Step-by-step technology for mounting PVC panels on glue

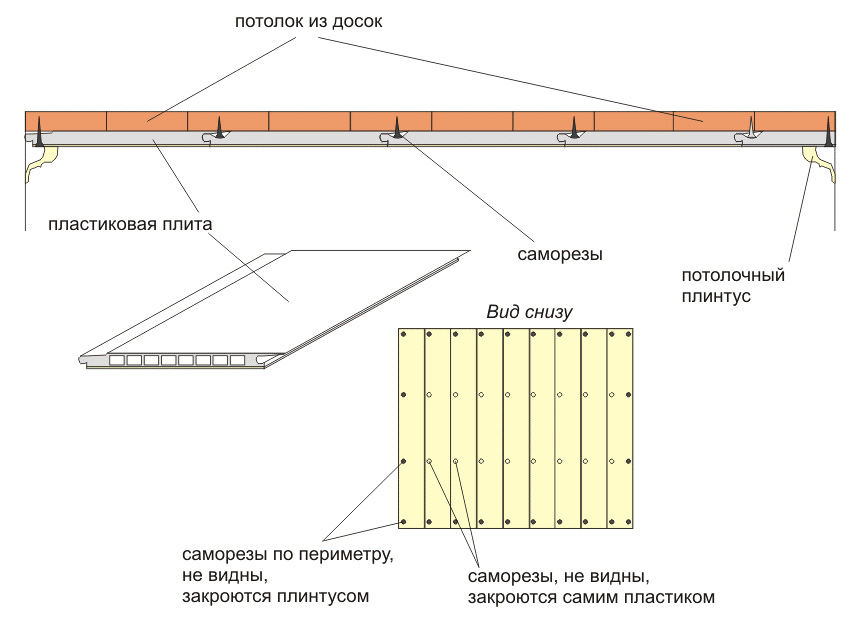

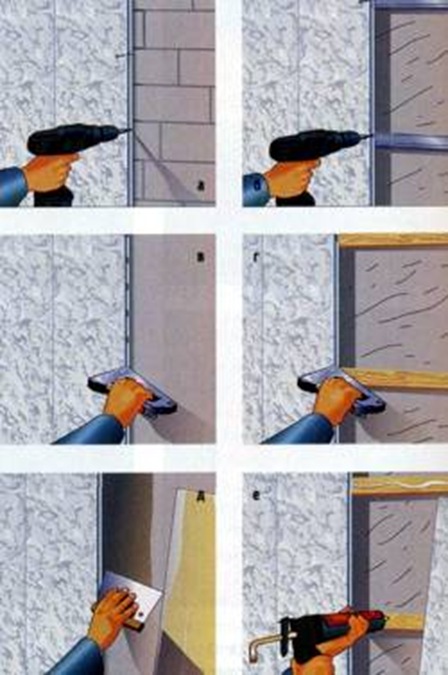

Before starting work, it is necessary to vacate the premises. To work on the ceiling, you will need a sturdy table or ladder. It is more convenient to work on the table - there is where to lay out the necessary tools and materials. Recall that fixing plastic panels to the ceiling without glue lathing is possible only if the base is perfectly flat.

The stages of work are as follows:

- Remove all lighting fixtures from the ceiling, determine the wiring points, mark the areas with a marker.

- To clean the surface from the old coating, removing pieces of plaster falling off. Lime and water emulsion are washed out with water until the base is exposed, the paint is removed with a spatula, cleaned with emery.

- Visually inspect the base, identifying areas with defects.

- Use a putty to remove drops in the base, repair cracks, chips.

- You can putty the ceiling with minimal defects, the depth of which is no more than 5-6 mm. If you have to apply a thick layer of putty, it is better to do two layers. Apply a second leveling coat after completely drying and priming the first one.

- To clean the dried putty with emery, prime and allow to dry.

- Pull the cord along the diagonal corners of the room, determine the center - work will be done from here.

- Begin the installation of PVC boards, joining the corners exactly in the center. And how to glue PVC panels on the ceiling, the owner himself can determine by choosing a layout scheme.

All other tiles are laid parallel to the first rows or according to the calculated laying pattern. The layout is clear, but how to glue the plastic panels to the ceiling? The entire perimeter of the reverse side is smeared with the composition, it is possible to apply the glue crosswise, especially in rooms with a high level of humidity or with a large thickness of lamellas. So the elements will hold stronger. The lamella must be brought to the base, pressed and held a little, at the same time leveling it. A couple of minutes is enough for adhesion, then the next lamella is laid out.

If the panel does not sit on the base, it means that the surface is not cleaned well enough or the adhesion properties of the adhesive are weak.

How to glue PVC panels to the ceiling in this case:

- Remove the elements, clean and prime the ceiling over again. Wait until dry, then mount the cladding.

- Clean the lamella and base from glue residues, grease the panel and ceiling with a mixture, press down. This “zero” layout provides grip even in difficult cases.

If it was not possible to solve the problem in any way, then it is necessary to replace the glue, picking up a thicker composition. Epoxy mixes are suitable for particularly difficult situations, but they should be used in well-ventilated areas and work quickly - epoxy resins have a short pot life.

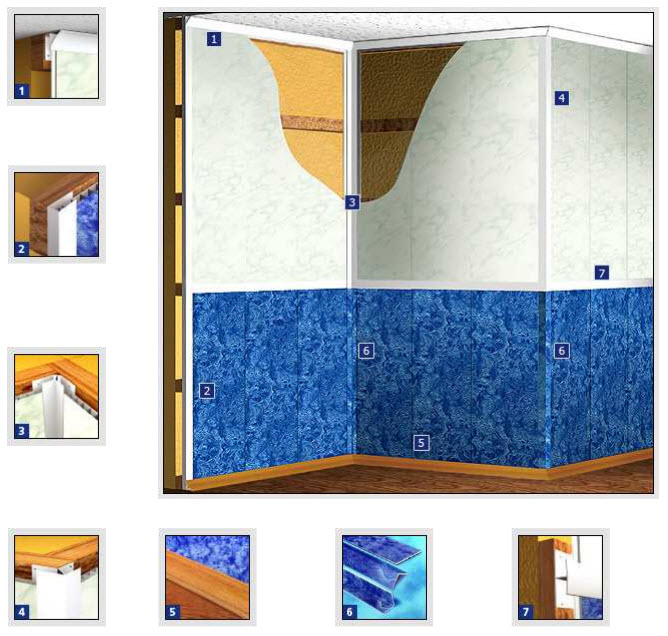

After facing the plane, it is the turn of finishing the corners. For them, plastic corners or ceiling plinths are bought, covering the cracks, calculation errors. The elements sit on a transparent sealant - the composition does not expand after drying and does not change the color of the decor.

If you have any questions, see how to glue plastic panels to the ceiling in the video below in the article. Professional craftsmen will help you understand all the nuances of the work.

What glue is right

Despite the wide variety of adhesives for MDF, their main purpose is tight and reliable gluing and adhesion of panels to the wall. All of its types are divided into groups:

- universal compounds;

- special;

- polyurethane foam;

- liquid Nails.

Compounds for MDF sticker

Compounds, or polymer resin, contains "Moment", "Titanium" and other additives, thanks to which the glue is used on wooden, stone, and metal surfaces.

Special series

Chemists have developed this series for gluing not only on ordinary surfaces, but also on concrete. It can be used by both professional builders and amateurs who decide to make repairs on their own. As a supplement to the glue, a gun is used, working with which greatly simplifies the gluing of MDF.

Construction foam

Despite the fact that building foam is most often used for sealing, its use when installing panels is quite possible. Construction foam is produced in two types - for outdoor and indoor use. When fixing MDF panels, it is permissible to use both types of clamp. After drying, the polyurethane foam remains soft. Flexibility avoids deformation of MDF. This is especially true if their composition is based on chipboard materials.

Liquid Nails

The glue is universal, has high adhesion, resistance to corrosion, installation of various building materials, especially those containing wood, is possible. Due to its ease of use, the option of using liquid nails is very popular. Using a gun, glue application is convenient.

Liquid nails based on organic acids have an unpleasant odor, so personal protective equipment should be used. The glue is durable, but when moisture gets in, the seams can undo. This should be taken into account when renovating premises where the humidity is higher than normal.

Universal construction

Multifunctional glue is applicable not only for gluing MDF, but also for other types of repair work. It is characterized by heat resistance (from -30 ⁰C to + 60 ⁰C), quickly sets, and is resistant to moisture.

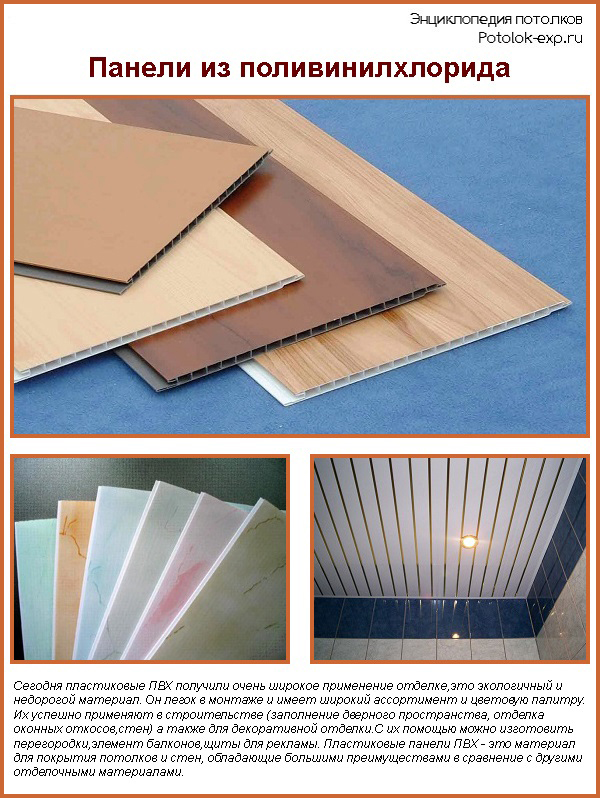

Description of PVC panels

The abbreviation PVC stands for "polyvinyl chloride". In fact, this is ordinary plastic, which was given the desired shape during production. PVC panels have been used as a finishing material for many years. This became possible due to the undoubted advantages that the panels have. Among them are:

- Durability, service life up to 10 years.

- Easy to care for.

- Environmental friendliness.

- Moisture resistance.

- Fire safety.

- Resistant to low and high temperatures.

- Good soundproofing.

- Can be mounted on different surfaces and the like.

Many buyers also like the fact that the stores offer a huge number of colors, the panels have a variety of patterns. If there is a desire to make an inexpensive but beautiful renovation, then this material will be a good choice.

The main thing is to choose a good manufacturer and pay attention to the presence of possible defects in the product.

The panels are easy to buy and, what is important, easy to install

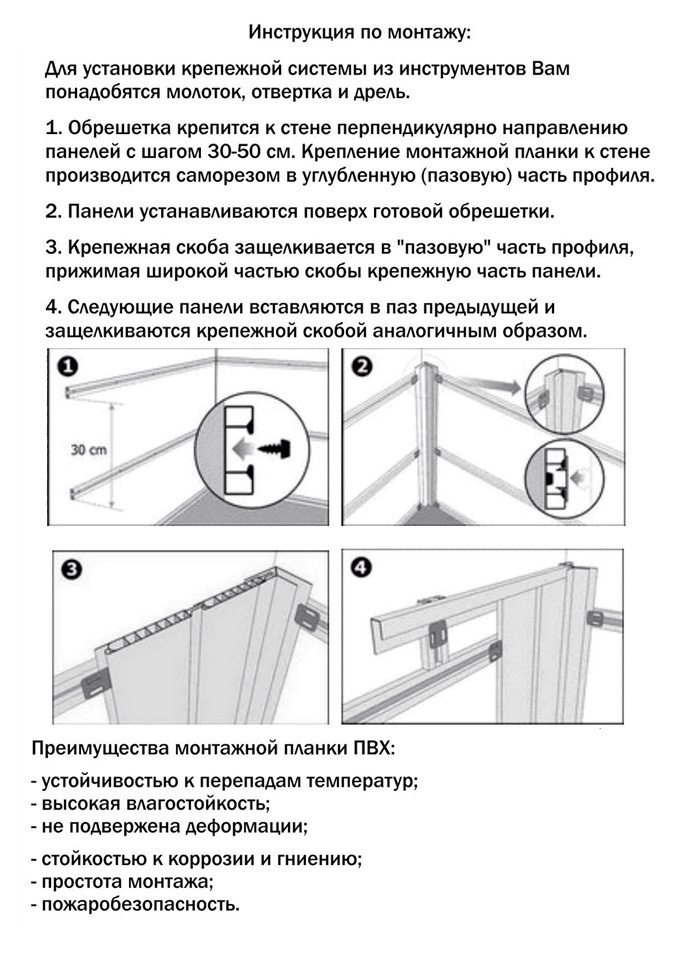

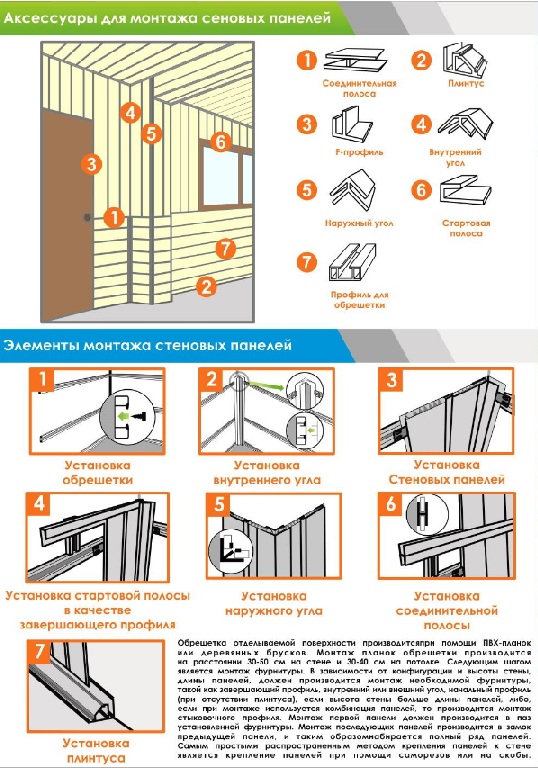

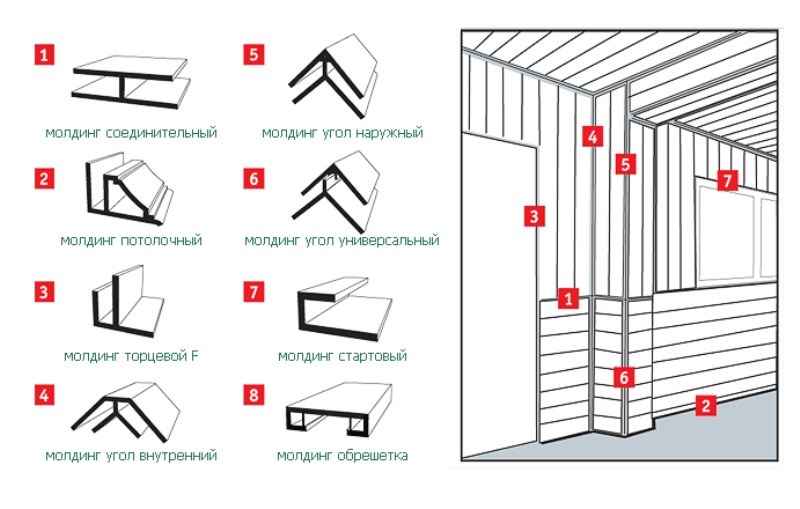

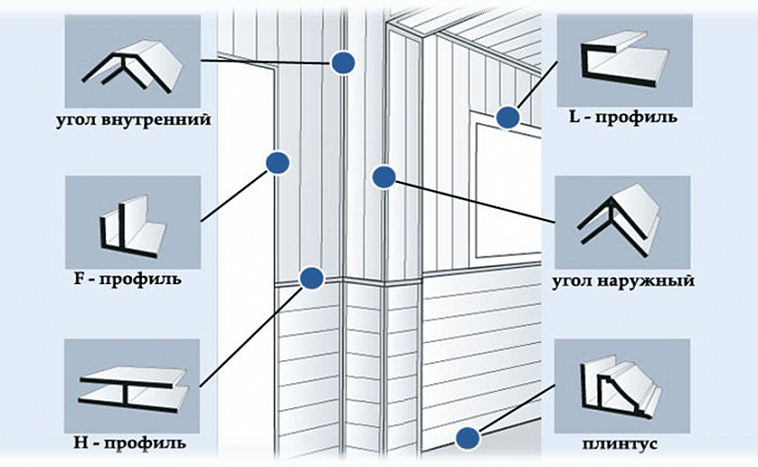

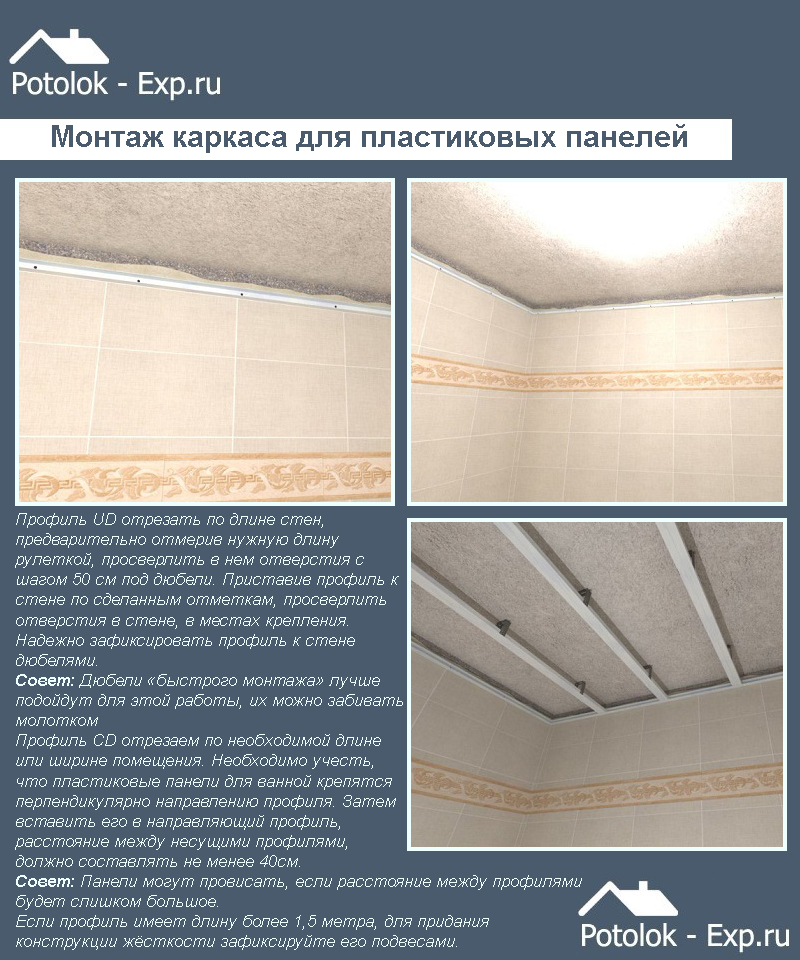

There are two main ways in which you can attach plastic panels to the wall:

- Attaching panels to the frame. This can be done mechanically, that is, using self-tapping screws, nails or staples. The lathing itself can be metal, wood or plastic. Also, the panels can be glued to the frame, which in this case will play the role of a wall equalizer. This method of fastening - to the crate - has its pros and cons. Those who do not want to mess around with installing the frame for too long and lose precious square centimeters in the bathroom may choose a different path.

- Bonding to the wall. This method has practically no effect on the area of the room being repaired. But it has its limitations. The walls must be flat, dry, and the adhesive well selected, then the repair work will give the correct result.

It must be understood that not every glue is suitable for attaching this finishing material. Some formulations can damage plastic or poorly withstand moisture. Therefore, it is better to know in advance than to glue PVC panels to the wall.

What to look for when choosing an adhesive

To properly glue PVC panels on the wall, you need to remember that this material has a smooth surface, flexible and lightweight structure.Therefore, not all types of adhesives are suitable for fixing plastic finishes. Some compounds can deform, discolor or completely melt PVC elements.

At the same time, the overpriced does not mean that the solution can be used for finishing from polyvinyl chloride. Before installing the panels, make sure that the bonding component meets the following requirements:

- Plastic panels are popular for wall decoration in bathrooms, showers and other areas with high humidity. Therefore, PVC glue must be resistant to water and temperature changes.

- After drying, the solution should remain colorless and not yellow over time.

- Have high adhesion properties to complex and porous surfaces.

- The setting time should be no more than 15 minutes. And the time for adjusting the segments is more than 3-5 minutes.

- The composition should not contain chemically aggressive reagents hazardous to health. If the solution has a pronounced chemical odor, it is better not to use it for internal work.

- The bonding compound must be of medium viscosity in order to remain on vertical surfaces. Too liquid formulations can drain off.

- It is better to give preference to materials that contain fungicides. This will prevent mold and mildew growth.

- The clutch must be durable (at least 5-7 years).

- The glue should create an elastic bond and not crumble over time. Withstand temperature extremes in the range of 25˚С.

- For ease of application, it is better that the package is equipped with a dispensing tip. The tip is cut off immediately before starting work. The higher the cut, the thicker the adhesive will come out.

- If PVC elements are intended for rooms with natural light, the adhesive must be UV resistant.

- When installing PVC tiles on the "Warm Floor" system, the glue must have heat-conducting properties, withstand regular heating up to 75˚С.

For the installation of PVC panels, there are special adhesives that meet all the requirements for working with vinyl coverings. Some of them are two-component. In this case, the packaging consists of two isolated components. Immediately before starting the attachment, both elements are mixed. However, to save time, it is better to buy ready-made mixtures.

In addition to special adhesives, liquid nails can also be used. These are universal solutions that are suitable for many types of textures and materials.

When using liquid nails and special adhesives in tubes, you may need a nail gun. It facilitates the application of the adhesive and distributes the adhesive economically over the entire surface.

Wall cladding with pvc panels in the interior of different rooms

Wall cladding with pvc panels will be relevant for different rooms, but do not forget about some combinations that may look the most successful. Below are some basic tips to help you create a successful and efficient home.

Pvc wall panels for kitchen

The kitchen is a room with high humidity and temperature - a large number of sources of moisture and heat contribute to the rapid deterioration of any finishing materials. PVC is quite sensitive to temperature, therefore, deciding on its use, the most important factors should be taken into account.

On the kitchen

First of all, when choosing finishing with PVC panels for walls, you should still add tiles or other types of tiles in order to limit the washing and cooking zone. The plastic does not tolerate heating well, and after a while the panels next to the stove are seriously deformed, and then completely melt.

According to the picture, mosaic options are perfect for the kitchen - they often imitate a tiled floor. Also a good option would be to build a stone or wooden surface, especially if this the kitchen is in a private house or is a summer kitchen.

Decorating the walls of the toilet with pvc panels - a photo of interesting ideas

Decorating the toilet walls with PVC panels (photo below) is a great idea - the panels do not absorb odors, are protected from water and are easy to clean. They can be attached directly to relatively flat walls using sealant or glue, but you can also create a frame that will hide all wires and pipes.

In blue

Ideas in this case are also not limited - you can use any solutions. Mosaics, 3D options, stone and wood are perfect

Also, you should remember about compatibility with the floor covering - this is of particular importance in the toilet.

Pvc wall panels for bathroom

A bathroom is similar to a toilet in many ways. PVC panels for walls in it have exactly the same advantages, which allows them to be fully used. In this case, it is better to avoid frames - with them it rarely comes out to create a truly sealed surface.

This is important when placing panels near the bath, since water from it very often gets on the walls.

In olive tones

Among the textures, it is better to avoid wood - for the bathroom, it will look too unusual, giving away a fake. The rest of the options are perfect regardless of the room - 3D looks especially advantageous, which allows you to create a special interior.

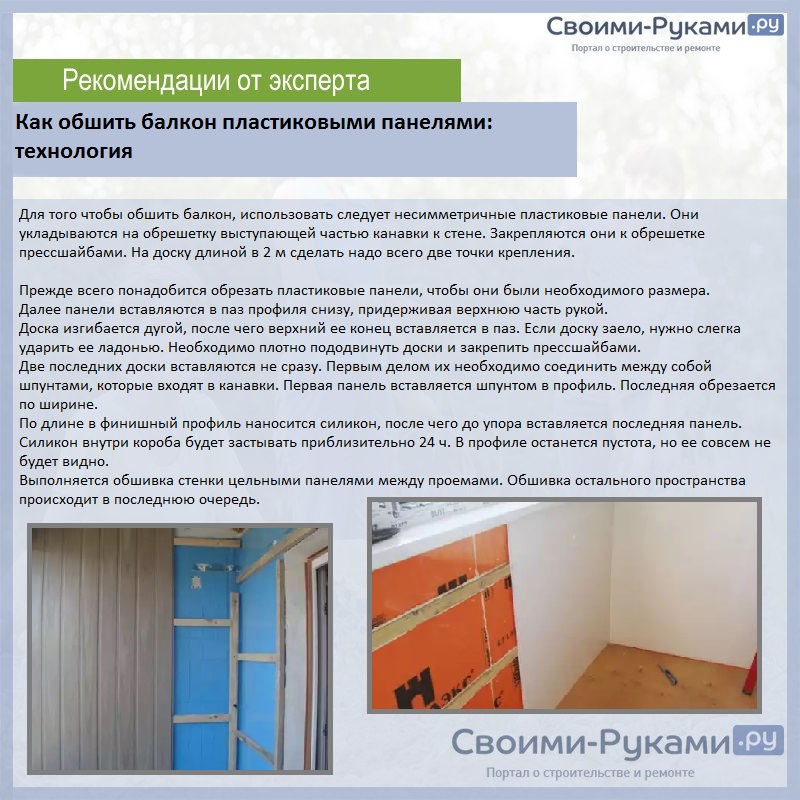

On the balcony

PVC panels can perfectly complement plastic or aluminum windows on the balcony. There are no special requirements in this case - the main thing is that the products can withstand negative temperatures. In addition, it must be borne in mind that the balcony is extremely open to all light sources. Ultraviolet very quickly destroys various color coatings that are applied to the panels.

With cabinets

In this case, the most optimal solution is to use colorless panels - for example, white ones. They are made without paint, so you don't have to worry about fading. Placing is permissible directly on the walls, since they are most often even on balconies. It is worth using adhesives resistant to negative temperatures. Further in this article, we will analyze how to fix pvc panels to the wall correctly on a profile from a bar.

In the living room

Panels in living rooms are rarely used. A full-fledged finish with their help is irrational - it is much easier to cover the entire surface with wallpaper. With PVC, you can create individual elements. For example, it is a great idea to create a finish on the bottom half of the wall, like wood or stone.

Country style

Also, the idea can be the creation of additional surfaces from 3D panels.

This will diversify the room, but you should not make them too noticeable and bright - this distracts too much attention to yourself, making the interior less uniform

Main varieties

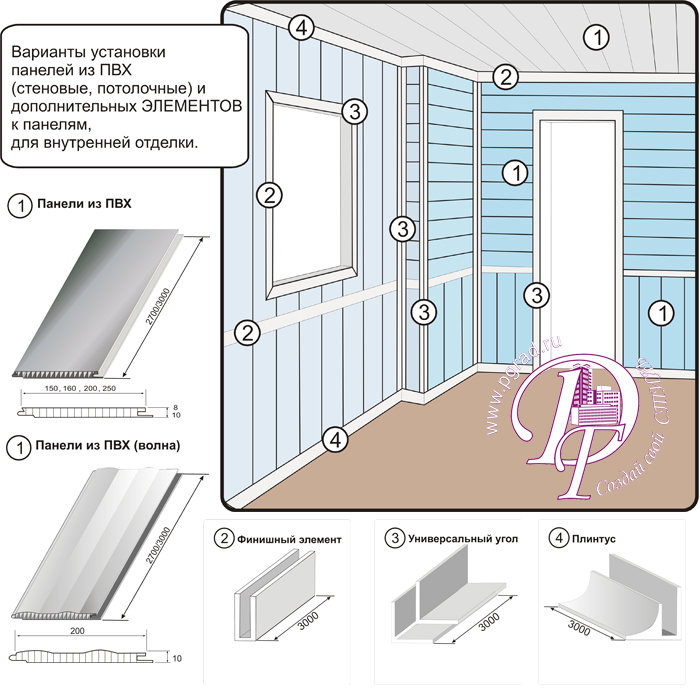

At the moment, PVC wall panels (catalog, photo, price will be presented at the end of the article) are presented in a fairly wide range. This is achieved both through various forms and through textures. The most common forms include:

- tiled;

- rack;

- leafy.

In the living room

All types have their own purpose, both in terms of location in rooms and for working with the surface. This must be taken into account when choosing a material, as it can seriously affect the work.

Tiled

Pvc tile wall panels for interior decoration are small tiles that can be laid out like regular tiles. The main difference from it is the significantly low weight, which allows you to use ordinary glue or sealant.

Tiled panels in the bathroom

The size of the tiles varies from large, 500x500mm, to very small, 50x50mm or even less. Their use allows you to achieve different visual effects, typing various drawings and even full-fledged images. Also, the tiles are much more convenient in those rooms where the walls are of different sizes and problem areas, which will be difficult to cover with other types of panels.

Rack

This type of PVC wall panels is considered classic.The slats are not wide (up to 300-400mm), long panels that outwardly resemble lining. They allow you to easily cover any vertical surfaces and ceilings, and due to their standardized sizes, they have a wide variety of colors and shades.

How to fix pvc panels to the wall - in more detail later in the article.

The dimensions of the slats allow them to be used in any room. With them, work goes most quickly - they simply stick to each other, creating a continuous wall covering. Various sealants and putties can be added to the crevices between them for added continuity.

In addition, it must be borne in mind that not in all places the slats are convenient - for example, in rooms with sloped ceilings, they will require additional cutting, which is sometimes quite complicated. Also, the slats do not withstand different pressures well, as, indeed, all PVC panels, and all fasteners must be fixed under them, cutting out the slats for them.

Leafy

Sheets for wall cladding with PVC panels are made in the form of a flat sheet material. The sheets themselves vary in size, providing a fairly wide range. They can be used both for curly cutting and for full-fledged wall covering.

PVC sheet options

Review of effective brands

Among the above groups of glue, the most popular are several brands with high characteristics. According to the reviews of professionals, when choosing, it is worth giving preference to such brands.

Titan wild

Glue belongs to the group of liquid nails and is a universal professional tool. Titan wild successfully replaces fastening with screws, self-tapping screws or nails. The adhesive is able to fix MDF panels on any surfaces. It is used both indoors and outdoors. The advantages of the brand include:

- reliable fixation without damaging the structure of the material;

- moisture resistance - 100%;

- cost-effectiveness of spending;

- setting speed;

- the possibility of using at different temperatures.

Titebond

The glue is based on an aliphatic resin. It is used in joinery for gluing wooden parts, applying laminate, MDF, chipboard, furniture assembly. The advantages of Titebond glue include:

- fast setting;

- readiness to work;

- resistant to moisture, heat, solvents;

- ensuring the strength of the adhesion boundary is much higher than that of wood.

The glue looks like a viscous yellow emulsion, after drying it is translucent. Resistant to freezing, ignites when exceeding 100 ⁰С.

"Moment-1"

Universal glue "Moment-1" is perfect for gluing surfaces made of different materials, is moisture resistant and can withstand temperatures from -40 ⁰С to +110 ⁰С. The glue dries very quickly thanks to the components included in it:

- rubber resins;

- rosin;

- ethyl acetate;

- acetone;

- hydrocarbons.

Moment-1 glue is a light yellow thick liquid. The optimum temperature for work is from +18 ⁰С to +25 ⁰С. When fixing the panels, an air flow should be ensured so as not to get poisoned by toxins.

Tytan Euro-Line 601

Glue belongs to the type of universal construction. It is used indoors and outdoors. The base on which MDF is mounted can be made of wood, concrete, brick, plaster.

Tytan Euro-Line 601 glue is based on rubber. With the help of it, they carry out repairs and decoration with MDF panels. The main characteristics are:

- strong and fast grip;

- strength;

- hardening within 24 hours;

- temperature resistance in the range from -30 to +60

"Moment Crystal"

The glue is colorless, transparent, dries quickly and leaves no residue as a result of working with it. Liquid nails securely fix the MDF panels installed on the ceiling or walls inside the premises. Moment Crystal is well suited for gluing panels without top trim.

A feature of this type is that the speed and reliability of the setting depends on the force with which the surfaces were pressed. Moment Kristall is distinguished by its high frost and moisture resistance.

Makroflex MF220 Heavy Duty

This brand of glue is intended for joining different materials:

- MDF;

- drywall;

- foam;

- Chipboard;

- metal;

- ceramics;

- wood;

- gypsum.

The form of the glue is a white paste based on polyacrylates. The optimum temperature for fixing is from +10 ⁰С and above. Among the characteristics of Makroflex:

- maximum exposure time - 15 minutes;

- lack of smell;

- the ability to use on the street and inside the house;

- high gripping force.

Liquid Nails LN-910 Panels

This brand of liquid nails is indispensable for quickly covering a room with panels, gluing decorative elements, baseboards, moldings. The adhesion is reliable if brick, concrete, wood, plywood, chipboard and other materials are used as a base.

The glue is intended for interior use. It is distinguished by a number of characteristics:

- elasticity;

- the ability to adjust the gluing within 15 minutes after connecting;

- deformation obstacle;

- long (up to 20 years) service life;

- the ability to freeze and defrost.

Liquid Nails LN-901 Extra Durable

The composition is based on synthetic rubber. Able to create the most durable connection in difficult conditions. Suitable for both indoor and outdoor use. Set quickly. It can be operated at temperatures from -40 ⁰С to + 70 ⁰С. The materials to be glued are used:

- MDF panels;

- wood;

- brick;

- tiles;

- cork;

- plywood;

- drywall.

Temperature from -40 ° С to +70 ° С is optimal for operation, from +5 ° С to +38 ° С - for work.

What to look for when choosing

It is clear that the choice begins with the color and pattern. But so that during the installation process there are no difficulties, during the purchase it is necessary to track some points:

Examine the cut of the selected plastic panel. The thicker the lintels and the front and back resin layers, the stronger the finish will be. You can also focus on weight - the larger it is, the thicker the panels will be.

The thickness of the plastic is the same everywhere, without thickening and thinner places

This is a sign of normal quality.

Pay attention to the geometry. The cells should not be wrinkled, the edges should be absolutely even

Even if everything is packed, it does not interfere with unpacking and inspecting - so that there will be no problems later.

Examine the front surface. The drawing should be applied evenly, clearly, without smears.

If you choose panels from different packs, but of the same color, carefully look at the colors - they may differ.

It is also worth checking the quality of the polymer used. It is necessary to take one bar so that it bends by about 30% and straighten it. Then examine it. If there is no damage to the plastic or the pattern, everything is fine.

How are plastic panels glued: how to figure it out?

Wall and ceiling decoration with plastic is carried out on a specially prepared metal or wooden frame, to which panel sheets are attached. Recently, gluing sheets has become more and more popular, rather than mounting them on a frame. This method saves 3-4 cm of the total space, and also prevents the appearance of dampness and rot on the walls between the profiles. What is the alternative to gluing the panels?

How to glue a pvc panel: wall requirements

Naturally, not every coating can be coated with glue, and not every coating can be glued to another element. PVC panels are fixed according to certain laws, for non-compliance with which you can pay with your money and invaluable time.

- Smoothness of the surface. There should be no curvatures and roughness on it, in addition, pits or drops of no more than 4-5 mm. If exceeded, the plastic simply will not stick, or it will be broken.

- Surface condition. It is a known fact that it is difficult to glue something to a greasy and dusty surface.This means that you must clean the panels and wash off the whitewash and dust, get rid of grease with household chemicals.

How to glue pvc mosaic and choose glue

The most correct option for gluing pvc is the "Moment" assembly glue, which is intended for technical and decorative gluing of parts.

When using this glue, the pistol technique is used, which allows it to be applied in a dotted manner.

In addition, there are also such adhesives: liquid nails, polyurethane foam and tile adhesive (cement). All of them easily fulfill their immediate function, but each of them is not perfect.

If we talk about thermal adhesives, then it is worth remembering the ability of plastic to expand, which can lead to a lag of the sheet. Such a trick will manifest itself over time, when, with constant thermal exposure, the sheet simply will not have a place where it will expand, but instead will fall off altogether.

Liquid nails do not cause such situations, but it is best to use a non-expanding sealant, which is sold in every hardware store. It is plastic and heat resistant. Professionals only use it.

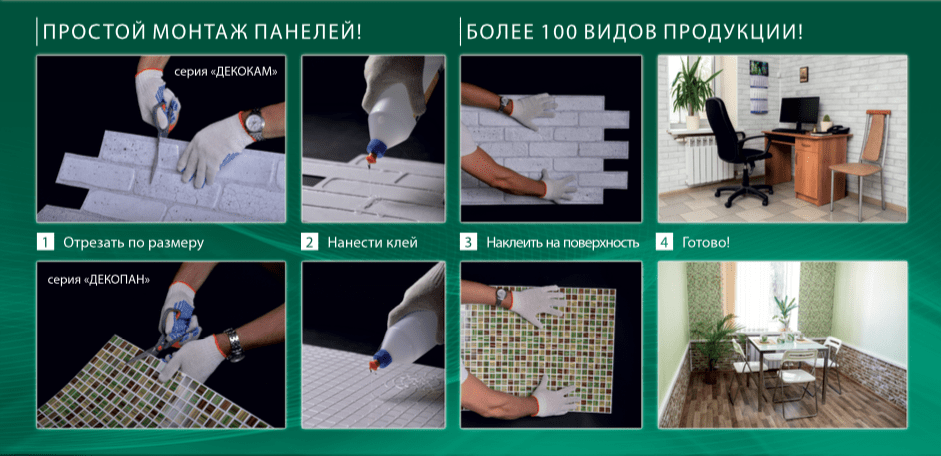

How to glue a pvc panel: the specifics of laying on glue

Like any other type of finishing work, the plastic cladding process begins with the preparation of the coating. It needs to be cleaned and primed first, but there are a few more things you need to do before you start priming.

- Corners. Often in rooms such as a bathroom or toilet, the corners are rounded, so that they become geometrically even, they are leveled with a puncher. If this is not done, it will be extremely difficult for you to display each turn of the wall with plastic, which means that this will also affect the uniformity of the surface. With the help of a powerful hair dryer, a plastic sheet can be bent, but if this is not possible?

When shaping the corners, the inner side can be trimmed to bend, but a 90 degree angle will look much better than a 60 or 120.

Preparation of the starting strip. This is not done if you plan to install a plinth and begin to mount a plastic ceiling. But it is necessary in order to make a neat connection between the panel and the floor covering.

- And now we proceed to the PVC panels themselves. It must be cut to the desired length and height of the room, then cleaned of dust with a napkin. Then apply the glue. By the way, it can also be applied in different ways. If the room has good walls, then glue is applied along the perimeter of the strip and in the middle, and if the walls, to put it mildly, are uneven, the glue is marked with a dot. Doing everything as written in the recommendations, you can rest assured that the panels will stick to the wall in the best way.

- Apply the panel with glue to the wall. But there are some bonding features for each adhesive:

- Liquid Nails. They must be left to “cool” for 5 minutes so that they can harden to the point that they will firmly adhere to the wall. Liquid nails are best at sticking sheets together.

- Sealant. It is constantly necessary to press against the wall until such time as he ceases to lag behind.

Tip: you don't have to buy factory connections and try to screw them on. It is enough to use the usual plastic corners, which are easy to glue on silicone or sealant. You can choose the width of these inserts for the corners in the range from 20 to 50 mm.

How are plastic panels glued: how to figure it out?

Features of gluing PVC panels in practice, what glue should be used and what kind of tools should be prepared. The article deals with how to glue panels on your own, but with high quality, like a professional.