Varieties of chargers for nickel-cadmium batteries

To restore the capacity of a nickel-cadmium type battery, 2 types of chargers are used:

- automatic type;

- impulse reversible blocks.

The automatic module is equipped with sockets of the appropriate size for the batteries. Such devices are designed for 2 or 4 elements; a switch is provided in the design of the unit that allows you to select the number of charged items.

The batteries start charging after connecting the unit to a 230 V household network. A step-down transformer with a rectifier stage is installed inside the module; a bar of LEDs or a multicolor indicator is used to display the charging status.

Dimensions of Ni-Cd battery.

Dimensions of Ni-Cd battery.

A yellow diode is used to indicate the discharge mode; after a decrease in capacity, the charger automatically switches to the battery charging mode. During the charging process, the temperature of the battery case rises, the unit has a sensor that turns off the current supply when the threshold value is reached.

The reversible charging unit belongs to the category of professional products, it is distinguished by the presence of a microprocessor controller. The equipment supplies continuous ones, which alternate with short-term discharges (the cycle time changes in accordance with the established algorithm).

The equipment allows you to maintain an efficient state of the current source and prolongs the life of Ni-Cd batteries.

Storage process

Proper storage of the battery prior to use is an important condition for its correct and long-term operation. Therefore, the storage process must be started not from the moment of purchase, but immediately after production.

When buying a product equipped with a battery, you should look at the date of its packaging. It must be remembered that the deterioration in the quality of the battery depends not only on how actively it was used, but also on the storage time.

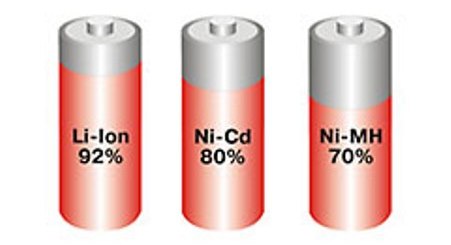

The battery life on the lithium - ion principle of operation is on average 5 years under normal load conditions. But if a screwdriver (another tool) has been on the counter for a long time, the battery loses 10 - 20% of its resource.

Storage of batteries should take place at temperatures from 0C to + 20C. The maximum allowable storage temperature should not exceed + 35C. In this case, the cooler, the better for the battery, but if the temperature is not below zero. Given this feature of the battery, some users store it on a refrigerator shelf. In principle, this is possible provided that the battery is in a sealed waterproof package. If you are not sure about the quality of the packaging, it will be more correct if the batteries of the screwdriver (other device) are stored in another cool place.

Charging the battery correctly also affects the battery life. So that its case does not overheat when connected to the network, it is better if this happens at a low ambient temperature. In this case, the power supply must be "native". Otherwise, the manufacturer does not guarantee normal battery life.

The time to fully charge a modern lithium - ion battery is on average 6 - 7 hours. More precise characteristics of a particular product are indicated in its technical documentation. But even without instructions, you can intuitively understand when the battery is fully charged. In most cases, it contains LED indicators (red - charging, green - charging completed). In addition, when the battery is fully charged, the voltage supply is automatically cut off and the power supply stops heating up.But even such a measure does not guarantee the complete safety of the battery resource. Therefore, it is not recommended to leave it connected to the charger for a long time after it is fully charged.

For lithium batteries, full charge and discharge is not critical. They, unlike nickel - cadmium, for example, do not have "memory of the charge level"

This means that at the level of the working capacity of the battery, the degree of its charge during the subsequent recharging is not reflected.

Battery types

According to their design features, batteries are distinguished in the form of sliders and clips.

Battery screwdriver in the form of a slider

But these are not significant differences compared to the types of batteries. Both the slider and the clip are used in different types of batteries.

Cage-shaped screwdriver battery

There are three types of cordless screwdriver batteries:

- Nickel - cadmium (Ni-Cd).

- Nickel - metal hydride (Ni-Mh).

- Lithium - ionic (Li-Ion).

Lithium polymer batteries (Li-Pol) are not available for screwdrivers. Their main areas of application: smartphones, cell phones, tablets, laptops, radio-controlled devices, electric vehicles.

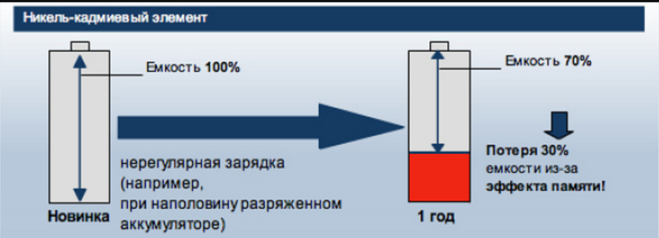

Nickel - cadmium batteries are the cheapest, quickly charge, have more than a thousand charging cycles. The batteries are resistant to use in low temperatures. But they have a memory effect. That is, they can be charged only after a complete discharge, otherwise the capacity will fall. They have a high self-discharge current. They are made from toxic materials and are difficult to dispose of. These batteries are in the highest demand.

Nickel - metal hydride batteries are more expensive, non-toxic, and have a low memory effect. Self-discharge current is higher than nickel - cadmium. The capacity is higher, the charge cycle is more than five hundred. These batteries are less tolerant of high discharge rates. They are less suited to making the most of the power of the tool. They need to be constantly recharged.

Lithium - ion batteries are more expensive, more powerful, and fast charging. They have no memory effect. Low self-discharge current. The voltage of the battery cells is higher, therefore their number is lower. Consequently, the dimensions and weight of such batteries are less than that of nickel ones. But they cannot be completely discharged, otherwise after several such cycles you will have to buy a new one. To improve the quality of lithium-ion batteries, manufacturers install a microcircuit in the battery or screwdriver case that monitors battery performance. A multi-level multi-stage protection is formed:

- From high fever.

- From full discharge. These batteries are afraid of full discharge and cannot recover if the discharge is below the permissible rate.

- Short circuit.

- Overcharge, as an explosion may occur.

- Overload currents.

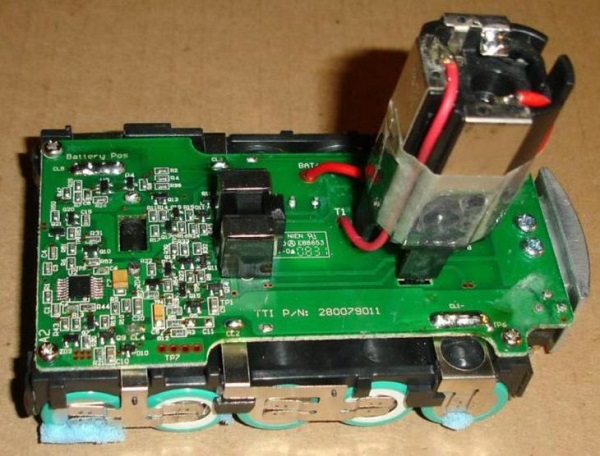

The control board installed in the battery case is more efficient. When the battery lies separately from the screwdriver and is not used, the microcircuit monitors its condition and opens the circuit in case of any problems. The battery is fully protected.

Charging the screwdriver without charger

It is not difficult to restore a battery without the help of a charger, but many do not know how. You can charge the screwdriver battery without a charger using any constant voltage power supply. Its value should be equal to or slightly greater than the voltage value of the battery being charged. For example, for a 12V battery, you can take a rectifier to charge a car. Using terminal clamps and wires, connect them, observing the polarity, to each other for thirty minutes, while controlling the temperature of the battery.

And you can also refine the power supply with high voltage using a simple integrated stabilizer. The LM317 microcircuit allows you to control the input signal up to 40 volts. You will need two stabilizers: one turns on according to the voltage stabilization circuit, and the second - current. Such a scheme can also be used when reworking a charger that does not have nodes for monitoring the charging process.

The scheme works quite simply.During operation, a voltage drop is formed across the resistor R1, it is enough for the LED to light up. As the charge progresses, the current in the circuit drops. After a while, the voltage on the stabilizer will be low and the LED will turn off. Resistor Rx sets the highest current. Its power is chosen at least 0.25 watts. With this scheme, the battery will not be able to overheat as the device will automatically shut down when the battery is fully charged.

The absence or complete breakdown of the screwdriver memory stops all planned work. But, using ingenuity, some available tools, the question that has arisen about how to charge a screwdriver battery without a charger can be successfully solved. There are several ways to solve this problem.

Selection of the charging unit, suitable for the characteristics.

On the battery, or the screwdriver itself, the parameters are indicated: voltage value (volts), battery capacity (ampere / hour). The same dimension of current, identical power should be given by the charger. A charging module from any other device that has identical indicators can charge the battery of a screwdriver: you need to strip the wires, connect the battery connectors using crocodile clips.

The use of a universal memory

For purchase, there are universal charging units, the output parameters of which are adjusted according to the needs of the user, the individual characteristics of the type of device that needs to be charged. Their complete set includes an adapter for the most popular connectors, crocodile clips, such gadgets are suitable for many types of devices and instruments.

Using the car battery charger.

Such a device can damage the battery of a screwdriver, because its output characteristics are different, therefore the charging process can be carried out only after their leveling. It is safest to use a car charger equipped with a voltage level control system. If there is one, it is recommended to set the following parameters: with a battery power of 1.3 ampere / hour, the current value is set at the level of 650 - 130 mA, that is, the current value is 0.5 - 0.1 part of the total battery capacity.

Making a homemade charging block

It is possible to fabricate a homemade unit to charge the drive. To do this, the terminals of the failed battery are soldered, respectively, the polarity through the expanded holes are soldered wires. The location of the wires is sealed with some kind of filler, for example, a roll of thick paper / cardboard. The lid is fixed with glue on the charging glass. The assembled unit is placed into the battery through an adapter.

Equipping the battery with a USB connector

To be able to replenish the battery of the screwdriver through the YUSB-charging unit, it is equipped with such a connector using a fuse. The contact points are soldered, the fuse is fixed with glue, the assembled body is secured with adhesive insulating tape.

Charging via external electricity sources.

If the power tool is very worn out, it is possible to purchase a universal charger for a screwdriver, or a unit that matches your particular model of tool. You will find a huge selection of power supplies for screwdrivers at.

Continuing the topic, you can connect the device to any source of electricity. This is usually done using an old battery of commensurate parameters. A 10A fuse is integrated into the circuit. Wiring must be oversized.

What is a protection board?

The protection board (or PCB - power control board) is designed to protect against short circuit, overcharge and overdischarge of the lithium battery. As a rule, overheating protection is also built into the protection modules.

For safety reasons, it is forbidden to use lithium batteries in household appliances if they do not have a built-in protection board.Therefore, all batteries from cell phones always have a PCB board. The output terminals of the battery are located directly on the board:

These boards use a six-legged charge controller based on specialized mikruh (JW01, JW11, K091, G2J, G3J, S8210, S8261, NE57600, etc. analogs). The task of this controller is to disconnect the battery from the load when the battery is fully discharged and disconnect the battery from charging when it reaches 4.25V.

For example, here is a diagram of the BP-6M battery protection board, which were supplied with old Nokia phones:

If we talk about 18650, then they can be produced with or without a protection board. The protection module is located in the area of the negative terminal of the battery.

The board increases the length of the battery by 2-3 mm.

Batteries without a PCB are usually included in batteries with their own protection circuits.

Any protected battery easily turns into an unprotected battery, just gut it.

To date, the maximum capacity of the 18650 battery is 3400mAh. Protected batteries must be marked on the case ("Protected").

Do not confuse PCB with power charge module (PCM). If the former serve only to protect the battery, the latter are designed to control the charging process - they limit the charging current at a given level, control the temperature and, in general, provide the entire process. The PCM board is what we call the charge controller.

I hope now there are no questions left, how to charge an 18650 battery or any other lithium battery? Then we turn to a small selection of ready-made circuitry solutions for chargers (those same charge controllers).

Types of batteries for screwdrivers

There are several types of cordless screwdriver batteries on the market. Each type of battery has its own advantages and disadvantages. Varieties represent such batteries:

- nickel-cadmium;

- nickel metal hydride;

- lithium-ion.

Nickel-cadmium

Most screwdriver models are equipped with nickel-cadmium elements. These are the simplest low-cost high-capacity batteries. The NiCd rechargeable battery has established itself as a long-lasting battery. She has served for about ten years. Due to the stable tolerance of low temperatures, the screwdriver can be used in the winter season in the open air without a sharp decrease in the charge.

Nickel-cadmium battery for a screwdriver with a voltage of 12v experiences more than a thousand charges and discharges during its entire service life. One of the advantages of a battery is that it can be stored completely discharged for a long time without losing its performance.

Nickel Cadmium Cans

Nickel Cadmium Cans

Important! They work with a screwdriver until the NiCd battery is completely discharged, without fear of a decrease in its quality characteristics. Along with this, it is worth noting some of the disadvantages of nickel-cadmium cells.

The battery pack is quite heavy. When working with it, the worker's hand quickly gets tired. Also batteries of this type for screwdrivers are subject to the "memory effect". If the battery is not completely discharged on the charger, it will “remember” the capacity level. Subsequently, the battery will lose performance, reaching this charge level

Along with this, it is worth noting some of the disadvantages of nickel-cadmium cells. The battery pack is quite heavy. When working with it, the worker's hand quickly gets tired. Also batteries of this type for screwdrivers are subject to the "memory effect". If the battery is not completely discharged on the charger, it will “remember” the capacity level. Subsequently, the battery will lose performance, reaching this charge level.

Nickel metal hydride

To get rid of the "memory effect", experts have developed new battery models. These are the so-called nickel-metal hydride (NiMH) batteries for screwdrivers.Compared to NiCd cells, the new batteries are lighter. The memory effect is insignificant.

Battery cases are now more durable and can withstand occasional dynamic loads. Metal hydride cells are more durable and can withstand up to 1500 charge / discharge cycles.

However, these batteries have their drawbacks. They cannot function in open space at negative air temperatures. Small capacity does not allow working with a screwdriver for a long time. Batteries must not be fully discharged. Service life is poor (4-5 years). The high cost should be added to the cons.

Li-ion

Lithium-ion batteries significantly outperform the aforementioned batteries. With the advent of Li-Ion cells, the problem of the "memory effect" was solved. You can charge batteries in any condition without fear of losing capacity.

The screwdriver does not lose power until the lithium-ion batteries are completely discharged. The service life reaches 5-8 years. The accumulators are practically not self-discharging in storage mode. Full charging takes place within 40-50 minutes.

Lithium ion cell

Lithium ion cell

The disadvantages of Li-Ion batteries include sensitivity to the slightest shock from the case. The battery may explode if dropped from a height. When operating in low temperature conditions, the batteries are quickly discharged. Their high cost should be noted.

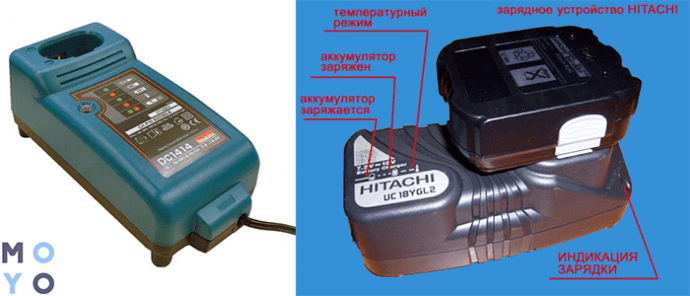

Views

There are many chargers available to suit specific brands and models of instruments. All of them can be divided into main types.

Analog with built-in power supply

Analog ones with a built-in power supply are quite popular. This is due to the low cost. Usually they do not belong to professional equipment, they quickly fail and "do not grab the stars from the sky." The minimum task that, as a rule, set by their manufacturers is to obtain a constant voltage and current load necessary for operation.

The devices work on the principle of a stabilizer. You can do it yourself using the diagram below. To work, you need to remember:

- The voltage at the output of the charging unit is greater than the battery rating.

- Any type of battery is suitable.

- You can use a regular circuit board.

- Such stabilizers apply the compensation principle: unnecessary energy, heat is removed. To dissipate it, you can take, for example, a copper radiator. The area is 20 cm².

- The transformer at the input (Tr1) changes the voltage from 220 to 20 V. Its power is determined by the current and voltage at the output.

- The current is rectified by a diode bridge (VD1).

- You can borrow the decision of the manufacturers: the assembly of Schottky diodes.

- After straightening, the current is pulsating, which is harmful. An electrolytic capacitor (C1) is needed for smoothing.

- KR142EN is used as a stabilizer. For 12 V, its index is 8B.

- Control - based on a transistor (VT2) and resistors (trimmers).

- Automatic shutdown after charging is usually not provided. You will have to independently determine the required time. Alternatively, you can use a circuit that includes a diode (VD2), a transistor (VT1). After charging, the LED (HL1) goes out. There are also more serious options with a switch and an electronic key that turn off automatically.

Analog chargers with external power supply

Analog with an external block, as the name implies, consist of:

- from the network block;

- charger.

Block - normal, includes:

- transformer;

- diode bridge;

- rectifier;

- capacitor filter.

Factory assemblies usually do not have a heatsink. Its role can be played by a high-power resistor. One of the typical causes of breakdowns is thermal conditions.

To remedy the situation, first you need to find out if the power source is working. If it functions, it is supplemented with a control scheme, if not, another is sought. It is quite suitable, for example, from a laptop. It has 18V output, which is sufficient. The rest of the details are usually easy to find.They cost very little, you can borrow from other equipment.

The control unit diagram is shown below. The transistor KT817 is used, for amplification - KT818. Need a radiator. The approximate area is 30-40 cm². Here will dissipate up to 10 W

Many Chinese manufacturers are trying to save on literally every little thing. This should be avoided if more or less decent quality is needed. The homemade circuit has a 1 kΩ trimmer. It is needed to accurately set the current. The output is a 4.7 ohm resistor. It dissipates heat. LED will notify about the end of charging

Impulse

Analog devices take a long time to charge: 3-5 hours on average. Although for domestic purposes this is not scary. The professional sphere, where “time is money”, is another matter. There are such products - accordingly, there are usually two batteries in the set.

Professionals are more likely to use impulse chargers. They have an intelligent process control scheme. Full charge time is impressive: about one hour. Of course, you can make the same fast analog charger, but then its weight and dimensions will be impressive.

Impulse devices are compact and safe. High quality requires a sophisticated, sophisticated design. However, you can repeat it. The circuit below is suitable for use with NiCd batteries with a third signaling pin.

The well-known controller MAX713 is used. The input voltage is -25 V. The power supply is simple, so there is no circuit diagram here.

The resulting charger for the screwdriver "is distinguished by intelligence and ingenuity." It checks the voltage and turns on the boost charge mode. The battery is ready in about 1-1.5 hours. The scheme allows you to choose:

- charge voltage;

- Battery Type.

It shows the value of the resistor (R 19) for switching modes and the position of the jumpers. Using the proposed drawing, you can repair the breakdown. The financial issue will become an additional incentive. Saving at least twice.

Cordless screwdriver with Ni-Cd or Li-Ion battery. What to choose?

In this article we will try to highlight only one question - what is the difference between Ni-Cd (Nickel-Cadmium) and Li-Ion (Lithium-Ion) batteries.

In the Bosch cordless screwdriver range, there are two models that have earned an excellent reputation with consumers for their characteristics as reliable, convenient and durable tools. 1. Cordless drill-driver Bosch GSR 12-2 with Ni-Cd accumulator; 2. Cordless drill-driver Bosch GSR 10,8-2 with Li-Ion accumulator.

However, a beginner in the use of battery technology sometimes asks one of the most significant questions in choosing a screwdriver - which battery to take? Let's consider the main advantages and disadvantages of Ni-Cd (Nickel-Cadmium) and Li-Ion (Lithium-Ion) batteries.

To the main advantages Ni-Cd batteries include:

· low cost;

· Work in a wide temperature range and resistance to its changes (for example, Ni-Cd batteries can be charged at negative temperatures, which makes them indispensable when working in the Far North, which is not particularly important in our latitudes); · They can give much more current to the load than other types of batteries; · Resistance to high currents of charge and discharge; · Easy to recover after long-term storage.

disadvantages Ni-Cd:

· The presence of a memory effect - if you regularly put an incompletely discharged battery on charging, its capacity will decrease due to the growth of crystals on the surface of the plates and other physicochemical processes; · Cadmium is a very toxic substance, therefore the production of Ni-Cd batteries is bad for the environment.

There are also problems with the recycling and disposal of the batteries themselves; · Low specific capacity - the amount of energy that a fully charged battery should have.It is customary to express ampere-hours (Ah); · Large weight and dimensions in comparison with other types of batteries with the same capacity; · High self-discharge (after charging, in the first 24 hours of operation, they lose up to 10%, and in a month - up to 20% of the stored energy).

To the main advantages Li-Ion batteries include:

· At least 2 times higher specific capacity;

· Very low self-discharge; · no memory effect; · The ability to recharge at any time; · A large number of "charge-discharge" cycles (if used correctly, they can withstand more than 2000 cycles); · Ecological cleanliness of production and safety in operation.

disadvantages Li-Ion:

· Susceptible to aging; · Low stability when working at low temperatures; · Require the use of only the original charger; · high price.

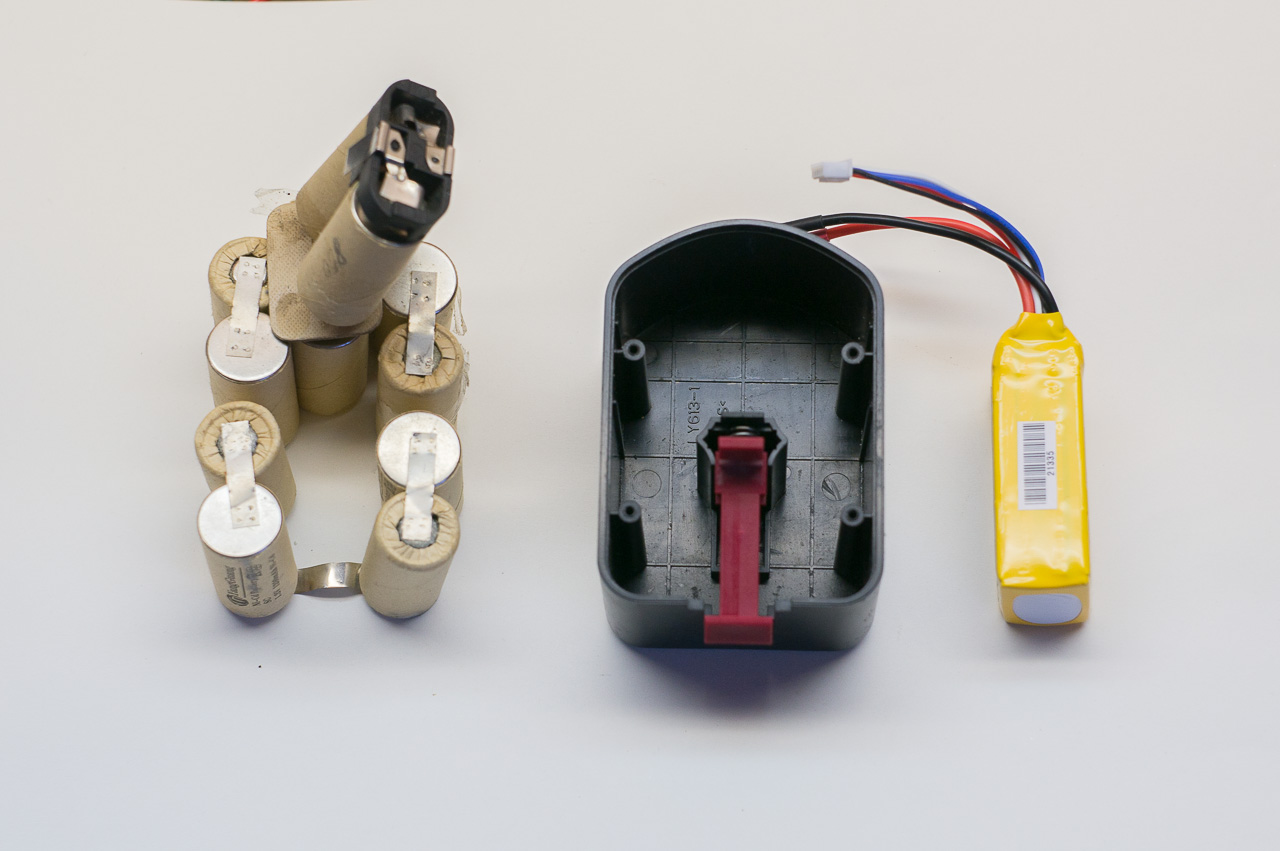

Screwdriver battery device

The number of cans in the battery depends on the power of the tool and the type of cans themselves. For household screwdrivers, drills, grinders and other small equipment of the same class, usually 4 to 16 cans are connected in series. Compact and powerful battery banks are more expensive (much more expensive), but they take up less space and are lighter in weight. The lighter the battery, the easier and easier it is to operate with a hand held power tool.

Banks are connected with contact plates. Contacts from the first and the last are brought out to an external block on the body. These are the power terminals through which charge / discharge is performed. On the same contacts, you can measure the total charge of the battery.

A screwdriver battery circuit is not needed. All batteries are connected one after the other

In general, there may be four or five contacts on the connector. Five contacts are more expensive in technology, the batteries of which are collected on lithium cans. In them, it is necessary to control the charge current of each of the cans, so a control board and a thermal sensor are also required. And they require a more sophisticated charging station that balances the charging currents.

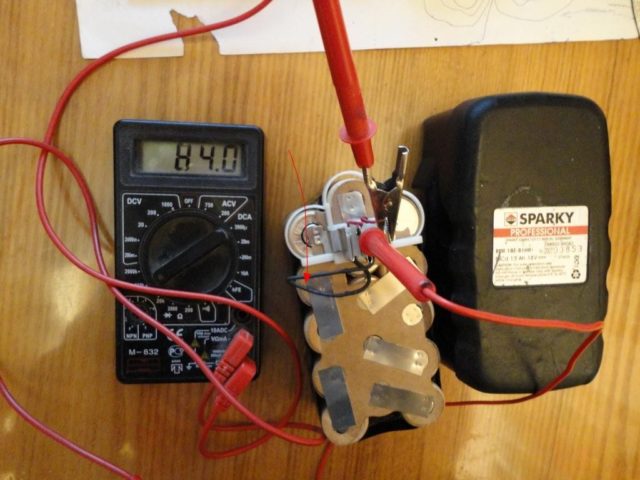

How to check the batteries in the battery

After the battery is fully charged, we take a multimeter and measure the charge on each one. Full charge - up to the extinguished light on the charger. On the multimeter, we set the voltage measurement mode by selecting the appropriate measurement limit. Applying the probes alternately to the contacts of each of the cans, we measure the voltage on them. Those on which it is lower than necessary are denoted in some way.

The charge level on each of the cans depends on the type. As already mentioned, on nickel cans it should be 1.2 V, on lithium - 3.6 V. The allowable difference is 10-15%. If the readings are lower, it means that this jar is "wasting" the total charge of the battery and it is worth replacing it, and we mark it.

To restore the battery of a screwdriver, you need a multimeter

We insert the battery and work until the power of the screwdriver noticeably sags. Disassemble the case again and re-measure the voltage. This time it's residual. On damaged banks, the fall will be greater than on normal ones. Thus, you will finally see which cans need to be replaced.

There is a second way to check batteries. An additional lamp of the corresponding voltage will be needed. For a 12V battery, the bulb is the same. After fully charging the battery of the screwdriver, connect the lamp to the working terminals of the battery and wait until it is completely discharged. Disassemble the battery and measure the residual voltage on each bank. Those on which it will be the smallest, and sit down the battery. They are marked and are being replaced.

How to choose battery banks for replacement

In general, it is better not to change the type of battery cans. And if you change it, then together with the charger - for nickel and lithium batteries, the charging currents are different, therefore the charging stations have different characteristics.

Key parameters are indicated on the body of the cans

Next, we look at such parameters of battery cells as voltage and the number of amperes / hours that the battery is able to accumulate. If you choose several cans for replacement, then it makes sense to take similar characteristics. If you change all the batteries, then the power (number of amperes / hours) can be taken even more - the screwdriver will work longer on one battery charge.