Content

- 1 What mushrooms can be grown for sale at home and on an industrial scale all year round?

- 2 Choosing a room for growing mushrooms

- 3 Equipment required for growing mushrooms for sale

- 4 Mycelium: grow it yourself or buy it?

- 5 All conditions and methods for growing mushrooms indoors and on the site

- 6 Highly profitable mushroom growing business plan

- 7 Reviews

- 8 Project summary

- 9 Profitability of growing mushrooms (oyster mushroom)

- 10 Product description (mushroom oyster mushroom)

- 11 Sales and marketing in the supply of oyster mushrooms

- 12 Oyster mushroom production plan

- 13 Financial plan for growing mushrooms (oyster mushroom)

- 14 Evaluation of the effectiveness of growing mushrooms

- 15 Risks and guarantees

- 16 20 types of business for retirees

- 17 Business plan. Seed mycelium production laboratory

- 18 Business plan: growing mushrooms

- Industrial cultivation of mushrooms

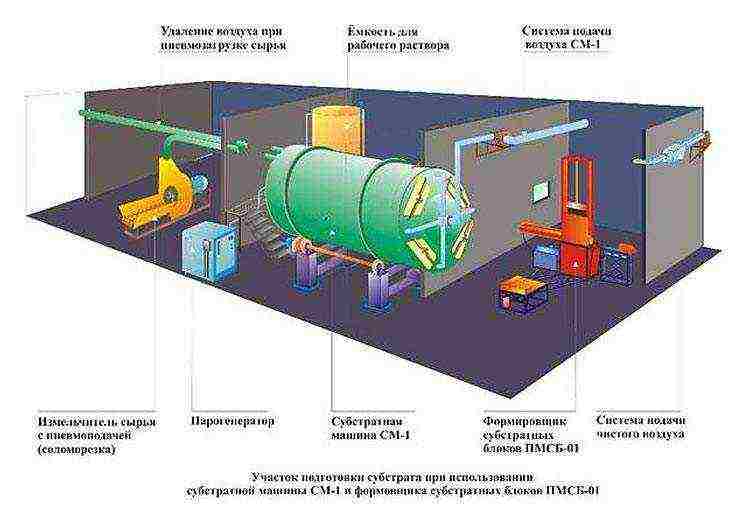

- Substrate component preparation process

- Substrate component inoculation process

- The process of germinating blocks with a substrate component

- The process of pasturing fruit bodies

- Harvesting process

- Growing oyster mushrooms on a mini-farm in Tula

Growing oyster mushrooms is a truly unique process, and all because for this purpose, agro-industrial waste is needed, thanks to which it is possible to grow high-quality mushrooms, rich in proteins, amino acids, minerals necessary to maintain health and full functioning of the human body.

Another indisputable advantage of oyster mushrooms is their low calorie content and the complete absence of cholesterol, which is dangerous for our body. Since mushrooms contain a large amount of polysaccharides, they do not lose their shape with any type of culinary processing, which makes them look even more appetizing. Due to their unsurpassed qualities in the old days, these mushrooms were called "ishvin", which is translated from Old Russian as "valuable". Our ancestors also realized that this mushroom is beneficial for the body and began to use it for food.

It is quick and relatively easy to grow oyster mushrooms on sawdust and shavings, as well as on any type of wood. The easiest way is to grow mushrooms on stumps, which remain after cutting down any tree species in the forest, on a personal plot, etc. However, in recent years, oyster mushrooms have been actively cultivated on an industrial scale.

Industrial cultivation of mushrooms

Oyster mushrooms grow quickly and are resistant to pests, which is why industrial cultivation of mushrooms is gaining momentum every year. These mushrooms, in contrast to the same champignons, are much easier to grow and, in terms of resources, are less costly, which won the hearts of farmers.

So, let's move on to the most important thing and find out how oyster mushrooms are grown in an industrial environment. It is divided into the following technological stages, which include:

So, let's move on to the most important thing and find out how oyster mushrooms are grown in an industrial environment. It is divided into the following technological stages, which include:

- Preparation of the substrate component.

- Inoculation of the substrate component.

- Sprouting the block with the substrate.

- Drive out mycelium.

- Harvesting.

Substrate component preparation process

Growing oyster mushrooms primarily depends on the preparation of the substrate component. It must be of high quality, otherwise there will be no harvest.Industrial mushroom growers use cereals, corn cobs and stalks, non-coniferous sawdust, sunflower husks, grape vine or reed stalks as a substrate component.

In order to prevent mold in the substrate, it is treated at high temperatures before sowing, pasteurizing the material. In nature, together with oyster mushrooms, mold also grows, competing with it in development, making the mushrooms weak and often unsuitable for food.

In order to prevent mold in the substrate, it is treated at high temperatures before sowing, pasteurizing the material. In nature, together with oyster mushrooms, mold also grows, competing with it in development, making the mushrooms weak and often unsuitable for food.

In the industrial production of oyster mushrooms, sterilization of the substrate is not carried out, since it will not be possible to maintain complete sterility at all stages of cultivation. It can be provided only in the laboratory, and this is very costly and simply pointless.

Amateur mushroom pickers who grow oyster mushrooms on their own in the country or at home pasteurize the substrate, just like in production. To do this, take bags of polyethylene with a thirty-centimeter layer of substrate, fill it with boiling water, wrap it up and keep it for two to four hours. The pasteurization temperature should not be below fifty-five degrees and above sixty. After pasteurization, the substrate is left to ripen at a temperature of forty-eight to fifty degrees for seventy-two hours. After the time has elapsed, it is cooled to twenty-five degrees, and only after that the myceliums can be planted.

Substrate component inoculation process

In a substrate cooled to twenty-five degrees, the mycelium is planted. The temperature regime should not exceed the declared one, since the mycelium may die. Before planting the mycelium, especially if it was stored in a refrigerator, it must be kept for twenty-four hours at room temperature. When planting myceliums in the substrate, complete sterility must be observed. Before planting the mycelium, the container in which it should be placed must be disinfected. It is necessary to put on sterile gloves on your hands, having previously treated them with a 1% sodium hydrochloride solution. It is necessary to introduce mycelium into the pasteurized substrate component in layers or evenly mixing the mycelium with the substrate.

The substrate component is placed in polyethylene bags or in other selected containers. Before placing the bags on the shelves, shake them a little and seal the neck with tape so that the substrate adheres well to the walls of the burlap. On the sides of the bags, it is necessary to make holes with a diameter of ten millimeters for perforation. Each bag carry up to fifteen kilograms. After filling the bags with the substrate component with myceliums, it is necessary to place them in a moist, well-ventilated room for germination. In industrial conditions, such premises are prepared in advance so that future mushrooms feel "comfortable"

The substrate component is placed in polyethylene bags or in other selected containers. Before placing the bags on the shelves, shake them a little and seal the neck with tape so that the substrate adheres well to the walls of the burlap. On the sides of the bags, it is necessary to make holes with a diameter of ten millimeters for perforation. Each bag carry up to fifteen kilograms. After filling the bags with the substrate component with myceliums, it is necessary to place them in a moist, well-ventilated room for germination. In industrial conditions, such premises are prepared in advance so that future mushrooms feel "comfortable"

The process of germinating blocks with a substrate component

Experts call this process incubation. It lasts from fourteen to eighteen days. During this time, all the prepared block substrate grows with myceliums. For this period, light and ventilation are not particularly important. The optimal microclimate is to maintain a temperature of twenty-four degrees and a humidity not higher than seventy-five percent and not lower than ninety. If the temperature in the substrate is higher than the temperature in the room, the walls will start to become covered with condensation.

This problem is fraught with a lot of trouble. A crust (stroma) can form on the mycelium, which will significantly reduce the yield of future mushrooms. It can also appear as a result of overheating of blocks with a substrate or in an excess of introduced mycelium.

This problem is fraught with a lot of trouble. A crust (stroma) can form on the mycelium, which will significantly reduce the yield of future mushrooms. It can also appear as a result of overheating of blocks with a substrate or in an excess of introduced mycelium.

Violation of the microclimate can lead to the appearance of mold, leading to the death of oyster mushrooms. It is manifested by the appearance of orange, black and green spots on the bags with myceliums. If this happens, the employees of the enterprise remove the affected bags, ventilate the room and equalize the microclimate to the required norm.

The process of pasturing fruit bodies

Oyster mushroom can bear fruit in another room. But often the cultivation of mushrooms in an industrial way involves the entire process from sowing to harvesting in one room. For this purpose, experts simply change the temperature and humidity, monitoring the growth of myceliums.

Three days after laying the bags with the substrate and mycelium in the room, the temperature is reduced to seven degrees and this regime is maintained for ninety-six hours. A similar temperature shake is done so that the oyster mushrooms begin to bear fruit. After the time has elapsed, the temperature is raised to fifteen degrees and kept stable until harvest.

Three days after laying the bags with the substrate and mycelium in the room, the temperature is reduced to seven degrees and this regime is maintained for ninety-six hours. A similar temperature shake is done so that the oyster mushrooms begin to bear fruit. After the time has elapsed, the temperature is raised to fifteen degrees and kept stable until harvest.

The optimal lighting for the normal growth of oyster mushrooms is considered to be eight thousand lux for twelve hours. To grow oyster mushrooms, it is imperative to comply with all of the above requirements. If during the growth of mushrooms there is a lack of light or the level of carbon dioxide is exceeded, the mushrooms will have long and deformed legs, and in the worst case, they simply stop growing.

Oyster mushroom has a wave principle of fruiting. If you observe all the optimal conditions for the growth of oyster mushrooms, then a couple of weeks after transferring the bags with mycelium to the prepared room, the first wave growth will begin after three to four weeks. He will bring seventy percent of the harvest. In the next two to three weeks, the second wave of fruiting will pass and bring the remaining thirty.

Harvesting process

Oyster mushrooms are cut from the very surface of the substrate component. You need to cut off all the mushrooms, it is not recommended to leave them. There is no need to water the mushrooms during harvest. This is done in order not to overmoisten the soil and not to stain the crop. Dirty mushrooms are poorly stored and quickly deteriorate.

Cut oyster mushrooms are placed in wooden boxes forty centimeters high. In boxes, the mass of mushrooms should not exceed fifteen kilograms. They are stored at a temperature of two to four degrees. This mode allows you to save mushrooms for up to two months. If the temperature is higher, then the mushrooms will be stored for a maximum of a week.

When the last crop is harvested, the substrate is removed, the room is washed and disinfected. Then there is preparation for the next fruiting cycle. The whole process from the beginning to fruiting takes from two to two and a half months.

Growing oyster mushrooms on a mini-farm in Tula

A farm for growing oyster mushrooms is located in Tula in the village of Arkhangelskoye. The farm has been operating for more than ten years, but it is still the only oyster mushroom growing enterprise of its kind in central Russia. Agrarians chose this type of mushroom due to the fact that oyster mushrooms are very popular among the population.

Every month, specialists grow about twenty tons of high-quality mushrooms. Almost all mushrooms are taken to large supermarkets in Tula. It is they who order the bulk of the oyster mushrooms to farmers and hope that in the future there will be even more mushrooms, since there is just a crazy demand for them.

Every month, specialists grow about twenty tons of high-quality mushrooms. Almost all mushrooms are taken to large supermarkets in Tula. It is they who order the bulk of the oyster mushrooms to farmers and hope that in the future there will be even more mushrooms, since there is just a crazy demand for them.

Enterprising farmers point out that industrial mushroom cultivation is profitable, but very costly. About 100 million rubles were spent just to start the farm. Now the farmers are thinking about expanding the enterprise in order to provide the residents of Tula and the Russians in general with high-quality and healthy mushrooms, which are still analogues in the region.

The vastness of Russia is rich in mushroom reserves, and access to them is free. But the same constant demand is enjoyed by mushrooms grown on "home" plantations. This is due to the deteriorating environment, because the cases of widespread poisoning by mushrooms collected in the forest are not decreasing. Meanwhile, mushroom growing is a highly profitable business. These are products that grow quickly, do not require special care, and are profitable all year round. In addition, the price of such mushrooms rises in winter. These are the factors that speak in favor of the mushroom business.

What mushrooms can be grown for sale at home and on an industrial scale all year round?

For year-round cultivation both at home and in industrial scale oyster mushrooms are most suitable. Entrepreneurs value them for unpretentiousness and a variety of growing methods.

Oyster mushrooms competitors in terms of breeding, winter mushrooms and ring mushrooms are.

Champignons are in second place. They are more capricious, but the substrate for them requires adherence to a complex technological process. Other types of mushrooms appear that are suitable for mushroom production. For example, shiitake.

Land owners cultivate mushroomsgrowing in the forest - white, boletus, boletus. In any case, to sell successfully mushrooms, you also need to arm yourself with information about the features of growing the selected type of mushrooms.

- Features of growing champignons in winter and summer

For year-round cultivation of champignons, any premises (a special greenhouse, an ordinary basement, a dugout), in which you can maintain an air temperature of at least +15 degrees and humidity within 70-80%. Lighting for growth these mushrooms are optional. The room should be damp and warm. For the soil, horse manure with the addition of urea is used. In the process of growing, boxes or racks are used. On the growth of mycelium it takes 14 days (a white bloom appears on the ground, which needs to be sprinkled and watered), its fruiting occurs in a month and lasts 2-3 months.

- Growing porcini mushrooms all year round

Industrial scale is not profitable for porcini mushroom. As a rule, this type of mushroom is cultivated by gardeners. This is explained peculiarities of growth these plants, their symbiosis with trees. In other words, the root system of the tree is capable of ensuring the growth of mycorrhiza. Therefore, for the cultivation of porcini mushrooms it is so important recreate environmentclose to natural conditions. For example, you can use a summer cottage where deciduous or coniferous trees grow. Young groves or 5-year-old plantings with oaks, pines, birches, spruces are also suitable.

- Features of growing oyster mushrooms in winter and summer

Oyster mushrooms are less whimsical. But at the same time they are the most highly productive mushrooms relative to their fellows. Technologies for their cultivation more than flexible... For example, intensive or year-round cultivation requires premises (during the growth stage, lighting will be required), compliance temperature regime and special humidity... With this option, mushrooms grow in bags filled with substrate (plant residues with mineral additives).

The extensive method can be applied in an open space. He will require minimum costs, since special equipment is not required in this case. Stumps or logs replace the substrate. They are filled with mycelium and placed on the site (in trenches, on plantations). The main thing is to follow soil moistureand nature will do the rest. Oyster mushrooms have up to four waves of fruiting from one mycelium, the growth of which will take at least 14 days.

See also: What business is the first to burn out in a crisis?

Choosing a room for growing mushrooms

The quality of grown mushrooms is influenced by the correct selection of premises... Places for champignons are recommended basement typewhere it is humid enough and not too hot. Therefore, a cellar or basement at home is ideal. You can also opt for damp buildings... If we are talking about a larger business, then special greenhouses are built on personal plots or rented (bought) for subsequent rebuilding premises old vegetable store, poultry house, cowshed and so on.

Wherever the mushroom production is located, you need take care of availability it has electricity, running water, and you may also need gas.

What are the main parameters of the premises?

- Sufficient humidity.

- Correct air intake - ventilation, but without drafts (if there is no opportunity for abundant ventilation, then air circulation is guaranteed by holes made at the base of the wall and by exhaust pipes).

- Adjustable heat supply (very important for year-round cultivation).

- Absence harmful microorganisms - mandatory disinfection before planting.

For example, if we are talking about a mushroom farm for growing mushrooms, then the choice of premises should be taken more seriously. First of all, it is determined square cultivation... Suppose that 20 tons of compost can be delivered to the farm at a time (this is exactly how much is placed in a truck), this amount will be enough for 200-220 m². This space is divided into six chambers for growing mushrooms. Each of them has two racks with several tiers. Their number depends on the height of the room.

In addition, the farm must have two corridors... One is narrow, in order to take out the harvested crop on trolleys, the second is wide (the width depends on the dimensions of the available equipment), for unloading and loading soil into the chambers. You will also need additional rooms: boiler room, two refrigerators (for storage and for cooling mushrooms after harvesting), a place for packaging products and other technical rooms (change house toilet, office). total area such a farm can be 1000-1400 m².

To grow oyster mushrooms all year round, you will also need several separate rooms.

- Inoculation site - this is a room where mushroom blocks (in bags) are formed from the prepared substrate, into which the mycelium is sown.

- Incubationwhere the mushroom blocks will grow, that is, the mycelium will grow.

- Cultivation, in which the direct forcing of the fruiting body takes place, that is, where the mushrooms will grow. The largest room relative to the previous ones. Blocks in it are located in three versions: on multi-tiered racks, hung on hooks (in several tiers) or strung on rods.

- Roomwhere the substrate will be stored, and a separate place for its preparation.

The premises are not used for growing porcini mushrooms. This is usually a seasonal outdoor business. Therefore, here you will need a piece of land with growing trees of the appropriate species.

Equipment required for growing mushrooms for sale

Correct equipment selection ensures that all the necessary conditions for the growth of mushrooms are met, and, consequently, the profitability of the mushroom business.

What do you need to stock up on or what to equip the room with to ensure a high yield of mushrooms?

- First of all, you need a high-quality system. air conditioning and ventilation, which will allow you to regulate the temperature and humidity. Cooling functions will be performed by a refrigeration machine or air conditioners. The heating system will require water heating boilers.

- You can use automated climatic installation, and a separate one in each chamber. This is a very important nuance, since the conditions for the growth of mushrooms at different stages are different.

- Refrigerators necessary for the rapid cooling of mushrooms. Their volume is usually not too large, it depends on the volume of the harvested crop per hour.

- Refrigerating chambers will ensure the storage of all grown products for no more than 3 days. They are only filled to 50% to maintain air circulation.

- For cameras where mushrooms grow, you will need racks... Depending on the type of mushroom, you need to pick up boxes or bags.

- It is important to remember about packaging of finished products... These can be jars, plastic containers, bags, etc.

- If there is a production of mycelium, then you should get an autoclave, or purchase a special grain processing machine.

See also: Growing greenery as a business - how to make money on growing greenery?

Mycelium: grow it yourself or buy it?

Growing mycelium can be considered as one of the areas of mushroom business... However, those businessmen who specialize in mushroom growing and whose main income depends on successful implementation of this product, the process of breeding mycelium is considered meaningless. Firstly, this is a rather laborious task. Secondly, it requires professional skills. Thirdly, you will need additional equipment and premises. There may be other costs.

Usually the mycelium is grown by amateur mushroom growers. They are passionate about their hobby, wanting to be sure master all stages mushroom business. Therefore, myceliums of those mushrooms are often grown that are rare species and whose purchase causes difficulties, as well as to exclude dependence on suppliers.

All conditions and methods for growing mushrooms indoors and on the site

There are two main ways to grow oyster mushrooms.

- Extensive

In this case, the role of the substrate is performed by wood trimming. The method is applicable both outdoors and indoors. However, in the first option, the stability of the crop usually depends on the weather, and in the second, the process takes place all year round. This technology is simple, affordable, and low-cost. But you can get high yields only at the expense of large production areas.

A striking example of this technology is growing mushrooms on stumps. Cuttings of birch, oak, alder, poplar and other trees are suitable as stumps. Stumps up to 40 cm long and 25 cm in diameter are soaked in water for seven days. Then holes are made in them, filling them with mycelium. Then they are clogged with moss or sealed with duct tape. The mycelium grows for 2.5 months. At the same time, the temperature in the room where these stumps are located should not be higher than +20 (in the barn, basement). In addition, they need to be constantly watered.

After the period of growth of the mycelium has expired, the stumps are placed in an upright position on an area under a canopy. You can stack them on top of each other. In this case, the lower ones are buried more than half into the ground. Permanent shadow is a must. The main thing is to regularly water such a plantation.

- Intensive

According to this technology, oyster mushrooms are grown on a substrate - a special material consisting of sawdust of deciduous trees, sunflower husks, straw and so on. But there is one caveat - in natural conditions, oyster mushrooms do not grow on such soil, there is too much competition with mold fungi. Therefore, the substrate must undergo a thermal treatment in order to suppress further mold growth.

Mushrooms are grown indoors (basements, cellars, special farms).

The whole process is divided into specific stages.

- The substrate is being prepared... One of the ways is a 3-hour pasteurization of the substrate at 70-80 degrees.

- In a substrate cooled to 20 degrees mycelium is introduced... Layer by layer, alternating mycelium and substrate, workers must fill polyethylene bags (50x100). Then 12 holes are made on the sides of the bag, and the neck is sealed. The mycelium should make up 5% of the total mass of the substrate in the bag. The total weight of the bag is approximately 15 kg.

- This is followed by a period when the substrate overgrown with mycelium... Its duration will be from 14 to 18 days. Prepared bags are placed in a room with a temperature of 24 degrees and a humidity of 80-90%. Lighting and ventilation are not needed at this time.

- Mushroom growth carried out at a temperature of 12-16 degrees with lighting for about 14 hours a day, ventilation and humidity not lower than 70%. Oyster mushroom fruiting is a wave-like process. From the first wave, 70% of the harvest is collected, from the second - 25, from the third - 10%, and so on - in decreasing order. The time from sowing mycelium to harvest is 2.5 months.

The process of growing mushrooms is divided into the same stages as for oyster mushrooms. But it is carried out mostly in basements or in purpose built.

Another method of preparing the substrate

The ideal component for him is horse dung, but also used manure of cows, pigs, chicken manure, mixed with straw (wheat or rye).

100 kg of straw requires up to 50 kg of manure.

First, a three-day straw soaking... Then, layer by layer, manure and straw are laid out in a compost pile. When bookmarked, all layers are additionally moisturize and sprinkled with urea... Since fermentation is uneven, the composting process requires constant mix componentswhile adding alabaster. If the collar is located indoors, then the temperature in it should not be less than 12 degrees. The substrate usually takes 25 days to cook. First sign of his readiness - lack of ammonia smell.

Then the substrate is distributed in boxes or other containers. When it cools down to 20 degrees, into it mycelium is introduced... Depressions with a depth of 8 cm are made on the surface in a checkerboard pattern, which are filled with pieces of mycelium and covered with soil. Then the beds cover up with old newspapersto prevent drying out. The temperature for the growth of mycelium is 24 degrees, ventilation is used as needed. Mycelium development period - 14 days.

After the growth of the mycelium is performed gobbing - the beds are covered with cover soil (a mixture of turf soil and chalk). The temperature in the room at this stage and before the appearance of the first mushrooms should be no more than plus 20. Regular humidification cover layer and maintaining high air humidity. The fruiting period of mushrooms will be approximately two weeks, starting from the 27th day to the 40th from the moment of planting the mycelium.

Porcini mushrooms are grown according to the technology that is closest to natural conditions.

- In preparation seed use the following components: mushroom caps with a diameter of 15 cm - 20 pieces, potassium permanganate - 1 gram, refined sugar - 15 pieces. Everything is placed in a bucket, poured with rainwater, the hats are kneaded until smooth, the resulting solution is infused for no more than an hour. The main condition is that the seed is planted only under the tree near which the mushrooms were taken for its preparation.

- Around trees (60 cm from the trunk) soil layer is removed, their exposed roots are watered with seed (about 300 grams per 20 cm²). Then the roots are covered with soil and watered. In the future, crops require additional watering. Sowing time is September.

- The harvest is going in a year, approximately one bucket under each tree.

Read also: How to organize and promote a flower business - 5 secrets of a successful business

Highly profitable mushroom growing business plan

It is difficult to talk about the high profitability of porcini mushrooms. Their growth largely depends on weather conditions, and it is difficult to influence the weather, because the harvest is removed once a year... By the way, according to some reports, this may pass in two years. Therefore, we will consider the profitability of the business from growing mushrooms and oyster mushrooms.

What needs to be done to implement this type of activity?

- Rent (buy) premises with an area of 550 m², where separate areas will be provided for the preparation and pasteurization of compost, germination of mycelium and mushrooms.

- Equip premises with sewerage and water supply systems, as well as electricity.

- Purchase equipment: a small tractor, a straw and grain crusher, a steam boiler, an irrigation system, containers, racks, etc.

- Checkout permits.

- Dial service personnel: three workers, a manager, an accountant.

- To fix sales of products (through wholesale or retail stores, using your own website, open your own retail outlet).

Economic calculation of payback

The costs for starting a business will amount to 1,600,000 rubles, they will include:

- rent (purchase) of a land plot and construction of a building - 1,000,000 rubles,

- equipment - 500,000 rubles,

- registration,, fuels and lubricants and other expenses - 100,000 rubles.

Monthly expenses will be 200,000 rubles:

- wage - 150,000 rubles,

- communal payments - 30 thousand rubles,

- - 5,000 rubles,

- transportation costs - 15,000 rubles.

The income part will look like this:

- a ton of compost seeded with mycelium costs 6,000 rubles;

- one ton makes it possible to collect 2 centners of the crop;

- the average wholesale cost of 1 kg of mushrooms is 70 rubles;

- income after the sale of the crop will be 14,000 rubles (200x 70);

- if over a period of three months to process 100 tons of compost, then the profit (after deducting costs) will increase to 200 000 rubles;

- the cycle is repeated 4 times in one year, therefore, the income will increase to 800 000 rubles;

- net annual profit after taxes is at least 750,000 rubles... The payback period for the project is two years.

Business plan for growing oyster mushrooms

- Given the fact that these mushrooms grow quickly and give several harvest waves from one sowing, to grow them at home you will need premises the size of 300 m².

- In this case purchase costs mycelium, substrate, expenses for maintaining appropriate conditions and other costs amount to 300,000 rubles.

- After selling mushrooms, you can get income in 1,080,000 rubles.

- Less expenses net profit will be 780,000 rubles.

The plan includes only one complete growing cycle - this is a two-month period, and but clearly shows how high the profitability of the production of oyster mushrooms.

Reviews

Growing oyster mushrooms is described as a business that does not require a large start-up capital, but brings a lot of income - about 700 rubles profit from 1 m² for 1.5 months. Entrepreneurs claim that it is very easy to master... Oyster mushrooms are much easier to care for than champignons. According to reviews, the main advantages of the oyster mushroom growing business are the minimum investment, high profitability, opportunities to expand the business and turn it into family business.

Businessmen specializing in champignons argue that difficulties can arise only at first, at the time of setting up production. When the process is running and debugged, everything is simple, the main thing is have time to harvest... And although champignons are considered not as fruitful as oyster mushrooms, the demand for them is much greater.

In search of ideas for their own business, many come to growing oyster mushrooms at home. In this post, we'll take a closer look at the costs, ROI, and feedback of these activities. Is it worth the effort, or do you need serious investment and a large enterprise?

Advantages and disadvantages

This business is in many aspects an ideal option for beginners to get acquainted with entrepreneurship. It requires a minimum start-up capital and allows you to start working with small volumes, increasing them over time. Moreover, it is possible to grow mushrooms at the very beginning and exclusively for personal use, and as soon as the technology is debugged, enter the market.

The following advantages should also be noted:

- Mushrooms can be grown both in rural and urban areas.

- High demand for the harvest.

- The broadest opportunities for business development and expansion.

- No need for hired workers, at least in the first stages.

- No need for a wide range of business contacts.

- Relatively stable income.

Among the disadvantages is the problem with the sale of really large quantities of mushrooms (though the problem will not start soon, it all depends on the growth rate). You will also need at least minimal knowledge of the subject (you can accumulate it in the process).

One should also note such an important factor as seasonality. In summer and autumn, sales often decline, and starting from the middle of winter, when the population's own stocks run out, the demand grows.

Reasons for choosing oyster mushrooms

Leaving aside the nutritional value, taste and usefulness, it is worth noting that compared to the more popular chanterelles, honey mushrooms, mushrooms and others, oyster mushrooms are easy enough to grow, and the growth rate is high. If under natural conditions the harvest of mushrooms can be obtained in 2-2.5 months, then in artificial conditions this period is halved.

Crops bear fruit in several waves, the weight of one bunch can reach 200 grams, and the record holders grow up to several kilograms, or even more.

A separate plus is to note that the mushroom can grow on almost any substrate: on stumps, straw, sawdust, even sunflower husks. In some countries, oyster mushrooms are even grown on waste paper. Modern technology makes it possible to further expand this list.

Selecting a sales market

Among the most obvious options are:

- Self-sale in the markets. In this case, you will have to attend to the search for a free trading place, make and correctly place advertising, attract the attention of potential buyers. In this case, sales are proceeding at a retail pace. As an advantage - the ability to set your own prices with an eye on competitors, if any.

- Sales through grocery stores and supermarkets. In every large enough city there is a trading network or a separate point that will be interested in the wholesale purchase of mushrooms. Unfortunately, most often they offer very low prices. Over time, it will be possible to switch to more favorable terms of cooperation, and the recruited base of regular customers will remain with you, even if you break off cooperation with the outlet.

- Sale to restaurants. Mushrooms are traditionally in great demand in restaurants. The reason is simple - such establishments prepare only the freshest ingredients. Cooperation will allow you to quickly and profitably sell large quantities of mushrooms. The rest can be sold using the first or second method.

Needless to say, whatever option it ultimately decides to resort to, the grown mushrooms must be of the highest quality.

Company registration

Before starting work, you should register a business. To do this, you need to select the OKVED code 01.12.31.

This type of business implies three options for the legal form: individual entrepreneur, LLC or peasant farm, that is, a peasant farm. All three have their pros and cons. A form such as a personal subsidiary farm in this case will not work.

SP

Allows you to grow mushrooms and sell crops.

To register, you will need to pay a state fee in the amount of 800 rubles, apply for the transition to the USN or ESNH, and also prepare an application in form No. P21001, which will need to be certified by a notary.

You should worry about a photocopy of all significant pages of your passport in advance.

OOO

It gives the right to attract investments through loans for agriculture and through state programs.

To register, you must pay a state fee in the amount of 4000 rubles, submit an application No. Р11001, prepare the charter of an LLC and a decision on its opening, certify copies of the passports of all founders with a notary, write an application for the transition to the chosen form of taxation.

The authorized capital of the enterprise must be at least 10,000 rubles.

Documentation

Documenting your own farm has an important role in this matter. The mushroom business in Russia does not provide for a special certificate.

However, in order to become a successful seller of your products, you need the result of laboratory research. You can get it in the food laboratory. Its employees are often asked to additionally prepare a security protocol. For him, you will already need to do an analysis for the presence of radioactive substances and heavy metals.

Documenting the cultivation of oyster mushrooms on an industrial scale (albeit in your own basement) is an overhead and slow business.Moreover, the resulting protocol will need to be updated every 3 months.

Room selection

The choice of premises for creating a mushroom plantation should be carried out as responsibly as possible. It is preferable to choose places that are sufficiently humid, but not too hot. If we are talking about the very beginning of a business, then the basement or cellar of a house may be suitable. As the business develops, old cowsheds, vegetable stores and similar buildings can be purchased and refurbished. In extreme cases, you can buy a special greenhouse.

Room requirements:

- Residual moisture.

- High-quality ventilation, but without drafts (if no other option is suitable, you can make several holes in the lower part of the wall and stretch the hood).

- The ability to adjust the temperature (especially important in winter).

- Mandatory disinfection before planting.

A few words about the size of the room. The truck holds about 20 tons of compost for cultivation. In order to fully distribute it and put it into operation entirely, an area of over 200 square meters will be required. The internal space is divided into sections, in which multi-level (depending on the height of the ceiling) racks are installed.

Each farm must have at least two aisles. According to the first, the harvested crop will be exported, it can be made narrower, the second should be much wider - the soil will be loaded along it.

Additional premises include a boiler room, a couple of refrigerators for storing harvested mushrooms, an area for packaging and various technical premises: change houses, a toilet and others. As a result, the total area of the farm grows to nearly 1-1.5 thousand square meters. Of course, at first you can get by with more modest premises.

If you plan to grow oyster mushrooms all year round and completely on your own, you will have to provide for several additional premises:

- A room for inoculation, where mushroom blocks will form from the finished substrate in bags, into which the mycelium is sown afterwards.

- Incubation room for mycelium germination.

- Cultivation room for forcing the fruit body (the largest room, blocks are strung on rods, laid out on multi-tiered shelves or suspended).

Equipment

The first thing that is required is a high-quality ventilation and air conditioning system, which will be used to maintain optimal temperature and humidity conditions.

Hot water boilers are used for additional heating in winter. Ideally, it is recommended to purchase several complete climatic systems that will help regulate the atmosphere parameters for mushrooms at different stages of ripening.

Refrigerating chambers are used for storing finished products. It is very important that they only keep the mushrooms for a period of three days. In addition, they must be no more than half full for proper air circulation.

A large number of shelving units will be required for the premises. Also, depending on the specific variety, bags or boxes will be required for production.

Staff

The vast majority of responsibilities are assigned to the owner. It is he who, at least at the start, deals with delivery and sales issues. Very often at the beginning of work, when several relatives are engaged in the case, one is responsible for the supply, while the rest are engaged in the direct issues of cultivation, fertilization, planting, etc.

As the farm grows and mushroom production expands, this will become more difficult to manage. At a certain stage, inviting new employees to your small business will become an urgent need. However, there are no special requirements for employees in this matter - they only need to be conscientious, have no bad habits and have a medical record.

Considering that not a single educational institution in the country has a mushroom science department, it will be simply impossible to find a qualified specialist. Of course, there is always a chance that an experienced person will come across. In this case, it is highly recommended to set his salary depending on the output.

It is difficult to say what the total number of employees will be required for breeding. One assistant will be enough for growing oyster mushrooms at home. If we are talking about a yield per centner every day, then you will need to involve at least a couple of employees.

At the same time, they will only be engaged in the mushrooms themselves, while additional forces will be required for the sale of products, preparation of raw materials for production and for the position of an accountant. Of course, one person, if desired, can combine several roles.

Approximate calculation

An approximate analysis of the costs and incomes of a large enterprise can be seen in the table.

| Start-up costs | Sum | |

| 1 | Renting or buying a piece of land or building | 1,000,000 rubles |

| 2 | Purchase of equipment | 500,000 rubles |

| 3 | Company registration, advertising costs | 100,000 rubles |

| Monthly expenses | ||

| 1 | Employee salaries | 150,000 rubles |

| 2 | 5,000 rubles | |

| 3 | Service costs | 15,000 rubles |

| Income | ||

| 1 | Profit from processing at a wholesale price of 1 kg of mushrooms at 14 rubles | 1,400,000 rubles |

Two important points should be noted here at once:

- These calculations imply work with a large farm, which contains about 100 tons of compost for growing, in case of scale down, the costs will be lower.

- The data are given on the basis of one processing cycle, but there can be up to four of them per year.

Summarizing all of the above, it can be noted that the net profit for one two-month growing cycle will be up to 780 thousand rubles. As a result, according to experts, the full payback period of the oyster mushroom farm will be about two years.

Those interested can download another business plan for growing oyster mushrooms.

Competition and risks

The issue of competition should be noted separately. At present, its level on the market can be assessed as rather low, which, coupled with low requirements for starting a business, makes it especially beneficial for beginners. Imported products have recently left the domestic market, but the price level has remained, and the demand for mushrooms is constantly high.

Competition should be feared for the most part from the larger commercial breeders. However, there are not so many of them on the market today, so there is no need to fear serious opposition to expansion. The risks in this area are also not too great, given the low investment requirements.

conclusions

The main advantage is high profitability. The advantage is that there is no need for significant investments at the initial stage. At the same time, the income is quite good - it reaches 650 rubles from each processed square meter in 1.5 months.

Another indisputable advantage is ease of learning. Oyster mushrooms require much less maintenance than other mushrooms, including champignons.

Experienced businessmen, however, do not deny the existence of a number of difficulties, but they all relate to the initial stages of establishing a process and sales. After settling these points, everything becomes much easier and all that remains is to collect and sell the crop.

Video: technology for growing oyster mushrooms.

Reviews

“Growing oyster mushrooms is a profitable business, as these mushrooms are always in demand. From personal experience, I would like to note that the extensive cultivation method brings greater results and, accordingly, profit. My farm reached its maximum productivity after 2 years of work ”- Nikolay.

“I doubted for a long time whether it was worth starting, but after thinking, I decided to take a chance. At first they worked with the whole family, the four of them coped quite well for the first few years.At first there were many failures, it is very important to follow the cultivation technology, otherwise everything will be in vain. I learned over time. I would advise you to grow it on poplar stumps and immediately from the purchased mycelium ”- Marina.

“You need to start a business with a detailed acquaintance with the technology of the process, otherwise time is wasted. At first, while honing his skills, mushrooms went into their own food, and gifts to friends and acquaintances. A couple of years later, he formalized an LLC, began supplying to markets and restaurants. They are in great demand, so it is definitely worth doing this business ”- Stepan.

If you find an error, please select a piece of text and press Ctrl + Enter.

(OKVED 2) 01.13.6 Cultivation of mushrooms and truffles

200 000 ₽

200 000 ₽

Minimum start-up capital

An oyster mushroom growing project is distinguished by a low level of risk due to its simplicity of organization, small start-up investments and low operating costs. The payback period of the project from the start of production will be 9 months.

Project summary

The purpose of this project is to grow mushrooms (oyster mushrooms) for the purpose of their fresh implementation in Rostov-on-Don with a subsequent increase in production capacity and expansion of the range of other types of mushrooms. The oyster mushroom is in constant demand among the population, it is distinguished by its unpretentiousness to temperature fluctuations, to the level of humidity and illumination, is easy to care for, and has a quick germination. The costs of growing oyster mushrooms are not high, which makes the business very profitable.

The production has unlimited resources in raw materials (straw, sawdust, corn cobs, seeds, seed husks, etc.) and is located in an ecologically clean area, 15 km from the city, due to which the costs of transporting products without losing their quality for the end consumer are minimal.

The process includes 4 main stages:

-

Purchase of seed (mycelium);

-

Preparation of the substrate (with a bag with a nutrient medium and mycelium);

-

Growing mushrooms;

-

Implementation.

The cost of the project will be 202,500 rubles, which will be taken from personal savings. Mainly, the funds will be spent on the creation and equipment of a greenhouse on the territory of the suburban area owned, as well as the purchase of mycelium, fertilizers and other consumables. The payback period of the project from the start of production will be 9 months.

|

Project net profit *, rub. |

54 919 |

|

Return on sales,% |

|

|

Profitability index, PI |

|

|

Payback period, months |

|

|

Discounted payback period, months |

* data for 12 months from the start of work sales

The term of the preparatory part of the project will be 2 months. The first harvest is planned to be obtained in 40-50 days after planting.

Profitability of growing mushrooms (oyster mushroom)

Oyster mushrooms are cultivated mushrooms. The market for cultivated mushrooms, unlike the market for wild mushrooms, is easily quantifiable. Until 2014, the largest share of the domestic market (about 85-90%) was occupied by imported products. The volume of Russian production in 2014 was limited to 8.02 thousand tons of mushrooms. However, already in August 2014, the mushrooms came under the embargo. Imports began to decline for all items. Foreign manufacturers began to leave the market, making room for Russian entrepreneurs. According to the Mushroom School magazine, for 9 months of 2015, Russian mushroom growers increased the production of oyster mushrooms by 17% compared to the same period last year.

Similar trends are recorded in the production of other mushrooms, in particular, champignons. As a result of the devaluation of the ruble, the selling prices for cultivated mushrooms increased. Today, to cover the deficit in the market and the transition to full import substitution, at least 158 thousand tons of mushrooms will be required.The current market conditions, as well as a weak level of competition, contribute to the opening of their own production.

The production itself is located on the territory of a summer cottage, 15 km from the city of Rostov-on-Don. The area of the greenhouse and the premises in which the mushroom growing process takes place is 60 sq. meters. For growing mushrooms, seed (mycelium) is purchased from a specialized company, the cost of which is 50-55 rubles. per kilogram. Further, on-site preparation of the substrate and the process of growing oyster mushrooms with the required level of humidity. Raw materials for the preparation of the substrate are prepared independently or partially purchased (the cost of 1 ton of straw is 2 thousand rubles). The term of one production cycle is about 40-50 days. The goods are sold at a non-stationary outlet in the grocery market of Rostov-on-Don.

Since at the initial stage the enterprise is focused on a small volume of production (about 1 ton of mushrooms per month), maintenance will not require regular and hired personnel. the main responsibilities, including the purchase of mycelium, planting, fertilization and mushroom picking, are carried out by the family members of the owner. The business owner is directly involved in the main production processes, and also carries out retail trade in the vegetable market. An individual entrepreneur with a simplified taxation system was chosen as the form of ownership - 6% of the income received.

Product description (mushroom oyster mushroom)

Oyster mushroom is an environmentally friendly product that does not use chemical treatment for its cultivation. Unlike other popular cultivated mushrooms - champignons, which grow on rotted manure, oyster mushrooms prefer trees. The popularity of this mushroom is attributed to the different ways it is prepared. Oyster mushrooms can be fried, boiled, salted, pickled. Oyster mushroom is also actively used as an ingredient in various dishes, added to salads. Oyster mushroom is especially in demand during the cold season, when the population's own mushroom reserves are depleted.

Oyster mushroom not only tastes great, but also has health benefits. Oyster mushroom lowers blood cholesterol levels. Oyster mushroom juice prevents the development of Escherichia coli. These mushrooms have a low calorie content (about 38 kcal fresh). Oyster mushrooms contain a large amount of carbohydrates, contain vitamins D2, E, C, B, PP. These mushrooms also contain enzymes that burn fat and glycogen. The mushroom pulp contains calcium, iodine, potassium, iron, biotin and thiamine. Another beneficial property of oyster mushrooms is considered to lower blood sugar levels. Eating oyster mushrooms helps prevent the development of diseases such as atherosclerosis, hepatitis, stomach ulcers, and cholesticitis. Also, doctors recommend eating oyster mushrooms for people who have bronchitis or have undergone chemotherapy.

Profitable franchises

The main disadvantage of oyster mushrooms its fragility is considered, and therefore this mushroom is difficult to transport over long distances. Fresh uncooled mushrooms are considered a very delicate cargo that requires a special temperature regime and the fastest possible delivery. Oyster mushroom also has a rather weak mushroom aroma. When spores of oyster mushrooms enter the lungs, they can cause allergies.

The quality of the goods and safety for end users are planned to be ensured through the purchase of certified mycelium, disinfection of production facilities and equipment, as well as through the use of modern production technologies.

Growing oyster mushrooms is a practically waste-free production, since the used substrate is used as a biologically active additive, which is used for feeding pigs, as well as fertilizers for gardeners and gardeners. The spent substrate is planned to be sold as an additional source of income.

Sales and marketing in the supply of oyster mushrooms

The main consumer demand for this type of product is freshness, which determines quality. The location of the mushroom farm is 15 km. from the place of sale allows you to organize transportation on your own transport (van "Lada Largus") without loss of quality. The products are sold at the food and vegetable markets of Rostov-on-Don. No special packaging for mushrooms is required. For transportation, plastic boxes are used.

The prices for products are based on material costs of production and fuels and lubricants, as well as the price of competitors, which on average in the city is 150 rubles. per kg. As a competitive advantage, it is planned to set a retail price of 140 rubles for the first time. per kg. Depending on the level of demand and other factors (for example, the devaluation of the ruble), an increase or decrease in selling prices is possible.

As a method of increasing sales, it is planned to use advertising on the Internet to attract wholesale companies.

Oyster mushroom production plan

Geographically, the mushroom farm is located 15 km from the city of Rostov-on-Don, due to which the delivery time of mushrooms to the place of sale is no more than half an hour. The process of growing mushrooms takes place in an ecologically clean rural area, on the territory of a summer cottage. Business technology can be divided into several main stages:

At the first stage there is a purchase of mycelium from specialized laboratory firms. The criterion for choosing a supplier is the availability of relevant documents, customer reviews, quality and affordable cost of products (50-55 rubles per kg.). The purchase of mycelium is made not once, but several times a year, since the shelf life does not exceed 3-4 months. At the initial stage, it is planned to purchase mycelium from different suppliers for a visual comparison of the results and making a further decision.

Second phase implies self-preparation of the substrate, that is, a nutrient medium for mushrooms. Due to the lack of experience in commercial mushroom growing, at the beginning of the activity, it is planned to prepare a substrate from various components to determine the best yield. Among them: wheat, rye, barley straw, oats, flax fires, stalks and corn stalks. The substrate should be aerobic, have air gaps between the particles, and the ability to quickly assimilate it by the mycelium.

It is also expected to use additives to increase yields: sawdust, shavings, tree bark, chaff and other plant waste. To clean the straw from microorganisms, a pasteurization procedure is used. The raw materials are kept in a special chamber, into which water vapor is injected for about 6-8 hours at a temperature of 60 ° C. The pasteurization temperature must be maintained within 55-60 ° C: a lower temperature does not kill diseases and microorganisms, and a higher temperature contributes to the development of Trichoderma, which will destroy the crop. After that, the temperature decreases, and the raw materials remain in the chamber for another two days.

Then the substrate is cooled and placed in plastic bags of 10-12 kg and sown with oyster mushroom mycelium at the rate of 150-200 grams per 1 bag. To remove excess moisture, holes are made in the bottom of the bag, after which the bags are placed in the germination chamber.

Stage three is to provide conditions for growing mushrooms. Direct sunlight is not allowed in the room. For germination, mushroom blocks are placed vertically, and the distance between them is 10 cm. The temperature is about 24 ° C, the relative humidity is about 60-65%. The mycelium germinates within 10-17 days, after which the bags must be transferred to the fruiting chamber. Mushroom blocks are installed in one row in several tiers, the distance between the rows along the axes is 1 m.In the fruiting chamber, a lower temperature level is maintained - about 12-18 ° C, and humidity is at 80-85%.

To maintain high humidity, a special irrigation system is used. If the conditions are met, the embryos of the fruiting bodies appear at 2 weeks. The harvest from each bag is collected in 3 waves, after which the mycelium is replaced with a new one. Mushrooms are harvested by druses (aggregates) at a young age. The optimal head size is up to 40 mm. The minimum yield from 1 wave of offering is 150-200 kg from 1 ton of substrate, 350-400 kg from 2 tons. The total duration of the production cycle is about 2 months.

The final stage involves the implementation of the resulting crop. Mushrooms are perishable foods that can be stored in the refrigerator for no more than 5 days. The main channels for the sale of mushrooms are considered to be markets, grocery stores, restaurants and catering points, enterprises for feeding farm animals. Due to the relatively small starting volumes of production, it is planned to sell one of the vegetable markets in Rostov-on-Don at a non-stationary outlet as an initial sales option. The rental price per day with VAT is 250 rubles.

Profitable franchises

The project will require an area of 60 sq. meters. To eliminate rental costs, it is planned to organize the cultivation of oyster mushrooms on the territory of their own suburban area. It is planned to equip 2 separate rooms - an incubator, where mycelium will grow, and a germination chamber with a hood. The planned production volume for the production cycle is 2000 kg, for the year (6 production cycles) - about 12000 kg.

The costs of building a greenhouse will amount to 100 thousand rubles. Another 114,500 rubles. required for equipment. Equipment costs are shown in Table. 1. Construction work is planned to be completed within 2 months.

Table 1. Equipment costs

For the operation of the enterprise, members of the owner's family are involved, who, along with the owner, carry out basic functions, including planting, fertilizing and picking mushrooms. The family business format is designed to reduce staff salary costs. The necessary experience is supposed to be acquired in the course of activities, as well as by reading special literature.

Current costs are the payment of electricity, the purchase of mycelium (50-55 rubles per kg.), The cost of fuels and lubricants. Mycelium purchasing costs may increase or decrease due to seasonal fluctuations in demand. Also, the expenses of the main period include the rent for a trading place in the market - 250 rubles. per day (on average 7600 rubles per month).

Financial plan for growing mushrooms (oyster mushroom)

The main management responsibilities are assigned to the project owner, who carries out business planning, as well as functions to ensure conditions for the germination of mushrooms, their delivery to the place of sale, and also directly manages sales at the outlet. Responsibilities for growing, caring for, picking mushrooms are also assigned to the family members of the owner.

For the preparatory period, 202,500 rubles will be required. This amount includes the construction and arrangement of a greenhouse (100 thousand rubles), the purchase of equipment (92.5 thousand rubles). The costs of the main period include the purchase of mycelium, payment for housing and communal services, rent of a retail outlet, fuel and lubricants. The financial indicators of the project are presented in Appendix 1.

Evaluation of efficiency in growing mushrooms

An oyster mushroom growing project is distinguished by a low level of risk due to its simplicity of organization, small start-up investments and low operating costs. The payback period of the project from the start of production will be 9 months. The discounted payback period is 9 months. Project performance indicators calculated for a five-year period are shown in Table. 2

The main prospects are: an increase in the selling price upon the project's return to recoupment by 10% (up to 150 rubles per kg), an increase in production volumes, an expansion of the offered assortment, a search for new sales markets and access to wholesale buyers.

Table 2. Project performance indicators

Risks and guarantees

Growing oyster mushrooms is a well-established business. The technology for growing oyster mushrooms is quite simple, moreover, there are many ways to increase yields without harm to the end consumer. The prevailing market conditions somewhat contribute to the reduction of risks. Today in Russia there is a shortage of mushrooms due to the imposition of the embargo. Imported products left the market, as a result, the cost of domestic mushrooms increased without any negative consequences for demand. Consequently, when the price decreases, demand acquires a significant level of elasticity.

The main risks are indicated in Table. 3.

Table 3. Assessment of project risks and measures to prevent their occurrence or their consequences

Applications

Production plan and main financial indicators of the project in a five-year perspective

Business calculator

Calculate the profit, payback, profitability of any business in 10 seconds.

Enter initial attachments

20 types of business for retirees

Elderly people should pay attention to the quietest types of business that either do not require complex processes, or are cheap to start, or make it possible to earn a hobby.

Business plan. Inoculum mycelium production laboratory

Financial calculations were made for a laboratory for the production of seed mycelium with a productivity of 4 tons of mycelium per month. The cost of the project will be 7,030,500 rubles. Payback period from the beginning ...

Business plan: growing mushrooms

The financial calculations of the project were made for an enterprise that includes 6 chambers with a total growing area of 570 sq. meters. The production cycle lasts about 60-63 days. The cost of the project will be 1 & ...