4 Desmokol

A shoe glue that is praised for its quality and durability. The composition is based on polyurethane resins. Thanks to this, it quickly connects the surfaces of various materials and holds them firmly for a long period of time. Even the hard parts of the shoe are subject to Desmokol. It is often used to seal the tops of boots or the soles. Also, the product is suitable for plastic, metal or glass. It is water-repellent and flexible.

Before use, it is necessary to prepare the product for application. It is recommended to clean shoes from dirt, remove the remnants of old dried glue and degrease the desired part of the surface.

It is very important to apply the product in a thin layer and wait about 10 minutes until it dries. If necessary, repeat the procedure until a film is formed.

The glue does not require additional compression enough to hold the desired parts firmly together. Customers are satisfied with the purchase and readily recommend this glue. The disadvantages include only an unpleasant smell.

Advantages of aerosol glue

Aerosol adhesive has several distinct advantages over other adhesives. Firstly, it is easy to work with it, you do not need brushes, spatulas, tampons and other materials at hand. Secondly, due to fast drying and good adhesion, there is no need for long-term fixation of materials when gluing. Thirdly, the composition does not dry out in a sealed aerosol can, which means it can be stored for a long time.

In addition, it does not leave stains or marks; you can adjust the width of the jet, and hence the economy of use; has high strength and heat resistance, resistance to vinyl plasticizers, does not destroy the acrylic coating.

Aerosol adhesive can fix objects to window panes when exposed to sunlight. During the gluing process, the surfaces can be moved within a few minutes, for example, to level the joint.

Useful Tips

Several recommendations that will allow you to properly handle Desmokol:

- The glue in granules must be diluted with a solvent. It is best to use acetone. For this purpose, 1 part of the granules is mixed with 10 parts of acetone. Usually, 200 milliliters of solvent is taken for 20 grams of glue. The resulting mixture is kept for 7 to 8 hours. For the process to be carried out faster, the room temperature should be maintained within 25 - 30 degrees above zero. The result is a colorless solution. The composition is thoroughly mixed until a homogeneous mass is obtained.

- An additive called "Desmodur" improves the quality of the glue. It is added to Desmokol from the following calculation: for 1 part of glue, 15 - 20 parts of an additive. As a result, the thermal stability of the adhesive and the strength of the joint formed by it are improved.

How to use?

Instructions for the use of "Nairit" glue will help in the process of using the product. This process is quite simple, so it can be done easily at home. The main thing is to take a responsible approach to implementation.

You can glue shoes with this glue in two ways: hot or cold. Both of them will provide a strong connection between the elements of the product. Their reliability indicator is almost the same. The main difference is the way the glue is used.

Bonding shoes

The cold bonding method involves the following procedures. First you need to prepare your shoes: remove dirt, dust, wipe dry with a napkin. After that, the surface that is glued must be degreased. If this is not done, then there is a risk of poor adhesion of the materials. The next step is to apply a small layer of glue. Then it is left for a while.Ten minutes will be enough. Then you should reapply the second layer of the product. The drying period of the product takes at least a day.

The last stage is one of the most important. The strength and reliability of the connection depends on the quality of its implementation. Therefore, it is better not to rush and dry the product well. Moreover, there is no need to put heavy objects on it. This glue will cope with its work without their help.

The hot method is a little more difficult, as it requires additional equipment - a liquid fuel burner. Before starting to glue, it is necessary to prepare and degrease the working surface. To make the glue easier to use, you can dilute it with a solvent.

Now it is applied to the product in a small layer and left for fifteen minutes. Then a second layer is applied and left for half an hour. After this time has elapsed, the product is held over a heating pad. When the glue reaches 80 degrees, you can attach to the other part and press them together tightly. Drying in this case is not so long. Only six hours are enough, and the product can be used for its intended purpose.

Shoe repair

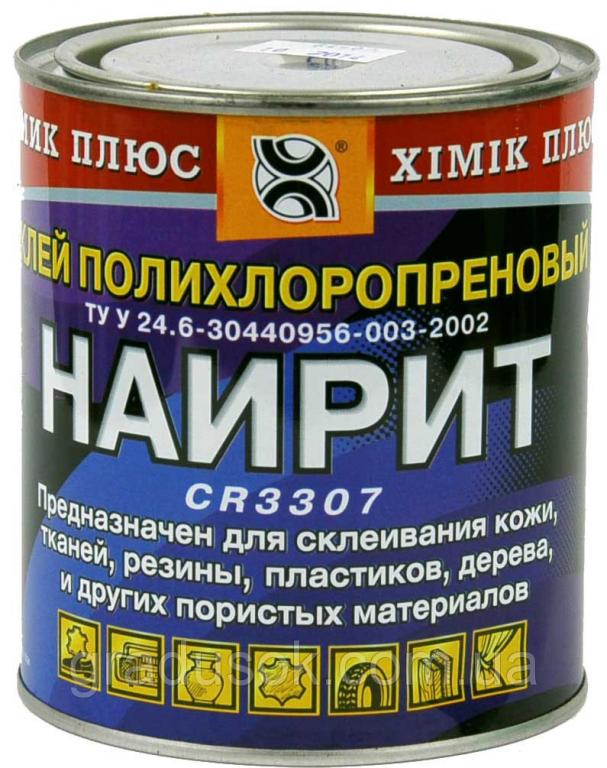

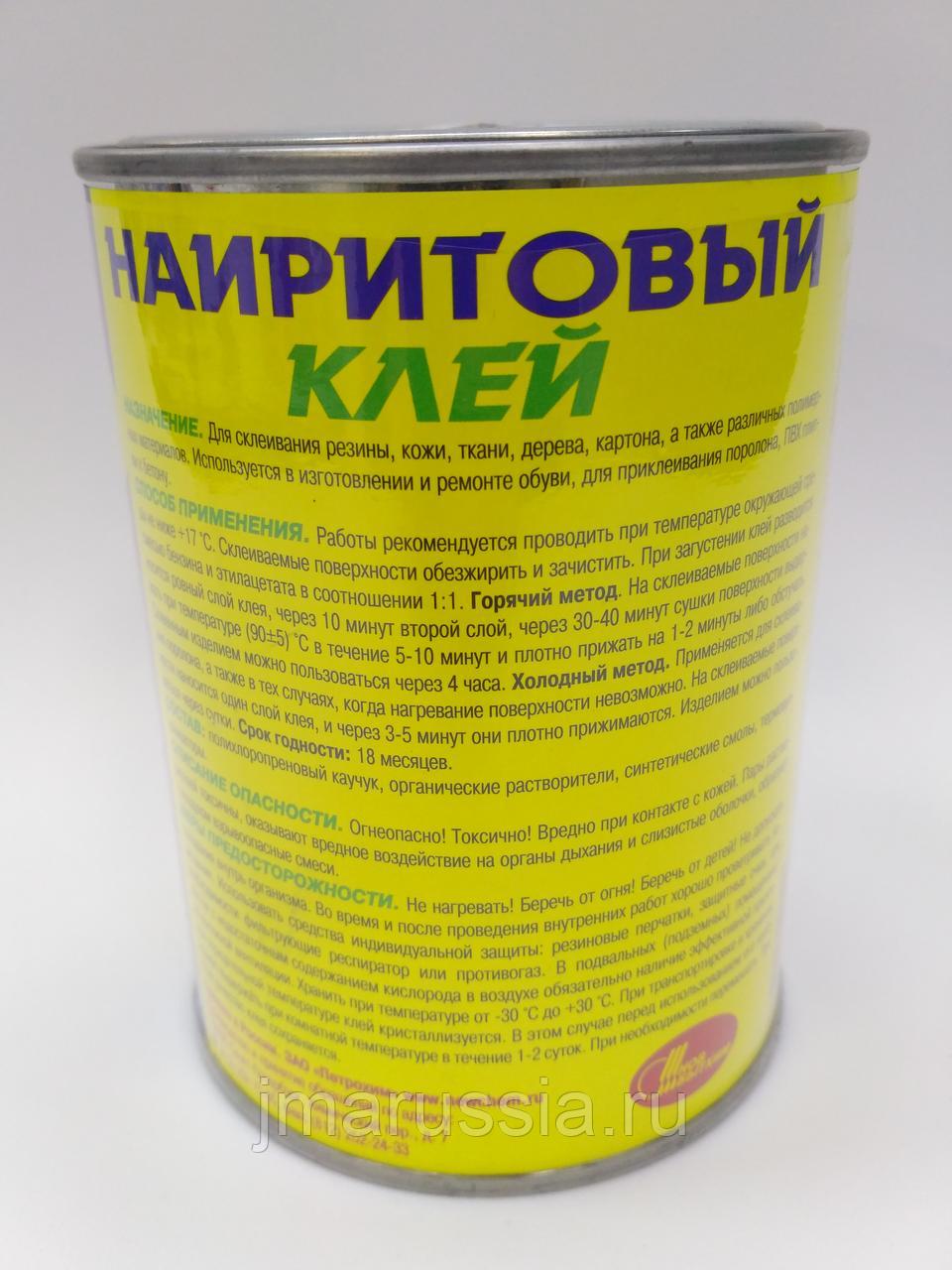

This glue is offered by many manufacturers. An excellent option for gluing shoes is Nairit CR-3307 glue, which is shown in the photo below.

It provides a highly durable flexible connection of materials, which is very important for such products.

Instructions for use

Working with Nairite is not difficult. It can be used in two ways: hot and cold.

Both methods lead to fairly stable and reliable performance and are not very different from each other. The instructions for use are as follows:

Cold gluing method

- prepare the product for use, wipe it with a dry cloth, remove particles of dirt, dust, and other unwanted elements (locks, zippers) that can only interfere with the gluing process;

- degrease the areas to be glued with a special compound to enhance adhesion;

- apply the first layer of shoe glue;

- leave to harden for 10-15 minutes;

- walk through the gluing places again, applying a second layer of glue;

- leave to dry for about 24 hours.

Learn more in the video:

The cold method does not require any additional equipment during carrying out and the adhesion properties of the glue will be much higher if it is allowed to dry properly. In addition, there is no need to put a sofa leg or a weight on top of the shoes for better adhesion of the materials to be glued to each other. Nairit glue will perfectly cope with its task without any special tools.

Hot way

The hot method is no less effective, but requires a liquid fuel burner on hand:

- clean all bonded elements from dust and dirt particles;

-

degrease the areas to be glued;

- in case of excessive viscosity, the glue can be diluted with gasoline, acetone or another solvent. For better adhesion, it is advisable to use sandpaper;

- apply the first layer, keeping for 10 minutes;

- apply a second thin layer of glue and leave for 0.5 hour;

- heat the surface above the burner to t 85-92 g, tightly pressing the materials to be glued to each other;

- leave the shoes to dry and secure bonding for at least 6 hours.

The maximum strength factor when gluing materials will be reached within 40 minutes after the cold method, and the shoes are wearable in about a day. If you use the hot method, you can put on and wear shoes after 4-5 hours.

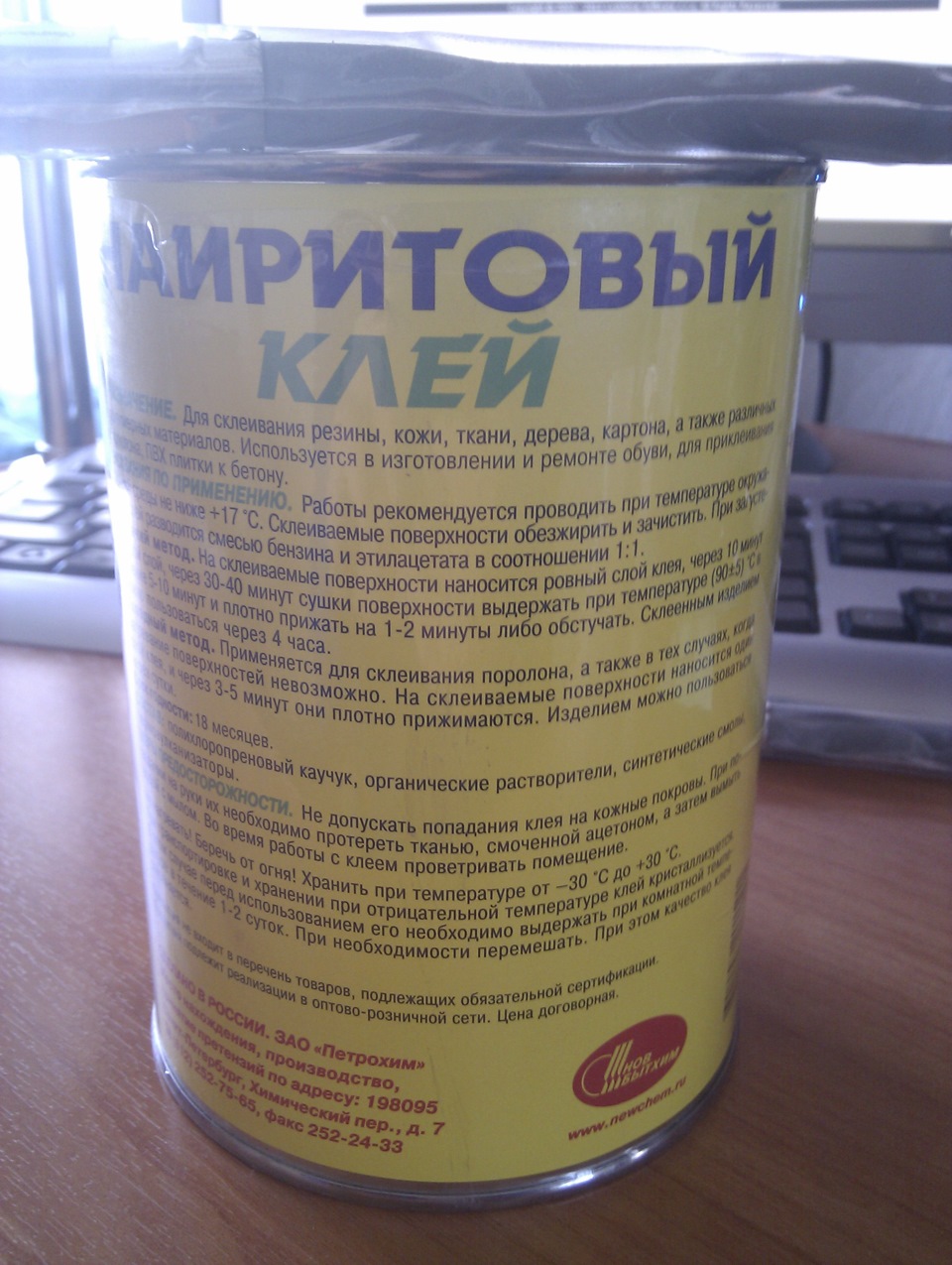

Storage rules

You need to store the mixture in the original container, it is very important not to damage it. Warranty period - no more than 1 year at temperatures from +6 to +22 degrees away from open fire

Shoe glue nairite can thicken even if all the rules are followed, but this is not scary. It can be dissolved with ethyl acetate and high octane gasoline.The composition is prepared simply, you need to mix glue and solvents in equal proportions. The main thing is to gradually pour them into the glue mixture and stir thoroughly.

When applying, it is important not to forget that the mixture is flammable. Work must be carried out away from open fire, smoking near an open can of liquid is prohibited

Nairite glue contains only low-toxic substances, but it is necessary to work with it only in buildings that are well ventilated.

If the glue is transported at a low temperature, then the viscosity index increases. However, this can be fixed by leaving it in a warm building for several hours. After which its qualities are restored.

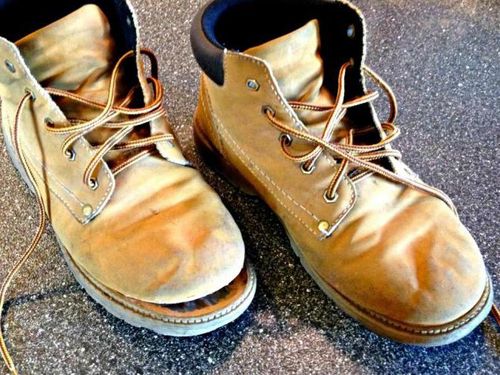

Shoe glue

Of course, it is better to give preference to more expensive products. Since their manufacturer provides a warranty period for their product. As a result, it is more wear-resistant and durable. But this is not always the case. Quite often, expensive, high-quality shoes deteriorate. For example, it breaks. The reason for this can be both a factory defect and a negligent attitude towards the product. As a result, it becomes unusable. But you should not be upset, you can restore its previous appearance. To do this, it is enough to repair the shoes.

Nairite glue

You can repair the product with your own hands, but this is provided that the damage is not significant. A shoemaker will better handle difficult cases. He has the necessary tools and materials for this, the cost of which is high and sometimes it just makes no sense for an ordinary person to buy them. Since many materials have a limited shelf life. After its expiration, it loses its properties and is unlikely to help solve the problem.

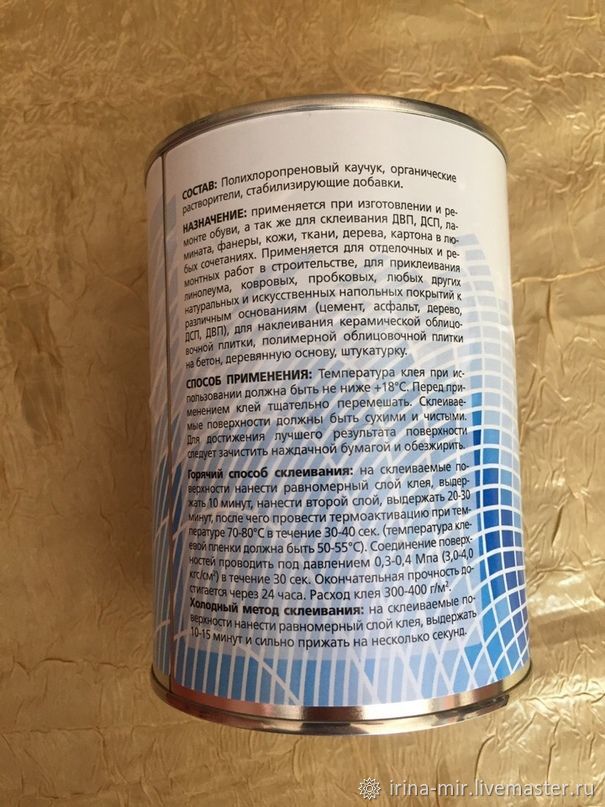

Main characteristics and scopes

The main component of nairite glue is chloroprene rubber (nitrite). This synthetic material is an elastic, light yellow translucent resin.

Nyrite is widely used in the production of industrial rubber goods. The material has excellent adhesion (ability to stick), good resistance to abrasion and weathering.

Due to its characteristics, the glue based on synthetic rubber has found wide application in the shoe industry. Nairite glue for shoe repair provides a reliable connection, has water-repellent properties, and reliably seals the joint.

This type of glue is suitable for bonding rubber, leather and leatherette, fabric, wood, metal and PVC in any combination.

Brand overview - choosing a shoe maker

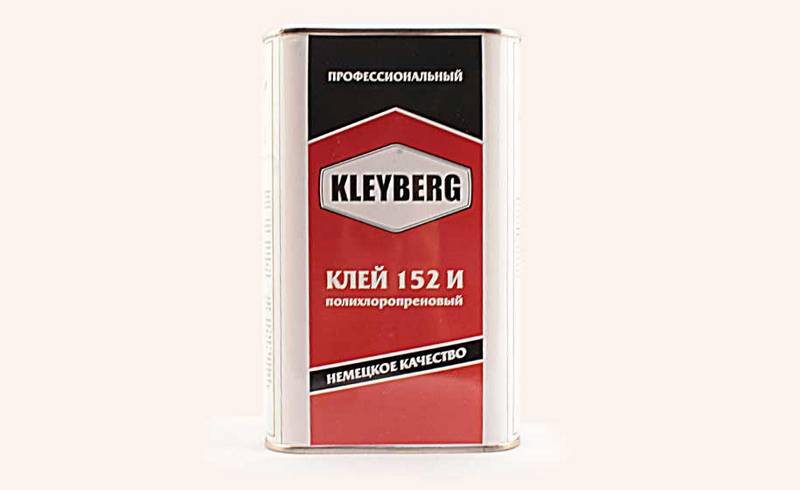

Professional shoemakers trust only proven brands of glue, and a special place in this list is occupied by adhesives based on chloroprene rubber resin.

The most popular among shoe makers are:

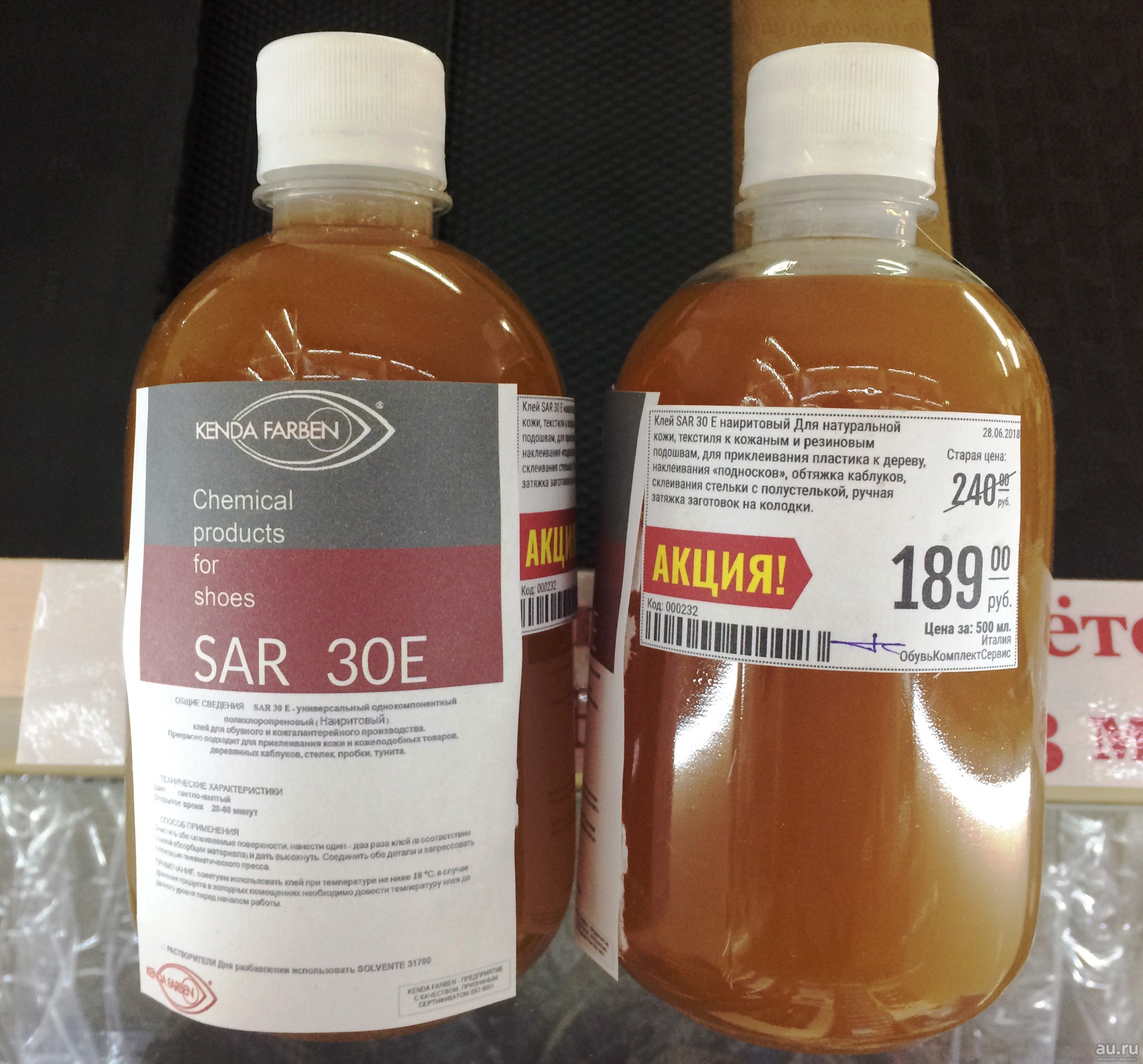

Nairite glue Sar 30E (Italy). Designed for reliable bonding of the upper part of shoes made of genuine leather (leatherette) and fabrics with rubber and other soles. Perfect for covering heels with leather, gluing insoles. When working in a hot way (with heating the adhesive to a temperature of 85-90 degrees), you can wear shoes after 4-6 hours. When using the cold method - in a day.

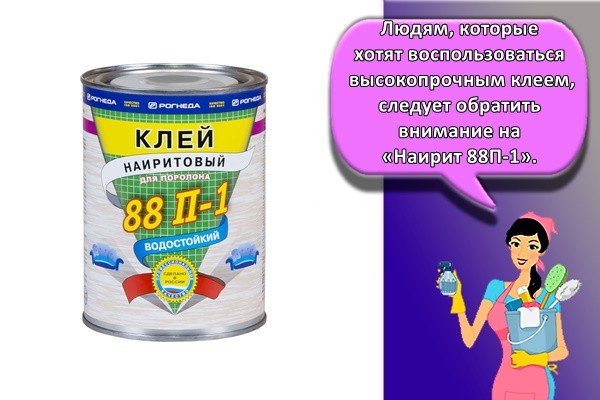

Glue 88 P-1 (Nairit-1) is a waterproof boot glue based on polychloroprene rubber. Forms a high-strength flexible seam. Convenient to use, as the applied adhesive layer retains a high adhesive capacity for a long time. The strength of the adhesive joint when using the cold method is achieved within 30-40 minutes, however, you can wear shoes only after a day. When working in a hot way - after 3-4 hours.

Shoe glue nairite Anles (Russia). One component, water resistant. Suitable for repairing shoes made of natural and artificial leather. In any combination, it glues rubber, leather, leatherette, micropore, leather fiber, textiles.For maximum bond strength and reliability, it is recommended to use the hot glue method. Shoes glued with Anles shoe glue can be used in the temperature range from -40 to +70 degrees.

Nairite glue Rapid-5 (Russia). Made on the basis of a rubber compound with chloroprene rubber resin. Designed for gluing leather, rubber, plastic in the manufacture and restoration of footwear.

VIDEO REVIEW

How to use nairite glue for shoe repair

One-component shoe glue is very easy to use. Bonding can be done cold and hot. Below is a step-by-step instruction on the example of gluing the sole.

In both cases, before gluing, it is necessary to thoroughly clean the surfaces from dust and dirt, dry, degrease and sand with sandpaper for better adhesion.

Bonding is recommended in a warm room with good ventilation at a temperature of at least 15 degrees.

Hot glue method:

- An even thin layer of glue is applied to the previously prepared glued surfaces.

- After 10 minutes, a second coat is applied.

- After half an hour drying, both surfaces are heated to 80-90 degrees for five minutes.

- The parts to be glued are connected and pressed firmly.

Shoes can be used after 3-6 hours (depending on the recommendations of the adhesive manufacturer).

Cold bonding:

- The adhesive is applied in a thin layer to clean and dry bonded surfaces.

- After 3 minutes, they are tightly squeezed for three to four minutes and placed under any press.

- It is recommended to use the product only after a day.

How to dilute nairite glue and how to store it

In case of strong thickening of an adhesive based on synthetic polychloroprene rubber as a result of evaporation of solvents, to restore the working consistency, it can be diluted with a mixture of ethyl acetate and gasoline, taken in equal proportions. The same mixture is used to clean the instrument.

Store nairite glue in a tightly closed container at temperatures from +5 to +40 degrees.

Advantages and disadvantages

Nairite glue is a versatile and very high quality product, this is its main advantage. The composition contains only low-toxic substances, and you can use glued products without fear. Other advantages:

- high temperature resistance;

- elasticity, flexibility, plasticity even when the temperature drops;

- reliability of the connection due to deep penetration into materials;

- resistance to water, salts, acids;

- the ability to operate at low temperatures;

- preservation of properties at temperature extremes.

The material is easy to use and easy to use. The downside is the drying time - it is slightly higher than that of a number of analogues. But this allows you to calmly place the glued parts and have time to fix flaws. The product can be left unheated before application and gluing - a “cold method” of application is possible. After drying, it does not deform even the thinnest leather, so it can be used on expensive shoes.

Application of glue

The glue is used both by professional factories and ateliers and by private shoe repair shops. Its price is available for enterprises with any capital. The cost recovery is immediate, which is why it is so widespread. The simplicity of working with the substance also played a role. To repair shoes with it, you do not need to study to be a professional shoemaker. It is enough to follow the manufacturer's recommendations, and no problems will arise.

Since the substance is used to make products that are directly used by a person, it does not include toxic and harmful elements. Shoe nairite glue is made from polychloroprene rubber resin, synthetic additives, organic non-volatile solvents and thermal vulcanizers.There is nothing superfluous among the components, each element plays a clearly assigned function. And in close interaction, they provide the glue with the properties necessary for work.

Since the manufactured and repaired products will be in direct contact with the environment, the glue is water-repellent. It not only completely seals the treated area, but literally pushes water outward, preventing it from absorbing. This keeps your feet dry in any weather. Therefore, many shoemakers, after stitching shoes, additionally process the seam with glue in order to protect the product from the influence of moisture. Some even use the substance to repair rubber boats, diving suits, and car cameras.

It is very easy to work with the mixture. There are two main ways to use it: hot and cold. The choice of a specific method depends only on the conditions of the repair and the wishes of the master. In terms of reliability, they do not differ from each other by a significant amount, so that one can say that one method is certainly better than the other. The use of cold is easier, since it does not require the use of additional tools. But if you want to get them is not a problem. A conventional oil-fired burner will do just fine.

6 DoneDeal

An adhesive that is suitable for almost all materials. It can be used to glue air mattresses, boats, camping equipment, shoes, sports equipment and more. It connects things of different origins - rubber with metal, plastic with wood, glass with leather. The tool perfectly tolerates temperature extremes and keeps reliably at low and high rates - from -45 to +105 degrees. The sealant is the best way to bond the sole or upper part of the boots. A strong connection will allow you to wear shoes for more than one season.

Apply glue to both surfaces. Then he quickly and reliably "grabs". A thin layer is a prerequisite. Within 24 hours, the consistency completely hardens and dries up. Heating the glue to a temperature of 70-80 degrees will help speed up the process. Customer reviews are mostly positive. Note the comfortable tube and easy use. In the column of deficiencies, you can find comments about a pungent odor.

Nairite shoe glue: where is it used?

Before talking about shoe repair, let's figure out what materials are used in its production. Since they will be needed in the repair. Shoes are pieces of material that are joined together. Moreover, it must be strong and reliable. This will significantly extend the life of the product. It will be wearable and durable during use.

As practice shows, it is not enough to sew shoes. Better to use connecting materials. The best option is nairite shoe glue. It will reliably and firmly connect different materials. Moreover, it is good to use it with the stitching of the product and apply it to the seams. Such shoes will have double protection that can withstand various factors that negatively affect them.

Nairite glue for shoes: features of the mixture

Nairitan glue is widely used in the manufacture of footwear. This is a fairly expensive mixture. But it pays off quickly. Therefore, it is beneficial to use it.

In addition, this type of glue is very easy to use. Therefore, it is often used at home in order to glue shoes. Thus, there is no need to seek the help of a specialist. Spend money and time on it. The main thing is to follow the instructions for its use, which is indicated by the manufacturer on the packaging.

Nairitan glue is a safe material. Since it is designed for human use. The glue does not contain various toxic elements, therefore it is completely harmless. Thanks to this, it can also be used to repair children's shoes.

Nairitan glue contains polychloroprene resin from rubber, synthetic additives, etc. Each of these is responsible for the fulfillment of their task. And in combination, they endow the mixture with a number of properties that are important when gluing materials.

Another important feature of the glue is its resistance to moisture. It is not absorbed and repels. This way, the feet always remain dry, even in rainy weather. Due to this ability, the glue can also be used as an additional treatment for seams.

Instructions for nairite glue

It is quite easy to work with this glue. To do this, you can use two different methods, which are called cold and hot. The degree of their reliability is quite high. There are no significant differences for this indicator. Therefore, when choosing a method of using glue, you can be guided by your personal desires, and, of course, by working conditions.

The main difference is the use of additional tools. They are not needed for the cold method. But for hot they are necessary. They provide strong and reliable adhesion. For these purposes, even the simplest oil burner can be used.

Nairite glue for leather: hot and cold application

This method includes a number of sequential works. The first is to prepare the product for use. To do this, it is necessary to remove dust, dirt and other undesirable elements from it, which will impede or worsen the bonding process. After that, it is degreased with an appropriate product.

The next stage involves applying glue, but this must be done according to a certain scheme. So, first layer first. It is left to freeze for ten minutes, then a second. Now the hardening period is half an hour. It should be noted that the room temperature should be no higher than 17 degrees.

When drying is complete, the surface must be heated to a certain temperature level. It is 85-92 degrees. Then the materials are pressed tightly. It is better to use closed fire sources for heating. Otherwise, damage to its elements is inevitable.

After the work is finished. Leave the shoes on for 5-6 hours. During this time, the product will stick together firmly and reliably. Then it will be usable.

The cold method is much easier and faster. Since it is enough to apply the mixture on the surfaces and connect them. Then leave for a while, during which the product will stick well.

Many manufacturers now offer similar blend options. But, as practice shows, the best glue is nairite Sar. It allows you to firmly and reliably glue any surface.

3 Nairit 1 (88-P1)

One of the best adhesives for shoes is Nairit. Numerous customer reviews tell about its effectiveness. Thanks to a wide range of glued materials, Nairit can be used in various household areas. The adhesion strength depends on the technology of work and the specifics of the material.

In the course of work, Nairit forms a waterproof, elastic seam of high strength. If you need to process a large area, Nairit glue is an irreplaceable assistant, since the layer applied by it remains sticky for a long time. The substance is safe to use. It does not contain any narcotic solvents such as toluene. Most materials in any combination can be processed with glue. It can be leather, rubber, fabric, wood and much more. Bonding methods are hot and cold. With the first option, the product can be used after 4 hours, with the second - in a day.

How to glue correctly

When working with aerosol glue, you need to follow a few simple rules that will ensure reliable fixation of materials.

First you need to clean, dry and degrease the bonding surfaces.Then, if the can was stored in a cold place, warm it up to room temperature or, if necessary, cool to it. Shake thoroughly and vigorously just before use, adjust the spray width by turning the spray head and apply the glue to the bonded surface.

The width of the jet and the thickness of the layer depend on the nature of the material. The more porous and heavier it is, the wider the layer is naturally applied; moreover, it may be necessary to apply a second layer after drying for several minutes, and on both surfaces.

Aerosol adhesive is sprayed from a distance of 15-20 centimeters from the surface. The can should be held parallel to the surface, while pressing the spray gun to the end, apply the composition evenly, slowly and without stopping.

It will take about half an hour to completely dry the glue.

So that it does not freeze in the bell, after using the cylinder, you need to turn it over, press the spray gun and hold it in this position until the remainder comes out.

Store the glue in a dry, dark place at a temperature of 5 to 30 ° C.