What does the market offer?

High-performance segments with a long service life are offered on the market by domestic and foreign manufacturers. A quality product differs in high price. Foreign manufacturers include Metabo, Bosch, Makita, Stayer, FIT. Preference is given to tools from Bosch, since, due to the four-spiral shape, after the end of the work, it is easy to get the remnants of construction waste material from the recesses.

The cheaper version of the tool is Interskol products.

Russian production, as well as companies from the CIS countries and China, offer tools that are more affordable. Among them are Interskol, Zubr, Enkor. When choosing a tool, you need to understand that the drills are covered with a high-quality alloy and are made using modern technologies, which means that the price should be appropriate. Fakes are often found in the markets, which are darker due to the use of poor quality raw materials.

Drilling principles

Getting started with tiles, you need to carefully study its characteristics and properties.

Drilling should be carried out as accurately and carefully as possible, without violating the integrity of the coating, strictly observing the principles of drilling:

- hold the drill at an angle of 90 degrees to the surface;

- add momentum only when they have reached concrete;

- constantly cool the work surface;

- exclude overheating of ceramics and tools;

- choose the optimal pressure on the tool;

- turn off the reverse mode, perform smooth revolutions according to the movement of the clock hand;

- position the hole in the center of the seam (there is no protective layer at the edge and near the edge of the tile).

Making an opening for the dowels to fix the toilet bowl, you must comply with some requirements:

drill the cladding only with a drill with a feather for tiles, and concrete with a percussion tool;

the size of the recess in the tile must be larger than in concrete to maintain the integrity of the tile;

Drive in the fastener very carefully.

Crowns

Crown or cutter - a cylinder-shaped drill for making large holes. The base material is tool steel. Cutting elements are fixed from one end (various materials are used), from the other there is a shank for mounting in a drill chuck.

By design, crowns are divided into two types:

- with a center drill: used for working with hand tools;

- without center drill: for stationary installations.

A crown without a center drill, fixed on a hand drill, "walks" on the tile when trying to drill. For drilling tiles, only spray cutters are used.

The serrated varieties (carbide) are designed for hammer drilling and are therefore not suitable for brittle ceramics. According to the material of spraying, cutters are divided into two types: diamond-coated and tungsten carbide.

The advantage of the crowns is the high quality of drilling. The edge of the hole does not need to be trimmed like after the "ballerina".

Diamond coated

Like the diamond drill, this tool is more commonly used by professionals. It has a significant resource, but is expensive.

Crowns heat up more than drills, therefore diamond-coated tools are divided into two types:

Crowns heat up more than drills, therefore diamond-coated tools are divided into two types:

for wet drilling. Here, diamond chips are fixed in the least reliable way - on solder. When heated, it softens and the crown loses dusting. To avoid this, water supply to the working area is required.

Mills for wet drilling have an important advantage: after the resource is exhausted, the cutting part can be replaced, so there is no need to purchase a new bit;

for dry cutting.Expensive crowns with laser brazing fixation, resistant to overheating

The tool is slotted into segments for efficient heat dissipation. The cutting part is not restored; after the resource is used up, you have to buy a new cutter.

Tungsten carbide

The cheapest, but also the least durable variety. Usually a tungsten carbide cutter is purchased for one-off work.

Abrasive grinding wheel

Abrasive wheels are made in the form of very thin sheets and have bore holes in the center with a frame in the form of a metal sleeve. To create such discs, different particles are used, fillers in combination with a special binder mass, which can be vulcanite or bakelite. In accordance with the technology, all of the listed components, after mixing, are sent to special forms, after which they are pressed.

Abrasive wheels are made in the form of very thin sheets and have bore holes in the center with a frame in the form of a metal sleeve. To create such discs, different particles are used, fillers in combination with a special binder mass, which can be vulcanite or bakelite. In accordance with the technology, all of the listed components, after mixing, are sent to special forms, after which they are pressed.

Abrasive wheels are of two types:

- grinding;

- detachable.

The former are designed for cutting solid non-metallic and metallic materials, including marble, brick, drywall, non-ferrous alloys and others. Grinding wheels are most commonly used for grinding and sharpening parts made from the same materials.

Both types of abrasive wheels are equally in demand in production. They are used for processing on the appropriate type of machine - grinding and cutting.

The necessary result when using abrasive wheels is obtained by the action of sharp tops of abrasive particles, which, during the rotation of the wheel, cut into the work surface. Typically, these particles are 100 to 2000 microns in size. It should be noted that with an increase in the size and hardness of the abrasive grains, the productivity of the wheel also increases.

Parameters and varieties

The main feature of the tool for concrete is that its working element has special solders from a special alloy with the highest level of hardness. Thanks to its excellent performance properties, this metal alloy has received the interesting name "win". Parts made from it are considered the most suitable tool for fully processing this material.

This type of instrument comes in several categories:

- products with a structure in the form of a polyhedron or a cylinder;

- a tool with a perforator and a cylindrical "tail".

Many home craftsmen often have a question related to the choice of tools and equipment for processing reinforced concrete structures. To solve this problem, you can use a hammer drill and elements designed for a hammer drill. This type of parts is of three types:

- Screw products. They are used to drill deep holes.

- Spiral tool. With its help, holes with a large diameter are made.

- Sloping elements that allow the creation of holes of small depth and diameter.

Thanks to the thickening in the area of the tail, the drills are very easy to fit into the drill chuck by means of a simple snap-in. Concrete handling attachments are usually selected by installation experts and builders.

In that situation, if you need to get a large hole, then a crown tool is often taken. These drills allow you to make holes with a diameter of up to twelve centimeters. Core drills for concrete are of several types:

- diamond drills for concrete in the form of a crown or a tube, fixed on a rod;

- victorious drills for concrete, which are characterized by a design similar to a diamond tool (they differ from their diamond counterparts in the material from which the teeth of the cutting surface are made).

The need to use a core drill appears in those situations when it is necessary to prepare the bore holes for switches and power outlets, stretch communications and perform other work that is related to the creation of recesses and large holes.

The choice of a suitable drill depends on the depth and diameter of the intended holes.

How does a diamond pencil work?

The diamond dressing pencil looks like a 5 cm long steel pin. Natural / synthetic diamonds are placed in the lower part of the product. The function of the connecting link is performed by a metal alloy with an expansion coefficient close to that of diamond crystals.

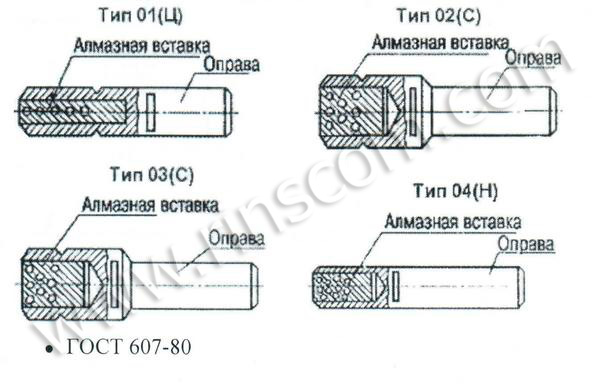

Image No. 1: Diagram of the device of diamond pencils types 01, 02, 03, 04 according to GOST

The frame of products can be of various shapes: cylinder, steps, cone. There are diamond pencils with carving. Inside the product, diamonds are held by soldering, embossing or metal clamps. Attach the pencil to the holder in such a way that the tool protrudes from the edges of the frame by a maximum of ¼ of its length.

Technical advice for drilling metals

the pin is inserted into the recess and the magnet is turned on

Decide on the optimal speed. This parameter is very important. Please note that if you select a higher speed than recommended, you will not be able to complete the drilling job. It is imperative to ensure that the speed is at least 25% of the recommended speed. When working with carbide drills, it should be remembered that they are sensitive to excessively underestimated speeds. In this case, you may encounter such phenomena as increased vibration and chipping of teeth. If the speed is overestimated by more than 20%, then when using a drill from HSS and powder steel, the latter will quickly become unusable.

You should choose the right feed. At the beginning of work, it is necessary to set the feed at a level 2 times lower than the recommended one. It should be borne in mind that if the drill pressure is too high, the speed will remain the same. In order to achieve higher productivity, it is recommended to use equipment with increased rotation speed in combination with carbide drills. Sometimes it may be necessary to apply more force while drilling. If this happens, it is highly likely that you are working with a blunt drill or trying to create a hole in a material that is too hard.