Content [show]

Technologies in all spheres of human activity are rapidly developing; progress has not spared agriculture either. New agricultural techniques are being designed, new methods of planting a particular crop are being created, every day there are more and more new ones. But even in such conditions, many gardeners are distinguished by a conservative attitude towards everything. You can even take the process of hilling potatoes as an example, the aforementioned gardeners carry out it with the help of hoes, which makes the process more complicated and energy-intensive. What can replace the "beloved" hoes? There are many answers to this question, but the best one is a manual hiller.

The hiller is a versatile tool that any gardener may need, with it hilling will become much more effective. Using such a tool saves you time and effort.

Manual

Manual hillers (disc) are designed for loosening and hilling... The use of such a tool can guarantee high-quality soil cultivation.

This tool can help the gardener carry out hilling, avoiding energy-consuming and tedious work.

To the tractor

They are used for automated processing. The device is able to immediately remove weeds from the cultivated area and, in fact, successfully carry out the hilling of tubers. After manipulating the tractor hiller the level of potato yield increases dramatically.

They consist of: a metal frame, a hitch, which is responsible for the hitch, two stamped wheels, iron lancet paws and dumps.

The tractor wheels reduce the load on the tiller, in turn, the paws cut the soil (up to fifteen centimeters). A steel support attaches the legs to the frame. Used for hilling lattice dumps.

Basically, tractors can be attached exclusively to the T-25 tractor, which has a rather small traction force, unlike MTZ. He is not able to work with a device that has more than 3 cases.

If the gardener has a goal - just to spud the potatoes, then you need unscrew the lancet paws.

To the walk-behind tractor

The device is installed on the walk-behind tractor in place of the coulter.

How it works: during the transitions between the rows, the device pours soil with its wings directly onto the tubers. A disc hiller can be attached to the walk-behind tractor.

In fact, "hillers to a walk-behind tractor" are not a separate species. We used this to let you know that the unit can also be mounted on a motor cultivator.

Plow

The potato hilling plow is designed to facilitate the work associated with the cultivation of potatoes. With the help of such a plow, they cut furrows and beds, loosen the soil, plant crops, and huddle.

By its configuration and mechanism of action, the plow similar to a disc hiller... At least their mechanism of action is absolutely identical.

Hilling potatoes

How potatoes are spud with a disc

The mechanism of action of manual hillers is rather primitive.Two gardeners should grip the device from both sides (front and back). One rests on the front link handle and sets the hiller in motion, another - pushes the discs into the ground, pushing the rear link handle.

The disc passes through the soil, leaving a noticeable trail behind it. With the help of such a device, it is possible to spud plants that are in close proximity to each other. But you can also adjust the distance between the discs, just install a few additional parts.

Why is it necessary

If you are reading this article, then you definitely know that potatoes need to be hilled. But why?

Now we will explain everything in detail:

- When loosening the soil, air enters the roots, thanks to which they grow much faster

- Again, when air is drawn to the roots, potato tubers form quickly.

- If you huddle potatoes, then you can increase the yield by 20-30%

You also need to follow some rules:

- You need to loosen in a timely manner

- Loosening is necessary in cloudy weather. The best option is after rain, irrigation or morning dew

- Potatoes should not be hilled during the heat, as the plant can simply burn out

As a rule, hoes, hoes and rakes are used; their use is energy-intensive and takes a long time. Against the background of the hillers, the above tools simply fade.

Pros and cons of homemade devices

The list of advantages of homemade devices includes:

- accessibility - since any person can make such a hiller

- gratuitousness - cases where a person paid himself was not registered

- efficiency - as a rule, home-made devices are in no way inferior to market counterparts, but it depends on the design

- raising self-esteem - after all, it is better to spud potatoes in a good mood

But the disadvantages include:

- work safety - but it depends on how well the hiller is designed

- quality - again, depends on how well the hiller is constructed

Tool Facts

What materials are needed

To create your own hiller you need:

- water pipe - it serves as a stand (Diameter - 1 inch, length - meter)

- tube 0.37 inch - it is necessary for the front and rear rods

- steel sheet (thickness - 2 mm.) - dumps will be made from it

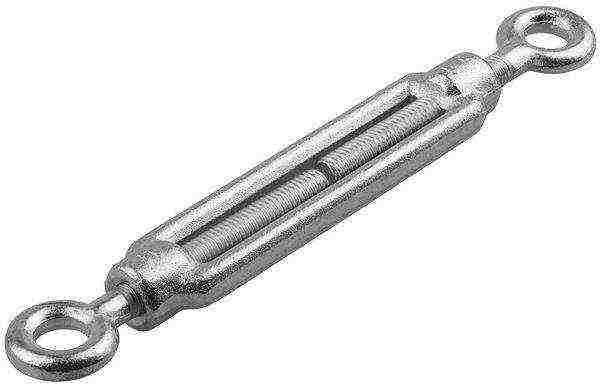

- lanyard - which will secure the front link and rack

You also need to have with you: any tools for bending pipes and a blowtorch (you can use a regular gas torch). She needs to heat the metal parts in the places where they bend. You will also need a welding device and a grinder.

Where can I find blueprints

The Internet has answers to all questions, even those. Drawings for making a manual hiller can be found on the net, or in any magazines on the theme Garden / Vegetable Garden.

-

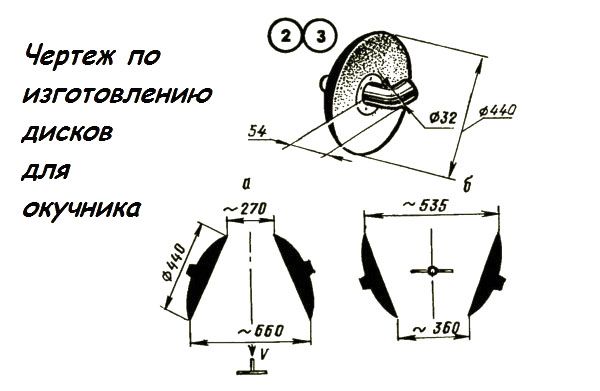

- Disc hiller drawing

-

- Drawing of a hiller for a tractor

-

- Hiller drawing

Installing a homemade hiller on a walk-behind tractor

To install a homemade hiller on a walk-behind tractor, you will need bracket... A homemade leash is attached to the bracket by means of a stopper and bolts to flat washers. The stopper is sent inside the pipe in the shape of a square and securely pressed against its outer surface

Do-it-yourself hillers to the walk-behind tractor

Vertical stand

You can adjust the height by means of the telescopic apparatus of the central part... It is required to insert into the pipe into a pipe that is smaller in cross section than the other, it goes into the rear thrust. If you use this method, you can easily adjust the hiller to the growth level of the gardener.

Adjustment

Tool bed must be mobile... To fulfill this condition, the front link is attached to the main strut with a hinge, the adjustment is carried out using a lanyard, which allows you to change the angle of inclination. In the case when there is no lanyard, a metal plate is used, it is fixed in the desired position and fixed with bolts.

Welding

The rear link and the blades need to be welded to the rack, then the front link is attached. Rear link width - 0.5 meters... Handles - 0.2 meters... A 0.3 meter long pipe is welded to the center of the fork, with this end the structure is inserted into the vertical rod cavity.

To adjust the height of the rack, you need to drill out the openings that are located at its upper end. Exactly the same manipulations must be done with the vertical fork. The front and rear links must have the same width.

Making a double-plow plow

To make a double-plow plow, you need plates, each two millimeters thick... They need to be given semicircular bends. Then the process of welding the two halves to the rack is carried out.

Two important aspects of work: the seam in the place where the parts are joined must be even, the plates must be sanded with a grinder.

Making a pruning knife

Then a knife should be cut out, which in its shape should be similar to an arrowhead, and sharpened carefully (the angle between the surface and the knife should be 45 degrees)

Why exactly 45? If you grind the knife at this angle, then it will not lose its sharpness for a long time. Next, you need to weld the trimming knife to the bottom of the rack and grind it.

Disks

First you need to cut 2 plates from a steel sheet, then you should give them the shape of a semicircle. Both discs are fixed to the rack. Welded the seam must be even.

Previously, all parts that are to be welded must be grinded with a grinder, and the discs must be carefully sharpened. The undercut takes almost all the soil resistance.

The hiller is almost an indispensable tool that every gardener who respects his time and strength must have.

As for garden tools, hillers are quite an expensive pleasure that can really help in the household. In any case, even this expensive equipment can be made with your own hands, it is enough to be able to use tools and use drawings.