Content

- 1 What mushrooms can be grown for sale at home and on an industrial scale all year round?

- 2 Choosing a room for growing mushrooms

- 3 Equipment required for growing mushrooms for sale

- 4 Mycelium: grow it yourself or buy it?

- 5 All conditions and methods for growing mushrooms indoors and on the site

- 6 Highly profitable mushroom growing business plan

- 7 Reviews

- 8 How to grow champignon mushrooms in the basement

- 9 Technology for growing mushrooms on an industrial scale

- 10 Indoor conditions for growing mushrooms

- 11 Composting mushrooms: pasteurization technology

- 12 Growing champignon mushrooms on shelves (with video)

- 13 Climatic equipment for growing mushrooms

Champignons grow naturally in open forest glades, meadows and open fields. This is one of the few mushrooms that can be cultivated under artificial conditions.

The main consumer qualities of champignons

These mushrooms contain a variety of useful elements necessary for the human body, namely hydrocarbons, fats, vitamins, mineral and nitrogenous substances, proteins, more than 20 types of amino acids. Also, the presence of compounds of iron, phosphorus, zinc and potassium has a positive effect on the body's immunity. The quantitative ratio of phosphorus in this mushroom species is comparable to that of seafood.

This kind of product recommended for people on diets... Despite the low calorie content and due to the high-quality composition of the mushroom, the body receives all the necessary proteins, fats, carbohydrates and vitamins.

For diabetics, champignons are one of the products that can be used in dietary nutrition due to the fact that it contains practically no sugar.

The positive effect of this product on the human body is achieved due to the presence of vitamin components, namely riboflavin (B2) and thiamine, which help prevent the development of migraines, and amino acids help relieve fatigue and improve the appearance of the human skin.

In dried form, this mushroom is recommended to be used for various diseases of the liver and gastrointestinal tract. Champignon also has excellent taste.

What is required to grow mushrooms as a business

When drawing up a business plan, one should take into account sanitary norms and rules, as well as be guided by the recommendations of the Ministry of Agriculture of the Russian Federation for the design of complexes for growing champignons.

Premises

To organize a mushroom business, initially decide on the volumes planned for cultivation for subsequent sale. For example, to receive from 2 to 3 tons of products, a room with an area of about 100 square meters is required.

There are several options:

- purchase of a land plot and construction of a new premises;

- purchase of premises already used for production purposes;

- rent of a suitable room.

It is rather difficult to say which of the options is preferable, since an important role is played by the region in which the decision was made to organize a business on the cultivation of champignons. Since the cost of land and buildings is determined based on the economic indicators of a particular region.

Pay attention to the state of the structure and the necessary financial investments in it; in some situations, building from scratch is cheaper than carrying out repair work. And rent can be beneficial to those who do not have significant funds at the initial stage.

Mycelium

The next item of expenses is the acquisition of soil with pores of mushrooms (mycelium). Do not look for dubious options, pay attention to companies that have been working in the field of selling this type of soil for more than one year and have positive feedback from customers who have used their services.

After all the preparatory work and planting the mycelium, you will see the first fruits of your labors in a month and a half, the next 2-3 months you need to take care of the mushrooms. Harvesting takes place in several stages (from 3 to 6) over several months. Basically, the most significant crops (about 70%) are harvested 2 and 3 times.

If you approach the cultivation of mushrooms as a business correctly, you can get profit after the first full harvest.

Fundamentals of the technology of growing these mushrooms

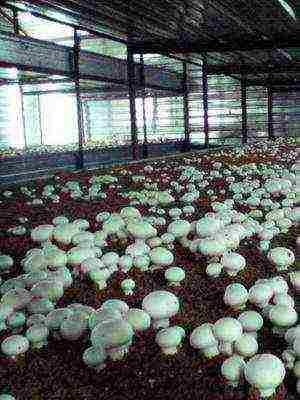

When growing mushrooms for personal consumption, you can use a low-cost technology - growing mushrooms in the beds. With this method, the entire process of leaving from planting to harvesting is carried out manually, so it is not suitable for running a business.

The main technological method used for growing large volumes, simplifying the process of caring for mushrooms, is based on growing mushrooms in bags or wooden boxes. This technology allows the most efficient use of the volume of the room and allows you to equip the room with automated control systems over the growing process.

Technologies for the production of mushrooms in bags, on racks, containers are intended for large producers and require significant financial investments, therefore, they are not always suitable for small farms.

For small farm premises, a container system is more suitable, when containers are arranged in 5 rows on moving racks, and the room is divided into several technological zones. Thus, the mushroom harvest increases up to 5 times during the year.

Conditions for growing mushrooms

At different stages of growth, mushrooms need to create different conditions of detention, namely:

- Watering is not required within a month after planting myceliums. It is necessary to maintain a constant humidity of about 90%. The temperature regime should be within 25 ° С - 27 ° С. Otherwise, the mycelium will die.

- After germination of myceliums, a layer of casing layer is laid and watered until wet (water should not collect on the surface and seep into the compost layer). This process is maintained throughout the entire fruiting period. In this case, the temperature regime should not be lower than 15 ° С and higher than 17 ° С. Air humidity is maintained at 80%.

At the fruiting stage, the air in the room must be cleaned of carbon dioxide. In this case, the ventilation system is adjusted in such a way that there is no air flow over the beds.

Basic requirements for premises

Failure to comply with the technological processes of growing mushrooms leads to loss of yield. Therefore, it is necessary to take into account all the requirements for the equipment of the premises. Consider a multi-zone system, since it is with it that many start their mushroom business.

The room should be divided into 4 zones:

- making compost;

- compost pasteurization;

- sowing and growing mycelium;

- growing the harvest of mushrooms.

If you intend to be engaged in mushroom production throughout the year, then your premises should be equipped with controlled heating, cooling, water supply and sewerage systems.

Indoor compost fermentation temperature regime should not fluctuate more than 12-16 ° C heat.The ventilation system must cope with the purification of the air space from ammonia vapors released during compost fermentation processes. For the production of 1 ton of compost, a room of 20 m² is required.

Separately from the rest of the zones, or better in a room with a separate entrance, a sealed chamber is installed for compost pasteurization. Often, such a camera is equipped independently, since the purchase of special equipment will cost an amount comparable to investing in a new small business.

In the zone for sowing and growing mycelium, the temperature regime is maintained at + 24-26 ° C, the air humidity should correspond to 95-100%. The presence of a powerful ventilation system is imperative.

Compliance with the rules for equipping the premises in the area for removing mushroom fruits does not differ from the premises for growing mycelium. The only nuance lies in the temperature, which must be maintained within + 14-16 ° C, and the humidity is 80%.

What mycelium to use and where to get it

There are two types of mycelium, grain and compost mycelium. Both types give good mushroom harvest, but grain is still better.

Entrepreneurs should start their mushroom growing business with the use of compost mycelium, since this species is more resistant to disturbances in storage, transportation and is not afraid of rodents, in contrast to the grain species.

When the technological processes are established and the entrepreneur acquires practical skills in the production of mushrooms, then you can proceed to the use of grain mycelium, which gives a more significant yield.

If you plan to make a profit solely from the sale of the finished product (mushrooms), then the creation of mycelium (mycelium) is irrelevant. This is a rather complex process that requires specialized equipment and experience. The mycelium can be purchased from farms or breeding centers focused on the production of mycelium.

Basic requirements for compost

The basis for the preparation of compost for growing mushrooms is horse manure. The value of this type of manure lies in its properties, such as:

- significant presence of nitrogen, phosphorus, potassium, calcium compounds in suitable proportions for growing mushrooms.

- horse manure refers to organic fertilizers containing trace elements such as copper, manganese, zinc, boron, nickel, etc.

Due to the obvious shortage of horse manure, it is replaced with cow manure. This manure has the distinctive ability of self-heating, thereby creating an environment for the reproduction of favorable microflora.

At present, the technology for preparing a mushroom substrate has been worked out both with the use of horse (cow) manure and without its participation. It all depends on the original components taken, and compliance with the following requirements for its composition:

- the presence of nutrients should correspond to the following percentages to the dry matter mass: 1.6-1.8% - nitrogen, 1.0% - phosphorus, 1.5% - potassium;

- the moisture content of the directly compostable mass must correspond to 70-72%, the temperature of the compost being prepared is maintained within 60-65 ° C.

During fermentation, the substrate is enriched with components that are necessary for the production of mushrooms. Special attention should be paid to nitrogen content of compost, since this is the basis for the passage of a qualitative process of substrate humus.

For the technological preparation of compost, the main thing is to observe the main three stages:

- thorough mixing and moistening of all components;

- fermentation of the substrate in containers;

- maintaining the thermal regime.

What documents and certificates will be required to issue

To run a business legally, you need to register your activity. In this case, it will be the production of crops and the sale (wholesale, retail) of food products without providing a permanent place of sale.

It will be required to obtain a certificate on the examination of premises for the state of the radiation background carried out by specialists of the phytosanitary service.

After harvesting, in order to sell it, you must contact the phytosanitary service. After analyzing the products for compliance with the norms for admitting the goods for sale, you will be given a quality certificate.

The quality certificate indicates its validity period. When submitting an application for obtaining a permit for the sale of products, indicate the timeframe planned for growing mushrooms before replacing the compost (the quality certificate is considered valid for the sale of mushroom products grown using one compost).

Realization of champignons

It is possible to sell the manufactured products independently on the food markets. This option is suitable for a small amount of cultivated mushrooms, it takes a lot of time.

Conclude contracts for the supply of products with shops, restaurants, hand over for sale. In this case, you need to take care of the delivery of the mushrooms to the destination.

Selling products in bulk, the price category will be an order of magnitude lower, but at the same time you will save time and will not be limited in sales volumes.

Estimated estimated profitability of a mushroom growing business

You can

DOWNLOAD

greenhouse business plan from our partners with a quality guarantee!

Consider the costs and benefits of a mushroom farm producing champignons based on one growing cycle of 2 months.

Costs

For the production of 30 tons of compost, it is necessary to purchase the appropriate components for the amount of 20,000 rubles. Mycelium will cost 10,000 rubles. The expenditure component for heating and pasteurization is 50,000 rubles. Payment of wages is about 60,000 rubles. Total 140,000 rubles.

Income

Thirty tons of compost raw materials gives 6 tons of finished products. On average, the cost of 1 kg of champignons is 100 rubles, respectively, for 6 tons you will receive approximately 600 thousand rubles.

Accordingly, the estimated profit will be 600 - 140 = 460.00 thousand rubles.

Do not forget about the initial costs for premises, equipment and other related expenses, therefore, when organizing a mushroom farming farm, expect to receive the first "net" profit no earlier than in a year and only if your business will work using the existing resources are maximally correct.

Above is the calculation for an average farm.

If you have the intentions and the appropriate conditions, then you can grow mushrooms in the country, in a greenhouse or in the basement of your house. Then the costs will be much lower and the profitability of the business can be increased. However, in this case, we can only talk about growing mushrooms at home, which is far from industrial scale.

Video: growing mushrooms on an industrial scale and the equipment used:

- A step-by-step plan for starting a mushroom growing business. Where to begin.

- "Pitfalls" in growing technology

- Harvesting subtleties

- Sales of products

- How much money do you need to start and how much you can earn on growing mushrooms

- What equipment to choose for growing mushrooms

- What OKVED to indicate when registering a business

- What documents are needed to open

- What taxation system to choose for business registration

- Do I need permission to open

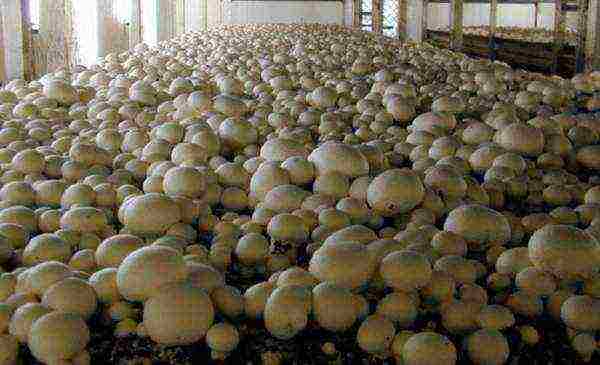

The cultivation of champignons is an interesting business in which many farmers are interested. This product is highly valued and is always in demand among the population. And how fast it grows. From one square meter, with strict adherence to technology, up to 20 kilograms of mushrooms are obtained! The mushroom business is superior in profitability to many agricultural activities.

A step-by-step plan for starting a mushroom growing business. Where to begin.

It is difficult to oversaturate the champignon market. According to some reports, an average city with a million inhabitants eats about 20 tons of mushrooms a month (2 tons for every 100 thousand people). It turns out that in the conditions of one city, at least two or three very large mushroom enterprises can easily get along. It should be noted that not every large city has such a production facility. As a rule, mushrooms are brought from neighboring regions.

"Pitfalls" in growing technology

For all the attractiveness of the business, mushroom business is by no means an easy task. The mountains of gold, which are promised to farmers by suppliers of equipment and mushroom mycelium, are mostly illusions. There are many examples of how budding farmers burned out on this business. There are too many nuances to consider in order to produce a mushroom. Allowed in something a little misfire - and there will be no harvest.

When growing mushrooms, a lot is important, from the microclimate to the harvest. In the mycelium, it is necessary to create conditions close to real ones. For example, champignons are watered by spraying, thereby imitating rain. If the water is simply spilled, the mushroom will not sprout. Indoor temperature and humidity are also extremely important. The optimum temperature for mushroom growth is 24 degrees with a casing moisture content of 75 - 80%.

Horse manure, wheat straw, lime and urea are most often used as a substrate for growing a mushroom. Some farmers do not come up with anything, but simply buy ready-made soil for growing flowers.

The big difficulty in growing mushrooms is getting mycelium. The same mother liquor from which mushrooms grow. Unfortunately, it is not possible to grow mushroom mycelium at home, only in laboratory conditions. A lot of conditions must be met in terms of sterility.

Naturally, the mycelium needs to be purchased on the side, from specialized companies. And here you need to be a good economist in order not to miscalculate with the calculations. For 1 square meter, approximately 1 kg of mycelium and 6 kg of compost are required. Buying mycelium will cost 200 rubles, and compost 50 - 100 rubles.

If everything is done according to Feng Shui, then no more than 4 weeks will pass from the moment of planting the mycelium to harvesting. It is possible to get up to 15 kilograms from one square meter in 2 - 4 months. For a year, a small farm of 100 square meters can produce up to 6 tons of mushrooms.

Harvesting subtleties

The main thing is correct harvesting - the mushroom needs to be twisted, and not pulled out and not cut with a knife. As a container, it is better to use containers with a capacity of 3 - 4 kg. The crop should be stored at a temperature of 0 - 4 grams. So the mushrooms can stay absolutely fresh for up to 12 days.

Sales of products

Champignons are in the greatest demand in the winter and spring seasons. But in summer and early autumn, demand drops sharply. The reason for this is the appearance of a forest mushroom, which, of course, tastes better than artificially grown products.

There may be problems with the implementation, any farmer will confirm this. The main buyers are food retail chains, which, alas, are reluctant to agree to cooperation, or demand an unbearable payment for the "shelf space". Another way of marketing is selling mushrooms to processors, cafes and restaurants, or wholesale resellers. A dedicated sales department is most likely indispensable.

How much money do you need to start and how much you can earn on growing mushrooms

Let's briefly calculate the main income and expenses for growing our mushrooms. I think this is the most interesting point for aspiring businessmen. We warn you in advance that the calculations are approximate and cannot accurately reflect the real picture of things. Because too many factors can affect the bottom line of profitability (cost of raw materials, heating, selling price, force majeure, etc.).

Input data:

- Sowing area - 1 chamber per 200 m2

- Property type - own heated premises

- The number of permanent employees is 4 people.

Estimated initial investment:

- Growing equipment (racks, boxes, watering) - 200,000 rubles.

- Installation of air conditioning and ventilation systems - 250,000 rubles.

- Lighting - 30,000 r.

- Refrigerating chambers - 100,000 rubles

- Purchase of mycelium and compost (per year) - 200,000 rubles.

- Other expenses - 50,000 rubles.

Total - 830,000 rubles.

Fixed monthly expenses:

- Utility bills - 12,000 rubles.

- Salary and insurance contributions - 100,000 rubles.

- Pesticides, film, paper - 15,000 rubles.

- Other expenses - 10,000 rubles.

Total for 12 months - 1,644,000 rubles.

Income:

- With a yield of 15 kg / m2 from 200 squares, we collect 36,000 kg of mushrooms per year.

- The wholesale selling price is 150 rubles / kg.

- Annual revenue - 5,400,000 rubles.

- Net profit for the year - 3,756,000 rubles. (excluding taxes)

As can be seen from the calculations, the investment pays off in fact from the first harvest. However, this is a very optimistic forecast that does not take into account possible crop losses (for example, due to errors in growing technology). Experienced farmers can get high yields, but beginners are not a fact. Another reason for monetary losses may be the banal lack of sales channels. This happens when the benchmark goes to several large buyers, and they, as a result, refuse to take the product.

In addition, we did not include the costs of furnishing the premises and its renovation in the initial investment. That is, we got the sown area ready-made. In practice, this happens very rarely. A novice farmer will most likely have to locate production either in a rented premises or build his own building, which will significantly increase the initial investment (up to 5-6 million rubles). In this case, the optimal payback can be considered 1.5 - 2 years with strict adherence to the technology of growing the mushroom.

What equipment to choose for growing mushrooms

To open a fairly profitable business related to the cultivation of mushrooms, first of all, you need to take care of the equipment that is required for this process. This may be a ready-made room that contains everything you need. If you do not have the opportunity to purchase an already equipped place, then the following equipment should be placed in it for growing mushrooms:

- air conditioning and ventilation system (for temperature regulation);

- refrigerating chambers (used for further cooling of products);

- steam generators and water heating boilers (to generate the required amount of thermal energy);

- lighting systems.

What OKVED to indicate when registering a business

To register production for growing champignons, you should indicate the OKVED code 01.13.6 - growing truffles and mushrooms.

What documents are needed to open

First of all, to create a mushroom growing business, you must have the following documents:

- IP registration certificate;

- personal passport details of the business owner;

- opening application;

- a document confirming the payment of the state duty.

What taxation system to choose for business registration

For those who consider mushroom growing as a profitable business, a taxation system that uses the unified agricultural tax (UST) is suitable.

Do I need permission to open

This type of activity is the most problematic, since to open it you need to have the following permissions:

- phytosanitary institution certificate;

- declaration of conformity to GOST;

- instructions for storage and transportation of products;

- a document confirming the passage of radiological control.

(

estimates, average:

out of 5)

Loading…

Related business ideas:

The vastness of Russia is rich in mushroom reserves, and access to them is free.But the same constant demand is enjoyed by mushrooms grown on "home" plantations. This is due to the deteriorating environment, because the cases of widespread poisoning by mushrooms collected in the forest are not decreasing. Meanwhile, mushroom growing is a highly profitable business. These are products that grow quickly, do not require special care, and are profitable all year round. In addition, the price of such mushrooms rises in winter. These are the factors that speak in favor of the mushroom business.

What mushrooms can be grown for sale at home and on an industrial scale all year round?

For year-round cultivation both at home and in industrial scale oyster mushrooms are most suitable. Entrepreneurs value them for unpretentiousness and a variety of growing methods.

Oyster mushrooms competitors in terms of breeding, winter mushrooms and ring mushrooms are.

Champignons are in second place. They are more capricious, but the substrate for them requires adherence to a complex technological process. Other types of mushrooms appear that are suitable for mushroom production. For example, shiitake.

Land owners cultivate mushroomsgrowing in the forest - white, boletus, boletus. In any case, to sell successfully mushrooms, you also need to arm yourself with information about the features of growing the selected type of mushrooms.

- Features of growing champignons in winter and summer

For year-round cultivation of champignons, any premises (a special greenhouse, an ordinary basement, a dugout), in which you can maintain an air temperature of at least +15 degrees and humidity within 70-80%. Lighting for growth these mushrooms are optional. The room should be damp and warm. For the soil, horse manure with the addition of urea is used. In the process of growing, boxes or racks are used. On the growth of mycelium it takes 14 days (a white bloom appears on the ground, which needs to be sprinkled and watered), its fruiting occurs in a month and lasts 2-3 months.

- Growing porcini mushrooms all year round

Industrial scale is not profitable for porcini mushroom. As a rule, this type of mushroom is cultivated by gardeners. This is explained peculiarities of growth these plants, their symbiosis with trees. In other words, the root system of the tree is capable of ensuring the growth of mycorrhiza. Therefore, for the cultivation of porcini mushrooms it is so important recreate environmentclose to natural conditions. For example, you can use a summer cottage where deciduous or coniferous trees grow. Young groves or 5-year-old plantings with oaks, pines, birches, spruces are also suitable.

- Features of growing oyster mushrooms in winter and summer

Oyster mushrooms are less whimsical. But at the same time they are the most highly productive mushrooms relative to their fellows. Technologies for their cultivation more than flexible... For example, intensive or year-round cultivation requires premises (during the growth stage, lighting will be required), compliance temperature regime and special humidity... With this option, mushrooms grow in bags filled with substrate (plant residues with mineral additives).

The extensive method can be applied in an open space. He will require minimum costs, since special equipment is not required in this case. Stumps or logs replace the substrate. They are filled with mycelium and placed on the site (in trenches, on plantations). The main thing is to follow soil moistureand nature will do the rest. Oyster mushrooms have up to four waves of fruiting from one mycelium, the growth of which will take at least 14 days.

See also: What business is the first to burn out in a crisis?

Choosing a room for growing mushrooms

The quality of grown mushrooms is influenced by the correct selection of premises... Places for champignons are recommended basement typewhere it is humid enough and not too hot.Therefore, a cellar or basement at home is ideal. You can also opt for damp buildings... If we are talking about a larger business, then special greenhouses are built on personal plots or rented (bought) for subsequent rebuilding premises old vegetable store, poultry house, cowshed and so on.

Wherever the mushroom production is located, you need take care of availability it has electricity, running water, and you may also need gas.

What are the main parameters of the premises?

- Sufficient humidity.

- Correct air intake - ventilation, but without drafts (if there is no opportunity for abundant ventilation, then air circulation is guaranteed by holes made at the base of the wall and by exhaust pipes).

- Adjustable heat supply (very important for year-round cultivation).

- Absence harmful microorganisms - mandatory disinfection before planting.

For example, if we are talking about a mushroom farm for growing champignons, then the choice of premises should be taken more seriously. First of all, it is determined square cultivation... Suppose that 20 tons of compost can be delivered to the farm at a time (this is exactly how much is placed in a truck), this amount will be enough for 200-220 m². This space is divided into six chambers for growing mushrooms. Each of them has two racks with several tiers. Their number depends on the height of the room.

In addition, the farm must have two corridors... One is narrow, in order to take out the harvested crop on trolleys, the second is wide (the width depends on the dimensions of the available equipment), for unloading and loading the soil into the chambers. You will also need additional rooms: a boiler room, two refrigerators (for storage and for cooling mushrooms after harvesting), a place for packaging products and other technical rooms (change house toilet, office). total area such a farm can be 1000-1400 m².

To grow oyster mushrooms all year round, you will also need several separate rooms.

- Inoculation site - this is a room where mushroom blocks (in bags) are formed from the prepared substrate, into which mycelium is sown.

- Incubationwhere the mushroom blocks will grow, that is, the mycelium will grow.

- Cultivation, in which the direct forcing of the fruiting body takes place, that is, where the mushrooms will grow. The largest room relative to the previous ones. Blocks in it are located in three versions: on multi-tiered racks, hung on hooks (in several tiers) or strung on rods.

- Roomwhere the substrate will be stored, and a separate place for its preparation.

The premises are not used for growing porcini mushrooms. This is usually a seasonal outdoor business. Therefore, here you will need a piece of land with growing trees of the appropriate species.

Equipment required for growing mushrooms for sale

Correct equipment selection ensures that all the necessary conditions for the growth of mushrooms are met, and, consequently, the profitability of the mushroom business.

What do you need to stock up on or what to equip the room with to ensure a high yield of mushrooms?

- First of all, you need a high-quality system. air conditioning and ventilation, which will allow you to regulate the temperature and humidity. Cooling functions will be performed by a refrigerating machine or air conditioners. The heating system will require water heating boilers.

- You can use automated climatic installation, and a separate one in each chamber. This is a very important nuance, since the conditions for the growth of mushrooms at different stages are different.

- Refrigerators necessary for the rapid cooling of mushrooms. Their volume is usually not too large, it depends on the volume of the harvested crop per hour.

- Refrigerating chambers will provide storage of all grown products for no more than 3 days.They are only filled to 50% to maintain air circulation.

- For cameras where mushrooms grow, you will need racks... Depending on the type of mushroom, you need to pick up boxes or bags.

- It is important to remember about packaging of finished products... These can be jars, plastic containers, bags, and more.

- If there is a production of mycelium, then you should get an autoclave, or purchase a special grain processing machine.

See also: Growing greens as a business - how to make money on growing greens?

Mycelium: grow it yourself or buy it?

Growing mycelium can be considered as one of the areas of mushroom business... However, those businessmen who specialize in mushroom growing and whose main income depends on successful implementation of this product, the process of breeding mycelium is considered meaningless. Firstly, this is a rather laborious task. Secondly, it requires professional skills. Thirdly, you will need additional equipment and premises. There may be other costs.

Usually mycelium is grown by amateur mushroom growers. They are passionate about their hobby, wanting to be sure master all stages mushroom business. Therefore, myceliums of those mushrooms are often grown that are rare species and whose purchase causes difficulties, as well as to exclude dependence on suppliers.

All conditions and methods of growing mushrooms indoors and on the site

There are two main ways to grow oyster mushrooms.

- Extensive

In this case, the role of the substrate is performed by wood trimming. The method is applicable both outdoors and indoors. However, in the first option, the stability of the crop usually depends on the weather, and in the second, the process takes place all year round. This technology is simple, affordable, low-cost. But you can get high yields only at the expense of large production areas.

A striking example of this technology is growing mushrooms on stumps. As stumps, cuttings of birch, oak, alder, poplar and other trees are suitable. Stumps up to 40 cm long and 25 cm in diameter are soaked in water for seven days. Then holes are made in them, filling them with mycelium. Then they are clogged with moss or sealed with duct tape. The mycelium grows for 2.5 months. At the same time, the temperature in the room where these stumps are located should not be higher than +20 (in the barn, basement). In addition, they need to be constantly watered.

After the period of growth of the mycelium has expired, the stumps are placed in an upright position on an area under a canopy. You can stack them on top of each other. In this case, the lower ones are buried more than half into the ground. Permanent shadow is a must. The main thing is to regularly water such a plantation.

- Intensive

According to this technology, oyster mushrooms are grown on a substrate - a special material consisting of sawdust of deciduous trees, sunflower husks, straw and so on. But there is one caveat - in natural conditions, oyster mushrooms do not grow on such soil, there is too much competition with mold fungi. Therefore, the substrate must undergo a thermal treatment in order to suppress further mold growth.

Mushrooms are grown indoors (basements, cellars, special farms).

The whole process is divided into specific stages.

- The substrate is being prepared... One of the ways is a 3-hour pasteurization of the substrate at 70-80 degrees.

- In a substrate cooled to 20 degrees mycelium is introduced... Layer by layer, alternating mycelium and substrate, workers must fill polyethylene bags (50x100). Then 12 holes are made on the sides of the bag, and the neck is sealed. The mycelium should make up 5% of the total mass of the substrate in the bag. The total weight of the bag is approximately 15 kg.

- This is followed by a period when the substrate overgrown with mycelium... Its duration will be from 14 to 18 days. Prepared bags are placed in a room with a temperature of 24 degrees and a humidity of 80-90%. Lighting and ventilation are not needed at this time.

- Mushroom growth carried out at a temperature of 12-16 degrees with lighting for about 14 hours a day, ventilation and humidity not lower than 70%. Oyster mushroom fruiting is a wave-like process. From the first wave, 70% of the harvest is collected, from the second - 25, from the third - 10%, and so on - in decreasing order. The time from sowing mycelium to harvest is 2.5 months.

The process of growing mushrooms is divided into the same stages as for oyster mushrooms. But it is carried out mostly in basements or in purpose built.

Another method of preparing the substrate

The ideal component for him is horse dung, but also used manure of cows, pigs, chicken manure, mixed with straw (wheat or rye).

100 kg of straw requires up to 50 kg of manure.

First, a three-day straw soaking... Then, layer by layer, manure and straw are laid out in a compost pile. When bookmarked, all layers are additionally moisturize and sprinkled with urea... Since fermentation is uneven, the composting process requires constant mix componentswhile adding alabaster. If the collar is located indoors, then the temperature in it should not be less than 12 degrees. The substrate usually takes 25 days to cook. First sign of his readiness - lack of ammonia smell.

Then the substrate is distributed in boxes or other containers. When it cools down to 20 degrees, into it mycelium is introduced... Depressions with a depth of 8 cm are made on the surface in a checkerboard pattern, which are filled with pieces of mycelium and covered with soil. Then the beds cover up with old newspapersto prevent drying out. The temperature for the growth of mycelium is 24 degrees, ventilation is used as needed. Mycelium development period - 14 days.

After the growth of the mycelium is performed gobbing - the beds are covered with cover soil (a mixture of turf soil and chalk). The temperature in the room at this stage and before the appearance of the first mushrooms should be no more than plus 20. Regular humidification cover layer and maintaining high air humidity. The fruiting period of mushrooms will be approximately two weeks, starting from the 27th day to the 40th from the moment of planting the mycelium.

Porcini mushrooms are grown according to the technology that is closest to natural conditions.

- In preparation seed use the following components: mushroom caps with a diameter of 15 cm - 20 pieces, potassium permanganate - 1 gram, refined sugar - 15 pieces. Everything is placed in a bucket, poured with rainwater, the hats are kneaded until smooth, the resulting solution is infused for no more than an hour. The main condition is that the seed is planted only under the tree near which the mushrooms were taken for its preparation.

- Around trees (60 cm from the trunk) soil layer is removed, their exposed roots are watered with seed (about 300 grams per 20 cm²). Then the roots are covered with soil and watered. In the future, crops require additional watering. Sowing time is September.

- The harvest is going in a year, approximately one bucket under each tree.

Read also: How to organize and promote a flower business - 5 secrets of a successful business

Highly profitable mushroom growing business plan

It is difficult to talk about the high profitability of porcini mushrooms. Their growth largely depends on weather conditions, and it is difficult to influence the weather, because the harvest is removed once a year... By the way, according to some reports, this may pass in two years. Therefore, we will consider the profitability of the business from growing mushrooms and oyster mushrooms.

What needs to be done to implement this type of activity?

- Rent (buy) premises with an area of 550 m², where separate areas will be provided for the preparation and pasteurization of compost, germination of mycelium and mushrooms.

- Equip premises with sewerage and water supply systems, as well as electricity.

- Purchase equipment: a small tractor, a straw and grain crusher, a steam boiler, an irrigation system, containers, racks, etc.

- Checkout permits.

- Dial service personnel: three workers, a manager, an accountant.

- To fix sales of products (through wholesale or retail stores, using your own website, open your own retail outlet).

Economic calculation of payback

The costs for starting a business will amount to 1,600,000 rubles, they will include:

- rent (purchase) of a land plot and construction of a building - 1,000,000 rubles,

- equipment - 500,000 rubles,

- registration,, fuels and lubricants and other expenses - 100,000 rubles.

Monthly expenses will be 200,000 rubles:

- wage - 150,000 rubles,

- communal payments - 30 thousand rubles.,

- - 5,000 rubles,

- transportation costs - 15,000 rubles.

The income part will look like this:

- a ton of compost seeded with mycelium costs 6,000 rubles;

- one ton makes it possible to collect 2 centners of the crop;

- the average wholesale cost of 1 kg of mushrooms is 70 rubles;

- income after the sale of the crop will be 14,000 rubles (200x 70);

- if over a period of three months to process 100 tons of compost, then the profit (after deducting costs) will increase to 200 000 rubles;

- the cycle is repeated 4 times in one year, therefore, the income will increase to 800 000 rubles;

- net annual profit after taxes is at least 750,000 rubles... The payback period for the project is two years.

Business plan for growing oyster mushrooms

- Given the fact that these mushrooms grow quickly and give several harvest waves from one sowing, to grow them at home, you will need premises the size of 300 m².

- In this case purchase costs mycelium, substrate, expenses for maintaining appropriate conditions and other costs amount to 300,000 rubles.

- After selling mushrooms, you can get income in 1,080,000 rubles.

- Less expenses net profit will be 780,000 rubles.

The plan includes only one complete growing cycle - this is a two-month period, and but clearly shows how high the profitability of the production of oyster mushrooms.

Reviews

Growing oyster mushrooms is described as a business that does not require a large start-up capital, but brings a lot of income - about 700 rubles profit from 1 m² for 1.5 months. Entrepreneurs claim that it is very easy to master... Oyster mushrooms are much easier to care for than champignons. According to reviews, the main advantages of the oyster mushroom growing business are the minimum investment, high profitability, opportunities to expand the business and turn it into family business.

Businessmen specializing in champignons argue that difficulties can arise only at first, at the time of setting up production. When the process is running and debugged, everything is simple, the main thing is have time to harvest... And although champignons are considered not as fruitful as oyster mushrooms, the demand for them is much greater.

As with some other mushrooms, it is possible to grow champignons in the basement, but you cannot do without a special substrate. True, only real mushroom pickers-fans dare to engage in independent breeding. And all because the industrial cultivation of mushrooms is set on such a grand scale that it fully meets consumer demand.

As with some other mushrooms, it is possible to grow champignons in the basement, but you cannot do without a special substrate. True, only real mushroom pickers-fans dare to engage in independent breeding. And all because the industrial cultivation of mushrooms is set on such a grand scale that it fully meets consumer demand.

How to grow champignon mushrooms in the basement

Growing mushrooms champignons (Agaricus bisporus) is possible exclusively using a special substrate called mushroom compost. It is almost impossible to make it yourself in a small estate. Therefore, you need to buy compost and casing layer from a nearby mushroom production or from specialized compost producers.

Before growing mushrooms in the basement, you need to buy compost "in bulk", seeded with mycelium, ready for incubation. You bring it to the estate and place it yourself in bags or on shelves.Then the mycelium assimilates the compost in the cultivation room. After that, you need to fill in the casing layer, wait until it is overgrown with mycelium and, finally, get mushrooms.

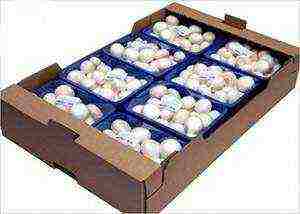

Currently, manufacturers of champignon compost offer it for sale in the form of compressed briquettes already seeded with mycelium. Briquettes measuring 20 x 40 x 60 cm are wrapped with plastic wrap. They can even be transported in a passenger car. Casing soil can also be purchased from the compost manufacturer (at the rate of 10 liters per briquette with compost).

Before you start growing champignon mushrooms in the basement, you need to measure the temperature in the brought compost briquettes. On the floor or on a shelf in the cellar, put the briquettes close to each other in the form of a bed 1.4 m wide. The temperature of all the briquettes will equalize within 24 hours. Then cut off the top film. You will get a bed 20 cm high.Cover the surface of the bed of blocks with kraft paper or newspapers. Moisten the paper using any sprayer at the rate of 0.2 liters of water per 1 m2 of the bed, preventing water from seeping into the compost. Duration of incubation is from 14 to 25 days. After the mycelium emerges on the surface of the compost (the appearance of individual spots of mycelium hyphae), it is time to apply the casing layer. The soil is applied in a layer of 4 cm (40 liters per 1 m2 of compost surface). It must be leveled and watered with water at the rate of 2 liters per 1 m2 of the ridge, spraying is necessary for the next three days. On the fourth day, mycelium usually grows into the casing layer to a depth of 0.5 cm.At this time, start regular watering twice a day with 1 liter of water per 1 m2 of casing layer. 12 days after the application of the casing layer, the mycelium penetrates the entire casing layer and reaches its surface.

The period of fruit formation begins. At this time, watering is stopped.

The air temperature should be + 14 ... + 17 ° С, relative air humidity - 85-95%. If these conditions for growing mushrooms in the basement are observed, on the 15-20th day, counting from the day the casing layer is applied, white "stars" from the mycelium should appear on its surface. A few days later - the rudiments (primordia) of mushrooms in the form of white peas. According to the technology of growing champignons in the basement, watering is resumed the next day after the appearance of the buds of peas "by mushrooms" at the rate of up to 1 l / m2.

When picking mushrooms, they should be pulled out of the ground, cut off the tip of the leg and carefully placed in boxes.

Now you know how to grow mushrooms on your own, it remains to equip the basement, and you can go for the substrate.

Watch the video of mushroom cultivation in a specially equipped basement to better understand the process technology:

The technology of growing mushrooms on an industrial scale

Cultivation of mushrooms on an industrial scale begins with the fermentation of the mushroom compost. Wheat straw mixed with farm animal manure is used as the basis for compost for these mushrooms. Attempts to replace straw with other ingredients have been unsuccessful. Manure can be horse, sheep, cow or pork, but more consistent results are obtained with dried broiler manure. For the necessary heating of the compost during its fermentation, the mass of the pile must be at least 7 tons.

The classic technology for growing mushrooms on an industrial scale is based on the fermentation of the compost mixture in long piles 1.8 m high and 2.0 m wide.

During the preliminary soaking of piled straw, the bulk of the irrigation water is discharged into the sewage system. For its reuse (circulating water), a container equipped with a pump is needed. Depending on the air temperature in the workshop and on the nitrogen content in the circulating water, the process of straw soaking takes up to 8 days.

According to the technology of industrial cultivation of champignons, for each ton of dry straw, a concrete area of 35 m2 is required for soaking in heaps, and a site of 30 m2 is required to form a pile. Three tons of "green" compost can be made from each ton of straw. For every 3 tons of finished compost, the composition of the ingredients for laying in the pile and the water consumption are as follows: wheat straw - 1000 kg, dry litter from chicken cages - 800 kg, gypsum - 60 kg, water 10,000 liters. From this amount, a pile weighing 7 tons will be obtained.

The piles are formed using wheeled technology or by hand, stacking layer-by-layer soaked straw, dry droppings and gypsum. The microbiological process of transformation of straw in a pile (fermentation) occurs at a temperature inside the pile of + 48 ... + 53 ° С. The optimum moisture content of the compost during fermentation is 68-75% at pH = 8-8.3 and in the presence of sufficient oxygen. Until the 20th day of fermentation, the pile is poured daily with circulating water and interrupted three times for aeration with air and mixing the ingredients. Fermentation of compost can be considered complete when the content of ammonium ions NH4 + in it falls below 0.6%.

Observing the correct technology for growing mushrooms in an industrial way, high quality compost is obtained only when using recycled water. Water from irrigation of straw and heaps is collected in a huge underground pit, in which a drainage pump is installed, which supplies water for irrigation. The water in the pit must be aerated around the clock. Oxygenation inhibits the growth of anaerobic bacteria and promotes the development of aerobic, compost-friendly bacteria. It is useless to try to aerate the circulating water by spraying it in the air. Only a powerful jet hitting the surface of the water will provide high-quality aeration of the circulating water. A separate drainage pump will help here, creating a pressure of 6 atm.

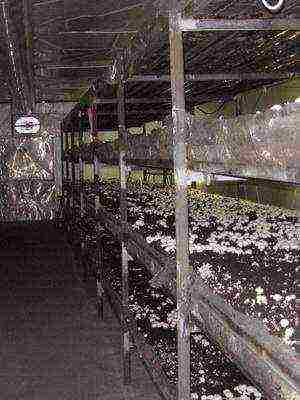

Indoor conditions for growing mushrooms

Premises for growing mushrooms on an industrial scale are special structures: bunkers and tunnels.

Premises for growing mushrooms on an industrial scale are special structures: bunkers and tunnels.

A more productive way of making "green" compost is its heat treatment and fermentation in bunkers. The bunker is a room with an aerated floor, fenced off by three walls. The fourth wall is absent, which allows loading and unloading compost using wheeled vehicles. The necessary conditions for growing champignons are supported by a high-pressure fan, which pumps air under a pressure of 5000 Pa into the system of pipes equipped with nozzles under the floor of the bunker, and this, in turn, is forced through the compost layer through the nozzles in the floor and aerates it. The diameter of the nozzles is 8 mm, the distance between the nozzles is 40 cm. For 60 tons of compost piled in a 4 m heap, a 40 m2 hopper is required. The compost in the bin does not have to be laid out evenly. There may even be a part of the floor that is not filled with compost, but the compost will still be aerated, because in the underground, even an empty bunker, the fan keeps the pressure not lower than 2500 Pa. To create optimal conditions for growing champignon mushrooms, better aeration of straw and compost heaps outside the hopper, aerated floors with nozzles are used. Under the required areas of the floor of the compost shop, an air underground room is built, into which a high-pressure fan blows air.

The composting process in the silo begins with soaking the straw. Then the compost (a mixture of straw, droppings and gypsum) on the aerated floor is poured with circulating water and stirred for 2 days. Then the compost is loaded into the hopper, where it heats up to + 80 ° C in two days. Unloaded, mixed and reloaded into the hopper for 3 days to warm up. Unloaded onto an aerated floor. The green compost is now ready and can be transported to the tunnel for pasteurization and conditioning.

Tunnel Is a narrow and long mushroom growing room where mushroom compost is prepared. Aerobic microorganisms play an important role in this process. The tunnel is designed so that thermophilic aerobic bacteria and actinomycetes develop in the "green" compost loaded there. For this, the floor of the tunnel is made perforated, and air is pumped into the underground space, which is passed through the compost, creating conditions for aerobic thermophilic bacteria and actinomycetes, which turn the "green" compost made in piles or in bunkers into "brown" ready for inoculation of the mushroom mycelium compost. For every 3-3.2 tons of "green" compost, 2 tons of "brown" are obtained.

Unlike a bunker, the tunnel must be filled with compost in an even layer so that there are no open spaces in the floor, through which air will escape from the underground, causing a drop in pressure there.

Composting mushrooms: pasteurization technology

To prepare compost for mushrooms, pasteurization and conditioning technology is used. The perforated floor of the tunnel, permeable to air, is made of reinforced concrete or oak beams perpendicular to the long side of the tunnel with intervals of 3-5 cm.A tunnel with a width of 3 m is considered standard.The section of oak beams is from 150 x 150 mm to 200 x 200 mm, reinforced concrete is determined their strength. The cross-section is either square or in the form of a trapezoid with a wide base up. In the latter case, there is less chance of clogging of the slots. The perforated floor is laid so that its surface is at ground level or at the level of the substrate shop floor.

To prepare compost for mushrooms, pasteurization and conditioning technology is used. The perforated floor of the tunnel, permeable to air, is made of reinforced concrete or oak beams perpendicular to the long side of the tunnel with intervals of 3-5 cm.A tunnel with a width of 3 m is considered standard.The section of oak beams is from 150 x 150 mm to 200 x 200 mm, reinforced concrete is determined their strength. The cross-section is either square or in the form of a trapezoid with a wide base up. In the latter case, there is less chance of clogging of the slots. The perforated floor is laid so that its surface is at ground level or at the level of the substrate shop floor.

According to the technology for making compost for mushrooms, before loading the substrate, a strong bedding polymer net is laid on the perforated floor, which is fixed to the floor. A sliding net is spread over the bedding area for drawing compost on it using an electric winch. The walk-through tunnels are loaded from a conveyor belt or bucket tractor and unloaded from the other side using a slip net. At a distance of 0.5 m from the gate, a type-setting wall is made of horizontal bars. The wall allows the tunnel to be loaded to the desired level with the gate open and separates the compost from the gate with a heat-insulating air space. The foundation of the tunnel forms an underground airspace, into which air is injected at a pressure of 1500 Pa.

The loading schedule of compost fermented in piles or in bunkers can be as follows.

On the 1st day - loading of the tunnel until 12 noon. Equalizing the temperature in the mass of the substrate using recirculation air with a small supply of fresh air and heating up to 58 ° C in 12 hours. Pasteurization of compost for mushrooms lasts 10 hours, this is necessary for the destruction of insects. Then, to condition the compost, its temperature is reduced to + 48 ... + 50 ° C by increasing the flow of fresh air. Conditioning at this temperature with air blown through compost (10% fresh air, 90% recirculated air) lasts 5 days.

On the 6th day, the compost for growing mushrooms is cooled for 8-12 hours to 8 am by increasing the amount of fresh air. The content of ammonium ions in the compost at the exit from the tunnel must be less than 0.1%. "Brown" compost has almost no ammonia odor.

Now in Russia there are Italian automatic compost presses. They immediately form compost seeded with mycelium in the form of compressed briquettes and pack them in plastic wrap. The size of a standard briquette is 20 x 40 x 60 cm. The surface of the film in which the block is packed is not perforated, except for two large holes at the ends of the block, which almost do not violate the strength of the block, but provide oxygen to the mycelium in the block during transportation.

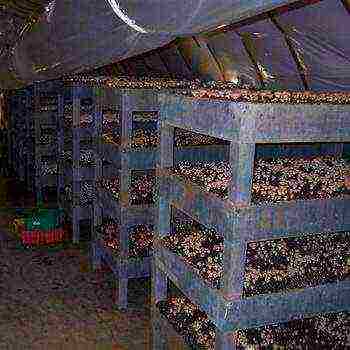

Growing champignon mushrooms on shelves (with video)

It is possible to cultivate champignon on multi-tiered shelves. In a standard cultivation chamber with an area of 200 m2, 11 x 18 m in size with a ceiling height of 3.8 m, designed to accommodate 40 tons of compost, 4 five-tier racks 1.4 m wide and 15 m long are installed. shelves, fenced with sides to prevent compost and casing layer from falling out. The first tier of the bookcase is at a height of 0.25 m from the floor, the subsequent ones are 0.6 m from each other.

It is possible to cultivate champignon on multi-tiered shelves. In a standard cultivation chamber with an area of 200 m2, 11 x 18 m in size with a ceiling height of 3.8 m, designed to accommodate 40 tons of compost, 4 five-tier racks 1.4 m wide and 15 m long are installed. shelves, fenced with sides to prevent compost and casing layer from falling out. The first tier of the bookcase is at a height of 0.25 m from the floor, the subsequent ones are 0.6 m from each other.

The width of the aisles between the racks for mushrooms is 110 cm, between the racks and the walls - 100 cm.

When placing the compost in the form of beds poured onto the shelves, 100 kg of finished compost can be placed on 1 m2 of shelf area. The thickness of the compost with proper compaction is 20 cm. With a bed width of 1.4 m, 1.4 x 15 x 5 x 4 x 0.1 = 42 tons of compost will fit on 4 five-tier shelves with a length of 15 m.

The compost is placed on racks for mushroom mushrooms, then leveled and compacted. Grain mycelium is poured evenly onto the surface of the compost, then it is embedded to a depth of 1 cm. The seeding rate of grain mycelium is 0.4-0.5% of the mass of the finished compost.

The surface of the compost is leveled and covered with paper. Moisten the paper by spraying with water (up to 0.2 liters per 1 m2 of the garden), preventing water from seeping into the compost. Using this method of growing mushrooms, the incubation of mycelium at a compost temperature of + 20 ... + 26 ° C ends in 14 days. After that, cover soil is applied and overgrown for 10 days. Watering on the casing layer up to 2 liters per 1 m2 of the bed.

After the mycelium has mastered the casing layer, the formation of fungi begins. The temperature in the cultivation chamber is regulated in the range from +14 to +17 ° C at a relative air humidity of 85-95%. For permanent removal of carbon dioxide during the period of setting and fruiting of mushrooms, ventilation with fresh air in a volume of at least 250 m3 / h per ton of substrate is required. The ventilation system must supply 10,000 m3 / h to the chamber.

According to the correct technology for growing mushrooms, fresh air must be provided in the chamber above the shelves with mushrooms.

To create a flow of air over the mushrooms, in each odd passage, there is a special equipment for growing mushrooms - an air duct with downward nozzles. In the simplest case, the air duct is a 15 m long air-inflated polyethylene sleeve suspended on wire rings in the middle of the aisle so that the nozzles are 40 cm above the compost surface on the top shelf, and the air flow from the nozzles is directed vertically downward.

When ventilated with fresh air, the carbon dioxide content in the upper casing layer is much lower than in the depth. This leads to the formation of rudiments of fruit bodies on the surface of the casing layer. On the 15-20th day, counting from the day of application of the casing layer, white stars from the mycelium appear on the surface of the casing layer, and after a few days - the rudiments of mushrooms in the form of white peas. Watering up to 1 l / m2 should be started the next day after the appearance of the buds-peas.

The video "Growing champignon mushrooms on multi-tiered racks" shows how this process takes place:

Climatic equipment for growing mushrooms

The room for growing mushrooms must be equipped with a ventilation system.

Fresh air is taken in through a filter, passed through a heater and a cooler, sucked in by a central fan and humidified by a steam nozzle. The condensate is removed by a droplet separator. This piece of climatic equipment for mushroom growing is a central air conditioner. Its functional purpose is preliminary air conditioning with a relative humidity of 80-90% and a temperature of 10-13 ° C in summer and 15 ° C in winter.After preparation, the air enters the central air duct, from which it is taken by chamber fans, in this case called "closers". From the central air duct of the equipment for mushroom mushrooms, air is drawn through the wall of the cultivation chamber into a mixing box with an air regulation valve, passes through a cooler and a heater, and is pumped by a fan into the air duct of the chamber. Directly in front of the chamber air duct, there is a steam nozzle and a droplet separator.

In mushroom production, centrifugal fans with backward-curved blades are recommended. The capacity of a chamber fan-closer in equipment for growing mushrooms in a chamber for 40 tons of compost should be 10,000 m3 / h. This fan provides 250 m3 / h of fresh conditioned air for every ton of compost. The working pressure of the fan must be at least 500 Pa.

The volume of air distributed by the nozzles in one chamber is 10,000 m3 / h.

The fresh air supply control valve is capable of replacing, if necessary, fresh air with chamber air (recirculated air) within the adjustment range from 0% fresh air in the chamber duct to 100%.

Abroad, plastic nozzles in climatic equipment for champignons are made with an inner diameter of 5 cm. Nozzles can be made from polyethylene water cups, which hold well in polyethylene, if the holes are made slightly less than the diameter of the wide part of the cup. Long beer glasses with a volume of 0.5 liters with a bottom diameter of 6 cm have proven themselves best of all. The bottoms of the glasses are cut off so that the inside of the nozzle is smooth. The holes in the polyethylene sleeve are cut with scissors so that the nozzles are, after straightening the inflated air duct, directed downward, in the middle of the middle passage in the chamber. With a rack height of 3 m, the air outflow rate from nozzles with a diameter of 6 cm should be 8 m / s. A chamber fan, developing a pressure of 400-500 Pa, will provide such a speed. With a nozzle diameter of 6.0 cm and an air flow rate of 8 m / s from the nozzles, the air flow through one nozzle will be 81 m3 / h. The total number of nozzles in the chamber is 10,000: 81 = 120 pcs. The speed of air movement in the distribution duct of the chamber should not be higher than half the speed of air outflow from the nozzles.