Varieties

Liquid PVC adhesive "Cosmofen" in all its technical characteristics performs the function of a sealant. It is necessary when finishing the joints of window blocks. Its advantage over conventional sealant is that it does not fade in the sun, does not flake or change color. With such liquid plastic, you can work with all kinds of polymer coatings, when repairing plastic windows, doors, accessories. It is also used in plumbing work for gluing pipes, gutters, fittings and more. It is necessary in the manufacture of trade pavilions, billboards.

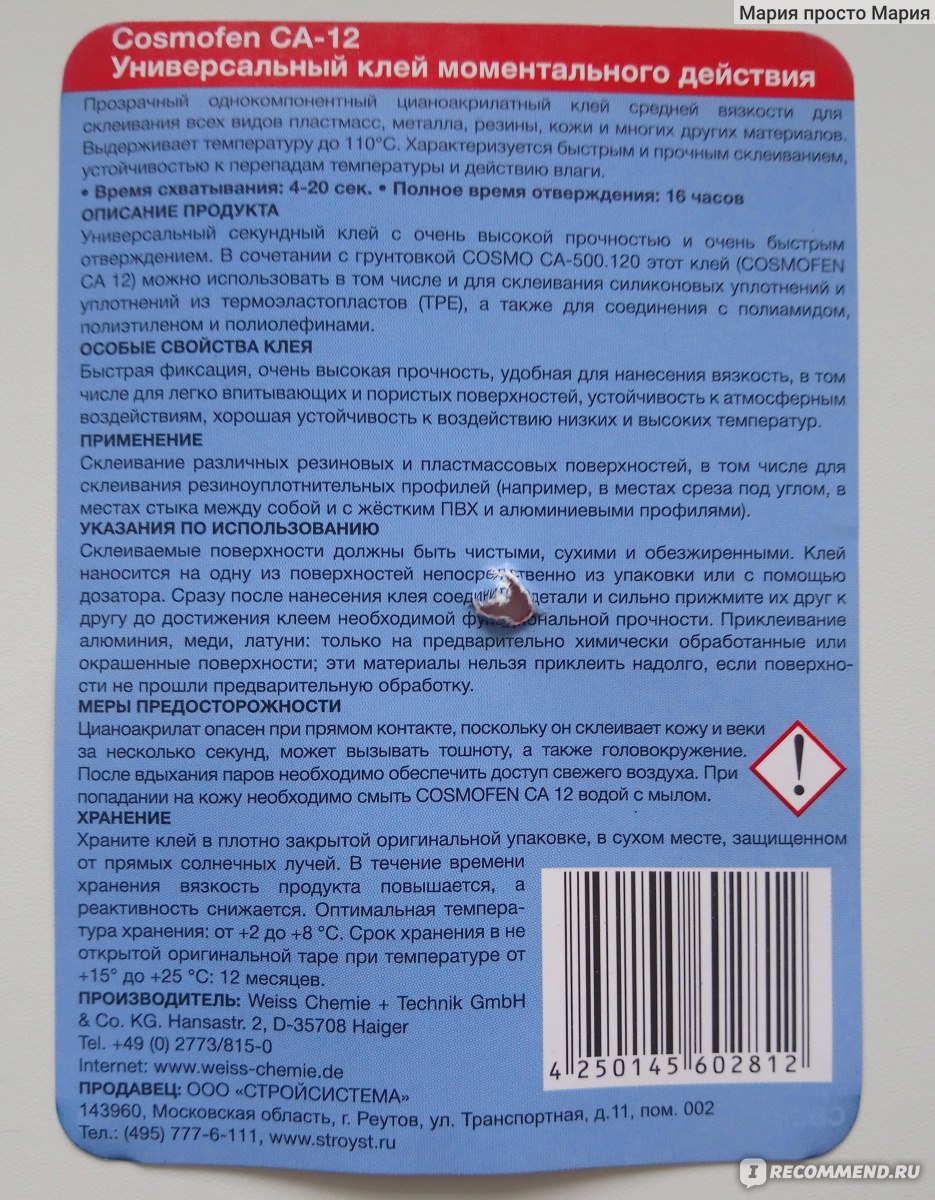

Cosmofen CA 12 is a fast hardening high temperature one-component adhesive. It is very practical and easy to use. They can glue many materials used in everyday life.

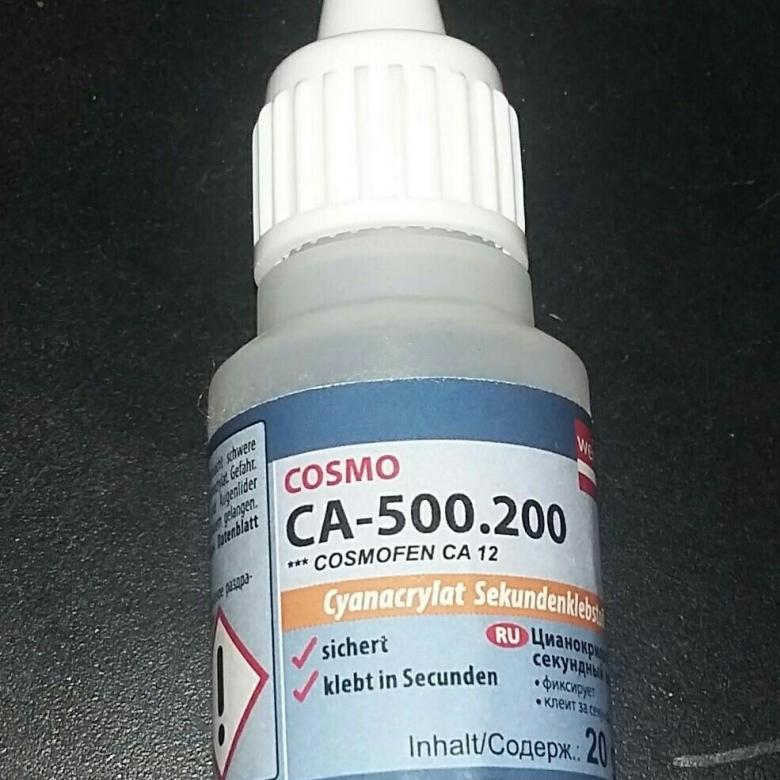

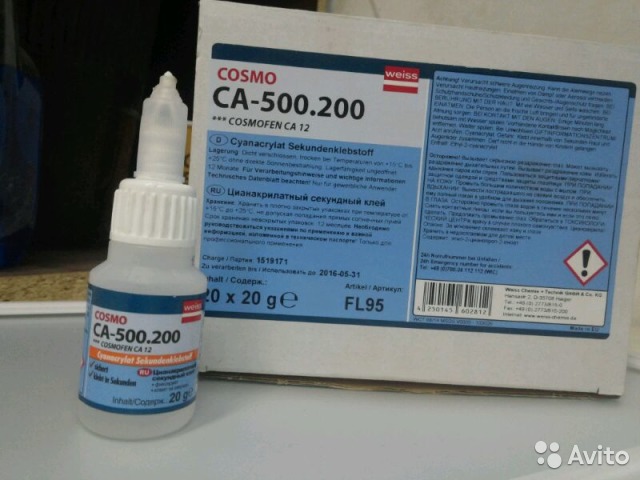

Cyanoacrylate second glue "Cosmo CA-500.200" has the property of fast fixing. The adhesive composition has good adhesion with a large number of different types of materials. The seams are durable and waterproof. The glue is resistant to temperature extremes and aggressive chemical environments.

Another worthy representative of "Cosmofen" is the activator of cyanoacrylate glue "AC-12". It comes in a very convenient spray package. It is used to improve the effect of any adhesives and gels of the Cosmofen brand. Activator "AC-12" is a catalyst that accelerates the work of adhesive materials. Creates the right environment to accelerate the polymerization of the glue and helps it quickly glue parts from various materials.

Scope of application

Cosmofen has a wide range of applications:

- It is used when working with various types of plastics (including PVC and polypropylene surfaces). When installing windows, an adhesive is used to join the sealing profiles. It is not used for gluing porous plastic, since the adhesive composition, when absorbed by the pores, cannot give the required strength to the joint.

- "Cosmofen" is indispensable for plumbing work.

- The adhesive composition has found wide application in the manufacture of toys and the manufacture of various jewelry.

- Used in sailing modeling.

- Not a single assembly of products of the radio-electronic and electrical industries can do without Cosmofen.

- Used in the manufacture of optical devices.

- The adhesive composition perfectly manifests itself when working with glass, rubber, metal.

- Medicine has appreciated the quality of the glue - it is widely used in the production of equipment for orthopedics and dentistry.

- "Cosmofen" is also intended for installation of stretch ceilings.

- The polymer is applicable in the fields of automobiles, aircraft and ships.

- It is used in the woodworking industry for joining together wooden products, chipboard, fibreboard.

- When "Cosmofen" is mixed with a primer, a compound is formed that sticks together products made of silicone and thermoplastic elastomers.

Glue Cosmofen instructions for use

This glue has gained wide popularity and application due to its unique ability to quickly harden and glue various materials with high joint strength.

Cosmofen Ca 12 glue can be used for:

- high-quality gluing of parts made of polycarbonate and PVC;

- gluing polystyrene products;

- gluing plexiglass and polyethylene products;

- bonding of various fabrics, on natural or synthetic bases.

Cosmofen glue belongs to universal adhesives, but, unlike its counterparts, it has very high adhesion to various materials. The glue is moisture resistant and is not afraid of sudden changes in temperature, which greatly expands the possibilities of its use.

The best quality of Cosmofen glue

Clay Cosmofen Ca 12 and its capabilities:

The glue quickly and efficiently glues the necessary parts.Provides high seam strength

It is also important that no devices are needed to apply glue to the glued surfaces, it is applied using a standard bottle.

To fix the surfaces during gluing, it is quite enough to press hard, after applying the adhesive, and hold for about five seconds. While most adhesives reach their maximum strength after 24 hours, Cosmofen glue reaches this value in 14-16 hours.

Cosmofen even glues metals, but at the same time it is necessary to remove rust and thoroughly degrease them.

Cyanoacrylate adhesive is extremely convenient, practical and economical

A few grams are enough for gluing. The advantage is the absence of a second component for accelerated hardening.

All the necessary substances are in the mixture.

The release of glue in small-sized bottles is an absolute plus. You can always have the bottle with you and use it whenever you need it for gluing.

Cosmofen - specifications

Cosmofen universal glue technical characteristics, which are quite high, are listed below.

The mixture is based on ethyl cyanicrylate, which makes it possible to obtain a colorless, transparent seam after complete crystallization.

If the temperature is equal to or higher than +20 degrees, the glue completely cures in 16 hours, but with high humidity it takes more time. The lower temperature limit at which Cosmofen can be used is +5 degrees.

The glue goes on sale in tubes weighing from 20 to 50 grams.

Fields of application of Cosmofen Ca 12 glue

Universal glue Cosmofen technical characteristics, which provide gluing of parts from: MDF; plastic; skin; metal; the size of parts during connection is unlimited, provided that a fixed connection is created

It is important that this glue cannot be used to create elastic seams.

How to use Cosmofen correctly

- To ensure the shortest possible glue hardening time, the temperature should be at least + 20 degrees, and the humidity should be up to 60%.

- The fastening of the parts to be glued takes place after a few seconds, but complete solidification occurs only after 16 hours.

- You can glue any surfaces, the seam will be colorless and invisible.

- It is often used for shoe repair because it provides reliable bonding of materials used in the shoe industry.

- Cosmofen has a wide temperature range from 5 to 80 degrees with a plus sign. This is the effective range of the glue. In addition, the high degree of adhesion permits the bonding of metal parts. The quality of gluing directly depends on the processing (degreasing) of the parts to be glued.

Glue Cosmofen instructions for use

Cosmofen 10 is used as a solvent cleaner in window production, when working with PVC profiles. There is no worthy substitute for it when preparing surfaces before gluing and when removing stains of any complexity. Perfectly cleans plastic surfaces of aprons and boards made of polyvinyl chloride. It is an antistatic agent.

How to work with Cosmophen 10

- Application to a cleaned and well-dried surface is carried out using lint-free wipes.

- In case of severe contamination, treatment is carried out with a Cosmofen 20 cleaner from the same manufacturer.

- The room must be dry.

- Usually, the dirt is removed with one swipe of the napkin.

- If there is a need for repetition, then polishing is carried out with Cosmofen polish.

Storage of the drug in its original packaging is allowed for 12 months after the date of manufacture. Temperature from +5 to + 26 degrees.

Popular types of Cosmofen glue

The manufacturer produces a wide range of Cosmofen glue. So, the company has developed a whole series of specialized formulations for the high-quality performance of specific tasks.

It is important to note that each of the considered means is intended for gluing certain materials.We present a list of names and descriptions of properties of several popular Cosmofen glue subspecies on the market.

Cosmophen CA 12

This Cosmofen adhesive is positioned as a universal adhesive. Cosmofen sa 12 glue can be used both at home and at home. It is characterized by excellent resistance to low and high temperature conditions, as well as to temperature extremes.

The advantage of this glue is that it sets quickly enough on any surface. Suitable for working with plastics, rubber and metals. Forms a strong and reliable connection that does not lose its adhesive function for a long period of time during operation.

Liquid plastic Cosmofen Plus-S

Cosmofen liquid plastic is the best option for working with plastic surfaces. The material helps to attach different parts of the broken part to each other. Cosmofen plastic glue is used to firmly bond plastic coatings of various thicknesses.

In addition, liquid plastic is used to perform the function of a sealant. In other words, it is used to fill cracks and eliminate other deformations on different coatings.

Cosmophen 345

Cosmofen 345 is mainly used for sealing and sealing glue joints after the installation of various structures. In particular, it is customary to use the tool in the installation of window systems. Also, this composition is known to employees of advertising agencies: it is used when arranging outdoor advertising.

Ideal for bonding complex materials such as metal, wood, natural stone, concrete, etc. Thanks to the convenient dosage, working with the product is extremely comfortable and easy even for a beginner.

Clay Cosmophen Duo

It is a specially developed compound for bonding metal surfaces. Can interact with a wide variety of materials. Differs in high resistance to t drops and a humid environment.

Using this tool, it is easy to create a high-quality seam that will show itself at a high level during the longest possible operation of the product. Supplied in an easy-to-use tube.

Using this tool, it is easy to create a high-quality seam that will show itself at a high level during the longest possible operation of the product. Supplied in an easy-to-use tube.

Cosmofen PMMA acrylic adhesive

Cosmofen PMMA is marketed as a solvent-based adhesive for quick bonding of acrylic surfaces. The compound can be used in industrial conditions for gluing a profile with an outer acrylic layer. It is also used in advertising for the production of acrylic commercial equipment: showcases, exhibition stands, promotional stands, etc.

It is characterized by ultra-high adhesion properties and special strength of the glue seam. Thanks to these advantages, when using Cosmofen PMMA, you can count on a very long-term service even with constant use.

Cosmofen cleaner - product description

Cosmofen brand plastic window cleaners are liquid materials with the addition of a solvent, which slightly soften surfaces. In appearance, the cleaner is a colorless, transparent solution, the composition contains a mixture of carboxylic acid esters, which are capable of dissolving dirt and cleaning plastic.

Cosmofen 10 or 20, other means provide the following actions:

- remove dirt, grease, markings, glue, sealant, resin, and other contaminants that have penetrated the upper layers of PVC and other substrates;

- remove particles of polyurethane foam that have fallen on the plastic;

- prepare the surface to be glued to other substrates;

- give an antistatic effect, which protects windows from contamination in the future;

- "Erase" small scratches, cracks due to the slight softening of the plastic (not all products in the series are capable of this).

Such washes are used in dry rooms - the formulations do not tolerate high humidity. Means of this type have a lot of advantages. The quality of window cleaning will be very high with an economical consumption and a low price (about 270 rubles per liter).It is very simple to use the products, you do not need to be a professional for this.

Recommendations

To ensure high-quality bonding, you can use the recommendations of specialists:

- at a temperature of at least 20 degrees Celsius and a humidity of 60%, the glue will harden much faster;

- the aluminum surface is treated with special means before gluing, otherwise the connection will not be strong;

- do not use the composition for products with a porous surface;

- Cosmofen is ideal for bonding small parts;

- children and animals should not be in the room during work.

Cosmofen glue is suitable for gluing many types of materials. If we compare it with analogues, then judging by the reviews of consumers, Krox glue is an excellent substitute, it is also used in installation work. Good reviews are also left on the composition of Done Deal, this tool is very convenient to use. It has a needle in the lid that prevents the substance from drying out, so the tube is used many times. In addition to these brands, users highlight Contact glue, as well as Super Strength, which is sold together with a cleaner.

You can see the testing of Cosmofen glue in the video below.

Range of cyanoacrylate adhesives

The brand's products have a fairly wide range. All super glues are of good quality, functional and very durable after curing. Everyone can be considered a universal remedy, but it is still better to use what is ideally suited to the description.

Cosmofen CA 12

Instant cyanoacrylate glue Cosmo CA-500 200 has a different name - Cosmofen CA 12. According to the instructions, it is intended for plastic, as it showed the best results on this particular material.

Its use has been shown in other areas as well:

- gluing sealing profiles made of EPDM, joining them to profiles made of PVC, aluminum;

- connection of silicone seals, elastomers, rubber;

- gluing different polymers.

The hardening time of the composition is 16 hours. It has absolute transparency, it is realized in small bottles with a spout for dropping out. How long does the glue dry? The initial drying time does not exceed 15 seconds.

Cosmoplast 500

Cosmo CA-500.110 or Cosmoplast 500 is another cyanoacrylate instant glue that is sold in plastic bottles with the possibility of spot application.

Cosmoplast 500 is suitable for gluing different materials, the seam is highly resistant to moisture, temperature, solar radiation, hard and durable.

Most often, glue is used to connect rubber and plastic parts. The spheres of application of the glue are very diverse, here are the main ones:

- seals;

- sewer pipes;

- electronics;

- production of windows;

- shipbuilding, automotive industry;

- production of machinery, equipment;

- medicine;

- optics;

- toys;

- Promotional Products.

The product is not easy to remove, so it is recommended that the parts are correctly positioned right away. The composition instantly fixes the products, functional strength is achieved soon. The density of the material is 1.05 g / cu. cm, viscosity - 20 mPas. You can peel off the material at temperatures above +80 degrees - this is the temperature limit during operation.

Other adhesives

In the line of the series there are other analogues that have similar characteristics. For example, Cosmoplast 505 or Cosmo CA-500.120 are glue that has a very high curing rate. If you combine the material with a primer of the same name, the strength properties of the glue increase.

It is recommended to use it for gluing:

- polyamide;

- a polyolefin;

- polyethylene;

- silicone seals;

- rubber and plastic;

- elastomers.

The glue is used for shoe repair, bonding of orthopedic products, windows, doors, electrical engineering. It is not easy to clean the product - the composition fixes very quickly, has the highest strength, resistant to ultraviolet radiation.

Cosmo CA-500.130 or Cosmoplast 515 glue is intended for pasting over any substrates with decorative foil. The peculiarity is the absence of bubbles after the film is attached.The product becomes dry after 3 minutes, during which time you can have time to correct all possible defects. The glue is widely used in the automotive industry and a number of other production areas.

Glue Cosmo CA-500.140 or Cosmoplast 516 is intended for gluing metal parts, for joining plastic products, rubber seals to each other.

Glue Cosmo CA-500.170 or Cosmoplast 564 - an assembly agent used on highly porous surfaces, is widely used for installing sewers and making seals.

In addition to those described, the series includes Cosmofen adhesives plus Extra-strong white, Cosmofen PMMA and a number of other materials.

Specifications

The basis is the chemical compound ethyl cyanoacrylate. When hardened, the glue forms a hard, colorless film, which makes the seams almost invisible. Brockfield viscosity - mPa ∙ s. The density according to DIN 53479 at a temperature of plus twenty degrees Celsius is 1.05 g / cm3. The holding time of the glued surfaces is from five to twenty seconds. Final polymerization time at 20 ° C and 60% RH 60% - about 16 hours The temperature at which softening is possible is about + 80 ° C. The minimum bonding temperature is plus five degrees Celsius.

COSMOFEN 345

/> COSMOFEN 345 / Cosmofen 345 is a one-component, white thixotropic adhesive-sealant or liquid plastic based on a polyvinyl chloride (PVC) solution.

COSMOFEN 345 / Cosmofen 345 has good adhesion to various materials. ex. rigid PVC, painted aluminum, stone, concrete, wood, etc. and allows you to obtain a viscoelastic adhesive joint that is resistant to aging, UV radiation and weathering (more). The glue line does not change color, does not deform or peel off the treated surfaces. The glue has a slight shrinkage, which makes it possible to close gaps of up to 7 mm between different types of materials.

COSMOFEN 345 / Cosmofen 345 is used for fast and durable bonding of rigid PVC elements, in the production of billboards for constructive bonding of rigid PVC integrals with various materials. In the window industry, for gluing additional profiles such as, for example, window slopes, sills, shutters, etc. Liquid plastic COSMOFEN 345 / Cosmofen 345, used for processing the joints of PVC window blocks, is practically devoid of any drawbacks. With its help, technological seams in window structures used in rooms, on balconies and loggias are reliably and accurately closed, as well as drains, cover strips, protective strips, etc. are fixed. It is not recommended to use COSMOFEN 345 / Cosmofen 345 for gluing pressure pipes.

Main technical characteristics

| Open time (at + 20 ° С, 50% relative humidity, consumption 150 g / m² - glass) | 45 s |

| Achieving functional strength (when gluing stress-free planks) through | 8-10 minutes |

| Final cure time (at 20 ° C and 50% relative humidity) | 24 hours (about 80%) * |

| Minimum working temperature | + 5 ° C |

*) The process of diffusion of solvent residues can take up to 8 weeks

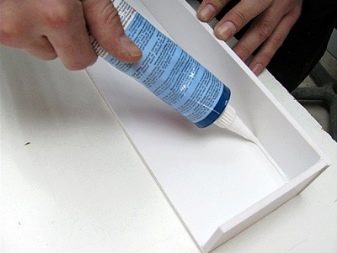

Before starting gluing, it is necessary to clean the glued surfaces from dirt, dust, moisture and other substances that prevent adhesion. Apply liquid plastic COSMOFEN 345 / Cosmofen 345 to one of the glued surfaces with a snake. Then, connect the glued surfaces to each other and squeeze (press if necessary) for at least 45 seconds until functional strength is achieved. The exact holding time and the required pressing time can only be established by local tests, since it strongly depends on the materials to be bonded, temperature, amount of adhesive applied, humidity and other criteria.

The adhesive can act as a power bridge when filling gaps no more than 0.2 mm wide, so it is important to ensure a tight fit of the parts to be glued. When using COSMOFEN 345 / Cosmofen 345 as a sealing sealant, the glue line is usually not smoothed

The glue seam can withstand the load not earlier than after 16 hours, the processing of the glued parts should be carried out only after this time has elapsed.Completion of the joint hardening process, depending on the conditions, can take up to 8 weeks.

COSMOFEN 345 / Cosmofen 345 should be stored in a dry place in tightly closed original containers, avoiding direct sunlight. Shelf life at temperatures from + 15 ° C to + 25 ° C - 12 months. During the storage period, the viscosity of the adhesive may increase.

CONSUMPTION

The width of the glued surfaces is 20 mm - 8 g / linear. m

The width of the glued surfaces is 40 mm - 16 g / linear. m

DELIVERY FORM

Cartridges with a capacity of 305 g (20 cartridges in a cardboard box).

How to use?

Before starting the bonding process, the surfaces of the parts to be joined must be cleaned of dust and various fatty substances. Aluminum products are pre-treated with a special solvent or varnished before gluing. On sale there is a cleaner "Cosmoplast 10" - it is a solvent cleaning agent used to prepare surfaces of various materials for gluing. It is applied to the treated surfaces of parts with a lint-free cloth. The cleaner is specially made with an antistatic effect.

An adhesive composition is applied to the pre-treated surface of one of the parts to be glued. Application is carried out using a dispenser, which is located on the lid of the container.

Very quickly and firmly, the parts to be connected should be pressed against each other and held for 10-15 seconds. If the connection is made incorrectly, then further correction of the position of the objects is impossible. The final hardening of the glue solution will take place no earlier than 6-16 hours. A characteristic feature of the Cosmofen CA 12 glue is that it has a very low viscosity, therefore, if the gaps between the parts to be glued are more than 0.1 mm, the joining process will not occur. For large gaps, other adhesive mixtures should be purchased. For a faster hardening process, the "Cosmoplast" catalyst is used.

Universal

Universal polymer glue is available in two packs, usually sold in a tube or in a bucket

Pay attention to the specifics of the work that needs to be done. There is a universal composition that perfectly glues tiles and linoleum, but the skin will be too tough for him.

To date, toxic substances are not included in the composition of polymer glue, however, precautions should be taken. If glue gets on the skin or mucous areas, rinse immediately with plenty of water.

As a rule, polymer-based glue is frost and water resistant, in addition, it does not collapse when bent.

When using glue for polymer clay, the surfaces must be degreased, the mixture must be applied in a thin layer, then the parts to be glued must be pressed down. And to withstand ten to fifteen minutes, this is the optimal period of time for all types of adhesive mixtures, although it is better to withstand several hours.

In our dynamic time, there are a huge variety of types of such glue. Many of them are produced by domestic chemical concerns, while others come from leading foreign manufacturers. Both those and others pass a strict selection for quality. Today, polymer glue can be purchased at any store, or on the Internet.

Let's sum up

Currently, it is safe to say that the most optimal adhesive element will be a universal polymer adhesive. Since it is capable of gluing a wide variety of materials. Another advantage is that it is non-toxic, which allows it to be used in the home.

Cosmofen: instructions for use

Clean the bonded surface from dust, degrease and wait until it dries. The glue must be applied only to one surface of the bottle using a dispenser located directly on the cap. Combine both parts of the product and hold for a while, pressing them to each other until the surfaces stick together. This is about 15-20 seconds.Final hardening depends on the ambient temperature and humidity.

COSMOFEN CA 12 glue has a low viscosity, therefore it cannot be used with a gap of more than 0.1 mm between the surfaces to be bonded. For larger gaps, COSMOPLAST 516 and COSMOPLAST 564 can be used. To speed up the curing time, COSMOPLAST 583 catalyst is used. Careful preparation must be carried out before gluing. Namely:

- aluminum parts are treated with a special chemical composition or varnished;

- silicone and plastic surfaces must be tested first, since the range of materials is quite wide, and it can be difficult to immediately select the mode and speed of gluing.

The consumption of glue is different and depends on the material. The pot life of the adhesive and the retention time of the parts under pressure are different. They can be determined experimentally, since all these processes are influenced by the structure of the material, the volume of the glued surface, as well as the temperature and humidity of the air, the thickness of the applied layer, the squeezing force and other criteria.

Cleaning of uncured COSMOFEN CA 12 is possible with COSMOPLAST 597. It is possible to clean with acetone or mechanically remove the hardened film.

When working, it is necessary to observe safety precautions. The basis of COSMOFEN CA 12 glue is cyanoacrylate - ethyl ester of cyanoacrylic acid

It is a toxic substance that also has a high adhesion rate.

When it comes into contact with the skin, it instantly sticks together, and the eyelids can also instantly stick together. This happens within a few seconds. Avoid direct contact with the adhesive. Inhalation of the vapors sometimes causes nausea and even dizziness. If COSMOFEN CA 12 comes in contact with your skin, immediately wash off the cyanoacryl composition with soap and water. In case of contact with the eye, in no case should they be closed, you need to rinse off the glue under running water, the duration of rinsing is several minutes. After the procedure, you should immediately consult a doctor. If glue vapors are inhaled, the room must be ventilated. Fresh air will prevent poisoning.

It should be stored in places where there is no access for small children. The shelf life of the glue is six months, provided that the contents are in a container from the manufacturer in places that exclude moisture. The temperature should be in the range from + 15 ° C to + 25 °. Direct sunlight is harmful and will dry out the polymer. At a low storage temperature, for example, in a refrigerator (about plus six degrees), the shelf life is extended to 12 months.

It should be stored in places where there is no access for small children. The shelf life of the glue is six months, provided that the contents are in a container from the manufacturer in places that exclude moisture. The temperature should be in the range from + 15 ° C to + 25 °. Direct sunlight is harmful and will dry out the polymer. At a low storage temperature, for example, in a refrigerator (about plus six degrees), the shelf life is extended to 12 months.

Selling glue

Where to buy cosmofen ca 12 glue? You can buy on sales sites or in specialized stores where they sell various radio components, in hardware stores. This reliable assistant is simply irreplaceable in everyday life, he would quickly and efficiently do his job. Therefore, it is always advisable to have such a necessary component at hand. The price of a fifty gram bubble ranges from 300 to 320 rubles.

Wholesale sales companies in Moscow offer glue from the manufacturer, packaged in bottles of 20 and 50 grams each.

For purchases, delivery is carried out in Moscow and the Moscow region, for deliveries to the regions - to a transport company in Moscow.

Analogs

The following products are used as analogues of Cosmofen glue:

- Rezolen;

- Rtline.

A range of epoxy adhesives suitable for:

- metal;

- ceramics;

- glass;

- tree;

- polymers.

Rtline

Adhesive for industrial and domestic needs. Possesses good adhesion and hardens quickly. Low viscosity is distinguished from the minuses.

Below are the reviews of consumers who have been using Cosmofen products for several years.

“I use Cosmofen glue at home and in the country. I use it to glue the necessary parts, doing it quickly and reliably. Good value for money and product quality ”.

Vasily Petrovich. 49 years old. City of Bryansk.

“I bought Cosmofen glue by accident, when the usual Moment was not in the store. Since then, I have never regretted a purchase, and I have been using the products of this company for many years. I like the versatility and reliability in the glue. "

Varieties

Adhesives of this brand are divided into two main types: one-component and two-component compositions. Each of them has its own properties and characteristics.

Cosmofen CA 12

Cosmofen CA 12 glue is produced on the basis of modified cyanoacrylate. It is used for quick connection of plastic, metal, rubber products. Resists the effects of temperature extremes, moisture.

It is used in the production and repair of:

- Sewer, sealing systems.

- Household appliances, footwear, optical products.

- Industry: electronics, electrical, jewelry, etc.

Fixation and adhesion occurs quickly, adhesion to most surfaces is ensured. Not influenced by solar radiation.

Drying time depends on the following factors:

- Type of surfaces to be glued.

- The thickness of the adhesive mixture applied.

- Creation of the necessary conditions.

Cosmofen CA 500

This type of adhesive provides strong adhesion to all types of surfaces. Produced in a plastic container with a convenient tip. For spot, economical application on the surfaces to be glued. Used in industry mainly for bonding plastic and rubber parts. In the production of windows, it is suitable for gluing rubber seals.

- Strong, fast bonding.

- After drying, a transparent hard glue line is formed.

- Increased resistance to weathering.

- Thermal stability.

- Not influenced by sunlight.

- Suitable for bonding porous surfaces.

- The composition does not include solvents.

The application is widespread in industries: optical, jewelry, electrical, footwear, automobile, aircraft, shipbuilding.

Other adhesives

In addition to the listed adhesives Cosmofen, the company produces other types:

- Cosmofen liquid plastic - glue is suitable for working with plastic windows. It is capable of joining broken window pieces of varying thickness. The mixture also acts as a sealant. It fills openings, gaps, cracks on various planes. One-component composition with low viscosity. When applying, the fact of quick fixation is taken into account, so there is no time to correct defects. The seam resists the effects of temperatures, has low thermal conductivity, high resistance to external conditions.

- Cosmofen 345 is a mass for quick gluing of wood, stone, concrete, etc. It is used as a joint sealant, since after drying the joint is flexible, resistant to weather conditions and solar radiation. Low shrinkage, no dripping when applied vertically. It is applied to a previously cleaned surface. During the working period, use the means of IZ, exclude sources of open fire.

- Cosmofen DUO is a professional, two-component adhesive composition. It is used for gluing painted aluminum in the production of windows and doors. The composition does not contain solvents, does not spread, after complete drying, the coating can be painted. When exposed to sunlight, a change in tone may occur, but this does not affect the loss of properties.

- Cosmofen PMMA is an adhesive mass in the production of which a solvent is used. It is used for quick fastening of acrylic surfaces, in the production of display cases, stands for exhibitions, stands, etc. Provides high adhesion and strength. Durable with constant use of the bonded parts of the structure.

General rules and instructions for use

Before using super glue, prepare the surfaces to be glued.

It is important to clean them of dust and dirt. If they are rough, then this is not scary, this will not affect the quality of adhesion.

To use the Akfix 705 glue kit correctly, you need to apply an activator to one part of the joint, and a gel to the other.

Apply the activator spray thinly from a distance of 30 centimeters. Do not forget that the substance can have a negative effect on varnished surfaces, thermoplastic materials. You can also use the method of applying the spray activator to the gel. First, it is covered with a thin layer of a viscous transparent adhesive, then quickly sprayed on top with an activator liquid. Immediately press the surfaces to be glued.

One-component glue liquid nails Akfix 610 are applied to one part of the glued objects, pressing the parts tightly to each other. Do not cover the surfaces with a thick layer of glue. Adhesion will be better with a uniform thin application of 0.2 mm. If the excess glue comes out, then the drops are removed immediately, preventing them from hardening. You can use acetone for these purposes.