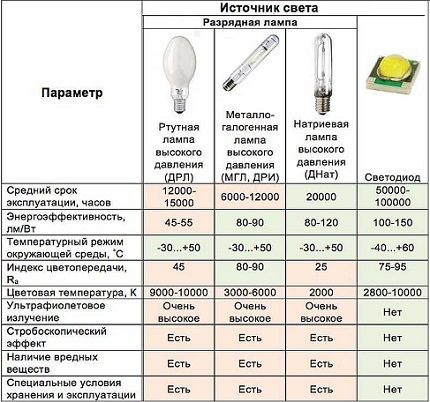

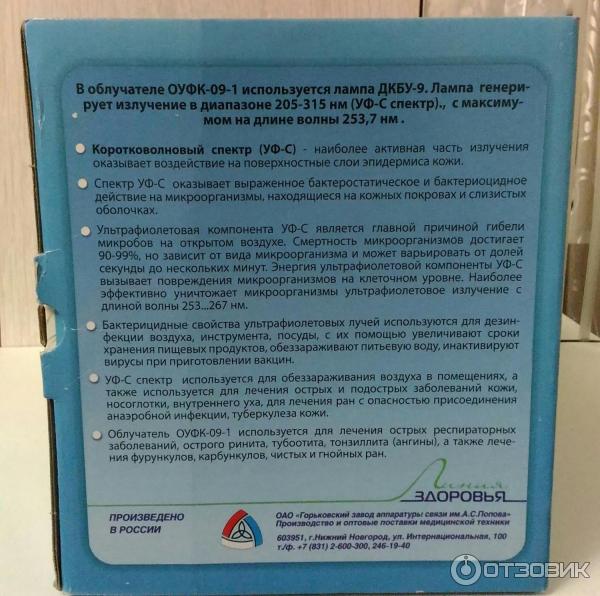

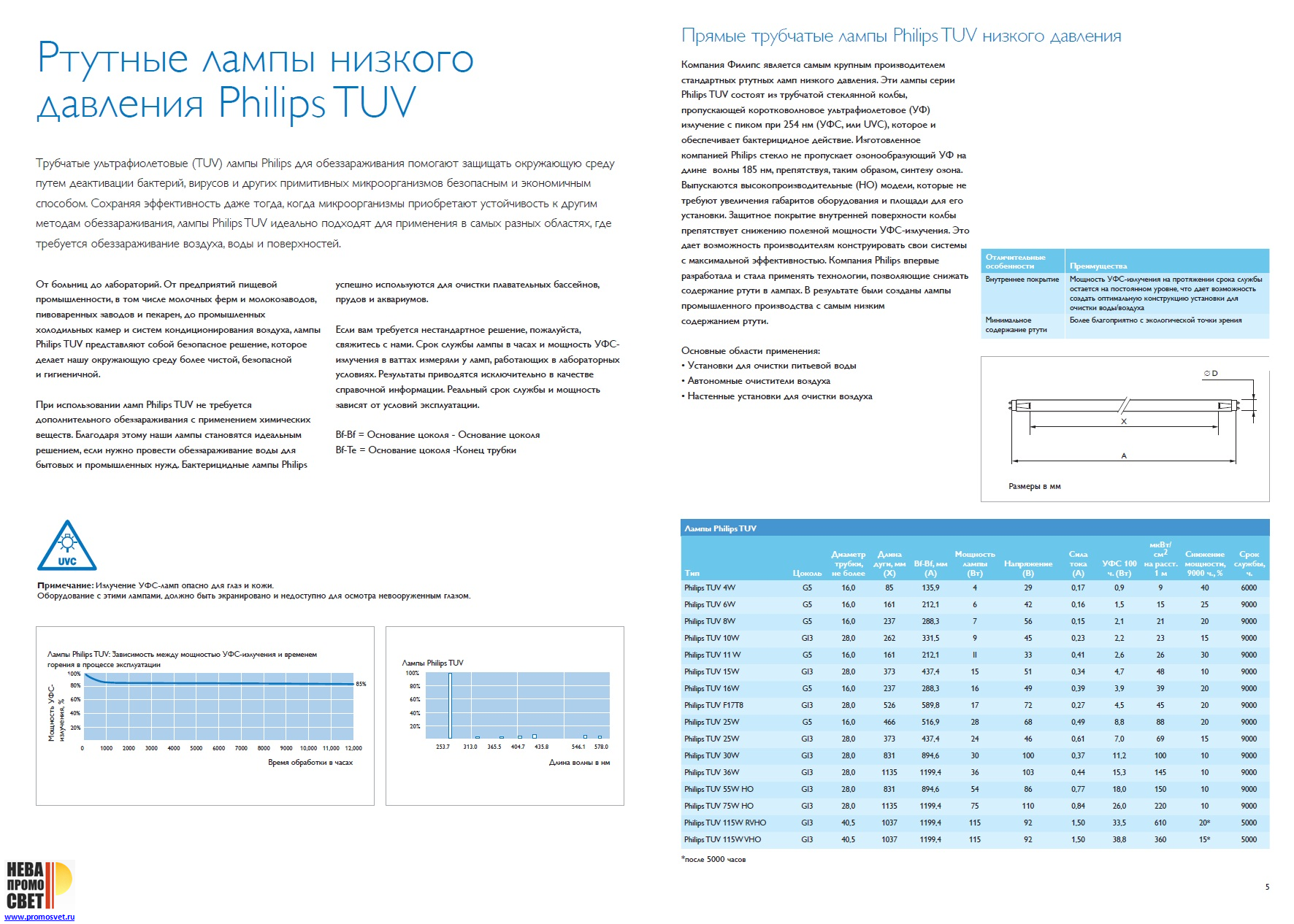

Life time

The lifespan of the UV lamp depends on the frequency of use. On average, a lamp is designed for 6000-13000 hours of operation, then its efficiency decreases.

The service life of lamps depends on the temperature conditions of the environment, the number of starts, the nominal power, the position of the lamp and the observance of the rules for working with it.

For lamps operating at currents above 13 A, the service life is lower, and its end is noticeable by the way the electrodes darken.

The invention of the ultraviolet spectrum lamp made life much easier for humanity. With its help, you can disinfect water and air, diagnose and treat some diseases, solve technical and cosmetic problems. The track record of UV lamps is extensive

It is only important to follow simple safety rules when working with them.

Previous

Ultraviolet Features of the use of a quartz lamp Solnyshko OUFK 01

Next

How to defeat insect pests? What can an insecticide lamp do?

UV glue for glass

Several brands of ultraviolet glue have been identified:

Spectrum UV glue provides a strong bond, the formed layer is completely transparent. Has three degrees of viscosity: low - repair of cracks in glass devices; medium - car glass repair; high - vertical gluing, making glass souvenirs.

The table shows examples of types of glue Spectrum with characteristics:

Bohle is a quality product that provides full bond strength, invisible docking point. A low viscosity adhesive mass is applied on top of the glass coating, after which it independently penetrates into the gap. Medium viscosity provides strength after complete drying, it can be used for planes with a load, connects glass to metal, plastic, stone, wood. High viscosity is used for overall glass surfaces, bonds glass to metal, plastic, glass, it is permissible to dry out under the influence of daylight without the use of ultraviolet radiation.

- Loca is a UV-curing adhesive that adheres perfectly to transparent coatings. The layer is durable. Fast polymerization is provided by ultraviolet radiation. If it is not there, then drying is allowed under the influence of daylight, but the duration of the process increases.

- Kafuter is a one-component formulation. Curing occurs when exposed to radiation or visible light. Bonds small and large sized items, is particularly durable. It is odorless, does not need to be mixed, ready for use, irradiation of fluorescent lamps or incandescent lamps is permissible, then the curing speed will increase. Under the influence of light, the final hardening occurs in an hour. Store under specified conditions. The unused composition is not allowed to be sucked back into the tube, the work is carried out, excluding direct sunlight. Only after the final drying of the layer, expose the product to loads.

Efficiency of use

The dry heat emitted by the blue Minin reflector lamp improves blood circulation and has a positive effect on the entire circulatory system. At the same time, depression decreases, pressure is restored. The patient gets relief, passing warming up, with various colds, partly infections. When dry heat acts on muscles, their elasticity, mobility increases, and a person's working capacity increases. Correct use will not cause side effects and will strengthen the immune system.

That is, when warming up:

- there is a strengthening of the walls of the blood vessels of the nose;

- breathing through the nose is freed;

- pain sensations are minimized;

- the process of tissue neoplasm is accelerated;

- nerve impulses accelerate their regeneration;

- viruses, bacteria are subject to elimination.

Do not confuse the emission of a blue device and ultraviolet radiation. These are two different ways that have medicinal properties.

Blue Stream is able to reduce the concentration of glucose and acetone in the urine, which helps people treat diabetes.

Description and purpose of ultraviolet glue

UV glue is an adhesive made of methacrylate. On the basis of this component, pure polymers with a transparent texture are created.

> The technical characteristics of the material allow it to be used for various purposes:

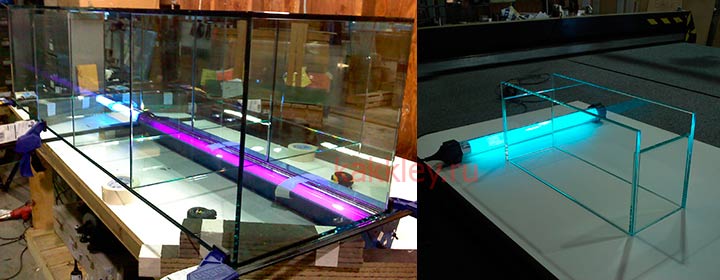

- for gluing the walls of aquariums;

- in solar panels;

- in furniture production;

- in jewelry;

- in electronics;

- in the manufacture of dishes.

Light-curing glue is used for gluing triplex, in repair work related to electronic devices. There are different types of glass, for which the appropriate type of adhesive is selected.

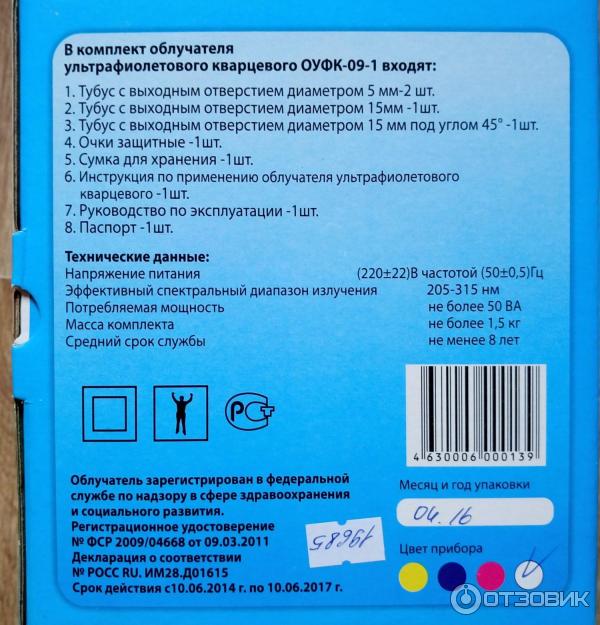

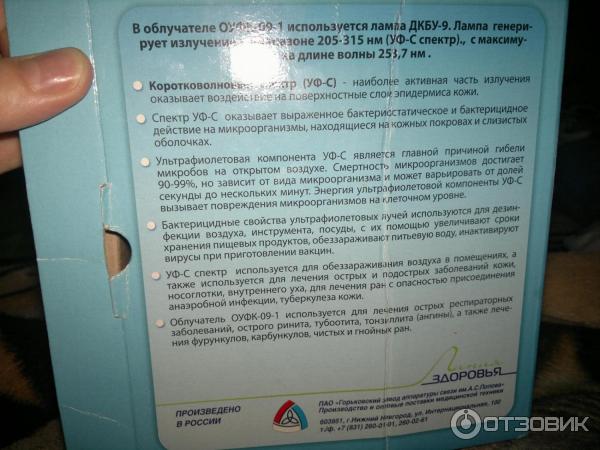

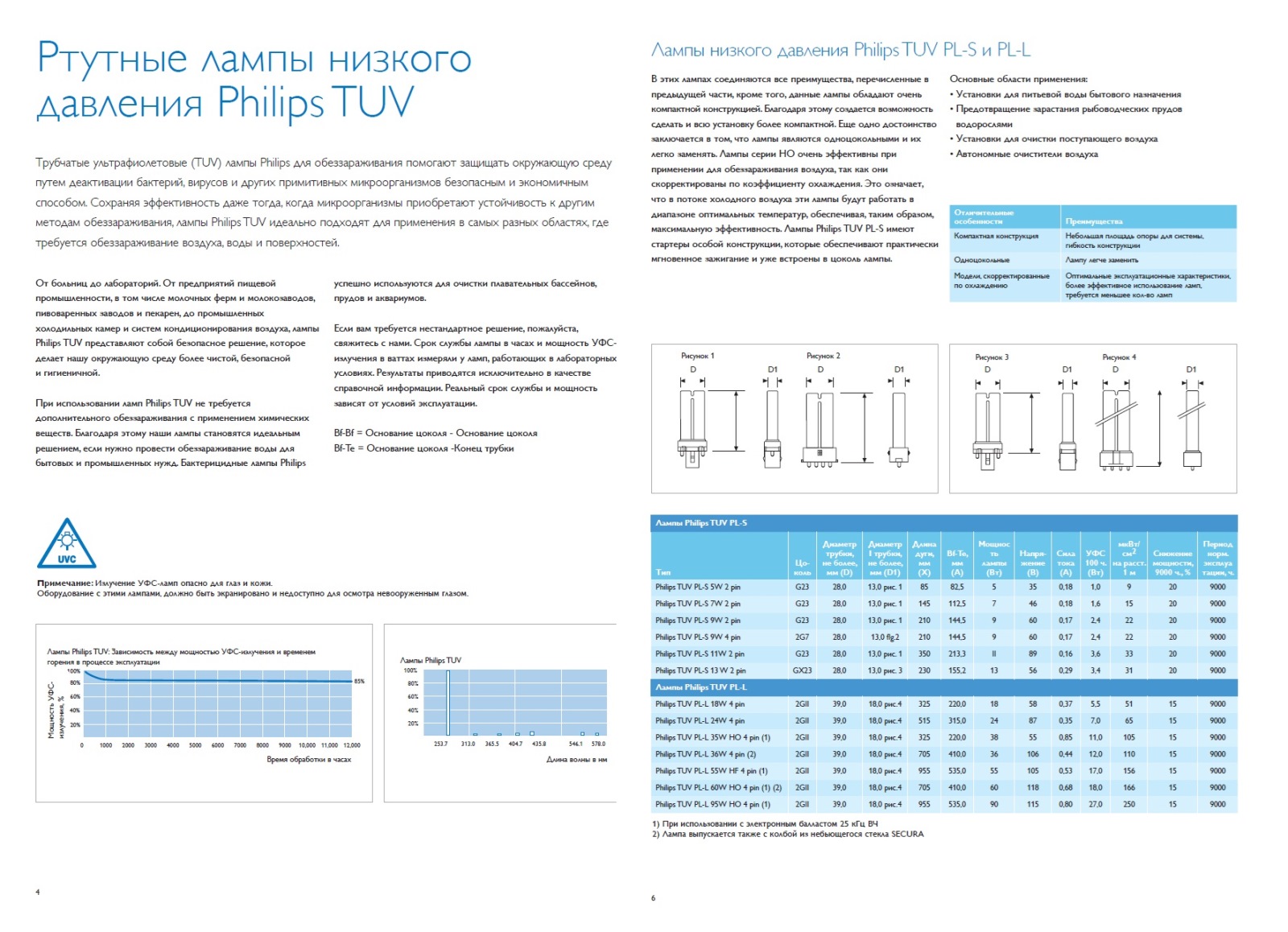

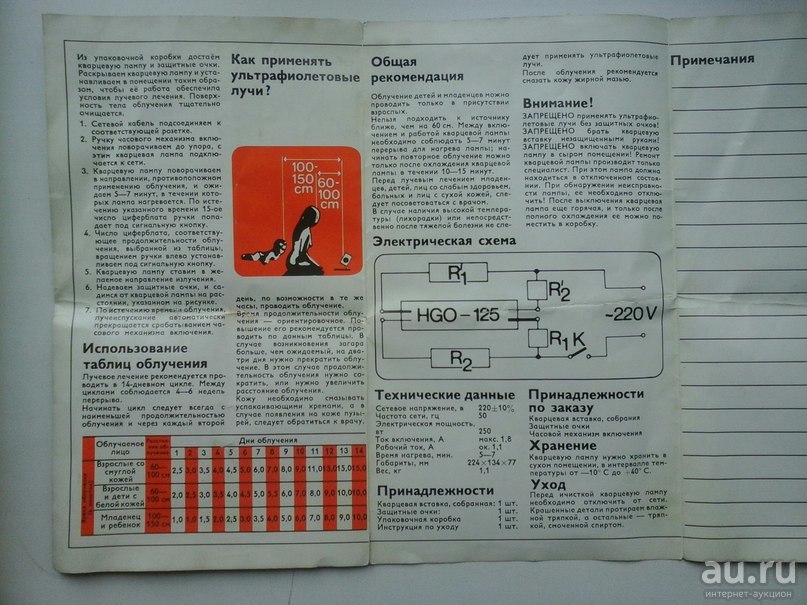

UV silica is a powerful weapon against viruses, bacteria and germs and a way to reduce dependence on pharmaceuticals prescribed by doctors of various specialties.

First of all, ultraviolet light is aimed at destroying pathogens.

By means of a home quartz emitter, the air is sanitized in residential and work premises.

Also, the device is indispensable for the following situations:

- prevention of skin pathologies and viral infections,

- treatment of ENT, gynecological, musculoskeletal, dermatological diseases,

- strengthening the immune system,

- disinfection of skin and nails after pedicure and manicure.

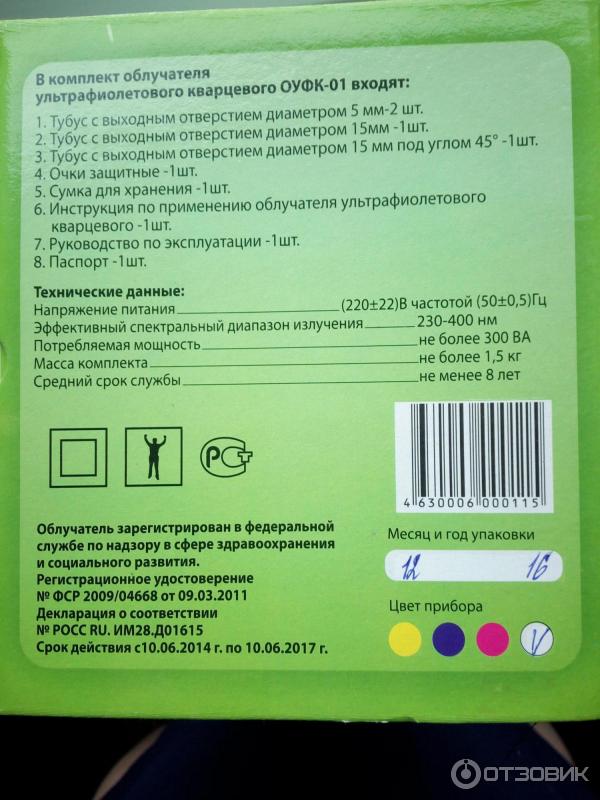

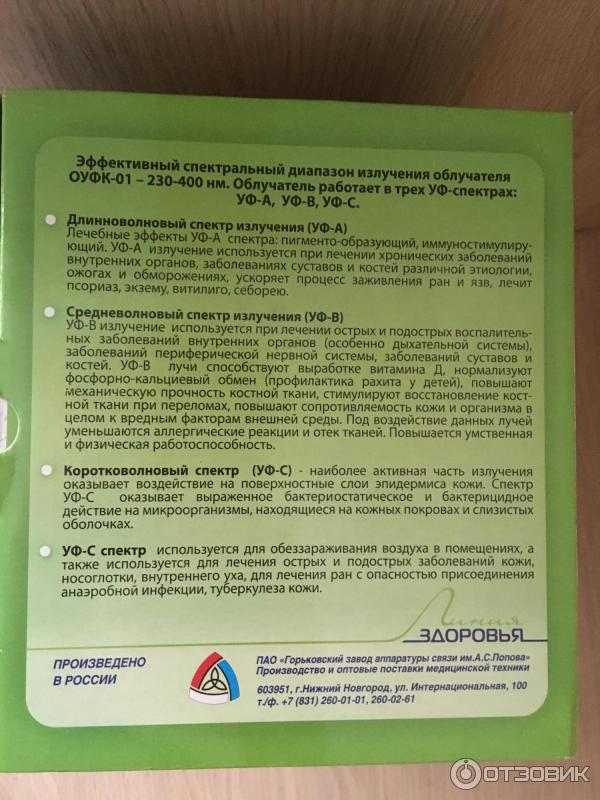

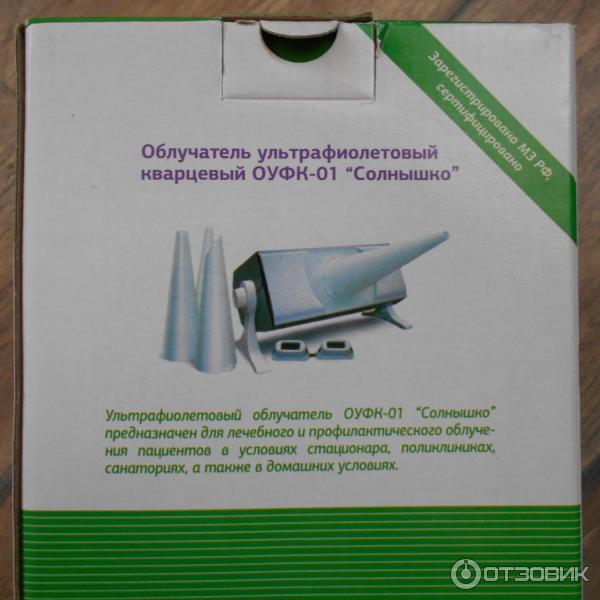

The use of the apparatus for home use - an ultraviolet quartz irradiator Solnyshko - is advisable for the treatment and prevention of various diseases and for general quartzization of the home. Numerous reviews of doctors and grateful patients testify to the strengthening of any therapy with dosed irradiation.

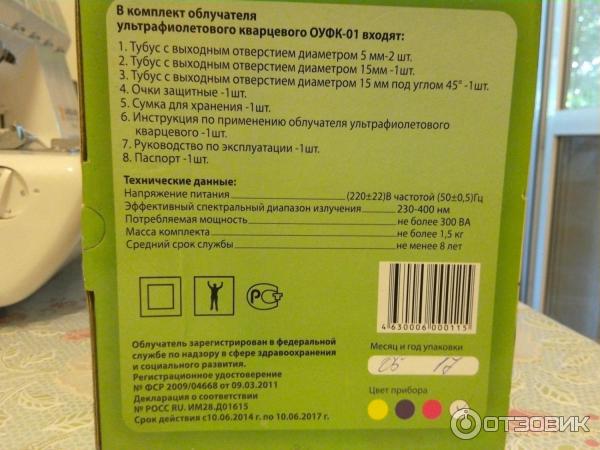

Among the devices produced by domestic manufacturers, the devices of "Solnyshko" LLC have gained special popularity among the people. On the domestic market, various models of devices for the home are presented, in the configuration of which there are special nozzles and light-protective glasses, they are certified and approved for implementation by the sanitary-epidemiological services.

Important: the information below is provided for the OUFK-01 "Solnyshko" device intended for home use.

UFO "Sun" indications for use

Indications for home use of ultraviolet radiation are:

- strengthening immunity and increasing the body's resistance to viruses, microbes and bacteria;

- treatment and prevention of influenza and other types of acute respiratory infections and acute respiratory viral infections;

- herpes treatment;

- treatment and prevention of bronchial asthma, tonsillitis, rhinitis;

- prevention and treatment of rickets in pregnant women, nursing mothers and children of all ages;

- strengthening the processes of regeneration of the skin and treatment of pustular skin lesions, furunculosis, carbunculosis, pyoderma, psoriasis (winter form of the disease), weeping navel in newborns, bedsores, diaper rash, burns, frostbite, erysipelas and other dermatological pathologies;

- stabilization of the immune status with a sluggish course of inflammatory processes in the human body;

- hardening of the body;

- activation of fusion processes in fractures and cracks of bones and normalization of calcium-phosphorus metabolism;

- in the complex therapy of arthritis;

- reduction of the manifestations of dental diseases (periodontal disease, stomatitis, gingivitis, etc.);

- replenishment of the deficit of sunlight, which is observed in residents of the northern regions and in all people in winter;

- treatment of diseases of the peripheral nervous system;

- activation of hematopoiesis processes and improvement of blood plasma composition.

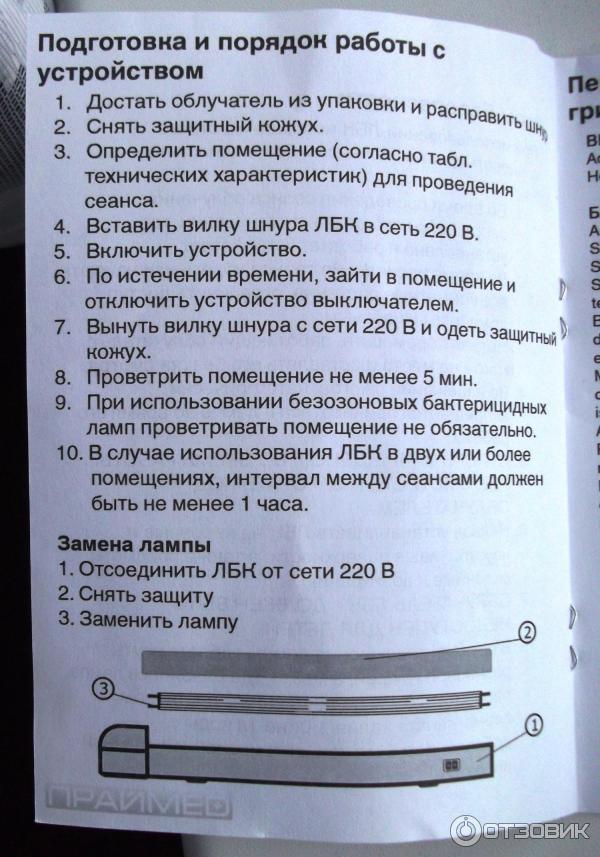

What should you do before using the UV emitter?

First of all, personnel must ensure their own safety by wearing special clothing and footwear, as well as checking the availability and condition of PPE. Then, using the log for monitoring the processing time, check whether the UV lamps still have a working resource. If it has already been exhausted, then the dump is replaced. Next, you should check that there are no people, animals, living plants in the room.

It is imperative to check the condition of the outlet and plug of the device. If during the inspection their malfunctions are revealed, then it is forbidden to start work, you should immediately seek help from the electrical personnel.

Depending on where you have to carry out disinfection, you need to make a choice of the level of bactericidal activity:

- I category of premises - 99.90%;

- II - 99.00%;

- III - 95.00%;

- IV - 90.00%

- V - 85.00%.

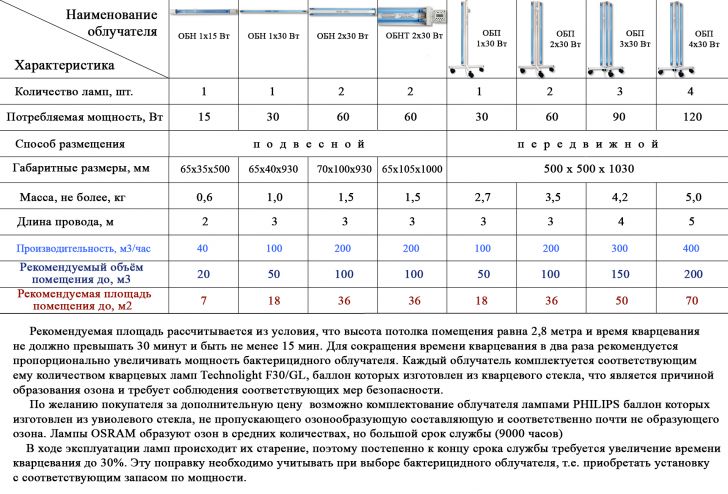

Next, the employee calculates the minimum time required to ensure the required level of efficiency, dividing the total volume of the room by the unit's performance.

The next preparatory step is the choice of the processing mode:

- continuous mode provides an effect for half or a quarter of an hour;

- the intermittent mode ensures that the illuminator is switched on for half or a quarter of an hour every 2 hours.

After setting up the equipment, the worker goes out, closes the door and turns on the irradiator with a switch, which simultaneously supplies power to a light board with an inscription warning about UV radiation.

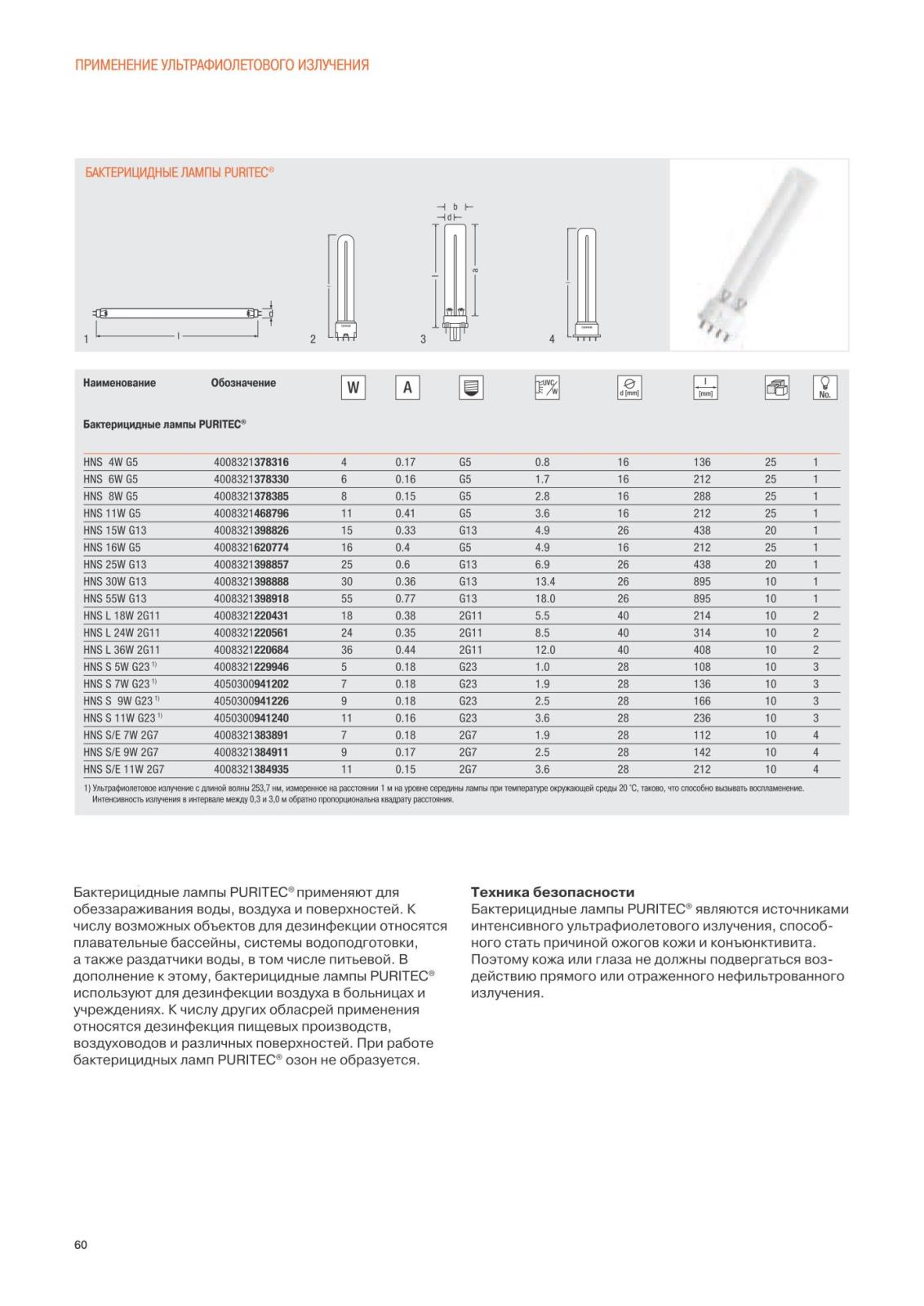

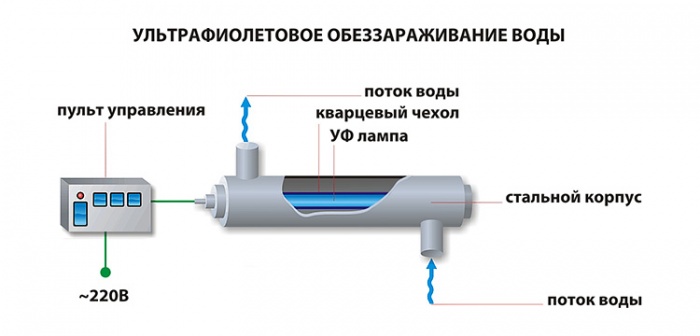

Ultraviolet lamps for water purification.

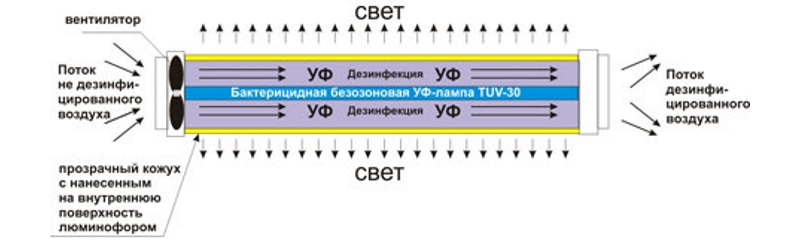

The use of chlorine for the disinfection of drinking water is gradually becoming a thing of the past. Ultraviolet water purification is relevant for those cases when drinking water does not come from a centralized, but from a local water supply system, where there is a possibility of infection with harmful bacteria.

With the help of ultraviolet lamps, disinfection is carried out today in the systems of general and domestic water supply, additional disinfection of wastewater, which contributes to the improvement of the environment. Ultraviolet is actively used for water purification, which is a raw material in the food, pharmaceutical and chemical industries.

Bactericidal treatment of water with ultraviolet light is actively used in the spheres of animal husbandry and poultry farming, and is used in veterinary medicine. Ultraviolet lamps work on fish farms, in aquariums and swimming pools, where bacteria can actively develop in the absence of "running" water.

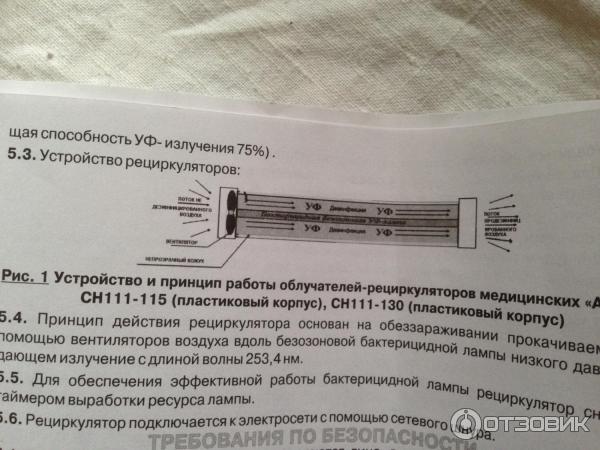

Device and principle of operation

The device is created in the form of a flask, it is filled with gas together with mercury. At the opposite ends of the flask, electrodes are located, through which voltage is supplied, a charge is created, and when it interacts with mercury, ultraviolet light is emitted. Its range depends on the material from which the bulb was made. For example, UV rays A pass through the erythemal glass, and B, but not C, through the UV glass.

If the bulb is quartz, then it will pass all three spectral ranges. Ultraviolet lamps are gas-discharge and are switched on with the help of an electronic ballast, otherwise, at a higher voltage, the discharge inside the bulb will become an arc.

Adhesive composition

The time required for such adhesives to cure depends on the activity and the ultraviolet wavelength (UVB).

When exposed to UV rays, the product and the required radiation exposure must be carefully selected. Under the influence of ultraviolet radiation, the photoinitiators are split. Free radicals change their condition and polymerization occurs.

Plastic Welding 5 Second Fix

Purpose of UV polymerization:

- Bulk polymerization. The best depth of polymerization is achieved in the range from 300 to 400 nanometers (sometimes this criterion is called near ultraviolet).

- Superficial. Sealing and bonding with UV materials. For exposure, waves below 280 nanometers are required.

- Additional (auxiliary). Not possible without adhesives. These are substances that can bond the material through surface adhesion.

Additional polymerization is required when ultraviolet rays do not penetrate all areas impregnated with adhesive. And here the intervention of special adhesives is already necessary. They have specific compositions for such difficult areas. List of technologies for auxiliary polymerization:

- Anaerobic (polymerizes in the absence of oxygen).

- Humidity (polymerized in the presence of moisture).

- Thermal (polymerized by heat).

- Activator (polymerized by the action of the second component).

Those areas (areas) of gluing, where ultraviolet light does not "cope" with the process, it is necessary to add one of the above impurities to the adhesive composition (by a system designed for additional curing), but the additional adhesive is selected so that it sets at a sufficiently slow speed so that have time to put all the details in the desired positions.

Thus, after activation, the UV glue will fix the glued objects together so that they do not move relative to each other. The second component of the composition will give the final hardness to the bond for the full functionality of the product.

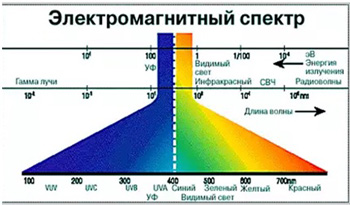

This diagram shows the radiation exposure and the wavelengths of this spectrum at the desired wavelength.

For a deeper polymerization, the UVB length should be 300-400 nanometers. In the diagram, this is UVA light - the closest ultraviolet. This is the principle of bulk polymerization.

The surface type of polymerization is of great importance when gluing or sealing occurs when using ultraviolet waves. If you allow a miscalculation in the selection of the source of ultraviolet radiation, surface hardening may not occur. And here the source should emit UVB abundantly with a minimum length of 280 nanometers. Light type - UVC.

Additional polymerization is required when ultraviolet rays do not penetrate all areas impregnated with adhesive.

Since for effective curing, waves of a certain wavelength are needed, and their activity at the bonding site. One more key criterion needs to be identified - the ultraviolet transparency of various materials. It is also worth choosing glue on it.

How to choose

Before buying, you need, first of all, to decide for what purposes you need a flashlight. If you plan to carry it with you constantly to check money in the store, then the device should be compact and lightweight.

If you decide to engage in amateur geo-prospecting and search for amber, then you need to focus on the power of the instrument. The number of LED elements does not affect the light output.

For children's and adults' entertainment, the simplest UV lamp is suitable. It can be ordered on Aliexpress for 80–100 rubles. If you order a device online, first go to the store and select the appropriate model. There you can clearly find out which lantern is right for you.

When ordering online, please specify what type of batteries you need for your flashlight. Some types of batteries are not available everywhere. Therefore, you will have to order them too.

We advise you to watch the video review:

Types of glass adhesives

Glass glue is made on the basis of different components. Therefore, there are several types of compositions.

Cyanoacrylate

The use of a cyanoacrylate type provides a secure fixation. The glued planes can easily be subjected to loads and vibrations. This composition has its positive aspects:

- Fast adhesion.

- Long service life of the seam to be glued.

- Application on glass surfaces with preliminary painting is allowed.

Works using this type are carried out quickly and efficiently. An example is the connection of elements in optics, microcircuits, assembly harnesses, etc.

The disadvantage is that the work must be carried out quickly, with maximum accuracy.Time to correct inaccuracies, there are practically no defects. Also, the glue does not withstand constant contact with water.

An example of such a composition is the cyanoacrylate adhesive Kleber CA. Designed for a wide variety of materials. Treats with a professional quick-hardening composition. Dries up in 5 seconds. Forms a colorless, heat-resistant seam.

Silicone

Silicone glue can also glue the glass. Produced on the basis of high molecular weight polymer, contains additives in the form of rubber, solvent, hardener. Resistant to chemical, biological influences. There are formulations that include antiseptic components that prevent the spread of fungal formations

This is especially important if the glass product is located in damp rooms (bathroom, swimming pool, etc.). Also, water does not penetrate into the seam, but collects in drops on the surface.

After complete curing on the plane with the applied adhesive, a film is formed that does not oxidize and does not lend itself to the influence of solar radiation. Silicone does not contain toxic compounds, therefore it is safe for the body. It is even used in the food industry.

It is creamy in viscosity. Drying time depends on the conditions created.

Example B-7000 is a multi-purpose compound for gluing various materials, including glass. Ease of use is ensured by a special tip that regulates the mass flow. When the seam heats up to 100 degrees, it is freed from the glue. Most often used when replacing gadget screens.

Polyurethane

It is easy to glue the glass with a polyurethane compound, since the mass is designed for gluing smooth surfaces. Available in two types:

- One-component - the mass is ready to use.

- Two-component - requires mixing with a hardener, on which flexibility when drying depends.

Composites are included in the adhesive to increase bond strength. Also included are resins and other active substances. They affect the viscosity of the material.

Example Soudal 47A is one component. Designed for gluing glass and mirror parts, indoors. It is based on rubber.

Silicate

Silicate or liquid glass - transparent glass glue. The composition contains substances used in the manufacture of glass material. Easy to use, fireproof.

The disadvantage is the speed of drying, the coatings are not subject to further staining.

Heat resistant glass adhesive

There are two types of heat-resistant glue:

- Natural base - silicate, chamotte fibers, refined sand, min. The coating can withstand heating up to 1200 degrees, while no harmful components are released into the air, so the mass is safe for the body. Can be used for household repairs (oven screen).

- Synthetic base - inorganic compounds, including phosphates, which can withstand temperatures up to 3000 degrees. Resistant to acids, used for gluing glass used in wet rooms.

TM Titan is a temperature-sensitive silicone compound that adheres firmly to glass surfaces and can withstand elevated temperatures.

UV glue for glass

In the process of polymerization of this type of glue, ultraviolet rays are involved. The compositions are used for gluing glass surfaces made of natural, organic glass with various planes and among themselves. It is based on methacrylic acid.

Provides an effective connection, heat resistance (range -40 - +150 degrees), water resistance, resistance to mechanical stress. The mass has no tone, the transparency remains when it dries completely. The composition does not include solvents, therefore it is safe for the body.

There are masses with different viscosities. For example:

- К-58ES - ultra-low viscosity (40cps).

- К-55ES - low viscosity (60cps).

- К-22В - high viscosity (390cps).

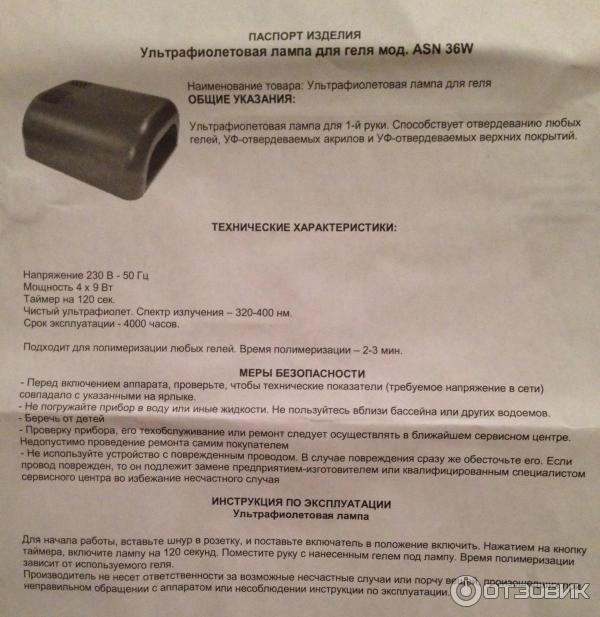

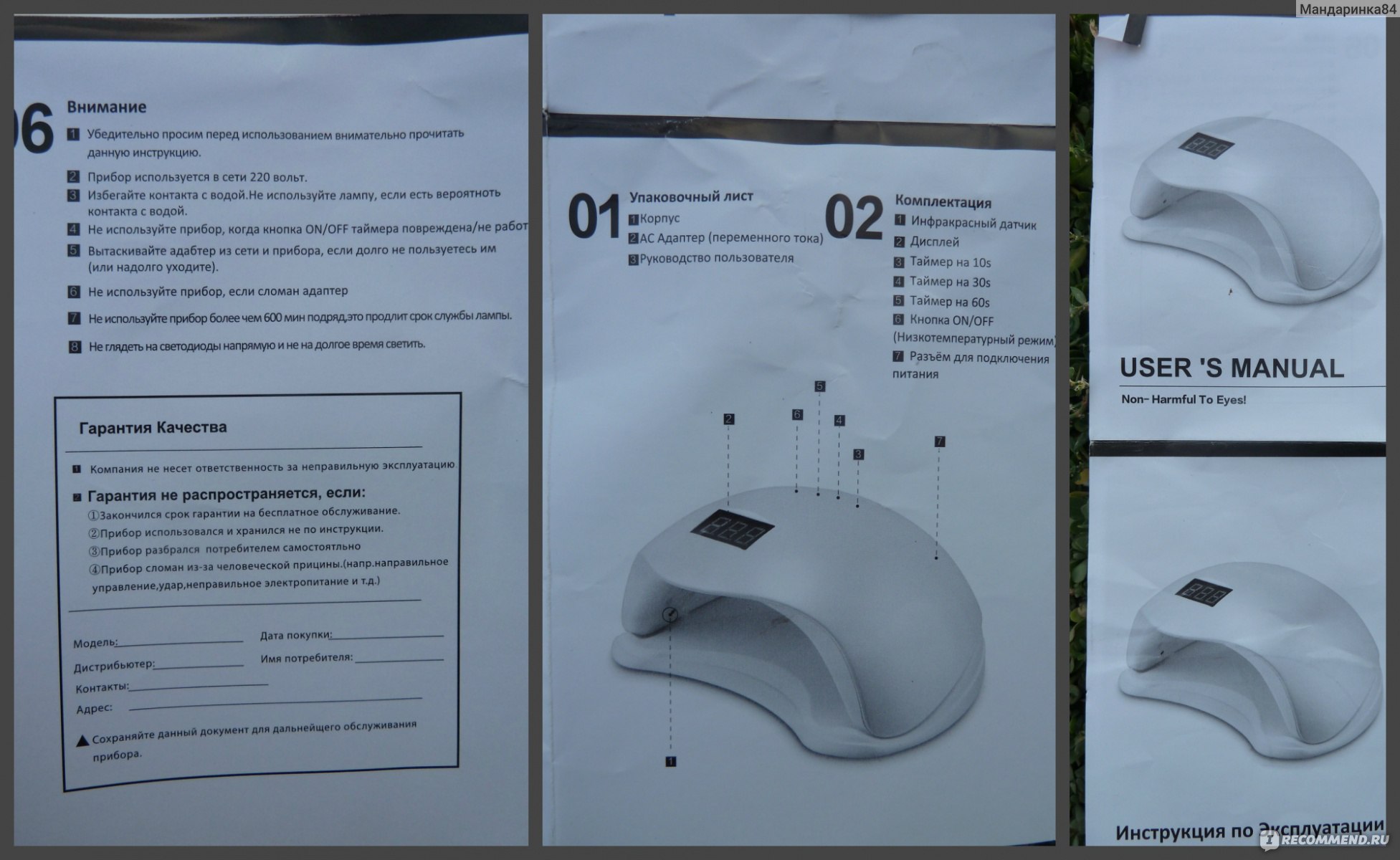

Recommendations for choosing a lamp for drying nails

Experts give the following tips for choosing UV lamps:

If you are a beginner, then give preference to the device of the simplest design. Such a device is usually designed for one hand and has medium power. Don't overpay for a more sophisticated model.

Before buying, decide on such points as:

- the maximum amount of money you can afford to spend;

- the purpose of the lamp is for home use or for mobile work to clients;

- possible types of material used;

- possible types of work performed (manicure, pedicure).

Before purchasing a UV lamp, pay attention to its weight. A quality device cannot be too light.

It is advisable to opt for a lamp with a long power cord. Such a device will last longer.

Which UV lamp is best for you is up to you. Happy shopping!

Advantages and scope

If we compare ultraviolet glue with other types of adhesives, then the following advantages stand out:

- The second name of the product is a photopolymer, it consists of methacrylate, it contributes to the formation of a transparent, strong layer.

- The substance is not susceptible to moisture.

- Durability.

- Heat resistance of the glue, the seam can withstand temperatures in the range of -40 - +150 degrees, while retaining all its properties.

- The composition is completely harmless, does not contain solvents, does not flammable.

- The adhesive layer can withstand heavy loads and impacts.

- Suitable for bonding glass to plastic, glass to metal.

Having such advantages, the mass is used:

- When assembling shop windows, furniture with glass elements.

- Gluing of aquariums, dishes.

- In the production of solar panels, electrical engineering, jewelry.

- Repair of screens of phone, tablet.

Advantages of gluing with photopolymer over screw connection:

- The mass is distributed over the entire surface, point loads are excluded.

- Mechanical impact (drilling, cutout) weakens the glass.

- The speed of work.

- One-piece glass looks more aesthetically pleasing.

- No additional materials are required.

Glasses are produced in several types, as well as ultraviolet materials. When fastening, it is better to use a multi-purpose tool.