Advantages of bolt glue

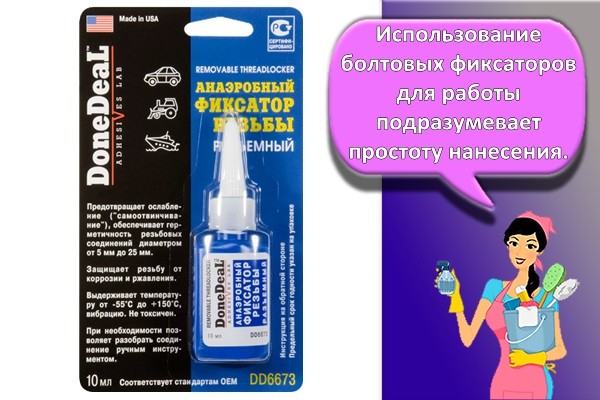

The use of bolt fasteners for work implies ease of application. This is facilitated by the packaging and the liquid consistency of the substance. In addition, such formulations are distinguished by the following features:

- the joints that are created using such compounds are not subject to displacement or shrinkage;

- the use of sealants helps protect the threads from corrosion;

- a variety of substances helps to use them on bolts of different diameters;

- sealants help prevent loosening and provide vibration and shock protection to joints;

- the low viscosity of the formulations helps them get into the smallest gaps between parts - this increases the reliability of fixation.

Benefits of Plumbing Sealant

The thread glue is at the same time a fixer, a sealant and a connector. Thus, it replaces the previously used cotter pins, seals and "spacers", thereby simplifying the procedure for strong fixation.

Threaded parts

Thread glue is also characterized by:

- economy;

- practicality;

- strength;

- resistance to the agents used to treat the working surface, vibration, pressure and temperature;

- providing protection against moisture;

- durability;

- ease of use;

- security;

- variety.

Its main difference from the previously used sealants is the ability to change its structure and chemical composition at the moment the air supply is cut off. If a liquid substance is applied to a threaded joint, then after aligning the required part, the threaded glue is already a substance with the properties of a metal polymer. This process occurs due to the formation of free radicals in an airless space.

Connection of threaded elements

Anaerobic sanitary fixture is used to connect products made of different materials. Another distinguishing feature of the sealant is its ability to penetrate the smallest holes.

Rating

The most famous brands of bearing glue:

- Adhesive sealant Permabond F202 - anaerobic adhesive for metal surfaces. The composition is used for parts that are under shock loads. Used to fix parts made of different materials. Due to its high viscosity, it is used in large gaps up to 0.5 mm. The composition does not change when interacting with chemicals, but is not used for compounds that are susceptible to contact with water vapor. The best setting occurs at room temperature. Lowering the temperature affects the drying rate.

- The EFELE 113 has an anaerobic structure of medium strength. This type is suitable for elements that are subject to frequent dismantling. Permissible joint gap up to 0.3 mm.

- The EFELE 126 retainer has a high strength anaerobic structure. Used instead of adhesive for roller bearings, sprockets, gears. Should be used for non-separable parts. Withstands temperature drops from -60 to +180 degrees, high pressure, while there is no displacement of surfaces.

- LIQUI MOLY Buchsen-und Lager-Befestigung 3806 is an anaerobic mixture for secure mounting of bearings. Applicable for parts that can withstand high pressure and loads. Contact with chemicals is acceptable. The composition is green. Drying time: superficial - 5 minutes, functional - up to 2 hours, full - 6 hours.

- Loctite 603 fixator is used for fixing roller bearings impregnated with oil solutions and in places where it is impossible to achieve thorough cleaning of surfaces.Sealing distances up to half a millimeter. Loctite is stable at temperatures from -55 to +150 degrees and in contact with industrial fluids. Application and dismantling of the composition is carried out without difficulty.

Before using parts under load, you need to make sure that the adhesive is completely dry.

Areas of use

The area of application of the anaerobic thread sealant is determined depending on the physical properties.

The area of application of the anaerobic thread sealant is determined depending on the physical properties.

- High strength compounds are used to fix parts that do not require disassembly during operation. An example is the screwed end of a threaded rod. It must be securely fastened and not displaced when force is applied to the other end of the stud. It is possible to use such components in high pressure hydraulic and pneumatic systems. They provide sealing of machined parts at pressures up to fifty atmospheres. High-strength anaerobic thread clamps are also used for large-diameter parts, the reliable fixation of which cannot be ensured by low or medium strength sealants.

- The purpose of the medium strength compounds is to fix dismountable threaded connections. These are the components to be used for bolts connecting flanges of various drive shafts or split parts such as cylinder heads for combustion engines, various covers or structural members. The use of high strength compounds can damage parts during disassembly.

- Low strength formulations are suitable for use in the assembly of small devices and mechanisms that are free from high loads and excessive vibration. These include small household appliances or clock mechanisms (of course, we are not talking about tower clocks).

Important points

Correctly applied and fully polymerized anaerobic thread fasteners remain functional for a long time - from a year or more. In the temperature range specified by the manufacturer, they are not afraid of exposure to water and most aggressive chemicals. Due to these properties, they can be used for fixing threaded connections and sealing various pipelines.

It is important to understand that anaerobic sealants do not increase the strength of threaded connections, but only ensure their reliable fixation. The tightening torque specified in the specification for a particular part must be ensured. The amount of agent applied to the thread depends on the result that needs to be obtained.

In the case when it is only about fixing the thread, the application of the composition can be pointwise. To completely seal the connection, the substance is applied along the entire circumference of the thread to prevent liquid or gas leakage.

Who recorded whom?

What can I say? The overall impression is pretty miserable. Of the twenty-one tested drugs, only six were able to withstand the modest initial moment of 5 Nm, and only two of the remaining ones advanced further than 10 Nm.

However, the Teflon nut and spring washer also went out of the way at the very first stage. And the nail polish turned out to be unsuitable for serious business. The extraordinary glue remaining after previous examinations lasted a little longer - it gave up at a load of 10 Nm. And the most curious thing is that at a torque of 30 Nm ... she cut off the cotter pin! It would seem that the metal part will last longer, but it only repeated the results of the best drug we tested.

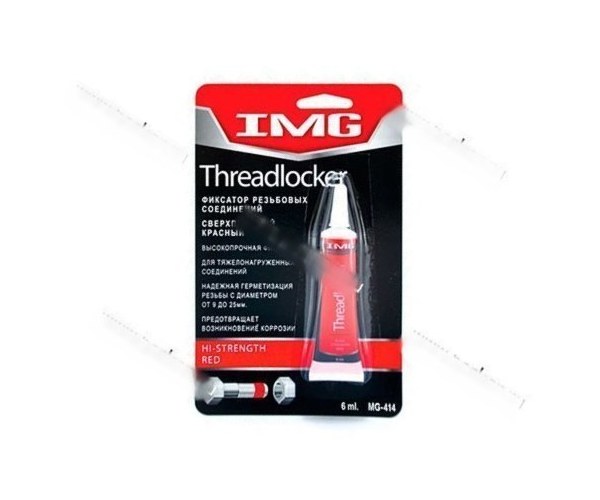

The winner is the American drug IMG MG ‑ 414 High Strength... By the way, it is far from the most expensive. The second result also belongs to the "American" - this is Permatex 24026... It makes no sense to award third place with such test results.

The results obtained refer to a specific sample of thread fixers and cannot serve as a characteristic of all the company's products as a whole.

And further.Remember: the larger the area of the treated surface, the stronger the fixative will "grab" it.

But do not be afraid to use clamps: our experiment has shown that, if necessary, you are guaranteed to unscrew any connection processed by them in the car.

Grover. It is a spring split washer used as a locking element. Grovers should not be used on deformable materials such as aluminum and its alloys, nor on copper or bronze.

Polymer insert. A sleeve is inserted into a special groove, which is deformed when the nut is screwed onto the thread. Once tightened, the polymer insert increases friction, preventing possible shaking from loosening the connection. The disadvantage of such fasteners is the limited number of assembly / disassembly operations.

Flex washer. Washers of this type are usually made of mild steel and are provided with tabs. One of the legs is bent to the edge of the nut, which must be fixed against screwing, and the other is fixed, if possible, on the part being pulled together. It is clear that such parts are disposable.

Glue or cosmetic varnish. Of the available tools for locking threads, nail polish or glue is often used. The main advantage of such techniques is simplicity and confidence that it will not get worse. But these drugs do not work for their intended purpose, so you should not expect serious protection from them.

Cotter pin. A metal rod is inserted into the through hole and its ends are bent. While the cotter pin is in place, the nut will not loosen. It is clear that cotter pins can only be used with special nuts and bolts with a hole. In addition, they will not help fix the bolt or stud in the body of the part.

Nut with locking collar. Those who dealt with the front hubs of the Zhiguli probably remember a large nut, in which a thin collar had to be bent in two places into the grooves of the trunnion. The disadvantage of this solution is the need for a special part such as a bolt and a rather rare nut.

Lock-nut. The most primitive solution in the fight against self-loosening is locknuts. An additional nut is pressed against the main one and locks it. This solution cannot be used everywhere - sufficient space is required on the threaded part of the stud or bolt.

Features of the use of the retainer

When connecting the necessary elements, it should be understood that if no mechanical action is subsequently applied to them, then the fixation will be comparable to the strength of the welded seam.

Of course, anaerobic glue for threaded joints can bond a lot, but with some metals it interacts especially effectively. These include brass, steel, copper, cast iron and bronze. Loctite reacts worst of all on oxidized, anodized and chrome-plated work surfaces.

There are also certain temperature limits (from +20 to +30 degrees Celsius), at which the highest threshold for the strength of the thread glue is reached in an extremely short time.

We must not forget that before starting work, you should thoroughly clean those parts that will undergo fixation. The result obtained can only be damaged by concentrated acids and alkalis, so it should be protected from them. In the photo, a bolt and a flange are connected by means of the "Loctite" plumbing fixture.

What is it for

These thread lockers are essentially one-component sealants of various chemical compositions. They are united by their principle of action. Under the influence of oxygen, a reaction is started in them, this oxygen is displaced, and then the reaction continues in its absence. This principle is borrowed from anaerobic microbes and is important so that polymerization can take place in spaces where oxygen is limited - for example, in the gaps of threaded connections. Do not use such compounds as a conventional sealant or adhesive. With an open access of oxygen, their polymerization may be incomplete.

These thread lockers are essentially one-component sealants of various chemical compositions. They are united by their principle of action. Under the influence of oxygen, a reaction is started in them, this oxygen is displaced, and then the reaction continues in its absence. This principle is borrowed from anaerobic microbes and is important so that polymerization can take place in spaces where oxygen is limited - for example, in the gaps of threaded connections. Do not use such compounds as a conventional sealant or adhesive. With an open access of oxygen, their polymerization may be incomplete.

Types and features of thread clamps

There are many types of thread-locking compounds. Thanks to this, it is possible to choose the right product.

3> Linen thread

Flax is actively used for winding pipes. It is used for all metal parts - brass, steel or cast iron. It is also permissible to use flax in areas where metal threads are soldered into plastic.

Plumbing thread

This is a great pipe reel option. This thread has only one drawback - high cost. It can be used to seal any joints, including plastic.

FUM tape

The product is not used as a pipe sealant. At the same time, the tape is suitable for use in a summer cottage and in a vegetable garden, since in such places there is no danger due to small water losses.

Sealant

Various types of sealants can be used to fix and seal threads. This allows you to choose the right product.

Non-hardening

These sealants are produced in the form of a viscous paste. They contain resins and polymers. The thick mass helps to achieve excellent sealing without loss of quality characteristics due to vibration.

The sealant does not secure the threads. Such a tool completely fills the gaps, ensuring a good sealing of the structure. The composition is completely safe. It can be used for pipes with water.

In this case, the substance will be expelled, which will cause a leak. This cannot be prevented. In such a situation, a different composition is chosen.

Hardening

These products are characterized by high strength. Moreover, they take a long time to dry. It depends on the quality characteristics of the substance. This is the only drawback of a hardening sealant.

It is recommended to wait after using the composition. The specific time period is shown on the package. Only after this is it permissible to start operation or proceed with subsequent work.

This type of sealant responds normally to pressurized water supply. After complete hardening, it cannot be displaced. It is permissible to choose compositions of different fixation levels. It determines the strength and untwistability of the pipe. With a small degree, the product can be disconnected manually, with a strong one - this is done by breaking, after heating.

Anaerobic

This is an innovative type of sealant. They are used by professionals and amateurs. The principle of operation of the composition lies in the crystallization of the substance after application.

When exposed to air, the substance retains a liquid consistency. In this case, contact with air provokes a chemical reaction. As a result, the substance acquires the consistency of an adhesive. This makes the fixation zone monolithic.

Loctite

This sealant has a long service life and high strength. It is sold in the form of a liquid mass and threads.

Anaterm

The product has similar properties. It is permissible to use it to fix various parts and eliminate cracks.

Plumber

The substance is suitable for threaded and flanged structures. It is resistant to the influence of alcohol, chemicals, high temperatures. The composition prevents corrosion and does not contain harmful ingredients.

This gel is usually used for cars. The composition helps to strengthen the thread. Gels give joints resistance to vibration, temperature and mechanical factors. To separate the structural elements, it must be heated.

ANTIBACTERIAL TREATMENT OF AIR CONDITIONERS

Every year, people are increasingly influencing the environment, and nature takes revenge for this. Recently people

faced with a new lung disease, and this led to another review of safety measures,

including transport. The ubiquity of air conditioning has increased comfort, but has led to the emergence of new

additional risks, namely the risks of lung infections. Air conditioner evaporator, whether it is a home split system,

central air conditioning system or

simple car air conditioner, has a constant temperature and high humidity. Any doctor

will confirm that it is the favorite breeding ground for a variety of bacteria. For the first time with lung infections caused by bacteria

of air conditioning systems, humanity faced in the 60s of the last century. Several dozen people became victims,

and there have even been deaths. Causative agent

found and named Legionella. Central air conditioning systems began to be disinfected, but isolated cases of the disease still occur.

What about the owner of a modern air-conditioned car? And if the air conditioner is in an apartment or a country house? Really run to

a sanitary and epidemiological station and pester doctors with requests that they do not understand? The solution to this question has been found.

Liqui Moly presents a range of products for antibacterial cleaning and disinfection of car air conditioners: as for an individual

use and for service operations.