Advantages and disadvantages

There are no perfect solutions. The glue stick has its pros and cons. Users include the following positive characteristics:

- Convenience. Easy to store, carry, can be taken with you.

- Ease of use. I opened the lid, pulled out the rod - and the pencil is ready to work.

- Profitability. The glue spreads well over the surface, no excess remains.

- Security. Glue sticks do not have a strong odor. They do not contain harmful substances and do not cause allergies.

- Hygiene. No glue spills. It is impossible for them to stain furniture and hands.

- No restrictions on use. Both adults and children work for them.

- Storage duration.

- Low cost.

- Washes off quickly with water.

Among the disadvantages, picky consumers noted:

- low adhesive power: does not stick together all types of paper;

- quick drying after a single use;

- poor smear on paper;

- not universal.

The negative comments were about products from different manufacturers. And the rules for storing and using glue-pencil by people who left negative reviews cannot be verified.

Characteristics

The vinyl-based wallpaper glue sold today belongs to the category of the most reliable adhesives. The tool is actively used in repair and finishing work. Vinyl adhesive can be applied to multiple wall materials. Most often it is wallpaper on paper, bamboo, metal, velor, embossed, fabric, vinyl, structural basis. Excellent sliding properties allow you to align and dock the drawing with the highest quality. If the composition has not yet dried, then the master can safely separate the canvas from the surface and glue it again. The final application directly depends on the type of wallpaper. If the master has to work with uneven walls and heavy material, then first of all, the glue is applied to the base and allowed to soak. After 20 minutes, the steps can be repeated and the strip can be glued.

Composition and properties

The glue product contains substances that can firmly bond any surfaces, parts of an object, a mechanism. The properties of Akfix 705 glue are excellent, which helps the product gain popularity among professional builders and ordinary consumers.

"Acfix 705"

Cyanoacrylate based adhesive first appeared in 1958. Cyanoacrylic acid esters are now part of many repair products. Such as Akfix 705 are used in construction, industry. The glue does not contain solvents, therefore, for gluing, a viscous gel must be used together with an activator, which is applied directly to the adhesive. Grasping is instantaneous. This happens as a result of the fact that the components of the activator accelerate the process of carrying out a chemical reaction up to 2-3 seconds. At the same time, the quality of the gel does not change: it remains transparent and durable.

The activator is based on isopropanol and additives to improve the functions of the chemical.

"Acfix 610"

Liquid nails are based on polyurethane. Advantage of glue in it:

- transparency;

- excellent viscosity;

- economical consumption;

- high quality connection;

- resistance to moisture, temperature extremes, chemical influences;

- harmlessness.

Gluing surfaces with liquid nails is quick and easy. The glue does not run off, making it possible to connect surfaces vertically or upside down.

Material disadvantages

Vinyl non-woven adhesive has several negative characteristics associated with improper use. The tool is designed to work with massive wallpaper.If the craftsman decides to use vinyl adhesive for lighter finishing materials, then it is economically disadvantageous. In addition, the prepared mass has a rather low air permeability. That is why vinyl glue is most often used in multifunctional, non-residential premises. But all the advantages of glue significantly exceed its negative parameters, which is why it is actively used by professionals.

General rules and instructions for use

Before using super glue, prepare the surfaces to be glued.

It is important to clean them of dust and dirt. If they are rough, then this is not scary, this will not affect the quality of adhesion.

To use the Akfix 705 glue kit correctly, it is necessary to apply an activator to one part of the joint, and a gel to the other.

Apply the activator spray thinly from a distance of 30 centimeters. Do not forget that the substance can have a negative effect on varnished surfaces, thermoplastic materials. You can also use the method of applying the spray activator to the gel. First, it is covered with a thin layer of a viscous transparent adhesive, then quickly sprayed on top with an activator liquid. Immediately press the surfaces to be glued.

One-component glue liquid nails Akfix 610 are applied to one part of the glued objects, pressing the parts tightly to each other. Do not cover the surfaces with a thick layer of glue. Adhesion will be better with a uniform thin application of 0.2 millimeters. If the excess glue comes out, then the drops are removed immediately, preventing them from hardening. You can use acetone for these purposes.

Varieties

A wide variety of adhesive mixtures are produced under the Litokol brand.

All formulations can be divided into three main groups:

- cement-based mixtures;

- acrylic dispersion mixtures;

- epoxy reactive composition.

Each group of adhesives has its own characteristics. Cement compositions have the widest range. Compounds such as Litokol X11, Hyperflex K100, Hyperflex K100 white and Litoflex K81 are especially popular due to their versatility in application. Such adhesive mixtures are characterized by fast hardening and no shrinkage. Cement-based materials have a low cost compared to other modifications of the Litokol product.

The material can be used both indoors and outdoors, withstands sudden temperature changes and the effects of atmospheric factors. Cement mixtures are produced in dry form.

Dispersion mixtures are represented by two products: Litoacril Fix and Litoacril Plus. The formulations are available in the form of a white paste, ready for application. The material has a fairly wide range of operating temperatures, which ranges from -30 to +90 degrees. The mixture is not afraid of direct contact with water and does not absorb it, which makes it possible to use this glue in rooms with high levels of humidity.

Requirements for the qualitative composition

Modern vinyl glue for paper wallpaper must have appropriate properties

Experts recommend paying attention to the following parameters:

- Environmental friendliness and harmlessness. All finishing materials and related compositions must meet these requirements. Since the glue has been used for processing wall coverings for several years, it should not emit toxic and irritating components. Modern manufacturers constantly monitor this parameter.

- Good solubility in ordinary water. Both powder and thick concentrate should quickly form a homogeneous mass. There should be no lumps or lumps in the glue when combined with warm water.

- Versatility. Vinyl-based wallpaper adhesive can be used as a primer on plastered walls. Such processing is especially important for high-quality wall decoration.

- Drying intensity.This parameter requires increased attention, since the wizard needs additional time to correct the sheets. Thanks to this, it will be possible to correct some defects, align the drawing, and also achieve the desired result.

The composition and distinctive features of EVA glue

In terms of its composition, EVA glue is a polymer composite based on foamed ethylene vinyl acetate.

> When compared with other adhesive solutions, the following list of EVA distinguishing features can be distinguished:

- The polymer used in the production is elastic and fine-pored, which gives the finished product an orthopedic quality - a memory effect. When defects are eliminated, the glue restores and retains the original shape of the product.

- The solution is resistant to moisture, so the refurbished shoes can be worn in all weather conditions, and also used for fishing, when you need to frequently stand in the water.

- The polymer is durable, which eliminates the need for frequent repair of products. In addition, the solution is impervious to chemically aggressive substances, including solvents and oils.

- EVA glue has a long shelf life, does not mold over time and does not contribute to the growth of bacteria.

- The substance is hypoallergenic, which expands the possibilities of its use in the field of repairing medical knitwear and footwear.

Along with a large number of positive aspects, EVA glue has a disadvantage, which is insufficient mechanical strength. The sealed area can be easily punctured or cut with a sharp object.

A little about the disadvantages

There are a number of disadvantages to polyurethane adhesive mixtures, which should be familiarized with before using them. The main disadvantages include the following:

- They do not tolerate long-term exposure to too high temperature indicators. Polyurethane-type sealants are not capable of being exposed to temperatures of about 120-130 degrees Celsius for a long time.

- Poor adhesion to damp substrates. Experts do not recommend applying glue to coatings with a moisture content of more than 10%. In this case, the connection will be unreliable.

- Duration of solidification. Some formulations harden too quickly, making the bonding process difficult.

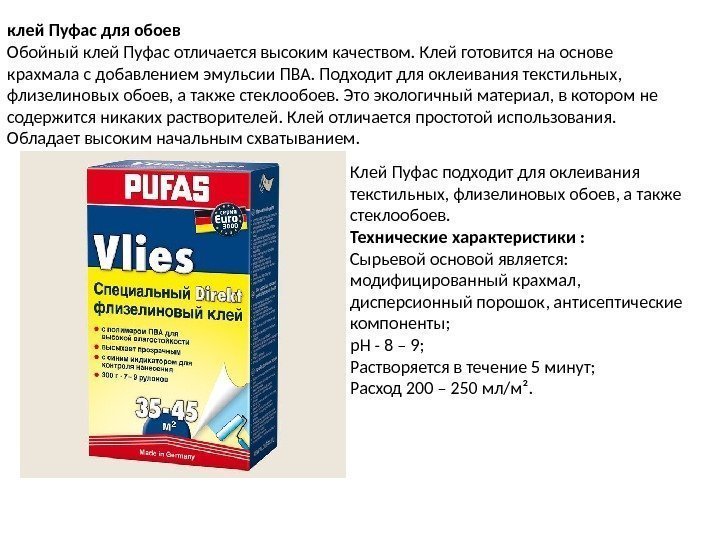

Release form, composition and cost

Pufas is a preparation for removing mold, green mold (bloom) and algae from various surfaces. Designed for outdoor or indoor use. Does not contain active chlorine.

The main active ingredient is active oxygen, which leads to the removal of mold from surfaces. Pufas technical data:

- the main raw material is sodium hypochlorite solution or didecyldimethylammonium chloride;

- the density of the substance is approximately 1.1 grams / cm3;

- acidity index (pH) about 12;

- normal consumption of the product: 50-100 ml / m2.

Pufas is well suited for processing materials at home, but it is better to use more powerful tools to eliminate mold from industrial premises.

You need to store the drug in a cool, but not cold place (a refrigerator or freezer is not suitable), the temperature should not be below zero. The storage container must be tightly closed. The shelf life is 5 years from the date of manufacture.

You can buy Pufas in household chemical stores, or in large hypermarkets (see the departments of disinsecting or detergents). The average cost of Pufas without chlorine is 460 rubles, with chlorine - 480 rubles (in both cases, we mean a container of 500 ml).

How does Pufas work on mold, and how effective is it? (+ video)

The main component of Pufas - active oxygen - upon contact with a mold focus gives an instant chemical reaction. There is a binding of the components of the mold, which simplifies their further removal (rinsing, wiping).

In addition, the drug has a destructive effect on the fungi themselves, which die.Therefore, even after a single treatment with Pufas, the surface remains protected from re-infection with mold for several more weeks.

However, a lot depends on the conditions in which the cleaning work is carried out. If the conditions continue to predispose for the appearance of mold (high humidity, dampness, lack of ventilation) - not a single drug will help, the problem will return.

It should be noted that there are several types of Pufas from mold: means for its removal and fungicide. Pufas fungicide should be used after mold removers (classic Pufas preparations). The fungicide significantly reduces the likelihood of re-infection.

What can be processed?

Pufas is ideal for a wide variety of surfaces, mostly hard. It can be used for surfaces like this:

- masonry;

- glass, tiled surface;

- wood or stone surfaces (including gravestones);

- concrete slabs and slate roofs;

- roof tiles.

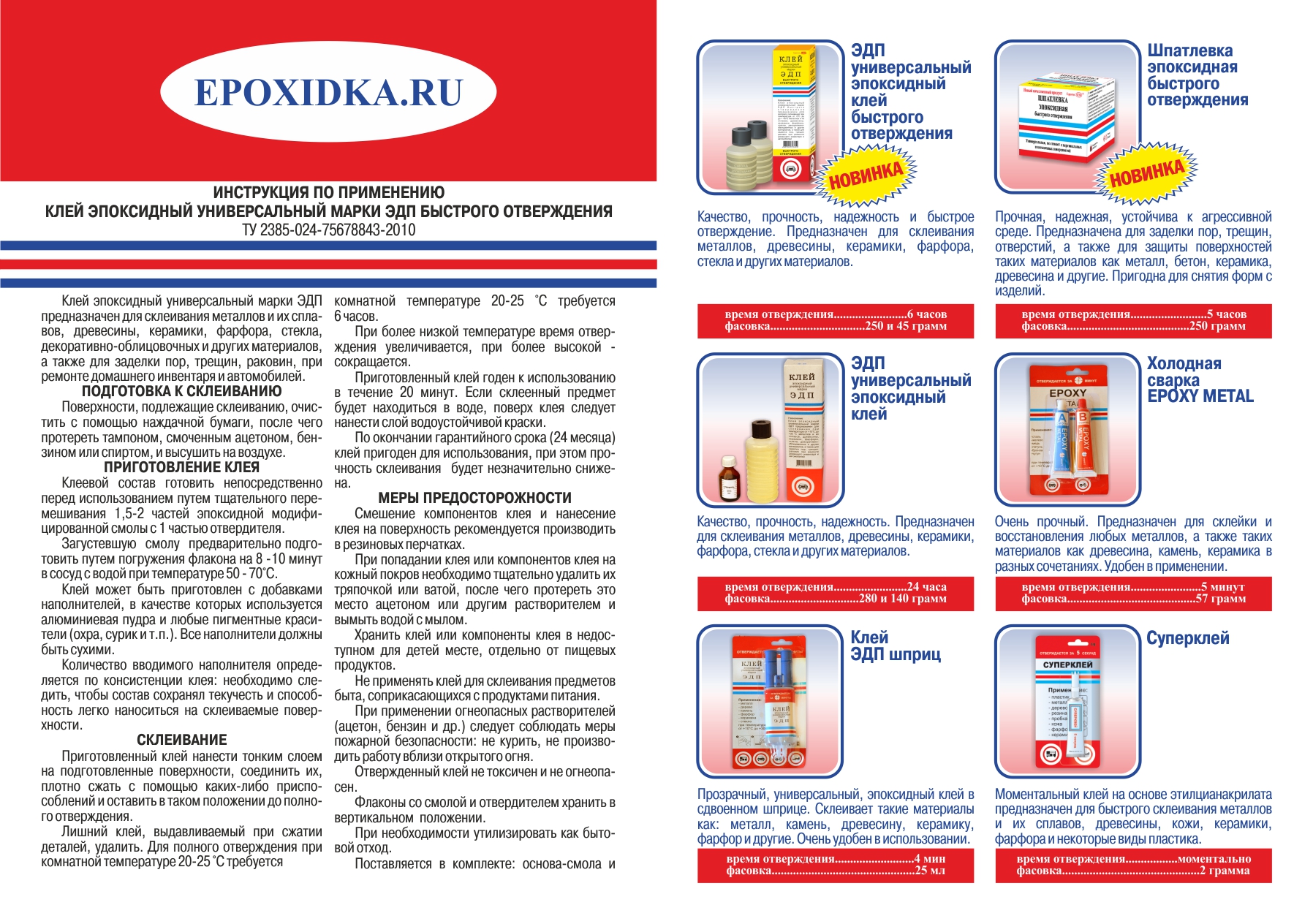

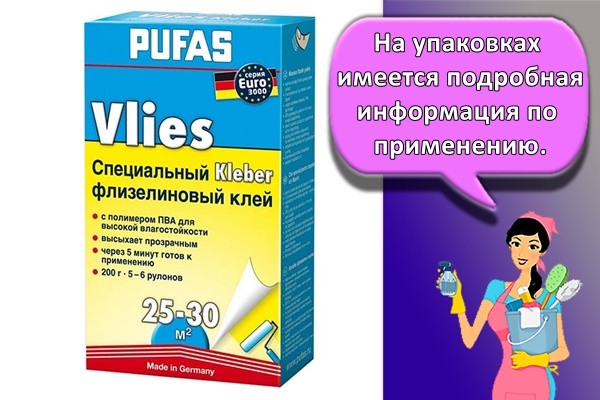

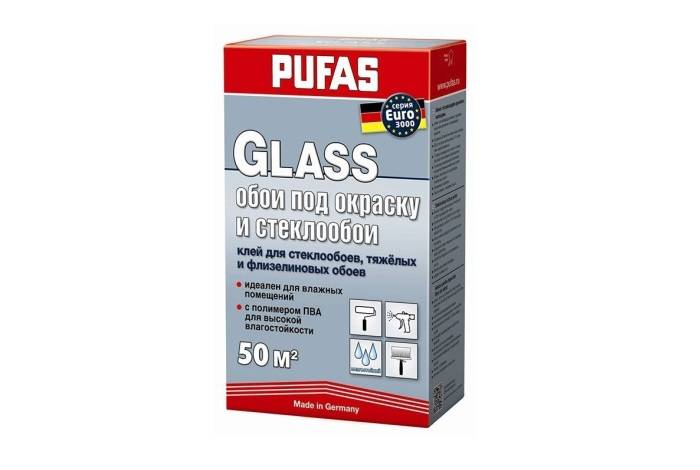

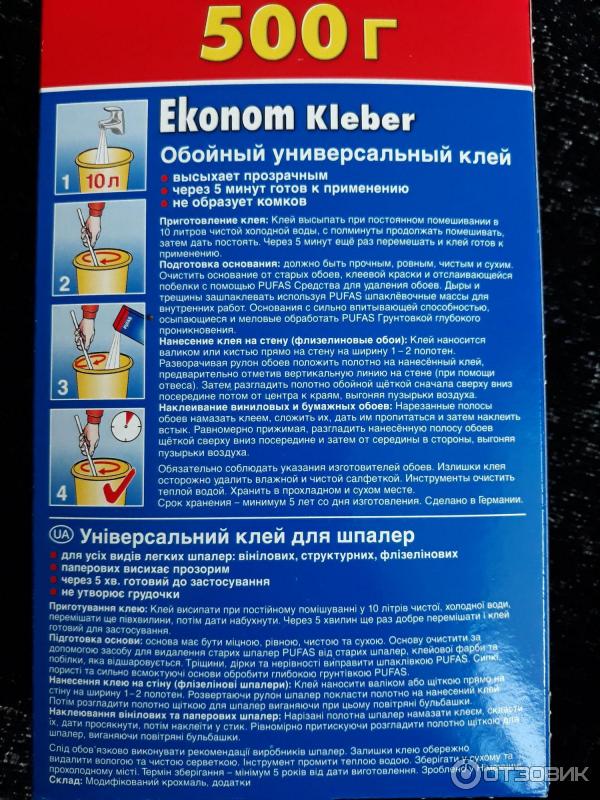

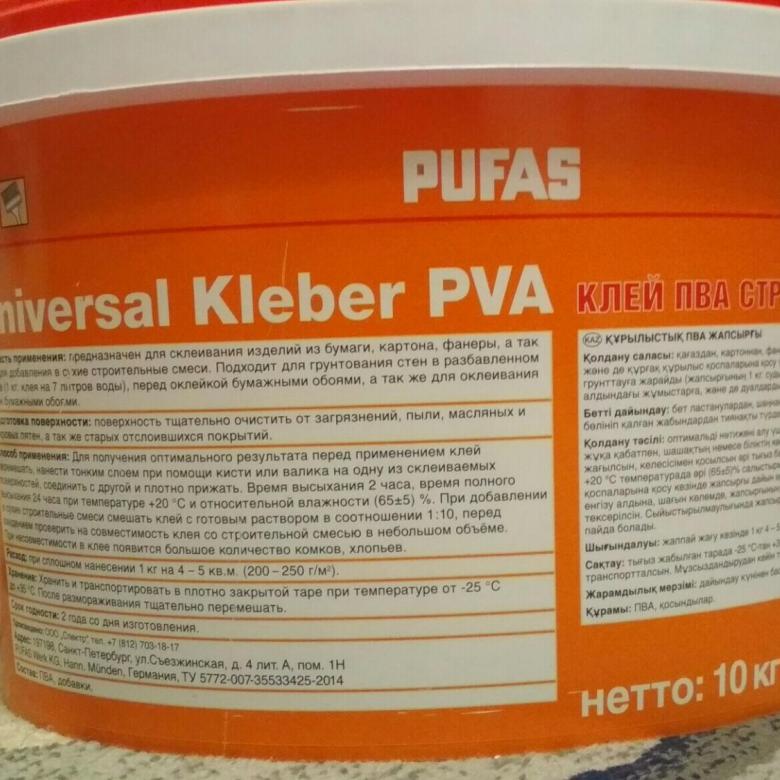

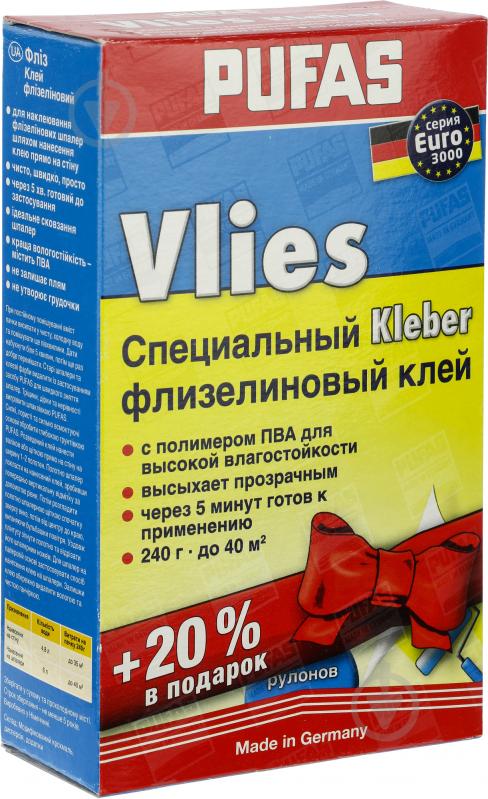

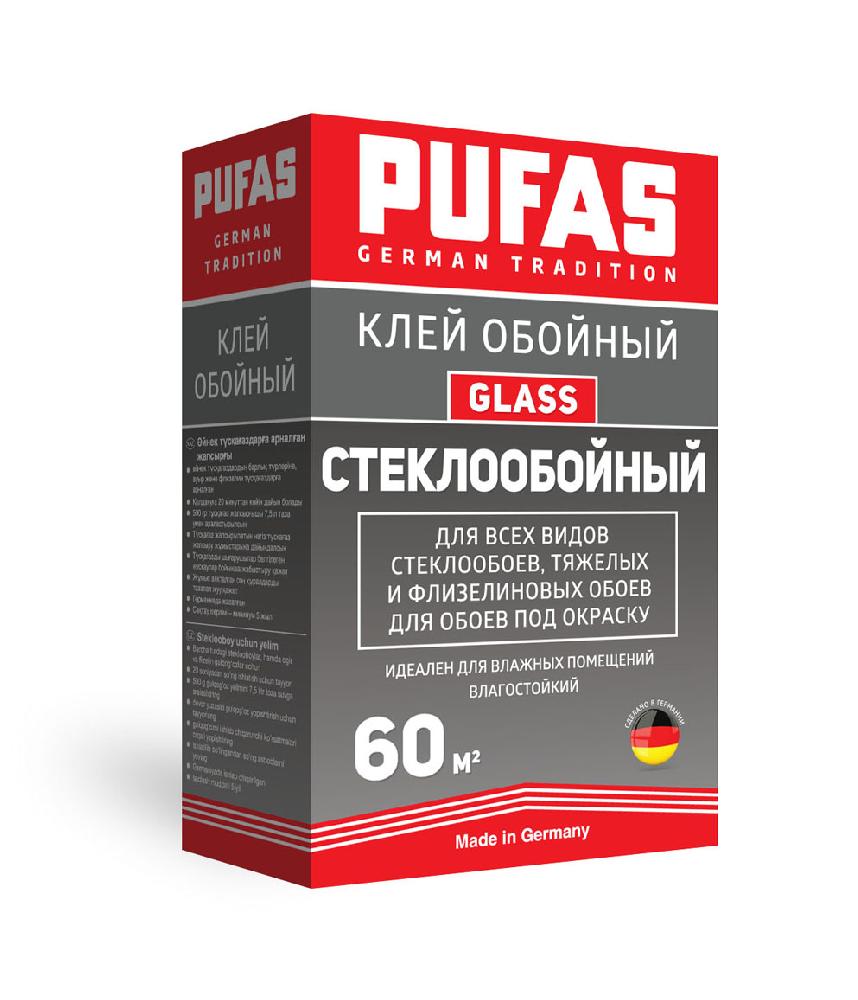

Range

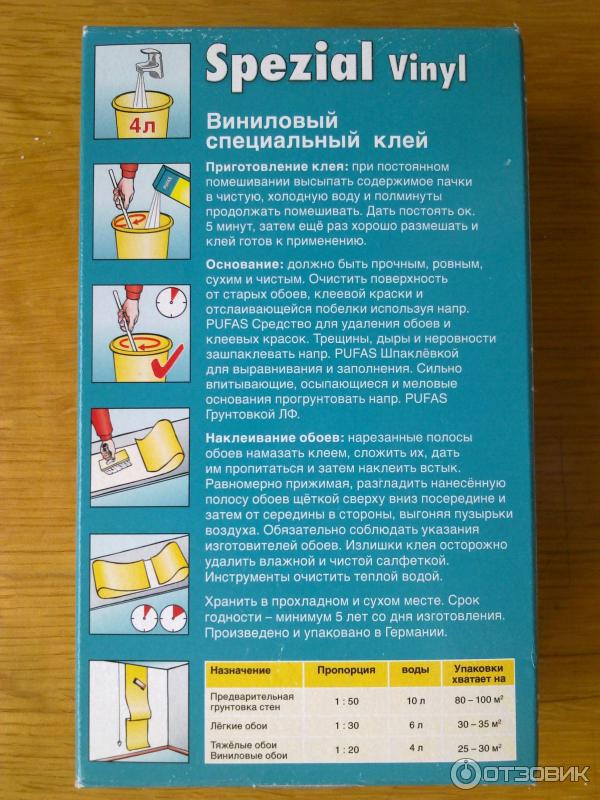

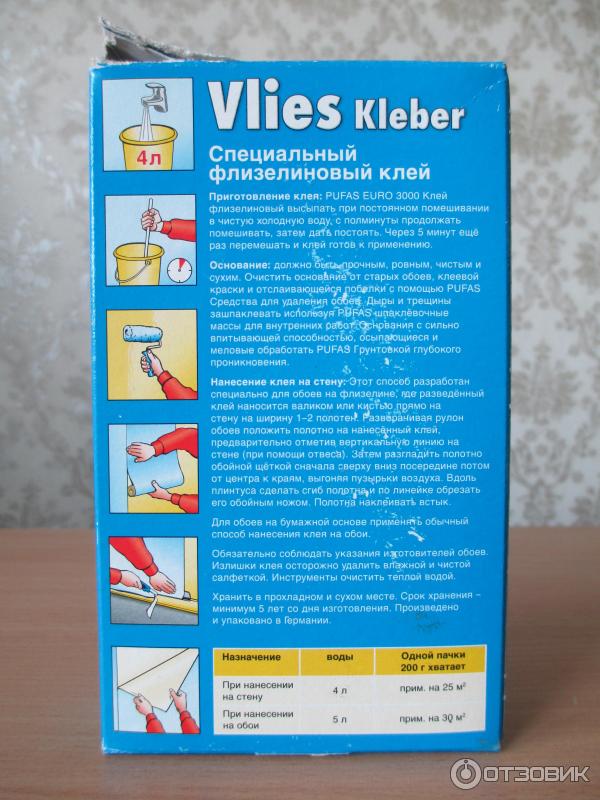

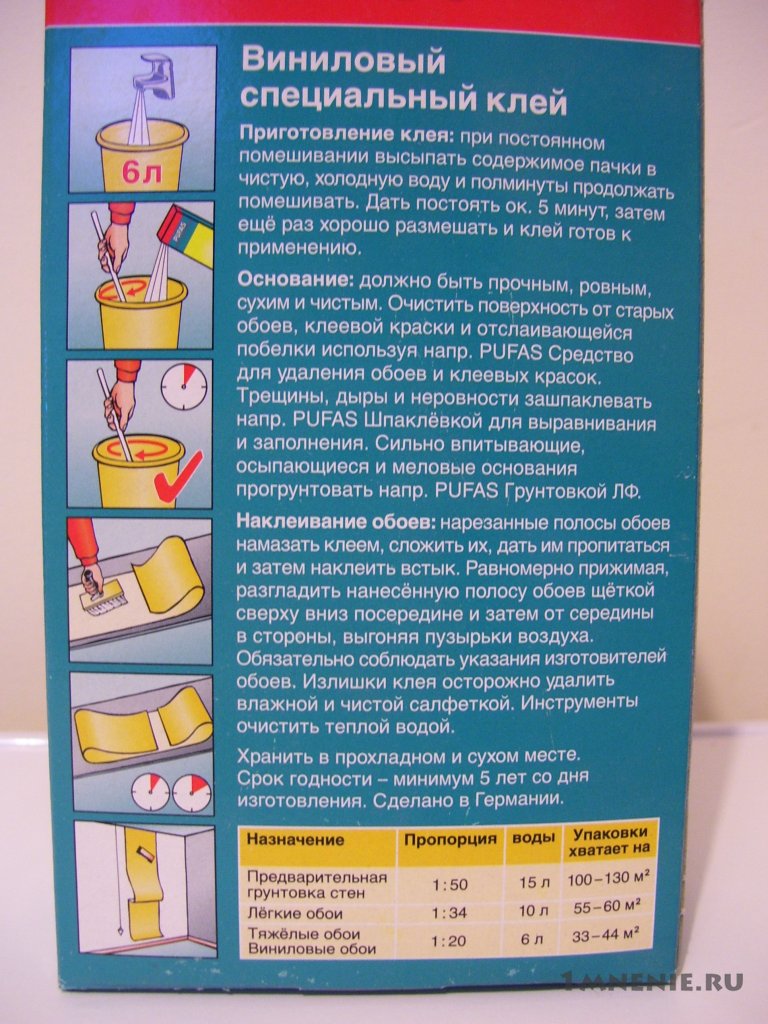

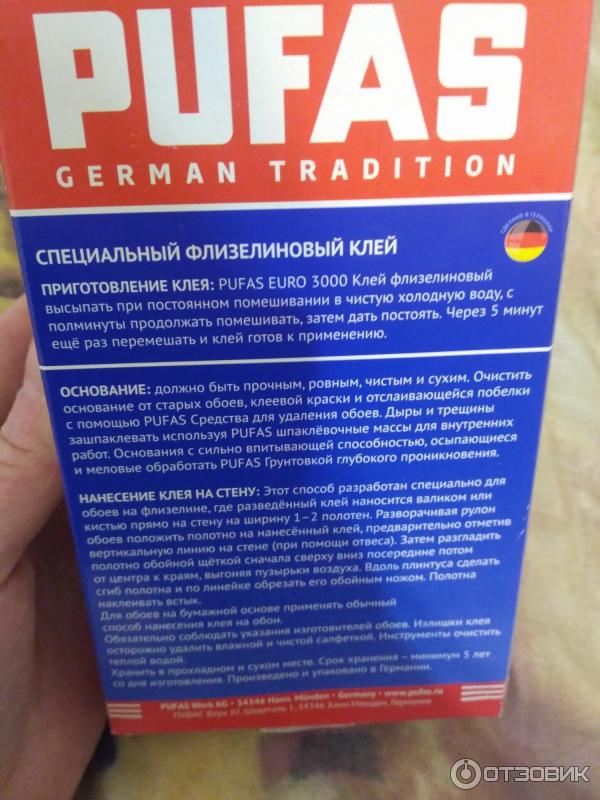

The line of Pufas wallpaper adhesives includes several types of adhesives, both dry and ready-made, liquid.

Now Pufas produces wallpaper glue:

- dry powder made of starch, intended for gluing light wallpaper (paper), the composition is reinforced with modern formulas;

- for heavy wallpaper (vinyl, non-woven), methylcellulose glue is produced, which simplifies the process of wallpapering;

- for difficult-to-stick fiberglass wallpaper, the Pufas brand produces its own composition, which is also applicable for gluing wallpaper to a poorly plastered surface;

- liquid universal adhesive composition, ready to use.

In addition, Pufas produces primers, liquids for removing wallpaper from walls, glue in tubes for gluing joints, these materials simplify the entire workflow.

Universal adhesive from the German brand

Gluing wallpaper with Pufas glue is no different from working with glue from another company, so we will not describe the whole technology of using wallpaper glue again, but dwell on the reviews about Pufas.

The choice of glue depending on the coating

Knowing the types of adhesives and their main brands is not enough

It is also important to take into account the specific type, size of the lamellas and the characteristics of the material. There are a number of recommendations for the use of compounds, depending on the different types of parquet:

- Piece material of ash, larch and oak, uncoated, glued to plywood. If the lamellas are up to 420/70 mm in size, it is allowed to use water-based products. The liquid in their composition will not be absorbed into stable rocks, deformation will not happen.

- Ash, oak, larch parquet with factory finish, glued to plywood. For this purpose it is necessary to buy a 1- or 2-component polyurethane-based product. Dispersion adhesives can cause warpage and rapid appearance of defects.

- Varnished material. It is necessary to choose a tool that is as resistant to separation as possible. Usually buy two-component formulations.

- Uncoated block parquet made of fruit species, maple and beech. In order to avoid damage to unstable wood, it must be glued to a product with solvents or other compounds without the slightest water content.

- Massive glued board glued to plywood. Large-format lamellas with lock fastening are glued with water-free products, with high elasticity. Otherwise, the adhesive layer will crumble.

- Solid board up to 120 mm, glued to plywood. Narrow - excludes the use of a dispersion agent, as it will greatly overmoisten the material. High strength and elasticity are essential characteristics of the composition. If this type of parquet is glued to a cement screed, which is rarely practiced, you only need to buy polyurethane compounds with maximum peel strength.

- Solid board over 120 mm, glued to plywood.With a large width of lamellas, the main characteristic of the composition is the vertical separation strength. You need to buy one-component synthetic resin products.

- Any type of parquet, glued to a fragile cement screed. The agent must adhere reliably to the coating literally at the molecular level. Purchase high quality two-component solutions.

- Industrial parquet. Narrow vertical boards are used in buildings with high traffic. Any two-component adhesive is suitable for fixing them.

Application features for PVC products

The composition of EVA glue is also suitable for repairing shoes, for the production of which PVC is used. To repair boots, you need to prepare the following set of tools and additional materials:

- several patches of a suitable size, made of waterproof material, to hide the damaged area;

- hairdryer;

- fine-mesh sandpaper;

- acetone for surface degreasing;

- protective gloves;

- wipes for wiping off excess squeezed glue.

Direct repair of PVC shoes is performed by sequential execution of simple steps. Including:

- Sandpaper gently clean the damaged surface and patch. The treated areas will become slightly rough.

- The place where restoration is required is degreased with acetone.

- A small amount of glue is applied to the defect and patch and left for 15 minutes. Then apply the next layer and wait half an hour.

- The glue is heated with a hair dryer and a patch is applied. Having exactly fixed the patch, it is pressed and held for 5 minutes.

Additional tips and tricks

When planning to purchase EVA glue for repairing shoes or other products, you should consider a number of tips and recommendations. The consumption of the adhesive solution will depend on the size of the existing damage, the method of application - manually or with the help of specialized tools and on the roughness of the surface to be treated. It is possible to ensure the optimal consumption of the substance without reducing the quality of setting, possibly experimentally.

During operation, do not expose solutions based on ethylene vinyl acetate to excessive heat, since exposure to high temperatures will negatively affect the physicochemical characteristics. At an ambient temperature ranging from 5 to 35 degrees, the solution can be stored for a year from the date of manufacture.

An important consideration when choosing an EVA adhesive is the material that needs to be repaired. Most of the products are suitable for working with silicone and rubber products, but there are also varieties for processing polyurethane and PVC items. Correctly selected glue solution will help eliminate defects on various products and prolong the possibility of their operation for a long time.

Share link:

Dignity

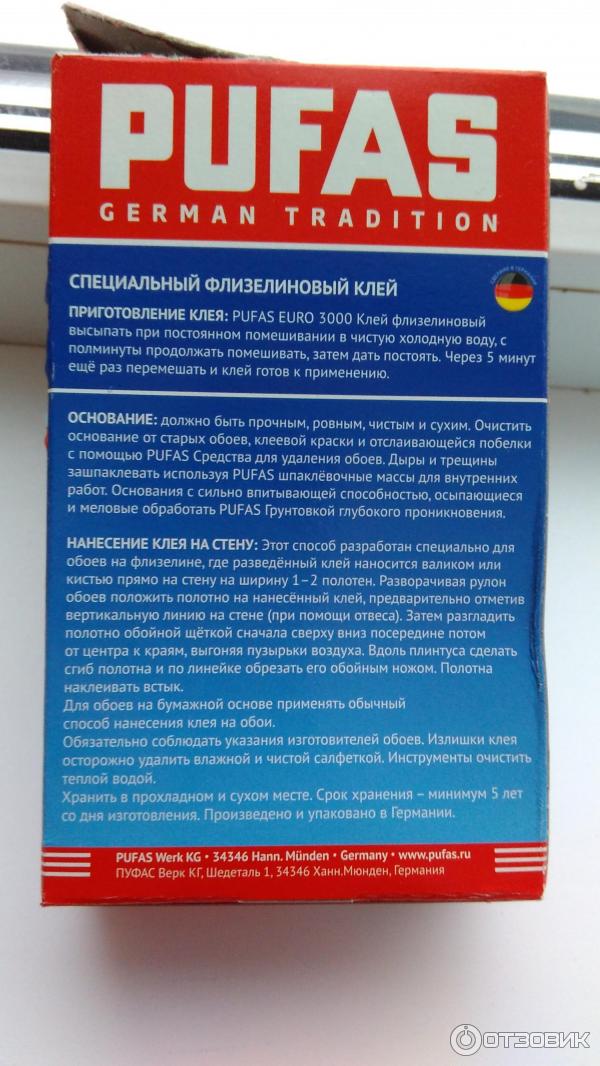

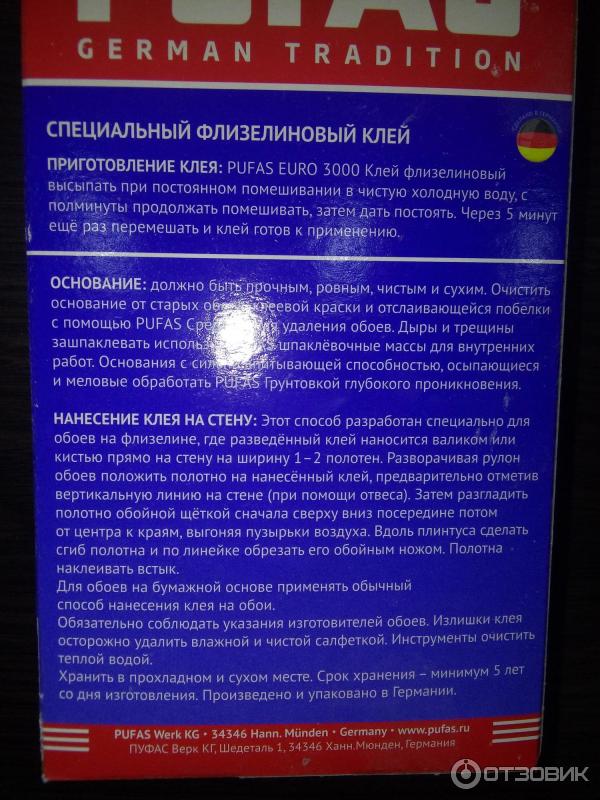

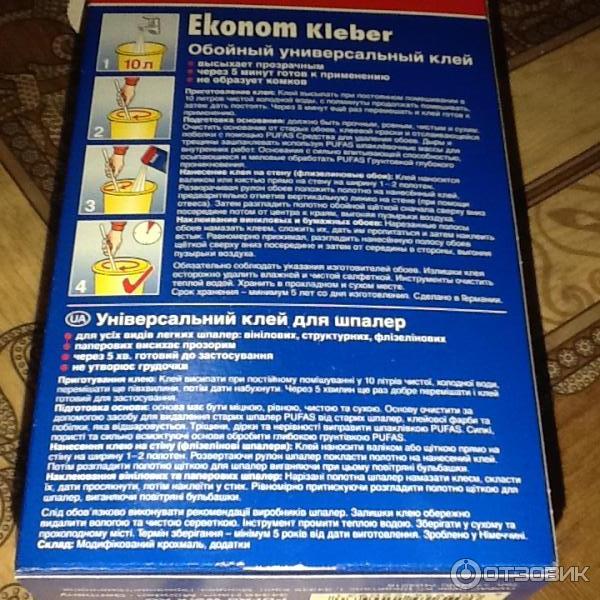

As in the case of any product, when choosing a mounting glue, it is necessary, based on its characteristics, indicated, as a rule, on the label on the reverse side, to determine whether it is suitable for the type of work that is planned to be performed with its help. This even applies to examples from the most famous manufacturers, and Pufas is no exception.

Pufas adhesive for fiberglass

First of all, you should pay attention to the packaging itself. All inscriptions on it, except for the name of the manufacturing company, are Russified, so it will not be difficult to figure it out

On the front side it is immediately indicated: what type of work it is intended for, some of its components, the volume of packaging. On the reverse side, you can familiarize yourself with the composition of the glue and detailed instructions for its preparation.

By the way, about cooking. "Pufas", unlike most analogues, dissolves easily when mixed with water and does not form any clots or lumps - a homogeneous substance is obtained.

Another common problem associated with the use of assembly glue is multiple streaks and contrasting spots in areas of heavy application. Fortunately, the Pufas glue has passed this problem. The color of the inner layer of the wallpaper, even after application, does not change its shade, remaining exactly the same as before the start of work. Despite the fact that the glue itself has a color - white, after it has been applied to the desired surface, discoloration occurs.

Pufas glue in a bucket

At the same time, even by attaching a piece of wallpaper with glue applied to it to the wall, you can for some time - before the substance hardens - change its position in order to compose a whole pattern and avoid further need for plywood.

For many, the decisive factor when buying is the cost of the product. In the case of "Pufas", it is more than acceptable, despite the fact that the glue of this manufacturer is not found on store shelves as often as the same domestic counterparts or options from manufacturers from neighboring countries. The shelf life is standard, 5 years, however, judging by numerous customer reviews, this is far from the limit for a dry mix.

As for certification and issuance of permits for use, Pufas has successfully passed this procedure, being approved in the European Union, which gives confidence when choosing a product from this manufacturer.

Main characteristics

Wallpaper glue CMC is protected from the formation of mold, mildew, which will not show through on the wallpaper. If the composition includes sodium tetraborate, then you should not worry about the appearance of insects. Due to these characteristics, the powder is often added to putty mixtures, concrete mortars.

This product is produced at Russian and foreign enterprises.

Main technical characteristics:

- moisture content up to 12%;

- dissolves in water by 96-100%;

- infusion, swelling of components, activation of properties - 2-3 hours;

- ready-made it is used within a week.

The amount of added water depends on the density of the wallpaper: for thin material - 8 liters of water per pound of powder; for dense canvases - 7 liters of water per pound of powder.

In order for the glue to fully activate its properties, warm water is taken for dilution, the mass for swelling is left overnight.

Parquet adhesive requirements

Not all adhesives sold in hardware stores are suitable for installing new parquet floors. Their components must reliably hold the lamellae together without causing material destruction. A good adhesive meets the following requirements:

- No shrinkage. After final drying, the adhesive layer retains its volume, otherwise the boards will move, creak after being laid on a concrete screed or plywood.

- Durability. A conscientious manufacturer of glue guarantees a long service life, especially since the parquet floor itself does not lose its properties and attractiveness for more than a hundred years.

- Elasticity. This quality allows the tool not to glue the parquet tightly, but to make it moderately mobile - within the limits of displacement when the temperature changes. Only elastic glue will not crumble at temperature extremes.

- No harm, no unpleasant smell. Some products are environmentally friendly, others contain solvents. After drying, the latter completely evaporate and do not harm a person.

There should not be a lot of water in the adhesive composition, otherwise the wood will swell and be damaged. For this reason, ordinary glue, such as PVA, is not suitable for installation. An unsuitable adhesive reduces the attractiveness of the coating and shortens its life.

Manufacturers of glue KMTS

In hardware stores, in the markets, there are Russian, imported TMs for sale. The price of the former is much lower, but the technical characteristics are not inferior.

Famous manufacturers:

- Pennant 75B is produced in Russia. The finished solution has a high viscosity, water-retaining qualities.Suitable for all types, types of wallpaper on all surfaces, including metal. No toxic substances, safe. Packing in bags.

- Carbocel produces a universal CMC product for all types of canvases. It is an environmentally friendly product with high solubility values. Highly effective filler-free product. Available in packages of 0.3 kg, 0.5 kg, 15 kg.

- Omega produces an adhesive based on carboxymethyl cellulose with the addition of antifungal components. Suitable for various wallpapers in structure, width. The solution is prepared within three hours, as a result, a homogeneous mass without lumps is formed. Shelf-life Unlimited.

- Polycell CMC-7 is a white fine-grained powder, readily soluble in water at any temperature. It is used in construction as a thickener for putties, increases the plasticization of solutions, adhesion strength.

- Malva produces glue designed for fixing multilayer wallpaper (foam), cloths on a paper, fabric basis. Fastening is carried out on painted, concrete, plastered, wooden surfaces.

Working solution preparation rules

To prepare vinyl glue for use, you need to carefully dilute the dry powder with plain water. The proportions must correspond to the attached instructions. The air and water temperature should not be lower than +25 degrees. Stir the powder as thoroughly as possible. Only in this case it will be possible to avoid the appearance of lumps. The mixture must be infused for the time indicated in the instructions. Before gluing the canvases, all the necessary preparatory work must be performed.

It is necessary to determine the free space on the clean floor. The canvas is leveled on the surface and greased with glue. It is best to use a clean, dry cloth to press down on the wallpaper. To improve the result, you can walk with a roller several times. All manipulations should be performed slowly and carefully, since there is always a risk of displacing the canvas, which causes folds to form. If the edges of the wallpaper bristle a little, then they must be additionally greased with glue and pressed against the wall. If there are screws or nails on it, then it is better to pull them out before starting pasting or drive them deeper. You need to be as careful as possible in the place where the sockets and switches are located. To make the result look as neat as possible, you need to cut out the necessary holes with scissors. To maximize the correct distribution of all efforts, two people should be involved in the work process. One holds the wallpaper at the top and the other at the bottom. The canvas should go behind the skirting board, which is better to dismantle in advance.

How to apply correctly

How to prepare the adhesive solution, write in the instructions on the label or package. Usually the slurry is prepared in a plastic bucket. Take water at room temperature (not hot). First, liquid is poured into the bucket. Then a measured amount of powder is poured in a thin stream, with constant stirring. Stir the glue well and leave to swell for 15-20 minutes or 2-3 hours.

Usually, a standard package of CMC weighing 500 grams is diluted in 7-8 liters of water. This solution should be enough for pasting an area equal to 50 square meters. Before gluing the wallpaper, the walls are primed with an adhesive solution based on CMC. For this purpose, take 500 grams of glue per ten liters of water. The liquid mixture is applied to the walls and left to dry for 3-4 hours. The wallpaper itself is lubricated with an adhesive mass and left to soak, depending on the thickness of the canvas, for 10-20 minutes. Before pasting the walls, the wallpaper is once again smeared with an adhesive mixture.

Popular brands of products

On sale you can find a large number of adhesives that are allowed to be used when installing a parquet board:

- Kiilto Standard. Finnish dispersing agent, suitable only for oak, larch, since it contains 35% water. Differs in low consumption - only 600 g / sq. m.

- UZIN MK 73.Contains synthetic resins and solvents, suitable for laying any parquet on all types of substrates. It can be used on heated floors.

- Bostik Tarbicol KP5 is a water-dispersion solution, most often used for fixing moisture-resistant plywood under parquet. Has a low price. Includes vinyl components, can be used on underfloor heating.

- Artelit RB 110. It is a professional solvent-based rubber adhesive for plywood, parquet, wooden mosaic. Highly elastic composition, very durable, suitable for all types of wood.

- Kiilto Flex Silan. Silane one-component glue, can be used on lacquered, oil-coated boards, helps to mount plywood and solid wood. The product dries only a day.

- BONA B-720. Dispersion mortar with a low water content (22%), suitable for substrates made of moisture-resistant plywood and parquet from oak, larch.

- SikaBond-95. Sikabond-95 adhesive sealant is a hard-elastic compound for fixing piece and modular parquet, plywood, OSB boards. It is a one-component product with high adhesion properties. Sika also produces Sikaflex-290 for sealing joints and simulating deck installation.

- Axton 2k. It is sold in cans of 14 kg, is a dispersion composition, suitable only for oak and larch, as well as for all types of laminate.

- Stauf-PUK 446. It is a two-component resin-free product suitable for all types of parquet, including decorative and large-format.

- Adesiv Pelpren PL6. Epoxy-polyurethane two-component composition, gives increased strength of the seam, while maintaining its elasticity.

- LiquiRock. Also applies to polyurethane compounds, includes a base and a hardener, does not harm even the most delicate varieties of wood.

Available applications

The universal composition of vinyl glue allows you to use this material for decorative and natural stone, concrete, brick, plaster, as well as porous surfaces. Some types go well with laminate and classic ceramic tiles. Before applying the glue, the work surface must be properly cleaned, degreased (with a special agent or solvent) and dried. The glue is used not only for decorating various rooms, but also for decorating various interiors with the help of popular decorative elements. The tool is effective for attaching various materials to vertical, horizontal surfaces. Vinyl glue is suitable for wallpaper as well as wood surfaces. The transparent, quick-drying compound is effectively used in the manufacture of prefabricated furniture.