generator, you should also pay attention to the cooling system.Most of the devices on the market are air cooled

These units are cheaper in terms of their cost, and the system is quite enough to ensure the stable operation of the generator. When buying, it is also worth considering the presence of the following additional functions:

- noise protection, thanks to which the unit works quietly;

- the volume of the tank, on which the station's operating time directly depends;

- a counter that allows you to control the work;

- overload protection, which significantly extends the life of the engine.

Autonomous power plant device

In fact, any gas generator is a device for converting energy stored in fuel, first into mechanical, and then into electrical. Based on this, any gas generator should consist of the following components:

1. Gas tank. 2. Ignition switch 3. Low oil pressure indicator 4. Output voltage voltmeter 5. Sockets.

6. Frame. 7. Electricity generator 8. Support wheel 9. Oil dipstick and filler neck 10. Engine.

11. Manual starter. 12. Carburetor. 13. Air filter. 14. Handle for moving the unit.

Internal combustion engine (ICE). Provides autonomous operation of the entire device, converting fuel energy into shaft rotation. Gasoline and diesel internal combustion engines are mainly used, and there are also models that run on gas. In addition to the type of fuel, engines are divided into two and four-stroke - the former are much more compact, but require a gasoline-oil fuel mixture for operation, and the latter are distinguished by smoother operation, better efficiency and less frequent need for maintenance.

Also in the characteristics of the engine you can find the abbreviations "OHV" and "OHC". The first signifies that "top valve" technology is used, which reduces fuel and oil consumption, and the second indicates a novelty in engine design - an overhead crankshaft, which allowed the manufacturer to reduce wear on parts, increase productivity and add fuel to the engine.

Starter - to start the engine. It can be manual (when the start is carried out by a cable) or automatic (the scheme is used as in cars - the start is made by turning the key). In the second case, the starting circuit can be supplemented with a controller, which is connected to the main network and when the voltage disappears in it, the gas generator is started.

Fuel tank. Everything is simple here - the larger it is, the longer the generator will work without refueling. But since utility-class generators need to take regular breaks, the size of the tank is often calculated so that there is enough fuel just for the period of time recommended for continuous operation.

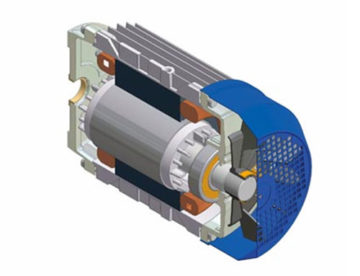

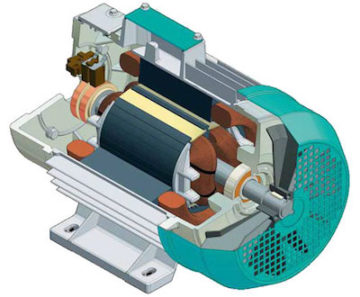

Electricity generator. Responsible for converting mechanical energy of rotation of the internal combustion engine shaft into electrical energy. In appearance, this is the same electric motor, but with the opposite principle of operation - when its shaft rotates, an electric voltage is induced at the winding terminals. Depending on the class of the entire device, synchronous and asynchronous generators are used.

Coupling. Each mechanical device, during operation, creates some vibrations due to which it is inappropriate to spend efforts on the exact alignment of adjacent mechanisms. The task of the clutch is to transfer rotation from the ICE shaft to the electric motor, while allowing their shafts to be positioned relative to each other with some error. Usually it is a pair of belts of hard rubber or similar material that will transmit torque, but still be quite ductile.

Power section of the electrical circuit. An analogue of the terminal board of an apartment - here are the circuit breakers and outlets for connecting electricity consumers.

Frame and body. The mobility of the entire device and the degree of its protection from rain and other climatic influences directly depend on the quality of their performance.

In addition to the mandatory components, generators often have additional elements, the presence which depends on the manufacturer or the set of the device offered by the store.

Connection and maintenance

If you use an external ATS device, then it is located next to the electrical panel for supplying power to the house. The ATS input is connected after the electric meter, power lines for the entire load are connected to its output, for which power is reserved. The control wires from the ATS are routed to the room where the generator is located: the circuits for starting and stopping the generator engine are connected according to the manufacturer's scheme.

If the battery is charged not during the operation of the generator set, but from the ATS unit, it is also necessary to extend the power wires to it. You should not place the battery next to the autorun device - since the starting current is much higher than the charging current, it is better to place the battery near the generator, shortening the length of the power wiring, and the wiring for charging can be taken with a small section - 0.5 or even 0.25 sq. Mm ...

Units with a built-in autostart system are placed in the selected room, and the input and output from the backup device are brought out to the input electrical panel in the same way as the external ATS device is connected.

Regular maintenance of the generator with autostart includes, in addition to routine maintenance and adjustments for a gas generator, also changing the fuel and monitoring the battery status by voltage at its terminals or a test run.

If the voltage is less than 12V or if the starter does not rotate easily, the battery should be recharged or the battery should be replaced if it does not accept a charge.

Connecting the gas generator to the network at home

There are several optimal ways, based on the presence of an autorun system. The mini-power plant itself is connected through a special power outlet. As a rule, there are three sockets on the case: two for 16A (with a limit of no more than 3 kW for each) and a power one for 32 A. From the power one you can “pull out” the entire power of the generator, therefore a backup line is connected to it.

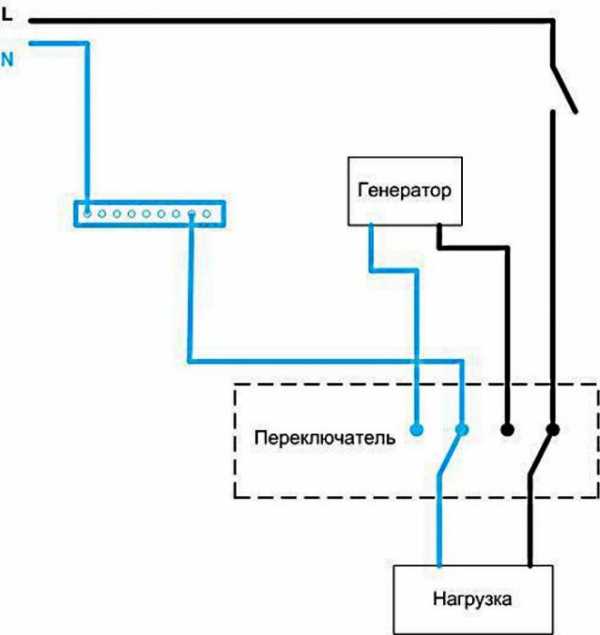

Option for manual connection of the reserve

The easiest way is with a toggle switch, which must be three-position (1-0-2): 1 - main power supply, 0 - no voltage, 2 - backup power. After the input line is de-energized, you can manually start the generator and switch power to it, and in the event of an emergency, you can de-energize the entire circuit by switching the switch to the zero position.

The circuit is quite simple: the spare line is connected directly to the switch, then the load goes to the home automation and distribution lines. But, there is one important disadvantage here - the backup line is turned on manually, as well as shutdown, so you need to independently monitor when the voltage appears in the input cable in order to switch back to the main power supply.

Automatic transfer switch option

This is the most versatile method and only works with the ATS system. The circuit is structured like this:

- After a power failure in the city network, the automatic device sends a pulse to the generator's electric starter;

- After starting and warming up the power plant, the ATS switches to the backup line;

- When electricity enters the city grid, the system switches the power supply back to the main line;

- After switching, the ATS automatically turns off the gas generator.

Despite such a high cost, this scheme is the most effective, since in case of interruptions, the backup power supply is supplied within a few minutes (not immediately, since these two minutes are needed to warm up the engine).

Engine

As you know, a gasoline engine can operate both in a two-stroke cycle and in a four-stroke cycle.At the same time, low efficiency and limited resource makes two-stroke engines not the best choice for driving an electric generator, although they are simpler in design, which means they are cheaper and lighter.

As you know, a gasoline engine can operate both in a two-stroke cycle and in a four-stroke cycle.At the same time, low efficiency and limited resource makes two-stroke engines not the best choice for driving an electric generator, although they are simpler in design, which means they are cheaper and lighter.

A four-stroke engine, although it is more complex and more expensive, consumes significantly less fuel and is able to work much more. Therefore, generators up to 10 kVA are usually equipped with this type of motor.

Gasoline engines of electric generators are mainly single-cylinder units with forced air cooling, the preparation of the combustible mixture is carried out using a carburetor. To start them, either a rope starter is used, or an electric start is additionally included in the design (then, in addition to the battery, such generators also have a 12 V output: the battery is charged from this circuit and consumers designed for low-voltage power can be connected to it). The most common motors with a cast iron sleeve and an overhead valve timing mechanism are usually Honda GX motors and their Chinese counterparts.

The engines of household gas generators are not designed for long-term continuous operation. Exceeding the operating time specified in the operating instructions (as a rule, no more than 5-7 hours) will shorten the life of the motor.

However, even the most advanced gasoline engines have a limited resource: with proper care, they will last 3-4 thousand hours. Is it a lot or a little? With occasional use on the road, for example, to connect an electric tool, this is a fairly large resource, but constantly feeding a private house from a gas generator means annually sorting out its engine.

Diesel power units have a significantly longer resource, in addition, they are more profitable during long-term operation due to greater efficiency. For this reason, all powerful generating sets, both portable and stationary, use diesel engines.

For such units, a number of disadvantages of diesel engines compared to gasoline ones (high cost, greater weight and noise) are not fundamental, a certain inconvenience is only when starting diesel engines in cold weather.

When operating a diesel generator, it must be borne in mind that prolonged idling without load is harmful for them: the completeness of fuel combustion is disturbed, which leads to an increased formation of soot, clogging the exhaust, and the dilution of the engine oil by diesel fuel seeping through the piston rings. Therefore, the list of routine maintenance for diesel power plants must include their periodic output to full capacity.

In addition, there are natural gas generators. Structurally, they are no different from gasoline ones, except for the power system: instead of a carburetor, they are equipped with a reducer to regulate the gas pressure and a calibrated nozzle that supplies gas to the intake manifold. At the same time, such generators as a fuel source can use not only a bottle with liquefied gas, but also a gas network - in this case, fuel costs become minimal. The disadvantage of such generators is low mobility (a gas cylinder is larger and heavier than a gas tank, which, moreover, can be refueled right on the spot), as well as increased fire hazard, especially in case of illiterate operation. However, as a backup power source in a house connected to a gas main, this is a good option: there is no need to worry about maintaining the level and quality of fuel in the gas tank, and the engine resource when running on gas is higher than when running on gasoline.