Types of potals and application technology

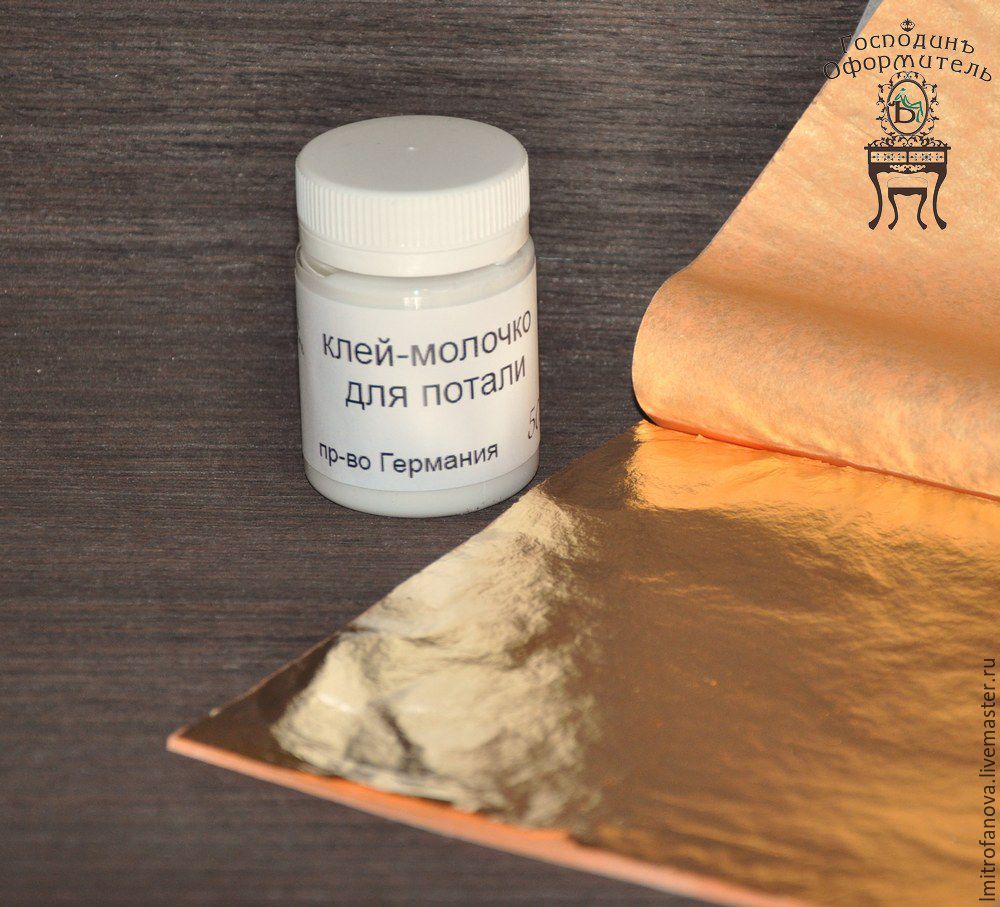

Full-fledged work with gold leaf is impossible if you do not understand its types. A certain category is suitable for a specific job. If a needlewoman needs to decorate the product, one type of gold leaf will be required. For one-time use or large-scale production, another will be required. The type of material is also determined based on the texture to be decorated.

Liquid

Possesses a bright metallic shine, consists of pigments, varnishes, solvents. It is chrome-plated paint. Used for glass, wood, metal surfaces, plaster, ceramics. Liquid potal has high moisture resistance, durability, does not oxidize. It resembles sour cream in consistency, not too liquid and not too thick.

Before working with gold leaf, the product is well cleaned, degreased with alcohol. Apply the liquid material with a foam sponge or flat brush. First you need to paint over the first layer. Leave it on for a few hours to dry completely and paint over the second coat. Depending on the product and material, gold paint can dry for about a day. Liquid gold leaf is applied in several layers.

Today you can buy a special airbrush. It is a spray gun for liquid pot that helps to apply paint accurately and evenly. Application with an airbrush has a significant advantage - the leaf dries quickly, about 2-3 hours. Ideal for needlewomen and craftsmen.

Roll

It is used when it is necessary to apply gold paint on a large product and even. Sold in a roll 1-15 cm wide, about 50 meters long. Made on papyrus paper under pressure. The joints are glued to her, the seams are covered.

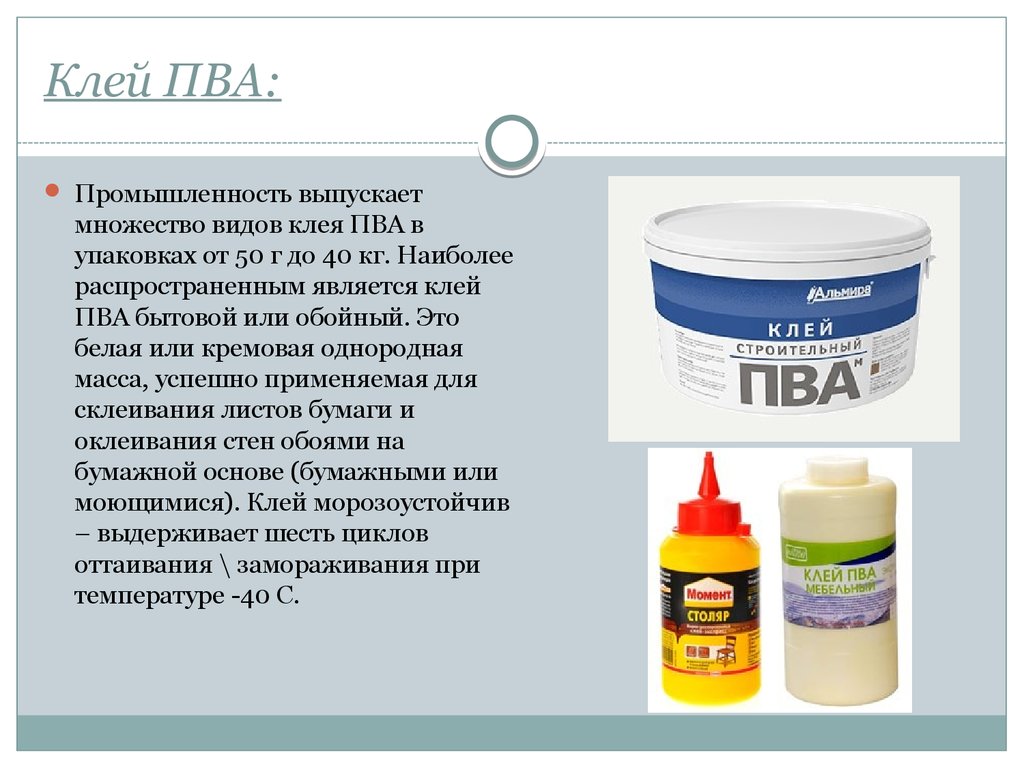

To apply a roll look, you will need a special glue for the gilding. First, glue is applied in a thin layer and after a roll of material, after that, a layer of glue must be reapplied on top. A specialized transparent glue on a different basis is used for the leaf.

Sheet

Sheet material is used much more often than other types. It is great for handicrafts, craftsmen, it allows you to make gold plating on any product: plaster, wood, glass, metal, ceramics, cardboard. In this case, gilding with gold leaf is carried out by analogy with a roll view. First, the glue is applied in a thin layer, after the material itself, the surface layer of the glue.

Leaf gold is necessary when you need to cover a large surface. Materials are sold in the form of thin plates, fastened in a thick book. One such book contains about 15 or more pages. The diameter of the plates is 16 or 15 cm and has a bronze, gold or silver color.

Leaf gold

Leaf gold

Gilding with sheet gold leaf is carried out only after thorough cleaning of the surface. It should be smooth and clean, and free from fat. You can apply a primer before using the gilding. For the sheet type, oil or water glue is used, as a rule. In the first case, you will have to wait for it to dry for about 12 hours and then apply the leaf of potal. In the second case, the material can be applied immediately after the glue.

To remove air layers and irregularities, fabric is used after the veil is applied. It is applied on top and gently ironed all the roughness. Gilding with gold leaf will last for a long time if you cover the product with a special transparent varnish on top.

Chit

Craftsmen who make jewelry from epoxy resin like to use the leaf in the form of crumbs. It is sold in a free-flowing form, often has multifaceted shades, which is beautifully reflected in a decorative product. Often use this type to decorate an uneven object with bends.

If the glue is water-based, the crumb is applied directly to the surface.The difference between the crumb is that it is poured onto the product. In order for the potal to take root better, a layer of varnish must be applied on top.

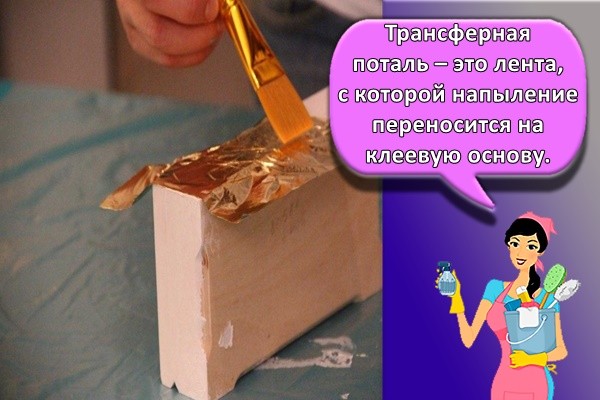

Transfer

This type is considered reusable, since the gold paint is applied in several layers to tracing paper, paper or parchment. A thin sheet is applied to the product until all the leaf is used up. Practical and easy to use. Often used by craftsmen and needlewomen. The work process is as follows:

- the product is degreased and cleaned;

- gold, bronze or silver paint is applied to the cleaned layer (it is not necessary to cover it with paint);

- after the paint has dried, glue for the glue is used;

- a sheet of gold leaf is applied on top;

- the film should be well smoothed and removed from the product.

Review of popular brands

When repairing friction linings, motorists most often prefer 3 adhesives.

"VS-10T"

The glue is made up of special resins and organic solvents. The parts to be glued are first removed to the side until completely dry, only then they are installed under the press. By its appearance "VS-10T" is a viscous homogeneous transparent liquid of beige or brown shade. This glue does not contain water, which makes it stable, even in case of direct contact with liquid. Also, the composition is resistant to most aggressive environments: sea water, alcohol-containing liquids, acetone.

The VS-10T glue is specially designed for reliable fixation of materials in units that operate at temperatures up to 300 ˚С. It can be used at low pressure. The adhesive is widely used for bonding brake linings with a metal backing. The composition guarantees high adhesion strength.

Poxipol

Two-component, high-strength, universal epoxy adhesive. Its main purpose is assembly and construction work, but the composition of "Poxipol" has proven itself well in gluing and repairing various mechanisms. After working with it, a seam forms on the surface. For this tool received a second name - "cold welding".

Glue is sold in a set of 2 tubes:

- in a tube marked "A" - resin;

- in the second, with the designation "B" - hardener.

The kit also includes instructions for use, a spatula, a plate. The resin has high flexibility, guarantees increased adhesion of parts. The acceptable temperature for gluing is + 18 ... + 23 ˚С.

The disadvantages of the adhesive include:

- Poxipol is not suitable for working with polypropylene, polyethylene, Teflon;

- high product cost;

- before applying the composition, it must first be prepared, and then used within 5-6 minutes.

Natural glue is sold only in specialized stores.

Epoxy resin "ED-20"

Epoxy-diane resin is a reliable universal viscous liquid of high quality without mechanical impurities. Under the influence of a hardener, at normal room temperature + 20˚C, it turns into an infusible polymer.

Technical characteristics of the composition:

- shows resistance to moisture, mechanical damage, alkaline, acidic environment;

- the prepared mixture is used within 30-60 minutes;

- when compared with acrylic resins, it is toxic;

- low elasticity - in the process of movement on the surface, which is covered with "ED-20", cracks may form;

- has anti-corrosion and dielectric properties;

- provides high durability under heavy loads.

In industry it is used in its pure form. Without additional components of the composition "ED-20" amber or orange color.

Review of the best manufacturers and brands

The choice of the manufacturer should be taken very seriously. Now the market for decoupage glue is not yet so wide, it is not subject to compulsory licensing. Therefore, there is a high probability of meeting a fake. Do not hesitate to ask for certificates confirming the quality and instructions for use.

Mod podge plaid

Mod Podge PLAID is a glue developed by an American manufacturer. It is used for outdoor work around the house. Best glues slate, wood, concrete and metal. It is not only an adhesive, but also acts as a sealant and adhesive for surface coating. He is one of the strongest rosters on the list. Suitable for decorating bulky items with large pieces of material. Its peculiarity is that it dries for at least 15 minutes, you need to hold it all this time to ensure better grip.

Decola

Decola is a versatile and effective glue created in Russia. It is designed to work with wood, glass or metal. The tool cannot be called completely devoid of flaws, sometimes there are reviews on the network that it cannot cope with heavy layers. But the minimum price, ease of use make it possible for novice needlewomen to use it.

La Doratura

La Doratura is an adhesive that can bond even heavy surfaces. It is intended for outdoor work, as well as decoupage. Copes with metal, wood parts.

Art potce

Art Potce is a popular tool often used by Russian needlewomen. It combines the advantages of conventional glue and varnish. Perfectly copes with surfaces of ceramics, metal, wood, cardboard and natural stone. They can also process the surface of products, as it leaves a bright shine. But the strong strength of the glue cannot be noted - products covered with it are better placed as a decoration at home, and not actively exploited.

Glitter art potch

Glitter art potch is a unique tool that not only holds parts of the product together, but also helps to decorate it. Leaves holographic particles like tiny sparkles.

Kerzen potch

Kerzen Potch is used for working with paper napkins and fabrics. But the main area of its use is wax products. Due to the fact that the wax particles contained in the composition do not melt the picture when burned in the wax. The composition reliably glues the parts together, does not peel off the surface of the candle or other material. It dries in 1-2 minutes without leaving an unpleasant odor, yellow spots or smudges.

Porcelain glue

Porcelain glue is used to decorate glass, ceramic and porcelain products. It is used to decorate dining room inventory, sets. The peculiarity of porcelain glue is that it must be dried in a special hot oven for at least 90 minutes. But then you can use plates, jugs, glasses without fear for your health, and it is also easy to wash them in the usual dishwasher mode.

"Mordan"

"Mordan" is an Italian-made glue. Its distinctive feature is its ability to work with water-repellent surfaces. Glass and ceramics are covered with gold leaf or gold leaf with its help. The cost of glue is quite high, but only it is used to decorate expensive surfaces (others can damage expensive materials).

Mod podge

Used for working with metal, concrete, wood and slate. Although it is intended for outdoor work, needlewomen around the world actively use it for decoupage. It is especially effective, it dries for 15 minutes.

How to make a DIY mixtion: two recipes

Craftsmen have been using their own secrets for many centuries to prepare Mordan glue. Previously, icon painters were engaged in this art, they found a way out in simple improvised means, creating masterpieces that are still revered by connoisseurs.

And today, simple glue potal with your own hands can be made from what is in the kitchen. Experienced craftsmen use egg whites, garlic juice, sugar syrup, starch, and other astringents. We suggest that you take note of two of the most durable and easy-to-prepare composition, recognized by most decorators.

Do-it-yourself starch glue

So, you need a glass of water, 70 g of granulated sugar, 1/3 cup of food starch and a tablespoon of white vinegar. To prepare in stages, follow these steps:

- heat 200 ml of water until warm, dissolve sugar in it and bring the syrup to a boil;

- pour vinegar into the mixture and mix the workpiece thoroughly.

- the liquid must be kept on fire for no more than half a minute;

- add starch to the syrup, stirring the emulsion constantly;

- when the resulting mixtion cools, then in consistency it should resemble sour cream.

The advantages of this composition are that it becomes completely transparent and invisible, polymerizing. At the same time, a homemade starch mixtion firmly fixes the foil on the surface of the products.

Creamy mordan for potal

So, a mixtion for gilding can be prepared using milk cream. To create glue, you need to take 100 ml of brandy and the same amount of heavy cream.

Initially, the components are thoroughly mixed and applied to the surface prepared for gilding. The composition is allowed to dry for 30-60 minutes. After this time, it is time to start processing the product with a shiny film.

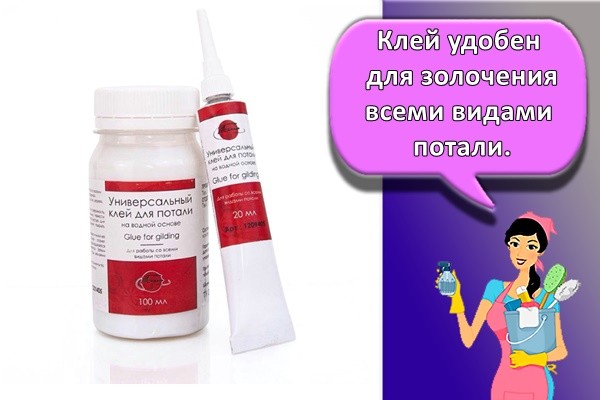

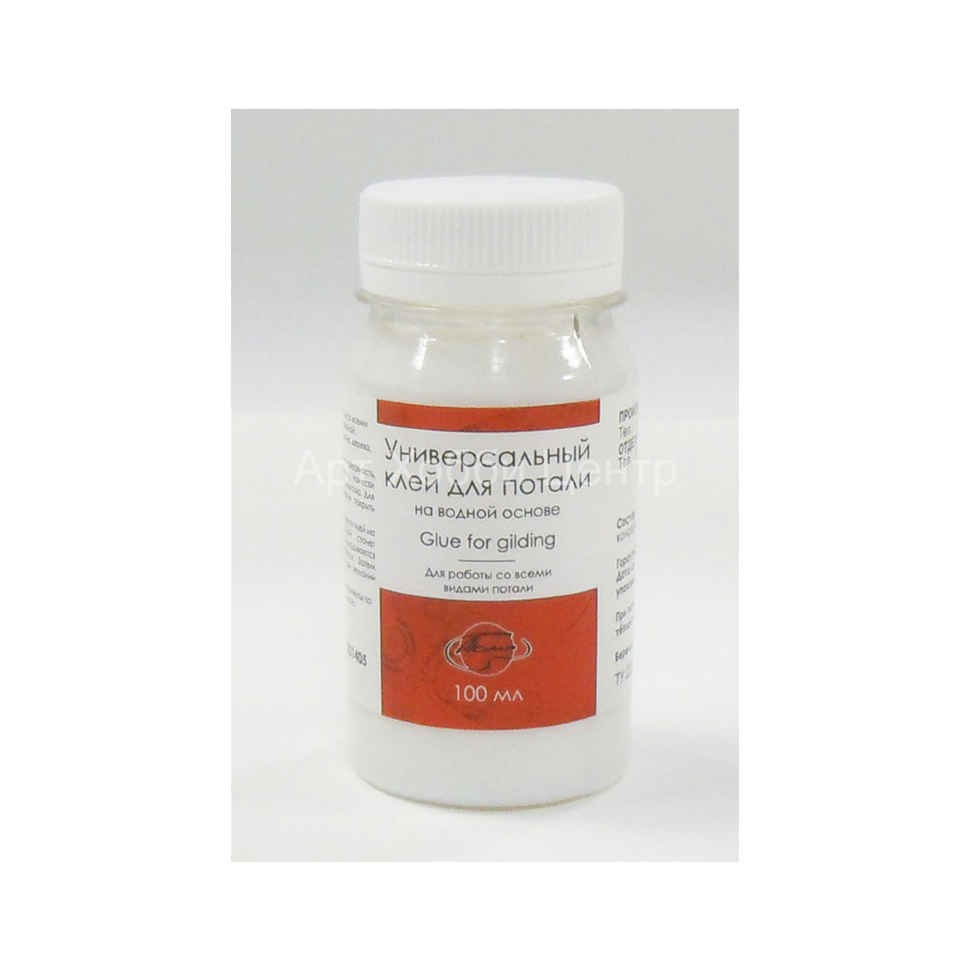

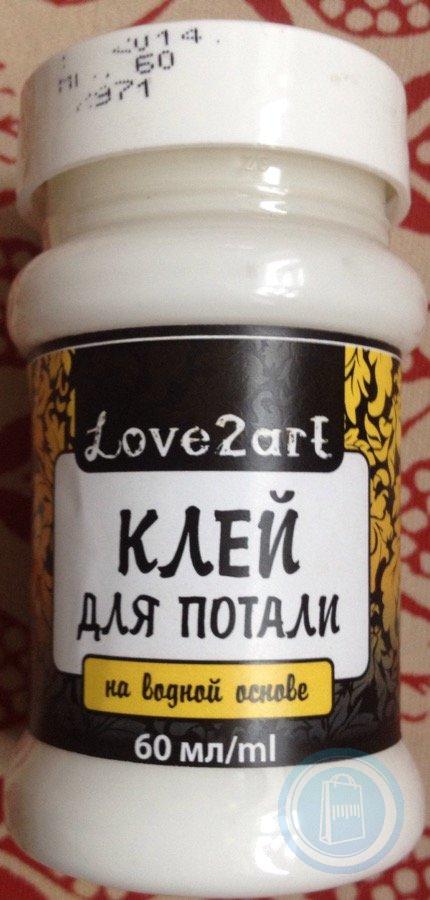

Choosing a high-quality glue for glue on a water or alcohol basis

The leaf is intended for decorative gilding and silvering of various surfaces - ceramics, wood, glass, plaster moldings, metal, cardboard and plastic.

Depending on the task at hand, various brands of glue can be used, such as:

Kolner Permacoll Size

- special acrylic-based glue for glossy gilding. Permacoll has long-term adhesion, which means that it is possible to cover the glue-treated surface with gold leaf within a few hours.

The adhesive does not contain solvents and can be diluted with water if necessary. This brand of glue is widely used in decorating artificial and natural gilding of icons, in the manufacture of handicrafts, interior items, etc.

Permacoll glue is available in two colors - transparent and red (pigmented with a pigment to control glue application). A 100 ml jar of colorless glue costs about 700 rubles, red is sold a little more expensive.

Tahir transfer glue

- a universal transparent water-based adhesive. Designed to work not only with transfer, but also with other types of gold leaf (free sheet and in flakes).

It can be used to decorate all types of bases: plastic, wood, metal, glass, etc. It is enough to apply a thin layer of glue and wait a few minutes, and you can start working.

Tair glue retains its adhesive ability for a long time, which makes working with it convenient and comfortable. Glue for potal Tair is more often found on sale in 20 ml tubes, it costs about 150 rubles. For large volumes of work, it is more profitable to buy glue in 100 ml jars (it costs about 250 rubles).

Mordan "Ferrario"

- universal adhesive mixture for gold leaf and leaf. The composition is applied in a thin layer to the surface to be decorated and kept for 15-30 minutes.

After partial drying of the mordan, you can start gilding. Glue (Mordan) for potal, after application, does not lose its adhesive properties for two to three hours, which allows you to do the work neatly and unhurriedly.

Mordan "Ferrario" is available in packs of 75, 250 and 1000 ml. The cost of a 250 ml jar is about 1200 rubles.

Recipe - how to make glue for potal with your own hands

Ready-made adhesives for potal are expensive, so if you wish, you can make an analogue of a store-bought Mordan from the available ingredients.

Here are two easy recipes:

Potato starch and sugar based glue for pottery.

- Dissolve 70 grams of sugar in 200 ml of warm water, put on the stove, bring the solution to a boil.

- Then add a teaspoon of vinegar to the composition, mix and boil for another half minute.

- We remove the future glue from the heat and, constantly stirring, pour in a third of a glass of potato starch.

- After cooling, the composition should resemble a creamy mass in consistency. In terms of properties, such glue is close to PVA - after drying, it becomes almost transparent.

Glue for gilding on cream and cognac.

- We take 100 grams of heavy cream and the same amount of brandy, mix thoroughly - the glue is ready.

- We apply the composition to the surface to be treated, wait about 30-60 minutes for the glue to dry and proceed to gilding.

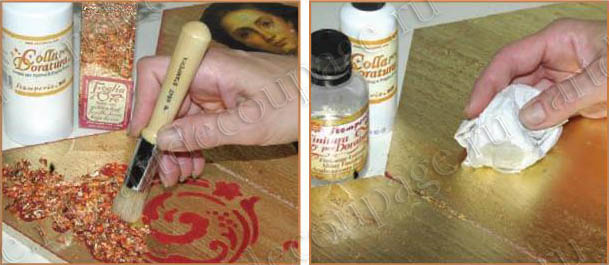

How to glue - an example of working with a transfer sheet

Method of using Tair glue when working with transfer leaf (foil on film):

- Product preparation. The surface is degreased, highly absorbent substrates (gypsum, wood, etc.) are pre-primed with glue.

- Glue application. A thin layer of glue is applied to a clean, dry surface to be decorated with a brush.

- Technological pause. A 5-10 minute pause is maintained (the glue will dry out and become transparent during this time).

- Decorating. The inner side of the transfer sheet is applied to the surface and gently smoothed with a cotton swab, excess glue is removed. Then the film is removed with a sharp movement.

- Coating with varnish. If desired, to fix and protect the "gilding" from oxidation, you can cover the leaf with a special varnish (Ferrario, Daily ART, etc.).

- Cleaning tools. At the end of the work, brushes should be rinsed immediately with warm water.

VIDEO INSTRUCTION

At present, chemists and technologists manage to find an alternative - to invent a material that, in terms of its characteristics and external data, is in no way inferior to real gold used in arts and crafts! Meet this - gold leaf ...

Some helpful tips

For those who have just recently discovered the art of gilding with gold leaf, we remind you of a few simple rules. These recommendations will help you achieve better results and avoid annoying mistakes in your work:

The simplest but most important piece of advice when working with glue for metal is to read the instructions carefully. Even if you have already worked with home formulations, be sure to check the manufacturer's recommendations anyway.

Typically, the bottle describes in detail the rules for applying the glue, timing of work and precautions.

Use gloves when applying gold leaf to the piece of art. Delicate foil covers the base well

However, for complete accuracy, protect the coating from extraneous marks and accidental fingerprints, and the skin from contact with the sticky substance.

If you are just learning to work with film gilding, then in order to save money, you can train on homemade compositions. But on the other hand, a high-quality industrial mixture will allow you to better master the subtleties of work and achieve an excellent result without the threat of spoiling the surface.

Finally

If you enjoy doing artful work with gold trim, then be sure to try professional materials. Only special formulations will allow you to achieve an impeccable decoupage effect.

For those who want to learn how to work with gold plating or hone their skills, we recommend watching the video instruction on how to glue the gold leaf:

Potal is a material used for decorative purposes, which has the external properties of gold. In order to work correctly and easily with it, it is necessary to choose the right glue for the gold leaf, to study the features of the material. There are several types of decor that can be used on various surfaces that differ in volume, size, texture. With the help of potal, it is easy to turn an ordinary decor item into gilded, bronze or silver. An experienced craftsman can create a product that is indistinguishable in appearance from a real precious metal.

How to replace gluten in baked goods. What can replace meaty foods in lean baked goods?

If everything is more or less clear with lean soups, vegetable stews and cereals, then lean dough and lean pastries in general raise many questions. The famous baker Alena Spirina tried to answer the main ones, for example, how can eggs and butter be replaced in lean baked goods.

To understand how to make lean baked goods really tasty, let's figure out how the quality of the dough is affected by foods that we are deprived of during fasting, and vegans always. How their absence affects the quality of finished products, and how can this absence be compensated for? How to replace butter in lean baked goods? The butter contains about 80% fat and 20% water. Thanks to the butter, the dough becomes moist, flaky and voluminous. Shortbread dough becomes crumbly, including due to the steam that is formed when water evaporates from the oil. And no other fat will give a dough the flavor and texture that butter comes from. The closest, but not the healthiest, alternative is margarine. If you are a categorical opponent of this product, then only the usual vegetable oil remains. Which is not so bad, although it contains neither water, nor air, nor emulsifiers, which help to retain a large volume of air, and therefore cannot affect the loosening of the dough. But vegetable oil perfectly envelops the flour, preventing the gluten from developing excessively. Yes, shortbread dough mixed in vegetable oil will not be as layered and aromatic as in butter, but it remains crumbly and soft. It is the eggs that are responsible for the formation of the structure of some types of dough and are practically the only ingredient that simultaneously contains a significant amount of both natural thickeners (proteins) and leavening agents (fats and emulsifiers). Alternatively, you can beat the eggs to enrich the dough with air. Eggs also keep the water from separating from the fat, but we don't have eggs, so you'll have to forget about the fluffy biscuits for now. But cupcakes are quite accessible to us if we know how to compensate for the lack of emulsifiers and baking powder. You will have to create an emulsion forcibly, as in a vinegar salad dressing: mix vegetable oil with an acidic liquid, for example, fruit juice or coffee, jam syrup or fruit puree. If the recipe for a muffin needs to take a couple of eggs, try replacing them with ripe bananas, taking as many the same by weight: for two eggs - 100-110 g of banana. Just add not just mashed banana with a fork, but beat it with vegetable oil in the bowl of a blender or food processor: you will see what a stable emulsion you get! This is not surprising, because sugar, honey, and jam have to compensate for the lack of butter and eggs. Sugar not only softens the texture of the dough, but also attracts water, protecting it from excessive gluten development. The more sugar you add to the dough, the softer it will be. If there is not enough sugar, the structure of the dough will not form properly and the dough will either not rise or rise and settle. And sugar also retains the moisture content of the finished product, making it soft and protecting it from staleness. What can be the options for lean baking? , sugar. And so that the surface of the cake is ruddy and shiny, brush it with strong tea before baking and vegetable oil - after. With loose dough for pies, everything is also simple: just mix an equal amount of vegetable oil and water and add about twice as much flour, in which added salt, baking powder and, for sweet pies, sugar.Just do not knead the dough until smooth, it can get rough. Muffins are the hardest. Try to find a cake recipe that you generally like and change it depending on the circumstances: use a different liquid, try to play with the taste of butter, add a variety of additives: nuts, dried fruits, candied fruits, spices and herbs. Or, pour the muffin dough over slices of fruit - apples, pineapples, oranges - to make it look like a charlotte. Material taken from the Internet.