Content

- 1 Distribution and habitat

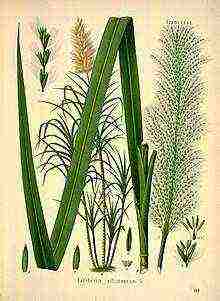

- 2 Botanical description

- 3 History of domestication

- 4 Cultural biology

- 5 Method for extracting sugar from sugar cane

- 6 Production

- 7 Notes (edit)

- 8 Links

- 9 10. People's Republic of China - 8 million tons

- 10 9.UK - 9.4 million tonnes

- 11 8. Egypt - 11 million tons

- 12 7.Poland - 13.5 million tons

- 13 6.Ukraine - about 16 million tons

- 14 5.Turkey - 16.8 million tons

- 15 4. United States of America - 28.5 million tons

- 16 3. Germany - 30 million tons

- 17 2. Russian Federation - 33.5 million tons

- 18 1. France - 38 million tons

Current version of the page so far

not checked

experienced participants and may differ significantly from

versions

, accessed January 30, 2018; verification requires

1 edit

.

Current version of the page so far

not checked

experienced participants and may differ significantly from

versions

, accessed January 30, 2018; verification requires

1 edit

.

| Cultivated sugar cane | |||

General view of a group of flowering plants, Mozambique |

|||

|

intermediate ranks

|

|||

|

Saccharum officinarum L. (1753) |

|||

Cultivated sugar cane, or Sugarcane noble (Latin Sáccharum officinárum) - plant; species of the genus Sugarcane (Saccharum) of the Cereals family. Used by humans, along with sugar beets, to obtain sugar.

Distribution and habitat

Cultivated sugar cane is a perennial herb cultivated in numerous varieties in the tropics, from 35 ° N. NS. up to 30 ° S sh., and in South America, rising to a height of 3000 m.

Sugarcane comes from the Southwest Pacific. Saccharum spontaneum is found wild in eastern and northern Africa, the Middle East, India, China, Taiwan, and Malaysia and New Guinea. The center of origin is possibly northern India, where forms with the smallest chromosome set are found. Saccharum robustum is found along river banks in New Guinea and on some of the surrounding islands, and is endemic to the area. The cultivated sugarcane is most likely from New Guinea. This reed can only grow in tropical regions with a suitable climate and soil. Saccharum barberi may have originated in India. Saccharum sinense is found in India, Indochina, southern China, and Taiwan. Saccharum edule appears to be the pure form Saccharum robustum and is found only in New Guinea and the surrounding islands.

Botanical description

Rhizome perennial fast-growing plant up to 4-6 m high.

The rhizome is short-segmented, strongly rooted.

Stems are numerous, dense, cylindrical, glabrous, knotty, green, yellow, purple. The stem diameter is up to 5 cm.

The leaves are large, wide (from 60 cm to 1.5 m long and 4-5 cm wide), reminiscent of corn leaves.

The stem ends with an inflorescence - a pyramidal panicle 30-60 cm long; ears are small, monochromatic, collected in pairs and pubescent from below with hairs.

History of domestication

Sugar cane harvesting

The sugar cane culture began in ancient times. Sugar extracted from sugar cane is known in the Sanskrit language: "sarkura", in Arabic it is called "suhar", in Persian "shakar". Sugar is mentioned by ancient European writers under the name "saccharum" (by Pliny), but also as a very rare and expensive substance used only for medicine. The Chinese learned to refine sugar as early as the 8th century, and the Arab writers of the 9th century refer to sugarcane as a plant cultivated along the shores of the Persian Gulf. In the 12th century, the Arabs brought it to Egypt, Sicily and Malta. In the middle of the 15th century, sugarcane appeared in Madeira and the Canary Islands. In 1492, sugar cane was transported from Europe to America, to the Antilles, and on the island of São Domingo, it began to be cultivated in large numbers, since by this time the use of sugar had become extensive.Then, at the beginning of the 16th century, sugarcane appeared in Brazil, in 1520 in Mexico, in 1600 - in Guiana, in 1650 - on the island of Martinique, in 1750 - on the island of Mauritius, etc. reed was always very small, since sugar imported from the tropics was cheaper. Finally, after they began to make sugar from beets, the cultivation of sugar cane in Europe was completely abandoned.

The main modern sugarcane plantations are located in Southeast Asia (India, Indonesia, the Philippines), Cuba, Brazil and Argentina.

Cultural biology

Sugarcane is bred by cuttings.

Sugarcane cultivation requires a tropical or subtropical climate with a minimum of 600 mm of annual rainfall. Sugarcane is one of the most efficient plants for photosynthesis, capable of converting more than 2% of solar energy into biomass. In regions where reed is a priority crop, such as Hawaii, harvests are up to 20 kg per square meter.

Method for extracting sugar from sugar cane

Cut sugarcane stalks

To extract sugar, the stems are cut before they bloom; the stem contains up to 8-12% fiber, 18-21% sugar and 67-73% water, salts and protein substances. The cut stems are crushed with iron shafts and the juice is squeezed out. The juice contains up to 0.03% protein substances, 0.1% granular substances (starch), 0.22% nitrogen-containing mucus, 0.29% salts (mostly organic acids), 18.36% sugar, 81% water and a very small amount of aromatic substances that give the raw juice a peculiar smell. Fresh lime is added to the raw juice to separate proteins and heated to 70 ° C, then filtered and evaporated until the sugar crystallizes.

Production

Combine KTP-1 for mechanized harvesting of sugar cane, developed on

Lyuberetskiy

agricultural engineering plant named after A. V. Ukhtomsky in the second half of the 1970s to work on

Cuba

and subsequently licensed in the city

Holguin

Up to 65% of the world's sugar production is obtained from sugar cane.

Sugarcane is one of the main export items in many countries.

Until 1980, India was the leader in the production of sugar cane, since 1980 - Brazil. Until 1992, Cuba steadily occupied the third place, where its production fell sharply since the beginning of the 1990s due to the termination of the existence of the USSR.

Notes (edit)

Links

- FAO production figures

Sugar is one of the most important components of life. With him, people make tea or coffee, prepare various dishes: cakes, pies, cookies and much more. Sugar is made from sugar cane, which grows mainly in Cuba.

In addition to this plant, there is another way. Sugar beets provide the most valuable sugar in cooking, according to many chefs in the world. The production of this type of sugar is directly related to the cultivation of beets. There are countries that not only do an excellent job of this, but are also leaders in the production and export of beet sugar. Some countries practically do not do this at all, and some of them are very good at growing this plant. We represent 10 leading countries.

10. People's Republic of China - 8 million tons

China is generally one of the leaders in agriculture. It is in the last place in the ranking and grows eight million tons of sugar beets. Sugar is very much needed in China, as Chinese tea and sweets are especially popular in this country.

There are few sugar beet fields in China. This is not due to the fact that the population density in China is off scale, but to the fact that this country grows everything a little bit.

9.UK - 9.4 million tonnes

Sugar is grown quite well in England. As you know, in this country it rains very often (rain and heat are needed, at times).This is what sugar beets need to grow properly. For export, of course, not very much, if we talk about mass trade, but for our own citizens it is quite enough.

The state is not very big, and growing 9,400,000 tons is not bad at all, and agriculture is not particularly a priority there.

8. Egypt - 11 million tons

You can often find various vegetables from Egypt on supermarket shelves. Many people think that this country has a very hot climate and there is nothing to grow there. However, this is not the case. Egypt is one of those countries where agriculture can easily become more developed than in other states. For example, Egyptian potatoes can often be found in supermarkets in Russia. The Egyptians grow eleven million tons of sugar beets, which are exported almost all of them.

7.Poland - 13.5 million tons

In Poland, as in many other European countries, many cultivated plants are grown. Usually Poland does not export beets, but finished products of its production. Polish sugar is rarely found on the shelves of Russian stores. Poland grows thirteen and a half million tons of sugar beets, which is quite impressive for a small European state.

6.Ukraine - about 16 million tons

Despite the tense political situation in the country, sugar beets are grown very well. The climate allows, there is enough territory, so that nothing prevents Ukrainians from growing and selling. The functionality of agriculture in Ukraine is very similar to that in Russia. Reached the sixth place in the ranking of world leaders. Most likely, Ukraine will leave the top five, as the state of agriculture, the economy as a whole, is greatly deteriorating.

5.Turkey - 16.8 million tons

The state produces goods related to almost all branches of production. Including, of course, sugar beets. Just like in Ukraine: a good climate, there is where to grow. They export mainly the beets themselves. Turkey has bypassed Ukraine as it grows almost seventeen million tons. The country is hot, and for growing large beets, just such climatic conditions are needed.

4. United States of America - 28.5 million tons

For a very long time, the United States has been involved in agriculture. Back in the days of cowboys, Americans cultivated many cultural goods. Endless corn plantations, wheat fields are shown in films shot in the studios of this country. A little later, America began to grow sugar beets, and the success of this business remains the same. This is done here by both corporations and the most ordinary farmers - amateurs. 28 and a half million tons of beets. The United States is still in fourth place in the ranking.

3. Germany - 30 million tons

In third place is Germany, which has long been famous for its work and its high-quality results. In recent years, the Germans have grown a fairly significant amount of sugar beets, both for themselves and for sale to other countries. Both beets and sugar, including refined sugar, are exported.

Germany, in addition to growing beets, is similarly engaged in other cultivated plants. Also, Germany has a large number of equipment, which greatly helps both sowing and harvesting. Also, many people often notice that German citizens are not only good at work, but also like to work.

2. Russian Federation - 33.5 million tons

Our country took second place, since both the climate and the presence of a large amount of territory allow us to do this. Sugar beets grown in Russia are mainly exported, and about a third of the extracted beets are used for sugar production.

In this state, sugar beet does not enjoy the advantage, since at all times cereals were a priority here. Many people think that Russia is the world leader in sugar beet growing, but alas. The territory, of course, is large, including enough land favorable for beets.Almost no one can guess the country that took first place in this rating.

1. France - 38 million tons

The leader in the cultivation of sugar beets in the world. It may seem surprising, but France, in fact, specializes in this. The warm climate and the presence of endless fields make it possible to take first place. This applies primarily to the province Champagne... This province is the southernmost in France, where a variety of crops are grown, such as grapes for the production of the famous French wines. The French grows the most sugar beet, its amount is about 38 million tons.

Since the beginning of 1900, sugar production in the world has increased more than tenfold and currently stands at about 130 million tons.

Currently, sugar is produced in 127 countries of the world: 79 from sugarcane, 38 from beets only and 10 from beets and sugarcane.

Currently, there are 1,613 sugar cane, 890 beet sugar and 139 refineries in the world. Of this amount, in South Africa - 38 canes and 36 beets, in Central America - 228 canes, in North America - 38 canes and 36 beets, in Asia - 872 canes and 102 beets.

If at the beginning of the XX century. more than half of the amount of sugar was produced from beets, then at the beginning of the XXI century. the share of sugar from sugar beet is only about 30%. Most of all it is produced in Europe (about 37 million tons), less in North America (Canada, USA), Asia (China, Iran, Japan, Kazakhstan, India, Pakistan, Syria, Kyrgyzstan) and very little in Africa (Egypt , Morocco, Tunisia) and South America (Chile).

In the European Community, France and Germany are the largest sugar beet producers, producing more than half of the EU's sugar. These countries have a high sugar harvest per hectare (about 10 tons), which is about four times higher than in the Russian Federation. An increase in this indicator for the agro-industrial complex of the Russian Federation is the most important problem, the solution of which will significantly increase the efficiency of sugar production in the Russian Federation.

The dynamics of world sugar production over the past 40 years, starting from 1961, shows that during this period, sugar production in the world has more than doubled. The increase in world sugar production during the period under review was mainly due to the faster growth rates of sugar production from cane. This is evidenced by the data on changes in the share of beet sugar in the total volume of its production. So, if in 1961 the share of beet sugar in the total production volume was about 42%, then in 2000 it dropped to 30%.

Analysis of the data shows that sugar cane production has played an increasingly important role in global sugar production over the past 40 years. At the same time, the production of sugar from beets has been steadily declining over the past 50 years and has generally declined by about 15%. Only in the period 1955 ... 1960. the production of beets has slightly increased, while the maximum increase in the production of sugar from cane refers to 1900 ... 1995, when it was 6.0%.

Sugar production in the period 1990 ... 2000, as follows from the published table. 1, was annually 3.6 ... 7.8 million tons higher than its consumption.

Due to the excess of production in comparison with its consumption, there is a constant increase in the world supply of sugar (unsold sugar), which, in turn, leads to a decrease in its price.

The use of sugar as a raw material for other industries in the world is still very insignificant. Only in Brazil and Thailand for the production of alcohol is used 1/3 ... 1/2 of the amount of sugar cane grown in these countries - several tens of millions of tons. France and Germany process only 20 thousand tons of sugar beet for alcohol.

Dynamics of production and consumption of sugar in the last 10 years of the XX century.in individual regions for various reasons, as follows from the data in Table. 1 changed significantly.

Almost two-fold decline in sugar production in 1990 ... 2000 in Eastern Europe is associated with well-known political and economic factors that occurred in the countries of the former Eastern Europe. On the contrary, in South America, Asia and Africa, ie in the regions growing sugar cane, sugar production and consumption increased, which, in turn, contributed to the increase in the share of cane sugar in total production in the world.

According to the forecasts of the International Association of Breeders, the main increase in the production of all food products, including sugar, will come from higher yields, as in the near future the amount of land used for agricultural production will stabilize.

Compared to production, global sugar consumption is much more stable. So, for the period 1993 ... 1997. the world average per capita consumption changed from 20.4 to 20.9 kg per year. In the long term, according to forecasts, it is expected to grow by about 2 ... 2.5 kg per year, that is, in parallel with the growth of the population. In individual countries or regions, due to their characteristics, the amount of sugar consumption is quite different. This is evidenced by the data in table. 2.

Increases in sugar consumption in recent years have occurred in South America, Africa, Asia, Oceania and Australia. In Europe, on the contrary, there is a downward trend in consumption.

World sugar production and trade depends mainly on a number of countries: Brazil, USA, India, China and the EU. However, the relationship between sugar production and consumption in these countries differs significantly. For example, India produces about 14 million tons of sugar a year, China - about 9 million tons. All this amount of sugar is consumed in these countries. China in recent years, due to high population growth, covers the needs of sugar both by importing it and by synthetic sweeteners, mainly saccharin.

Brazil has a significant surplus of sugar, in which about 345 million tons of sugar cane is grown on an area of 4.4 million hectares, from which about 34 million tons of sugar are produced. Of this amount, about 40% is used for the production of alcohol, produced in the amount of 140 million m3. Of the remaining amount of sugar (~ 20 million tons), ~ 9.2 million tons is used for domestic consumption, and the remaining sugar in the amount of more than 9 million tons is for sale on the world market.

Brazil regulates the ratio between the amount of sugar consumed in the country, intended for export and for the production of alcohol, depending on the economic situation in the country, prices for sugar, oil, etc.

The relationship between the processing of sugar cane for sugar and alcohol is shown in table. 3.

Besides Brazil, Australia, Thailand, Cuba and South America are important global sugar exporters.

Into the EU, raw sugar imported from the overseas departments of France and Portugal is refined and then exported.

The main importers in recent years have been Russia and Ukraine.

The analysis shows that the increase in the share of cane sugar in the total volume of production in the world in the last decade is mainly due to the increase in acreage and, as a result, a larger harvest of sugar cane and, accordingly, the amount of sugar produced.

If the area of sugar cane cultivation over the past 10 years has increased by about 1.5 million hectares, then the area of sugar beet cultivation has decreased by about 2.3 million hectares.

However, despite a significant decrease in the area of cultivation of sugar beet, its harvest in 2000 was about 30 million tons more than in 1991, the latter is associated with a higher harvest of it - about 7 t / ha more than in 1991.

The upward trend in yields has recently been characteristic of both sugar beet and sugar cane.However, for sugar beet it is more pronounced, especially in the EU, where the yield of sugar beet differs significantly less from the average world yield of sugar cane.

The efficiency of the cultivation of both sugar beet and sugar cane depends on many factors: climatic conditions, agrotechnical measures, etc.

The above is confirmed by data on the cultivation of beets in the ten largest producing countries (Table 4) and sugar cane (Table 5).

The given data show that in the world production of sugar beet the first three places are occupied by France, the USA and Germany. Of these, in terms of yield, only France is among the ten countries that produce beets, ranking second. At the same time, the difference between the yield of beets in France and in Denmark is about 16 tons, which is quite a significant value.

The yield of sugar cane, as follows from the data table. 5, ten comparable cane sugar producing countries are significantly higher than ten beet and beet sugar producing countries.

If we compare the yield of beets in France with the yield of sugar cane in Brazil, that is, in the countries occupying the first places in the production of beets and cane, then in 2000 the beet yield in France was higher (72.56 t / ha), than cane in Brazil (67.47 t / ha).

In general, sugar cane gives a 20 ... 25% higher yield and, accordingly, a large amount of sugar obtained from it. This is primarily due to the fact that it is grown in areas with more favorable climatic conditions - with a lot of solar energy and precipitation.

It is known that the component of climatic facts in the size of the yield of both sugar beet and sugar cane is 15 ... 20%, and in extreme cases, more than 30%.

The given data on the yield of sugar cane and sugar beet in different countries differ significantly, which is primarily due to different climatic conditions and a number of other factors. It is therefore difficult to obtain reliable comparative data on the economics of these crops.

One of the main explanations for the increase in the share of cane sugar production in total production is usually considered to be the lower overall costs of its production.

Approximate data on the costs of growing sugar cane and beets, their processing in five regions of cane and four sugar beet production in 1999 are given in table. 6.

From those given in table. 6 of the data, which, as noted, are more informative in nature, it follows that the costs of growing sugar cane and the production of sugar from it, in comparison with sugar beets, are not so different as it is often believed. On average, this difference for cane sugar is about 20% less than for beet sugar.

In addition to the problem under consideration are given in table. 7 indicators of sugar cane and sugar beet processing in the countries considered above in 1999

From the data table. 7 it follows that the sugar content of sugar cane is lower than that of sugar beet. This explains the fact that in spite of the larger yield of sugar cane per hectare, the collection of sugar per hectare during the cultivation of these crops is not very different. The average amount of sugar harvest from 1 ha in the world from sugar cane and sugar beet is practically the same and amounts to ~ 6.0 tons per 1 ha.

Due to the fact that the production costs of beet sugar are about 30% higher than cane sugar, the latter will remain cheaper for the time being than beet sugar.

According to experts' forecasts, the competitive pressure from cane sugar will affect to a lesser extent in the future.At the same time, they proceed, first of all, from an increase in the production of beet sugar in Europe, mainly in Eastern European countries.

Currently, Europe is the main producer of beet sugar, producing about 80% of the world's beet sugar - in 2000, 29.3 million tons, which was 81% of the world production.

Of the total amount of beet sugar produced in Europe, about 50% falls on the EU (19.3 million tons), 20% - in the countries of Eastern Europe (7.2 million tons of sugar in 2000).

The increase in sugar production in Russia, Ukraine, Bulgaria, Romania and the satisfaction of demand at the expense of their own beet sugar would force to reduce the production of cane sugar accordingly.

The issue of sugar production in China, which after the EU is the largest sugar producer and consumer, is also unclear. China produces about 5.5 million tons of sugar from sugar cane and about 2.0 million tons from sugar beets. China's need for sugar is 9 million tons, so it is forced to import about 1.5 million tons of sugar per year. The question of what kind of sugar in the future will cover this shortfall - produced in the country from beets or cane, or through imports, remains unclear.

Based on the comparison of biological and technological parameters of sugar beet, experts believe that in the future, sugar beet both in the world and in Europe has a good perspective.

The advantage of sugar beet over sugar cane is a shorter growing season and its important role in the structure of agriculture in terms of crop rotation. Frequent crop changes in the area of sugar beet growing versus planting sugar cane for a number of years is less associated with the risk of increased pests, disease and less soil depletion.

Getting seeds and forming an array of cultivated crops in sugar beets is easier than when propagating sugar cane by cuttings. The advantage of sugar beet is the possibility of its storage for a much longer time in comparison with harvested sugar cane, which can be stored for up to 48 hours, since then there is a sharp deterioration in the quality of its juice.

An important factor in the import of raw cane sugar to European countries is the cost of its transportation.

Sugar beet is a highly productive agricultural crop that is a raw material for the industrial production of sugar and other products.

Introduction.

3000 BC NS. in the territory of modern India, a perennial herb of the genus Saccharum has already been cultivated. The locals called the sweet crystals obtained from sugarcane juice "sakkara", from "sarkar", which literally means "gravel, pebbles, sand" in one of the ancient local languages. The root of this word and entered many languages and is clearly associated with sugar: in Greek, sugar is saccharon, in Latin saccharum, in Arabic sukkar, in Italian zucchero ... And so on down to the Russian "sugar".

Sugar (sucrose) is a sweet crystalline substance isolated mainly from the juice of sugar cane or sugar beet. In its pure (refined) form, sugar is white, and its crystals are colorless. The brownish color of many of its varieties is due to the admixture of various amounts of molasses - condensed plant sap that envelops crystals. Sugar is a high-calorie food; its energy value is approx. 400 kcal per 100 g. It is easily digested and easily absorbed by the body, i.e. it is a fairly concentrated and quickly mobilized source of energy. Sugar is an important ingredient in various foods, drinks, bakery and pastries. It is added to tea, coffee, cocoa; it is the main component of sweets, glazes, creams and ice creams.Sugar is used in meat canning, leather dressing and in the tobacco industry. It serves as a preservative in jams, jellies and other fruit products. Sugar is also important for the chemical industry. It produces thousands of derivatives used in a wide variety of industries, including plastics, pharmaceuticals, effervescent drinks and frozen foods.

The history of sugar.

The production of sugar for human consumption goes back centuries.

The initial raw material for sugar production was sugar cane, which is considered to be its homeland in India. Warriors of Alexander the Great, participating in the campaign to India in the IV century. BC, the first Europeans to get acquainted with this plant. Upon their return from India, they enthusiastically talked about the cane, from which you can get honey without the help of bees, and use the fermented drink as a strong wine. Sugar cane gradually spreads from India to neighboring countries with warm climates.

Ancient manuscripts contain information about the cultivation of sugar cane in China in the 2nd century. BC, and in the 1st century. BC. sugarcane has already begun to be grown in Java, Sumatra and other islands in Indonesia. The cultivation of cane and the production of sugar from it in Arabia is mentioned by the Roman scientist Pliny, the elder in the 1st century. AD The Arabs brought the culture of growing and processing sugar cane during the conquest of Palestine, Syria, Mesopotamia, Egypt, Spain, Sicily in the 7th-9th centuries, and in the 9th century. Venice began to trade in sugar from cane.

The Crusades contributed to the spread of the use of sugar cane for sugar production in European countries, including in Kievan Rus.

The Venetians, the first of the Europeans, learned how to make refined sugar from raw cane sugar. But for a very long time, until the beginning of the 18th century. sugar remained a rarity on the tables of Europeans. Portugal played an important role in the spread of sugar cane and the production of sugar from it. In the XV century. the Portuguese planted sugarcane on the islands of Madeira and Sao Tome in the Atlantic Ocean, and after the discovery of America by Columbus, large plantations appeared on the islands of Haiti, Cuba, Jamaica, and then in Mexico, Brazil, and Peru. The trendsetters in sugar production in the 17th century. became Holland. She intensively began to plant sugar cane plantations in her colonies, and also significantly expanded the production of sugar in Java. At the same time, the first sugar factories began to be built in the city of Amsterdam. A little later, similar factories appear in England, Germany, and France. The history of the sugar industry in Russia begins in 1719 with the construction of the first sugar factories in St. Petersburg and Moscow.

In Russia, for the manufacture of sweet syrups, drinks and tinctures, not sugar cane was used, but dried or dried roots of beets, rutabagas, turnips. Beets have been cultivated since ancient times. In ancient Assyria and Babylon, beets were grown as early as 1,500 BC. Cultivated forms of beets have been known in the Middle East since the 8th-6th centuries. BC. And in Egypt, beets served as the main food for slaves. So, from wild forms of beets, thanks to appropriate selection, varieties of fodder, table and white beets were gradually created. The first varieties of sugar beet were developed from white varieties of table beet.

Historians of science associate the emergence of a new alternative to cane, sucrose, with the epoch-making discovery of the German scientist-chemist, a member of the Prussian Academy of Sciences A.S. Marggraf (1705-1782). In a report at a meeting of the Berlin Academy of Sciences in 1747, he outlined the results of experiments on obtaining crystalline sugar from beets. The resulting sugar, according to Marggraf, was not inferior to cane sugar in its taste. However, Marggraf did not see broad prospects for the practical application of his discovery. Further in the study and study of this discovery went a student of Marggraf - F.K.Ahard (1753-1821). Since 1784, he has actively taken up the improvement, further development and implementation of the discovery of his teacher in practice.

Akhard understood perfectly well that one of the most important conditions for the success of a new, very promising business is the improvement of raw materials - beets, i.e. increasing its sugar content. Already in 1799, Akhard's works were crowned with success. A new branch of cultivated beet appeared - sugar beet. In 1801, on his estate in Kuzern (Silesia), Achard built one of the first sugar factories in Europe, where he mastered the production of sugar from beets. A commission sent by the Paris Academy of Sciences conducted a survey of the Akhardov plant and concluded that the production of sugar from beets was unprofitable.

Only the only British industrialists at that time, who were monopolists in the production and sale of cane sugar, saw sugar beet as a serious competitor and several times offered Achard large sums on the condition that he refuses to carry out his work and publicly declares the futility of sugar production from beets. ...

But Akhard, who firmly believed in the prospects of the new sugar plant, did not compromise. Since 1806, France abandoned the production of sugar from cane and switched to sugar beet, which over time became more widespread. Napoleon gave great support to those who showed a desire to grow beets and produce sugar from them, because saw in the development of a new industry the possibility of the simultaneous development of agriculture and industry.

It should be noted that in France, along with the development of sugar production from beets, great attention was paid to improving the quality of beets as a raw material for the sugar industry.

This was facilitated by the successful activity of one of the first large seed-breeding firms in Europe, Vilmorin-Andrieu, founded by F.V. Vilmorin. The company has gained worldwide fame and has been successfully operating for about two hundred years, supplying seeds of various agricultural crops of its own selection to many countries of the world.

HISTORY OF DEVELOPMENT OF SUGAR PRODUCTION IN RUSSIA AND UKRAINE.

The first mention in historical documents of the appearance in ancient Russia of crystalline sugar imported "with overseas goods" appeared in 1273, but for the population it was still an inaccessible product for a long time. Sugar began to enter the markets of Russia and Ukraine more widely, starting from the 17th century, through the ports of the Black and Baltic Seas from different colonial countries. At first, sugar was a gourmet food and was used as an expensive medicine. But over time, the amount of sugar consumed has expanded. At the beginning of the 18th century. with the advent of exotic beverages such as tea and coffee, sugar consumption has increased significantly. The introduction of duties on the import of sugar forced Russian merchants to look at the sugar trade in a new way. Many of them began to understand that it is much more profitable to establish their own sugar production based on imported raw sugar. In 1718, the first government document appeared on the organization of sugar production in Russia. It was the Decree of Peter the Great that "the Moscow merchant Pavel Vestov should start a sugar factory in Moscow with his own cat", i.e. at his own expense, while he received privileges for 10 years and the right to import raw sugar, as well as "in Moscow to cook head sugar from it and sell it duty-free for three years."

“Peter gave a ten-year privilege to the Moscow merchant Vestov in March 1718 to set up a sugar factory, with the right to establish a company and recruit whoever he wants to join it. He was given a privilege for three years to bring raw sugar from abroad duty-free and to trade his sugar in his heads duty-free.In addition, a promise was given: if the plant multiplies, then completely ban the import of sugar from abroad. Indeed, on April 20, 1721, the import of sugar from abroad was completely prohibited. "

In 1723 Pavel Vestov completed the construction of sugar refineries in Moscow and Kaluga. The demand for sugar continued to increase and this prompted sugar refineries to increase its production from imported raw materials. New sugar factories appear. Among the largest of them, at that time, was the Moscow plant of Vladimirov. By the end of the 18th century. in Russia, 20 factories were built and put into production, operating on imported raw sugar. Interest in sugar production has increased every year. Many scientists of that time were worried about the question of what local raw materials could be used to obtain sugar. The search went in different directions. In the book of the academician of the St. Petersburg Academy of Sciences P.S. Pallas "Description of the plants of the Russian state with their image" it was for the first time indicated that from "maple juice ..., from beets ... and so on. Indian sugar cane ”. In 1786, an attempt was made to "cook sugar" from the "reeds of the Caspian Sea", i.e. from sugar sorghum. The year 1799 was marked by the fact that almost simultaneously the teacher of Moscow University I.Ya. Bindheim and the academician

Petersburg Academy of Sciences T.E. Lovitz obtained sugar from beets. At the same time, the center of sugar beet production is beginning to shift to Ukraine, where there was more fertile land suitable for growing sugar beet soils, a milder climate and a sufficient labor force.

An outstanding Ukrainian scientist-economist, academician of the All-Ukrainian Academy of Sciences K.G. Vobliy established that the first sugar factory in Ukraine was built in 1824 in the village of Makoshin, Chernihiv province, Sosnitsk district.

It should be noted that the authorities fully contributed to the development of beet growing and the sugar industry on the fertile Ukrainian lands. The construction of the first sugar factories and the excellent prospects that sugar production promised, caused a real boom among the first sugar refineries.

The most popular topic, which was discussed with interest at balls and in the foyers of theaters, in salons and at noble meetings, was sugar production.

In the 30-50s of the XIX century. the number of sugar refineries has increased significantly. In many periodicals, sugar beet production was widely promoted as the most effective way to increase the profitability of agriculture.

The fact is that the average sugar factory by the standards of that time in the 50s of the XIX century. annually gave up to 20% profit on the capital invested in the company (fixed and circulating). This high profitability has led to the rapid growth of the sugar industry.

But there comes a time for everything. For many reasons, which primarily include raw materials (small areas of landowners' land allotted for beets, low yield and sugar content), technical and technological, the boom began to slowly subside. Pink dreams didn’t come true. Small primitive sugar factories, instead of the expected profits, began to bring only losses. The number of factories began to decline dramatically. In 1887, the number of sugar factories decreased to 218 against 380, which operated at the end of the pre-reform period.

The first crisis in the sugar industry began.

It is difficult to say how long this crisis would have lasted if Count Alexei Alekseevich Bobrinsky had not taken up the revival of the sugar industry

Sources of sugar.

Several hundred different sugars are known in nature. Each green plant forms certain substances belonging to this group. In the process of photosynthesis from the carbon dioxide of the atmosphere and water obtained mainly from the soil, glucose is first formed under the influence of solar energy, and then it is converted into other sugars.In addition to cane and beet sugar, some other products are used as sweeteners in various parts of the world, such as corn syrup, maple syrup, honey, sorghum, palm and malt sugar. Corn syrup is a highly viscous, almost colorless liquid obtained directly from cornstarch. The Aztecs who consumed this sweet syrup made it from corn in much the same way as sugar is made from cane today. Molasses is significantly inferior to refined sugar in sweetness, however, it makes it possible to regulate the crystallization process in the manufacture of sweets and is much cheaper than sugar, therefore it is widely used in confectionery. Honey, which is high in fructose and glucose, is more expensive than sugar and is added to some foods only when you need to give them a special taste. The same is the case with maple syrup, which is prized primarily for its specific flavor. Sugar syrup is obtained from the stalks of grain sorghum, which has been used in China since ancient times. Sugar from it, however, has never been refined so well that it could compete successfully with beet or cane sugar. India is practically the only country where palm sugar is obtained on a commercial scale, but this country produces much more cane sugar. In Japan, malt sugar made from starchy rice or millet has been used as a sweet additive for over 2000 years. This substance (maltose) can also be obtained from ordinary starch with the help of yeast. It is much inferior to sucrose in sweetness, but it is used in the manufacture of bakery products and various types of baby food. Prehistoric man satisfied his need for sugar with honey and fruits. Some flowers, the nectar of which contains a small amount of sucrose, probably served the same purpose. In India, more than 4000 years ago, a kind of raw sugar was mined from the flowers of the Madhuca tree. The Africans in the Cape Colony used the species Melianthus major for this, and the Boers in South Africa used Protea cynaroides. In the Bible honey is mentioned quite often, and "sweet cane" only twice, from which we can conclude that honey was the main sweetener in biblical times; this, incidentally, is confirmed by historical evidence, according to which in the Middle East, sugar cane

began to grow in the first centuries of our era. For a not too sophisticated taste, refined cane and beet sugar are practically indistinguishable. Another thing is raw sugar, an intermediate product of production, containing an admixture of vegetable juice. Here the difference is very noticeable: raw cane sugar is quite suitable for consumption (if, of course, it is obtained in adequate sanitary conditions), while beet sugar tastes unpleasant. Molasses also differs in taste (molasses) - an important by-product of sugar production: cane is readily eaten in England, and beet is not suitable for food.

Production.

If the refining of beet sugar is carried out directly at beet sugar factories, then the refining of cane sugar, in which only 96-97% of sucrose, requires special refineries, where impurities are separated from the raw sugar crystals: ash, water and components, united by the general concept of “non-sugar ". The latter include scraps of plant fibers, wax covering the cane stalk, protein, small amounts of cellulose, salts and fats. Only due to the huge scale

m of production of refined cane and beet sugar, this product is so cheap today.

The subtleties of production.

In the old days, taking advantage of the cheapness of slave labor, the planters did not consider it necessary to mechanize labor in sugar factories. And the juice from the crushed reed chips was squeezed out by hand - it was hard labor.Now the labor of slaves was taken over by machines in which the reed is wrung out like in a washing machine - linen. The pomace is used for fuel, although it is strange to imagine that something needs to be heated in tropical countries. And the sweet juice is heated and impurities are removed. Thus, pure sugar juice flows out of the unit. It is carefully evaporated for a long time until the liquid reaches the required density, and the crystallization process is started. It can take place in three stages, due to which we have sugar of different colors and textures.

Consumption.

According to statistics, consumption of refined sugar in the country is directly proportional to per capita income. The leaders here include, for example, Australia, Ireland and Denmark, where more than 45 kg of refined sugar per person per year, while in China - only 6.1 kg. In many tropical countries where sugarcane is grown, this figure is significantly lower than in the United States (41.3 kg), but people there have the opportunity to consume sucrose in a different form, not in pure form, usually in fruits and sugary drinks.

CANE SUGAR.

Sugarcane (Saccharum officinarum), a perennial very tall herbaceous species of the cereal family, is cultivated in tropical and subtropical regions for the sucrose it contains, as well as some sugar by-products. The plant resembles a bamboo: its cylindrical stems, often reaching a height of 6-7.3 m with a thickness of 1.5-8 cm, grow in bunches. Sugar is obtained from their juice. In the nodes of the stems, there are buds, or "eyes", which develop into short lateral shoots. Cuttings used for propagation of reeds are obtained from them. Seeds are formed in the apical panicle inflorescences. They are used to breed new varieties and only in exceptional cases as a seed. The plant requires a lot of sun, heat and water, as well as fertile soil. That is why sugarcane is cultivated only in areas with hot and humid climates. Under favorable conditions, it grows very quickly, its plantations before harvesting are like impenetrable jungle. In Louisiana (USA), sugar cane ripens in 6-7 months, in Cuba it takes a year for it, and in Hawaii - 1.5-2 years. To ensure the maximum sucrose content in the stems (10-17% of the mass), the crop is harvested as soon as the plant stops growing in height. If harvesting is carried out by hand (using long machete knives), the shoots are cut off at the very ground, after which the leaves are removed and the stems are cut into short pieces that are convenient for processing. Manual cleaning is used where labor is cheap or where the site does not allow for efficient use of the machines. On large plantations, the technique is usually used, pre-burning the lower layer of vegetation. The fire destroys the bulk of the weeds without damaging the sugar cane, and the mechanization of the process significantly reduces the cost of production.

The history of cane sugar.

Two regions dispute the right to be considered the homeland of sugar cane - the fertile valleys in the northeast of India and the Polynesian islands in the South Pacific. However, botanical research, ancient literary sources and etymological data speak in favor of India. Many woody wild plants found there

sugarcane varieties do not differ in their main characteristics from modern cultural forms. Sugarcane is mentioned in the Laws of Manu and other sacred books of the Hindus. The word "sugar" itself comes from the Sanskrit sarkara (gravel, sand or sugar); centuries later, this term entered the Arabic language as sukkar, in medieval Latin as succarum. From India, the sugarcane culture between 1800 and 1700 BC penetrated into China. This is evidenced by several Chinese sources, reporting that people who lived in the Ganges valley taught the Chinese people to obtain sugar by digesting its stalks.From China, ancient sailors probably brought it to the Philippines, Java and even Hawaii. When Spanish sailors appeared in the Pacific many centuries later, the feral sugarcane was already growing on many Pacific islands. Apparently, the first mention of sugar in ancient times dates back to the time of Alexander the Great's campaign in India. In 327 BC. one of his generals, Nearchus, reported: “They say that in India there is a reed that gives honey without the help of bees; as if it could also be used to make an intoxicating drink, although there are no fruits on this plant. " Five hundred years later, Galen, the chief medical authority of the ancient world, recommended the "sakcharon from India and Arabia" as a remedy for diseases of the stomach, intestines and kidneys. The Persians, too, although much later, adopted from the Hindus the habit of consuming sugar, and at the same time did a lot to improve the methods of its purification. Already in the 700s, Nestorian monks in the Euphrates Valley were successfully making white sugar, using ash to refine it. The Arabs, who spread from the 7th to the 9th centuries. their possessions in the Middle East, North Africa and Spain, brought sugarcane culture to the Mediterranean. A few centuries later, the crusaders who returned from the Holy Land introduced the whole of Western Europe to sugar. As a result of the collision of these two great expansions, Venice, which found itself at the crossroads of trade routes between the Muslim and Christian worlds, eventually became the center of the European sugar trade and remained so for over 500 years. At the beginning of the 15th century. Portuguese and Spanish sailors spread the sugarcane culture to the islands of the Atlantic Ocean. His plantations first appeared in Madeira, Azores and the Cape Verde Islands. In 1506, Pedro de Atienza ordered the planting of sugar cane in Santo Domingo (Haiti) - thus this culture penetrated the New World. In just 30 years after its appearance in the Caribbean, it has spread there so widely that it has become one of the main in the West Indies, which is now called the "sugar islands". The role of sugar produced here grew rapidly with the increasing demand for it in the Nordic countries, especially after the Turks conquered Constantinople in 1453 and the importance of the Eastern Mediterranean as a sugar supplier fell. With the spread of sugar cane in the West Indies and its penetration

crops to South America required more and more workers for its cultivation and processing. The natives who survived the invasion of the first conquerors turned out to be of little use for exploitation, and the planters found a way out in the import of slaves from Africa. In the end, sugar production became inextricably linked with the slave system and the bloody riots that it engendered that rocked the islands of the West Indies in the 18th and 19th centuries. In the beginning, sugarcane presses were driven by oxen or horses. Later, in places blown by trade winds, they were replaced by more efficient wind turbines. However, production as a whole was still rather primitive. After pressing the raw cane, the juice obtained was purified using lime, clay or ash, and then evaporated in copper or iron vats, under which a fire was made. Refining was reduced to dissolving crystals, boiling the mixture, and subsequent recrystallization. Even in our time, the remains of stone millstones and abandoned copper vats remind in the West Indies of the past owners of the islands, who made their fortunes in this lucrative industry. By the middle of the 17th century. the main sugar producers in the world are Santo Domingo and Brazil. On the territory of the modern United States, sugarcane first appeared in 1791 in Louisiana, where it was brought by the Jesuits from Santo Domingo. True, it was grown here in the beginning mainly in order to chew sweet stems.However, forty years later, two enterprising colonists, Antonio Mendes and Etienne de Bore, established his plantations on the site of what is now New Orleans, with the goal of producing refined sugar for sale. After de Boret's business was successful, other landowners followed suit, and sugarcane began to be cultivated throughout Louisiana. In the future, the main events in the history of cane sugar are reduced to important improvements in the technology of its cultivation, mechanical processing and final purification of the product.

Processing of sugar cane.

The cane is first crushed to facilitate further squeezing out of the juice. Then it goes to a three-roll squeeze press. Usually, the cane is wrung out twice, wetting it with water between the first and second times to dilute the sweet liquid in the pulp (this process is called maceration). The resulting so-called. "Diffusion juice" (usually gray or dark green in color) contains sucrose, glucose, gum, pectin, acids and all sorts of impurities. The methods of cleaning it have changed little over the centuries. Previously, juice was heated in large vats over an open fire, and

removing "non-sugars" added ash to it; nowadays, milk of lime is used to precipitate impurities. Where sugar is produced on a local basis, the juice is treated with sulfur dioxide (sulphurous gas) just before the lime is added to speed up bleaching and cleaning. The sugar turns out to be yellowish, i.e. not completely cleaned, but pleasant enough to taste. In both cases, after adding lime, the juice is poured into a clarifier and kept there at 110-116 ° C under pressure. The next important step in the production of raw sugar is evaporation. The juice is piped to the evaporators, where it is heated by steam flowing through a closed pipe system. When the concentration of dry matter reaches 40-50%, evaporation is continued in vacuum apparatus. The result is a mass of sugar crystals suspended in thick molasses, the so-called. massecuite. The massecuite is centrifuged, removing the molasses through the mesh walls of the centrifuge, in which only sucrose crystals remain. The purity of this raw sugar is 96-97%. The removed molasses (massecuite outflow) is boiled again, crystallized and centrifuged. The resulting second portion of raw sugar is somewhat less pure. Then another crystallization is carried out. The remaining effluent often still contains up to 50% sucrose, but it is no longer able to crystallize due to the large amount of impurities. This product ("black molasses") is used in the USA mainly for livestock feed. In some countries, for example in India, where the soil is in dire need of fertilizers, the flow of massecuite is simply plowed into the ground. Refining it briefly comes down to the following. First, the raw sugar is mixed with the sugar syrup to dissolve the remaining molasses that envelop the crystals. The resulting mixture (affinity massecuite) is centrifuged. The centrifuged crystals are washed with steam to give an almost white product. It is dissolved, turning into a thick syrup, lime and phosphoric acid are added there so that impurities float in the form of flakes, and then filtered through bone char (black granular material obtained from animal bones). The main task at this stage is complete discoloration and ash removal of the product. Refining 45 kg of dissolved raw sugar requires 4.5 to 27 kg of bone coal. The exact relationship is not established because the absorption capacity of the filter decreases with use. The resulting white mass is evaporated and, after crystallization, centrifuged, i.e. they treat it in about the same way as with sugarcane juice, after which the refined sugar is dried, removing the residues (about 1%) of water from it. Production.