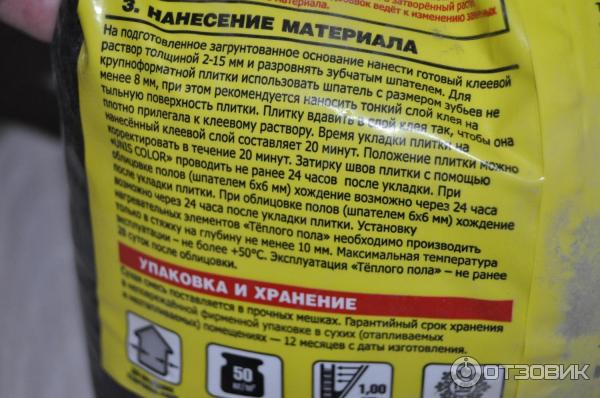

Packing and storage

Unis Plus tile adhesive is packed in sturdy, 25 kg paper bags. Store in cool, dry rooms on wooden pallets. Shelf life is 12 months in original, undamaged packaging.

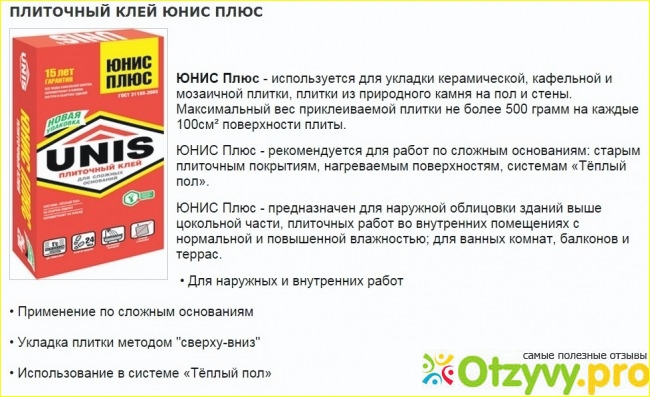

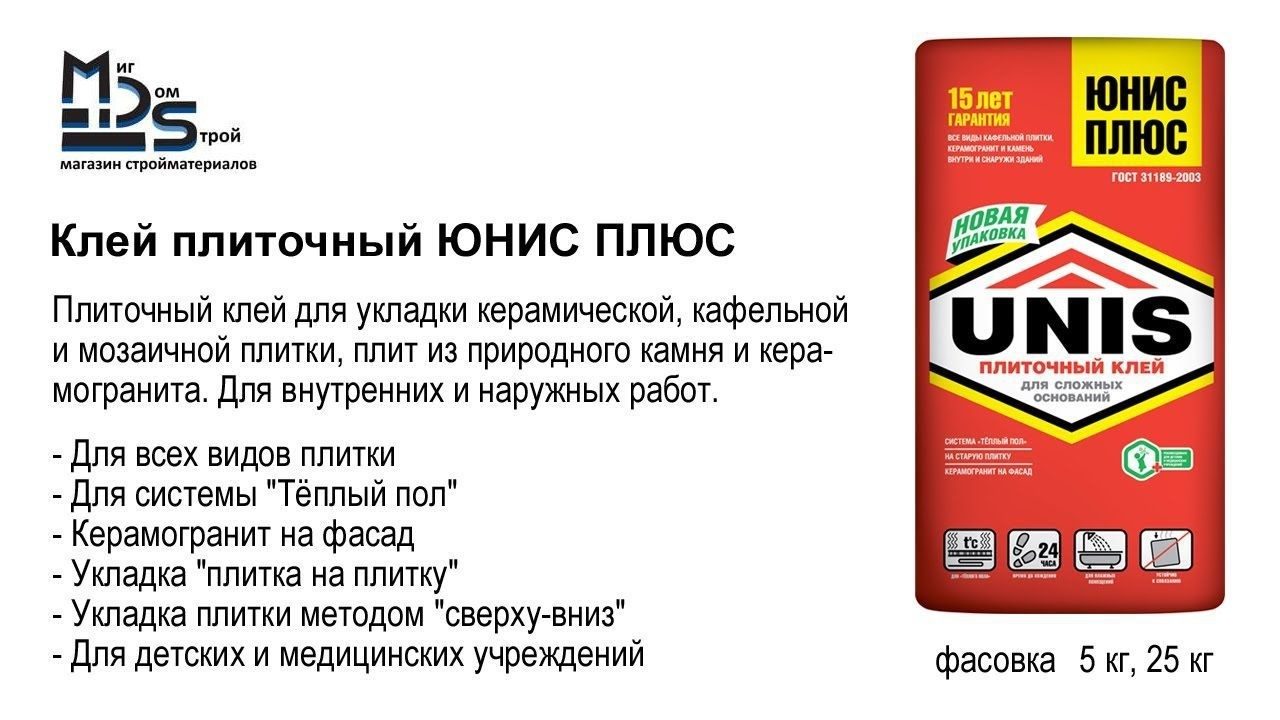

Glue "Unis Plus"

Glue "Unis Plus" is used for high-quality laying of porcelain stoneware, tiled and mosaic tiles, natural and artificial, on floors and walls. "Unis Plus" can be recommended for work on both standard and complex substrates (old tile coatings, "Warm floor" systems)

"Yunis Plus" is suitable for tiled buildings from the outside above the basement, indoors, both with normal and high humidity (bathrooms, balconies and terraces.) Yunis Plus, has increased adhesion strength and reliably fixes tiles on complex substrates. Exceptional adhesion of Unis Plus, ie. thixotropy, eliminates tile slipping.

"Unis Plus" is also used when working on surfaces with temperature fluctuations up to + 70 ° C, and is not replaceable in "Warm floor" systems. Unis Plus glue is resistant to direct contact with water and retains its properties when exposed to negative temperatures (at least 35 cycles.) The elasticity of the finished solution and its viability makes Unis Plus glue convenient to use.

Unis Plus is an environmentally friendly material. And since Unis Plus does not emit substances hazardous to human health and the environment, it can be used when working in kindergartens and hospitals.

Unis Plus is a C1-class glue, and therefore can only be used on non-deformable substrates such as concrete, cement and gypsum plasters, bricks, etc. ... you should also observe the conditions for working with Unis Plus and carry them out at an air temperature of at least +5 ° C and relative humidity no more than 75%.

The basis for using Unis Plus glue must be leveled, always dry and strong. by applying Unis Plus glue, it is necessary to remove the old paint from the surface with a spatula, wash off bitumen and oil stains, and other contaminants that interfere with the adhesion of Unis Plus to the surface. It is recommended to level the surface by using UNIS plasters: "Eunis Teplon" "Eunis Silin Facade" or "Eunis Silin for work". And to increase the adhesion of Unis Plus glue, the surface should be treated with one or two layers of the company's primers. soils should be produced in accordance with the type of substrate.

To prepare the Unis Plus solution, use clean containers and tools. Dry adhesive mixture "Unis Plus" must be poured into a container with clean water at the rate of 1 kg of dry mixture, 210 - 250 ml. water and mix thoroughly with a mixer or drill with a nozzle, then let stand for 3-5 minutes and stir again.

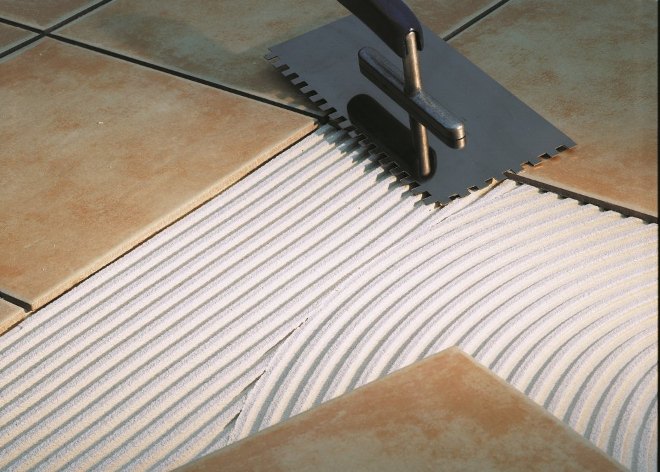

Unis Plus tile adhesive is applied to the primed base and leveled with a notched trowel. For porcelain stoneware in the 300x300 format, a spatula with a notch size of at least 8 mm is used. Place tiles on the Unis Plus adhesive layer and press down so that its inner surface is firmly attached to the adhesive solution. Correction and cleaning of the surface from excess Unis Plus glue must be performed within 10 minutes after installation. Grouting between tiles can be done no earlier than 24 hours after facing.

We also recommend that, in addition to the above information on how to use "Unis Plus", when working with it, you should follow the safety instructions and general construction work in construction.Before a specific application of Unis Plus glue, you should seek advice from a technician; the Unis Plus glue usage guide cannot replace professional training in the performance of work. When facing with light or glass mosaics, marble and tiles of light colors, it is recommended to use Eunice Belfix glue, Eunice Granite large porcelain stoneware, and for facing pools, Eunice Pool. It is strongly recommended not to use Unis Plus glue when lining swimming pools, stoves and fireplaces.

ATTENTION! Keep out of the reach of children. Observe safety instructions during operation

Work with gloves. In case of contact with eyes, rinse with water.

And also products from the companies are presented for you: Litokol, Prospectors, Ivsil.

Instructions for use

For interior work, it is recommended to dry the room well. For this, you can use a heat gun. The optimum temperature for styling is about 20 ° C.

It is better to carry out outdoor work in the warm season, at a temperature not lower than + 5˚С and humidity not higher than 70%.

Surface preparation

The reliability of the installation and the duration of the finishing service depend on the quality of the preparation of the base.

- Before laying, dismantle the old coating as much as possible. If it is impossible to completely get rid of the elements, level the plane with an assembly mixture. For greater strength, use a metal mesh as a reinforcing component.

- After leveling, dry the surface for 24 hours.

- When working in rooms that are constantly in contact with water, apply a layer of waterproofing material and leave again to dry for at least a day;

- Then prime, dry and mark the surface.

When carrying out preparatory work, do not rush and dry the base as thoroughly as possible after each stage of coating.

How to dilute the solution

It is recommended to dilute the solution in a high container or in a bucket. Do not use flat trays, the solution dries faster in them.

Pour the dry mixture into the container and add water in accordance with the instructions on the package

Each type of adhesive may require a different amount of water.

- Stir the mortar with a construction mixer or a drill with a screw nozzle for 3–7 minutes.

- Cover with a lid and leave the solution to mature for 7-10 minutes.

- Stir again, add some more water if necessary.

Glue application

After dilution, the mixture is immediately applied to the prepared surface.

- The composition is leveled first along the entire plane of contact with the finishing elements.

- A ribbed structure is then created with a notched trowel. The groove depth is calculated based on the tile size.

- When laying on a vertical plane, wait 7-10 minutes after applying the mixture. Then the elements are laid sequentially at a distance of 1–5 mm. apart. To make the distance the same use cross-shaped spacers;

- After placing the tile, tap it with a rubber mallet to evenly sink it into the mortar. The area of contact between the assembly composition and the elements must be at least 60%.

- Remove excess mixture immediately with a rubber spatula and a wet cloth. The optimum temperature for laying is 18–22˚С, humidity is 60–70%. After finishing work, allow the solution to dry completely for at least a day.

How to properly prepare the surface?

In order for the tile to lie flat, you must first carefully work with the base and prepare it as follows:

Old finishes are removed, whether screed or crumbling plaster.

- If the surface is in cracks and other defects, then the base is leveled with plaster.

- The surface must be dry and free from any dirt and oil stains.

- If the room is with high humidity, then before work it is better to complete the procedure of coating waterproofing.

- A primer is necessary to ensure that the base for laying is flat. So the grip will be more reliable and durable.If the surface is not leveled, then the tiles will begin to flake or crack over time. It is better to prevent these consequences in advance.

Overview of manufacturers of similar products

In addition to the Unis company, besides the Unis company, it is possible to refer to the number of conscientious manufacturers of dry mixes for laying tiles:

- Kilto.

The Finnish manufacturer produces both dry mixtures and ready-made solutions. Kilto products are not afraid of the aggressive influence of the environment, therefore they are recommended to be used for finishing complex substrates in rooms with a specific microclimate - bathrooms, swimming pools, open areas, etc.; - Mapei.

Italian-made glue has a long working time - not less than 5 hours, during which it is possible to veneer premises that are large enough in area. The manufacturer adds special components to the composition of dry mixtures that do not allow the solution to quickly solidify; - Moment.

The German factory for the production of mortar compounds produces products with high adhesion and plasticity. Due to this, it is possible to veneer rather uneven surfaces with the possibility of leveling height differences up to 20 mm.

Application features

In addition to these advantages, Yunis Granite tile adhesive (25 kg) is resistant to moisture, precipitation, temperature fluctuations. It is widely used on substrates with artificial electric / water heating "Warm floor".

The specially developed Eunice Granite tile adhesive (25 kg) is characterized by high adhesion to the substrate materials. Such characteristics make it possible to lay large and heavy slabs (up to 100 kg / cm2), for example, from stone, marble, porcelain stoneware, etc. The solution has excellent adhesion to surfaces made of brick, gypsum, cement, concrete (all varieties), sheet materials (gypsum plasterboard, gypsum plasterboard, gypsum plasterboard, etc.) and even asphalt.

Application features

Thanks to the cement base, the glue is used for exterior work (finishing of facades, building basements, columns) and interior cladding of floors, walls in rooms with different humidity / temperature operating conditions: bathrooms, washing facilities, basements, garages, terraces, balconies. It should also be noted separately:

- High strength characteristics, impact and crack resistance of the mortar - provide the possibility of using the material on objects subject to high operational loads, for example: entrance groups, stairs, paths, blind areas, floor coverings in shopping, sports, educational and other institutions / institutions characterized by high traffic.

- Laying tiles in any way, including "top-down" - due to the absence of slipping. Such properties can significantly speed up the time of work and easily create various patterns, ornaments on vertical surfaces.

- The possibility of using the solution when decorating complex substrates, for example, laying on old tile coverings.

- Safety of use - no harmful fumes, secretions and other by-products, can be used in medical, residential, children's premises.

Article: 02577

Manufacturer: Unis

Quantity per pallet: 48 pcs.

Weight: 25KG

You can see similar materials in the sections: Tile adhesive for interior work Tile adhesive universal Tile adhesive for exterior and facade works Tile adhesive for ceramic tiles Tile adhesive for porcelain stoneware Tile adhesive economy class Tile adhesive for natural stone

Other products of this manufacturer: Eunice dry putties Eunice plaster mixes Eunice self-leveling floor

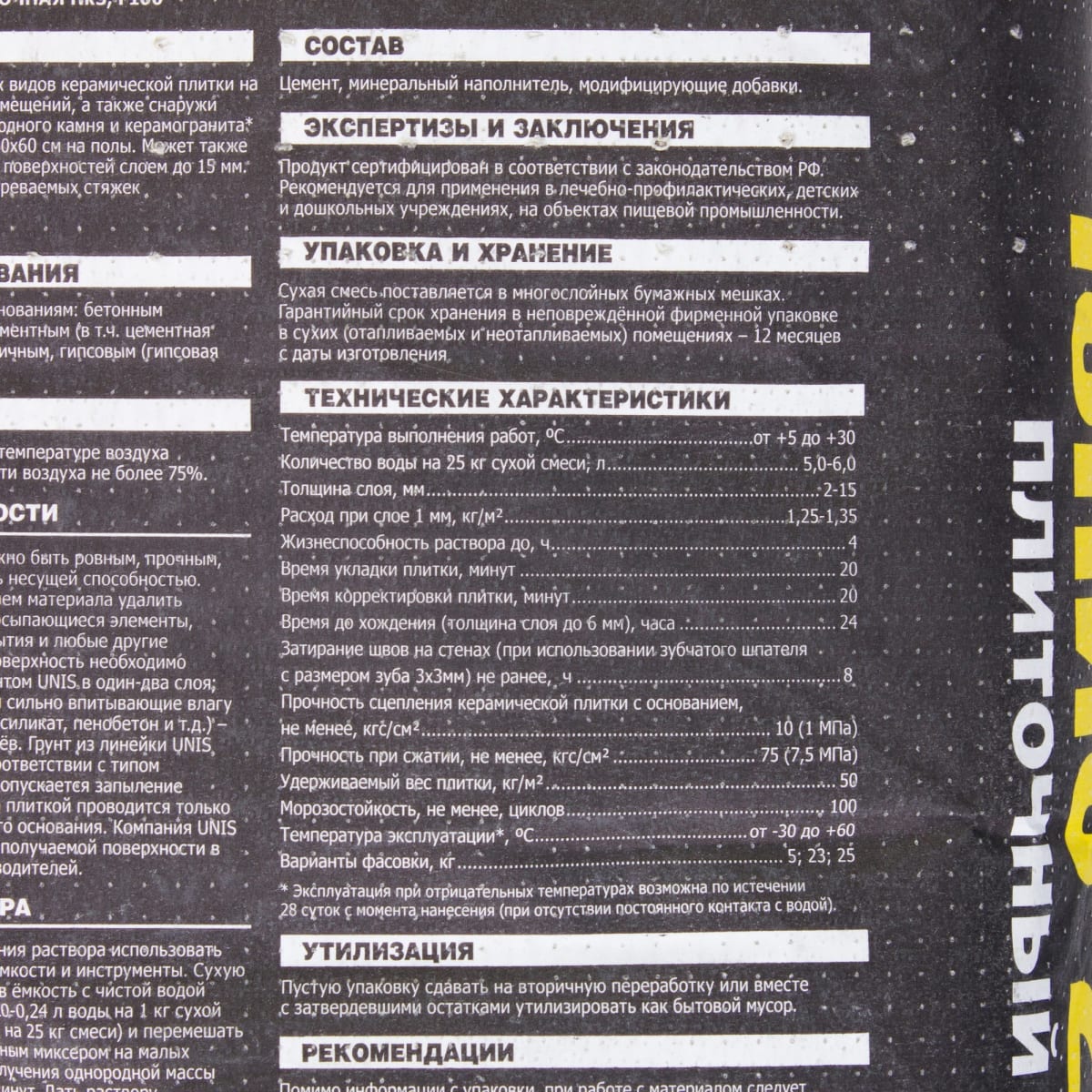

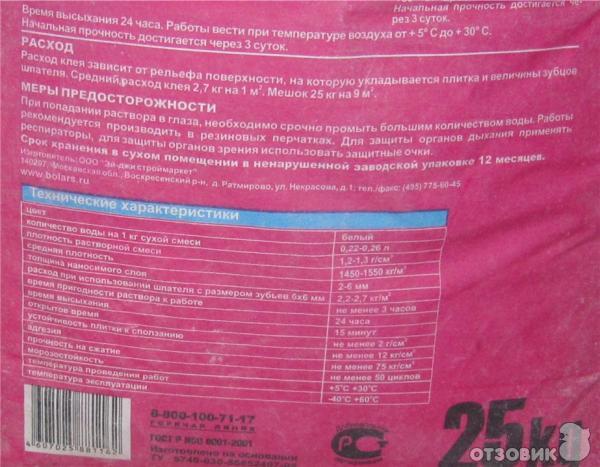

| Work temperature | + 5 ... + 30 ° С |

| Amount of water for 25 kg. dry mix | 5.0-5.75 l. |

| Layer thickness | 3-10 mm |

| Consumption when working with a spatula 6X6 | 3.5 kg / m2 |

| Pot life of the solution | 180 minutes |

| Tile laying time | 15 minutes |

| Time to correct tile position | 10 minutes |

| Hardening time | 24 hours |

| Adhesion to the substrate | 15 kg / cm² (1 MPa) |

| Supported tile weight | no more than 100 kg / m² |

| Frost resistance not less | not less than 35 cycles |

| Operating temperature | from -50 to + 70 ° С |

| Package | 25 Kg |

Yunis Group of Companies is a domestic manufacturer of dry mixes, which has been on the market for over 20 years. In terms of popularity among the standard tile cement glue, Eunice dry mixes are among the three most popular, along with Hercules.

In this article, you can see the characteristics of all Unis adhesives, choose the best one, calculate their consumption and study the instructions for use.

Fast navigation through the article

Advantages

- High strength index.

- Good adhesion properties on all types of substrates.

- The glue seam does not lose its properties when the temperature decreases or increases, but only frost-resistant glue, which is able to withstand even the conditions of the Far North, has resistance to freezing.

- The composition is environmentally friendly, has no pungent odor, no toxic fumes.

- At the same time, the lining is glued and the base is leveled.

- The consistency of the composition prevents tiles from slipping even from vertical or inclined substrates.

- Economy. The consumption of tile adhesive is small, its value varies slightly depending on the type.

- Long shelf life of the finished solution. There is enough time to lay the tile, adjust its position and fix it securely.

- Moisture resistance.

- Can be used when installing underfloor heating.

Product advantages

Among the advantages of this product stand out:

- rich assortment (for different types of surfaces);

- convenient packages of 25 kg;

- durability and efficiency;

- the glue is easy to dilute and apply;

- for each type of product, instructions for use are attached, which greatly facilitates the work with this composition;

- the glue is made in accordance with GOST and has all the certificates of conformity.

Unis plus is a quality product at an affordable price, suitable for cladding a wide variety of surfaces. The main thing is to follow the instructions for use, and the end result will delight the eye for many years.

Comparison of tile adhesive from different manufacturers is clearly presented in the video.

Properties

Eunice Plus - tile adhesive is used indoors and outdoors. Increases the adhesion strength of the surface and material, has a high adhesive ability, which makes it possible to glue the tiles during specific work "top-down". Weather resistant to adverse conditions, retains its properties at low temperatures, as well as in humid rooms and in contact with water. In its composition and after work, it does not contain and does not emit harmful substances that could harm human health and the environment, therefore it is environmentally friendly.

Apply the prepared Yunis Plus solution to concrete, foam and aerated concrete, cinder block surfaces, cement and gypsum plasters, brickwork and silicate surfaces, gypsum plasterboard and gypsum plasterboard.

Features of Unis tile adhesives

Tiling with Unis adhesives allows for the bonding of various types of subfloors, from non-deformable to those experiencing thermal expansion. Some of the types of dry mixes are suitable for use in extreme conditions:

- High humidity (over 80%);

- Significant temperature drops (about 80 degrees);

- Large mechanical load with a pressure of 100 kg per 1 m 2 of the coating.

The choice of a certain type of solution is determined by the microclimate of the room, as well as the specifics of the facing materials. The physical and mechanical characteristics of cement mixtures and, accordingly, the price directly depend on this. Next, we will consider several main types of Eunice adhesive solutions that are in special demand among consumers.

Eunice Plus

Unis plus glue, multi-purpose in areas of application, is suitable for mounting any type of materials:

- ceramic tiles;

- decorative bricks;

- artificial stone;

- porcelain stoneware slabs;

- mosaics;

- glass tiles;

- marble.

Of all the varieties of mortar mixtures, Unis plus tile adhesive is one of the most reliable and durable, as evidenced by its physical and mechanical features:

- Good adhesion - 1.25 Pa per 1 cm 2;

- Ability to withstand heavy weight - up to 90-100 kg per 1 m 2;

- Frost resistance - transfers up to 35-40 full freeze cycles;

- Resistance to temperature fluctuations - from -50 to + 80 degrees;

- The long period of "life" of the solution is more than 3 hours.

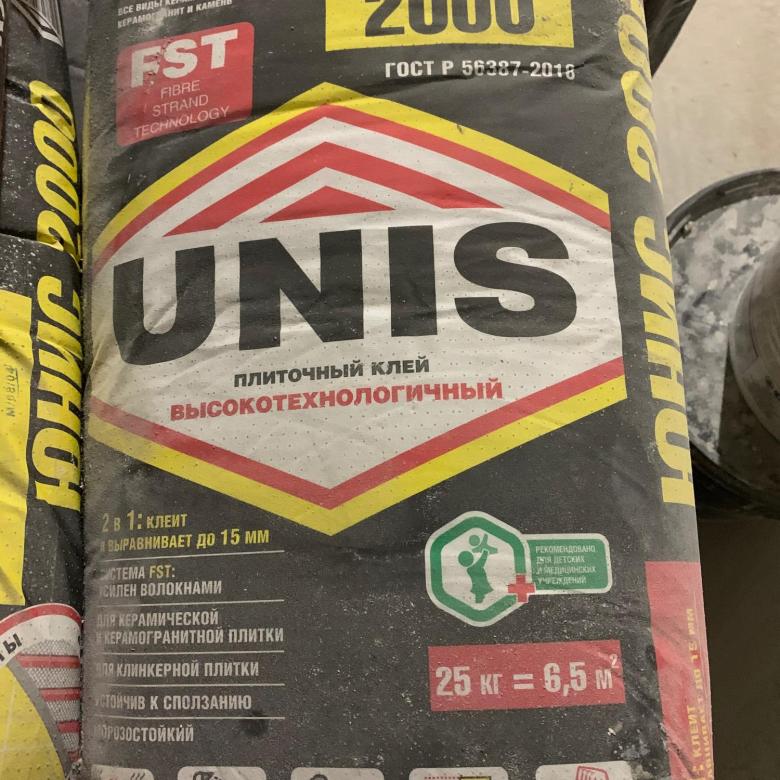

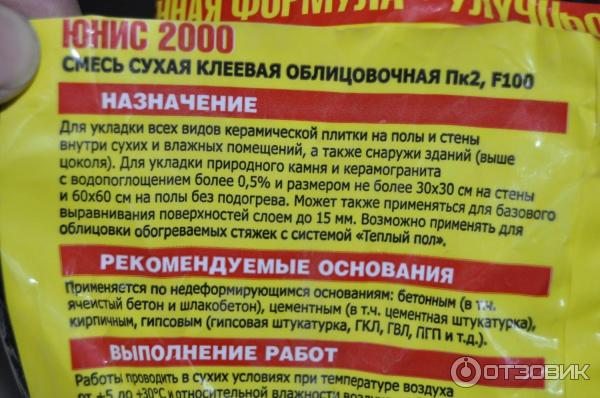

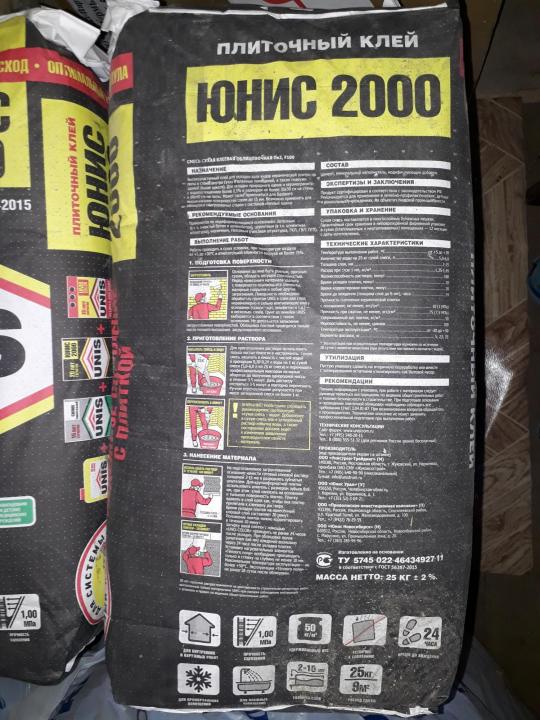

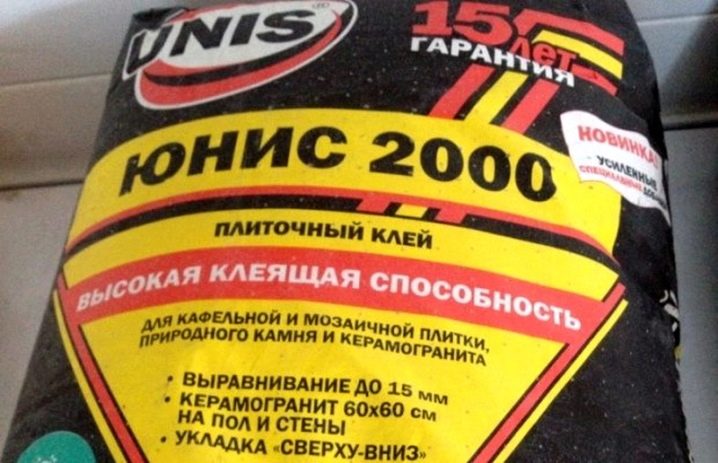

Eunice 2000

Unlike the previous adhesive, Eunice 2000 tile adhesive does not have such good frost resistance properties. Therefore, it is recommended to use it in not too extreme climatic conditions. However, this disadvantage is offset by another advantage of the composition - the ability to level surfaces.

Unis 2000 tile adhesive is capable of leveling height differences on a rough base up to 15 mm. Therefore, it is quite often used for finishing floors and walls, not only inside buildings, but also outside. What are the technical features of the solution?

- Good adhesion - at least 10 kg per 1 cm 2;

- Long period of tile adjustment after installation - about 10 minutes;

- Ability to support tiles weighing up to 80 kg per m2;

- High frost resistance - transfers up to 35 freezing cycles;

- Rapid hardening of the composition - no more than 36 hours.

Eunice Granite

The manufacturer of adhesives took care of providing different types of mixtures with different physical and mechanical properties. This allows the use of certain types of solutions for facing surfaces in rooms with special climatic conditions. For example, the Granite tile adhesive is specially designed for the secure attachment of large format porcelain stoneware slabs.

The material is resistant to slipping, so it can be used for finishing not only the floor, but also walls or even the ceiling. At the same time, almost any type of surface can serve as a basis for installing a tile, including those that experience constant thermal expansion. Adhesive for tiles Yunis granite is mainly intended for finishing the basements and facades of buildings, which is possible due to the high frost resistance of the mortar.

Technical features of "Granite":

- Adhesion to the surface - not less than 15 kg per cm 2;

- Ability to withstand heavy materials - not less than 100-110 kg per m2;

- High frost resistance - withstands up to 40 freezing cycles;

- Large operating temperature range - from -50 to + 60 degrees;

- The minimum drying time (at 20 degrees) is 36 hours.

Eunice Pool

Already from the name of the product, it becomes clear that the mixture has improved water-repellent properties. Adhesive for tiles Eunice pool is used for "damp" rooms, as well as tanks, which will subsequently be filled with water - swimming pools, jacuzzis, etc. The mortar can be used to treat various types of bases:

- Cement screed;

- Concrete floor;

- Plasterboard coatings;

- Brickwork;

- Complex surfaces (old tiles).

Due to its good physical and mechanical properties, the material is suitable not only for interior surface finishing, but also for facing facades outside structures. The main properties of the Pool glue include:

- Ability to withstand high humidity - more than 85%;

- Resistance to temperature extremes of 100 degrees or more;

- Low material consumption - no more than 3.5 kg per m2 of surface;

- Fast drying time of the solution - 24 hours.

General characteristics of the Ceresit line

Ceresit adhesive has the following distinctive characteristics:

- Waterproof. "Ceresit" does not allow moisture to pass through and therefore it is used for gluing tiles in the bathroom.

- Resistant to frost.Resistance to low temperature indicators allows the use of such glue not only indoors, but also outside.

- Possibility to apply to deformed coatings. The adhesive does not need to be used on a perfectly smooth surface.

- Durability. Since Ceresit is made on a cement basis, it does not deteriorate for decades.

Main types

The most versatile is the Unis Plus glue. It is suitable for both indoor and outdoor use, and has proven itself excellently when facing uneven surfaces. Retains its properties for 3 hours from the moment of dilution. It is not recommended to use glue for surfaces exposed to high temperatures (stoves, fireplaces) or constantly in contact with water (swimming pools).

Unis Hi Tech glue is made according to the latest technologies, due to which it can be used for facing ceilings, within 5 hours the solution is used without losing its qualities.

When facing work is carried out using natural stone or heavy granite tiles, special tile adhesive "Yunis Granite" will do. It is distinguished by higher strength characteristics, which makes it possible to use the composition for facing surfaces experiencing serious operational loads.

In rooms with high humidity (in saunas, swimming pools, bathrooms), where a particularly strong and reliable fastening of tiles is required, it is recommended to use Unis Pool tile adhesive.

Complex design solutions in the form of facing embossed and shell surfaces can be solved with the help of Eunice Belfast glue. Works on laying marble, transparent, mosaic tiles are performed with it just perfectly.

Unis plus tile adhesive

Work should be carried out in dry conditions, at an air temperature of +5 to + 30 ° C and a relative humidity of no more than 75%.

Surface preparation

The base must be flat, strong, dry and load-bearing. Before applying the material, it is necessary to remove from the surface crumbling elements, paint coatings, oil and bitumen stains and other contaminants that impede the adhesion of the material to the surface.

The base must be aligned horizontally (vertically) with deviations of no more than 1mm per 1m of length.

For leveling cracks, cavities and other small defects with a depth of more than 10 mm, it is recommended to use plasters of the "Silin", "Teplon" or "Standard" series, depending on the surface or operating conditions. For cladding damp and basements, it is recommended to use the “HYDROPLAST” coating waterproofing layer as a preparatory layer.

To increase the adhesion strength, it is recommended to treat the surface with UNIS primer in one or two layers; uneven and highly absorbent substrates (gas silicate, foam concrete, etc.) in several layers. The choice of UNIS soil is carried out in accordance with the type of substrate.

It is not necessary to wet the base or tile with water before.

Preparation of the solution

Use only clean containers and tools for cooking.

The dry mixture must be poured into a prepared container with clean water in a proportion of 0.18-0.22 l per 1 kg of dry mixture and mixed until a homogeneous mass is obtained for 3-5 minutes. Let the solution stand for 3-5 minutes and mix again. Mixing is carried out manually or mechanically (with a professional mixer or a drill with a nozzle at low speed). Manual mixing is allowed when the mass of the mixture to be mixed is not more than 1 kg. The prepared portion of the solution should be consumed within 180 minutes.

Attention!

When preparing the solution, it is necessary to observe the recommended ratio "dry mixture-water". Adding any components to a dry mixture or a mixed solution, including excess water, leads to a change in the material properties declared by the manufacturer.

Material application

On a prepared, primed base or work surface, using a trowel or a spatula, apply the prepared adhesive solution 3-15 mm thick and leveled with a notched trowel.

For large-format ceramic tiles, a trowel with at least 8mm notches is used. The weight of large tiles must not exceed the permissible value. The tiles are laid on the layer of glue and pressed. The inner surface of the tile must adhere tightly to the adhesive solution.

When applying the adhesive to the substrate, the mortar mixture should be applied to an area that can be tiled within 20 minutes.

Adjustment of the position and cleaning of the tile surface from excess glue must be carried out within 10 minutes after laying.

Subsequent grouting of wall and floor tiles with colored grout "UNIS COLOR" may be carried out 24 hours after facing.

Operation of the "Warm floor" system is possible no earlier than 28 days after the application of the material.

Recommendations

In addition to the information on the packaging on how to use the material when working with it, you should be guided by the instructions for conducting general construction work and safety in construction.

If you have any doubts about the possibility of using this material, you should contact the manufacturer for advice.

Specifications

These parameters are quite impressive. So, the composition can be operated in a wide range of temperatures: from minus fifty to plus seventy degrees. At the same time, frost resistance is more than thirty-five cycles.

The weight of the tiles held by the composition is one hundred kilograms per square meter of area.

From the point of view of the convenience of working with the mixture, all indicators are also normal. So, the solution is viable for three hours. However, the tiles should be laid in twenty minutes, and its position should be adjusted in ten. Within a day, you can walk on the products.

The glue is packed in 25 kg bags. For such an amount, about 4.5-6.5 liters of liquid are needed.

It should be noted that all the characteristics presented and further information are not only provided by the manufacturer, but are also based on feedback from those users who have had experience with such glue.

Consumers about Unis products

In order to objectively assess the advantages and disadvantages of Eunice dry mixes, we collected feedback from consumers who used glue from a domestic manufacturer:

- I used Eunice Pool glue to decorate the walls in the bathroom. I laid the tiles on the old tiles and was satisfied with the result. So far, all the tiles are in place, not a single one has broken out;

- I was not satisfied with the quality of our glue. Just yesterday I was almost nailed by a tile that fell off the wall. True, friends who used the same glue claim that I could run into a fake. I don’t know if this is true or not, but I’ll hardly risk using Unis glue again;

- I have been working as a builder for more than 10 years and during this time I have become convinced of the quality of cement-based adhesives. Among the entire Unis product line, I think the best option is Unis Plus.

Features and scope

The basic components of Eunice adhesives are almost the same. They contain cement, mineral filler and modifying components. Simple or quartz sand, dolomite or gypsum is used as a filler. Special additives give the mixture certain properties, for example, enhance adhesion, make it more plastic, frost-resistant, waterproof, etc.

All Yunis mixtures are certified in accordance with the norms and legislation of the Russian Federation. Suitable for use in preschool institutions, food factories, medical institutions.

The formulations show good adhesion to the following materials:

- gypsum;

- concrete, including cellular concrete;

- cement strainer;

- asphalt;

- brickwork;

- drywall products;

- slag and aerated concrete.

Eunice manufactures exterior and interior decoration products. The Unis series includes mixtures for underfloor heating, foundations with a complex structure, surfaces constantly in contact with water, as well as separately for glass mosaics, kerogranite, blocks, natural or artificial stone.

Eunice tile mix is used in dry and damp environments. Some types of adhesives can be used to level surfaces with slight imperfections and differences in height. The use of moisture-resistant Eunice compounds is possible even in places of direct contact with water (baths, saunas, swimming pools, toilets).

How to do?

You need to apply the glue with a spatula or trowel. On the surface, using a notched trowel, apply a mixture with a thickness of 0.3 to 1.5 cm.

The tile is placed on glue and pressed. In this case, the contact between its back surface and the Eunice solution should be maximized.

The mortar is applied to an area that can be tiled in twenty minutes. And within the next ten minutes, you can change the position of the tile, as needed.

Grouting can be done in a day. If a "warm floor" is created with the help of the Unis Plus mixture, it can only be used after twenty-eight hours.

Advantages and disadvantages

The key advantages of Eunice compounds will be good adhesion properties and fairly high strength. The adhesive gives a reliable adhesion to almost any substrate on which tiles are laid. It retains its characteristics at low and high temperatures. However, there are limitations - from -5 to +30 degrees.

The compositions from Eunice are environmentally friendly, which is confirmed by the relevant certificates. The adhesive can be used in medical institutions, schools, kindergartens

The advantage will be the ease of application of the glue, and, importantly, it has a low consumption. It is equal to 2-3.5 kg per square meter

Disadvantages should be considered for each individual composition, because a series of products from Eunice has unique technical characteristics and application features.

A Few Tips

- Do not mix too much glue at once. If you do not have sufficient experience or small tiles, mix no more than 5–7 kg once. dry mix;

- When mixing the glue by hand, do not dilute more than 2 kg., A larger volume will not allow you to mix all the components evenly;

- To increase the flexibility of the interlocking seam, use additionally Eunice elasticizers;

- When facing horizontal surfaces, start from the second row from the bottom;

- When the dry mixture comes into contact with water, an alkaline reaction takes place. Do not let the solution come into contact with exposed skin.

We recommend watching a video review:

Advantages and disadvantages

The main advantages of the Eunice glue mixture:

- High level of elasticity, suitable for fixing on a movable base (eg wood). Fills in all irregularities.

- Good adhesion, provides strong and reliable adhesion to the substrate. Allows you to stack it from bottom to top and prevents it from slipping.

- Wide range of applications. Suitable for interior and exterior use.

- High temperature resistance allows the use of an adhesive mixture for heated floors. It does not heat up from high temperatures, the fixation does not get worse.

- Dries quickly.

However, it has a number of disadvantages. Drying speed can also be attributed to them - it will have to be diluted in small portions, which takes a lot of time. If this is not done, he will lose most of his properties, and the master will waste the money.

Maybe you will also be interested to see - Ceresit tile adhesive: varieties and features