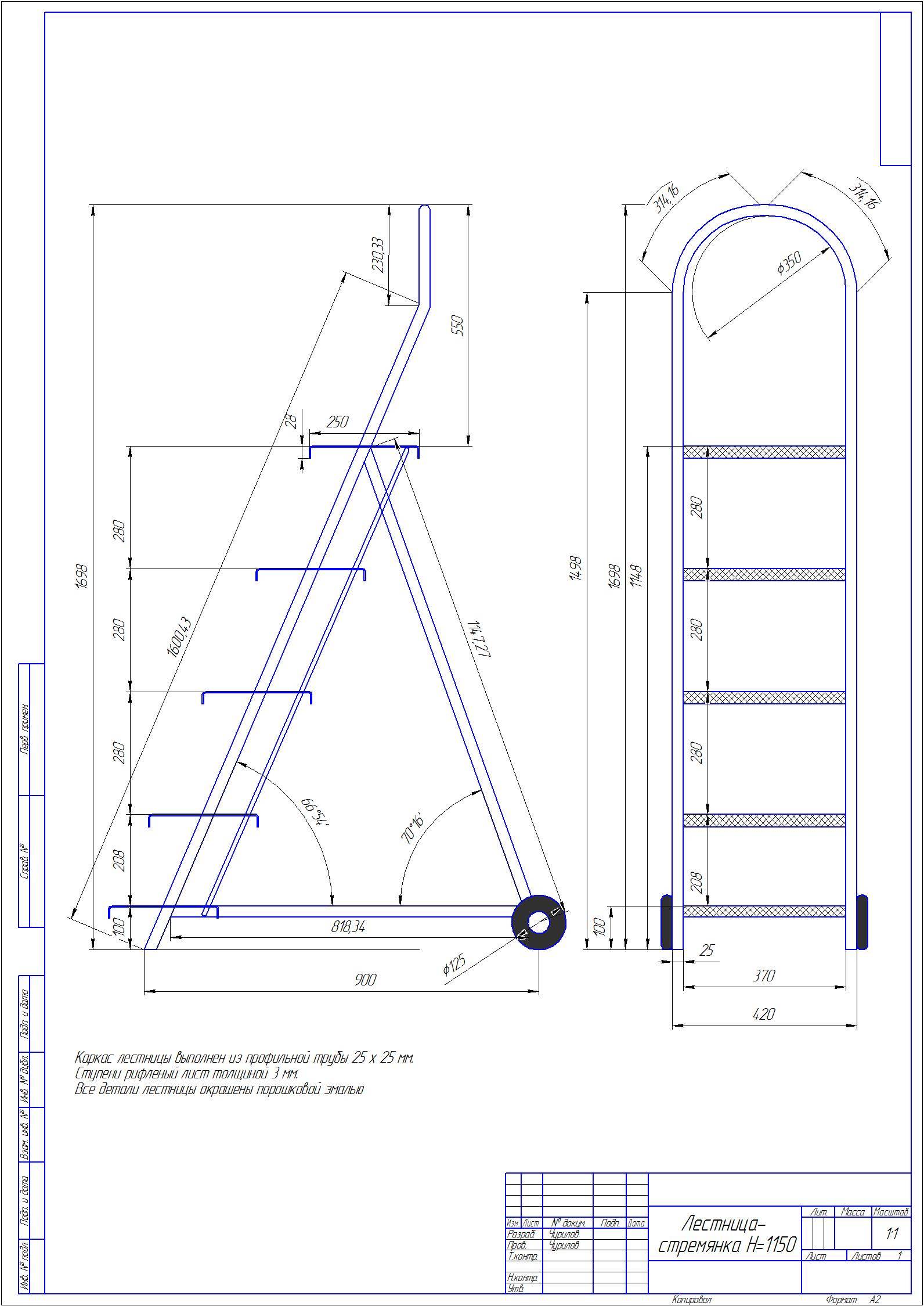

DIY stepladder: the easiest option

It is not so difficult to make a straight staircase made of wood, and all that distinguishes it from the simplest step-ladder is the presence of additional supports or, if we are talking about a two-sided staircase of this type, then the second straight staircase. Here is the beginning of the technology for making a wooden stepladder with your own hands - we make two straight stairs and at the same time we take into account several points.

- Width - they must fit into each other with a gap of up to 3mm on each side.

- The location of the steps. In order for the ladder to fold completely, the two ladders must be mirror images of each other - the steps must be located as close as possible to one of the sides' edges.

-

Lack of steps at the top of the ladder. This gap will have to be calculated based on the height of the structure you are assembling.

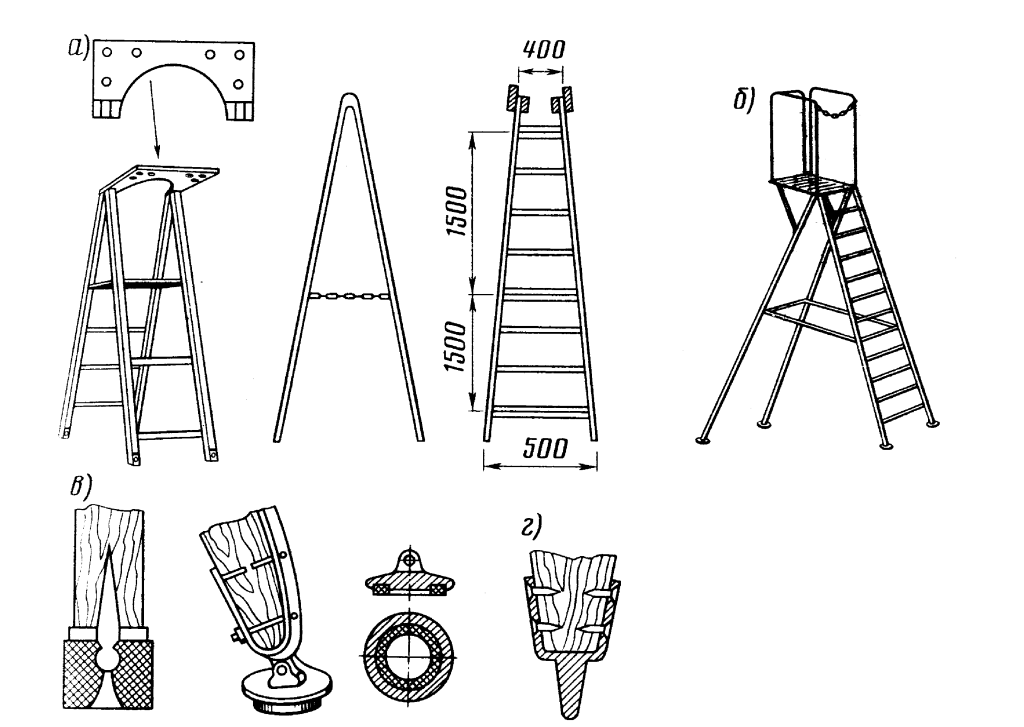

And then you need to combine these two ladders into a single product. The easiest option you can think of here is a long bolt with nut or stud. To reduce the rate of wear of the holes in the wood, metal tubes can be driven into them, then friction will occur on the metal, and the wood will not suffer. Naturally, you will also have to take care of the upper platform - it is better to make it from thick plywood. It can be attached to the top step using small door hinges. And don't forget about the grappling hook on the underside of the platform to keep the ladder from going apart - it needs to be powerful enough not to unbend under your weight.

In principle, this is all that can be said about the water of the question, how to make a ladder with your own hands? There are other technologies for the manufacture of devices of this type - if you know how to use welding, then it can be made from a thin-walled profile pipe. The principle is the same, and the material from which it is made has little effect on its design features. On the performance characteristics, yes, but not on the general manufacturing technology.

The author of the article is Alexander Kulikov

The video has been deleted.

| Video (click to play). |

Sources:

- Abramov, L. I. Organization and planning of construction production. Construction organization management. Textbook / L.I. Abramov, E.A. Manaenkov. - M .: Stroyizdat, 2015 .-- 400 p.

- MM Fatiev. Construction of urban greening facilities; Forum, Infra-M - M., 2016 .-- 224 p.

- Orlov, Vladimir Alexandrovich Pipeline networks. Automated support for project development. Textbook / Orlov Vladimir Alexandrovich. - M .: Lan, 2015 .-- 328 p.

- VB Belevich Roofer's handbook; Higher school - Moscow, 2002 .-- 464 p.

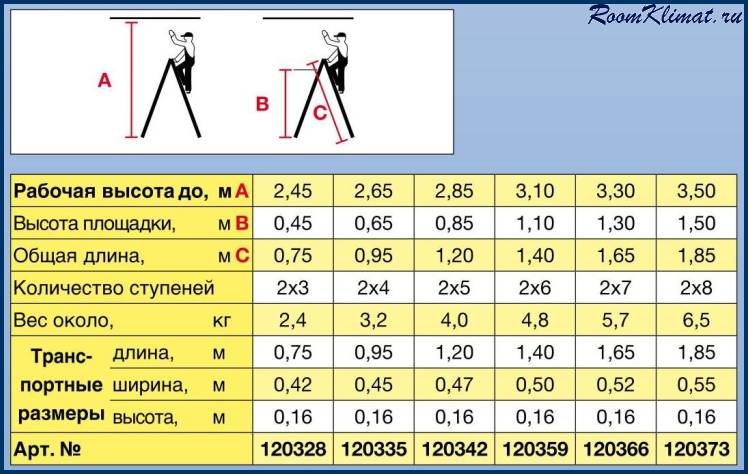

Aluminum stepladder and working height

And yet, the main parameter when choosing a ladder is the working height that it can provide. The height is measured in terms of the number of steps.

The smallest ladders have only three steps and they are most often used to reach something from a low height. A person of average height, standing on such structures, may well reach the ceiling of a low house, since the last step of the ladder is at a distance of 60 cm from the floor.

The staircase is popular, in which the material is aluminum, the number of steps is five pieces. Its height reaches 250 cm, which means that with the help of such a structure, the variety of high-rise work can be significantly expanded.

One of the most popular options is a step-ladder made of aluminum, the number of steps is seven pieces with a working height of 350 cm. It is it that is most often purchased for various household and professional high-altitude work.If you need a ladder higher and more serious, then there are modifications with ten steps, which have a working height of 410 cm.

When choosing a stepladder, you need to pay attention not only to its parameters, but also to its condition. So, a stepladder that is ideal in size can have a factory defect, which is expressed in different sizes of legs.

It is also important to pay attention to such useful options as an additional platform or an add-on container for keeping various things in it. This is convenient in order not to go down every time to find the necessary thing.

Pay attention to such a parameter as the distance between the steps. The average and optimal value is considered to be 25 cm

If you work often at a height, as well as if the ladder will be used by an elderly person, it makes sense to pay attention to the ladder with a handrail. Of course, such a design will be less compact, but more convenient and safe for operation.

Manufacturing material

Metal, plastic or wood are used as materials for the manufacture of ladders. Various combinations of these materials are also possible.

Wooden stepladders are comfortable in everyday life, stable, warm and pleasant to the touch. However, the tree is sensitive to changes in humidity, is subject to decay processes, and can become moldy. Such products require regular processing with special compounds.

Wooden stairs are not very compact and have a fairly large weight. They are not practical designs. However, in modern design, their decorative properties are often used. Interior wooden stepladders are very common.

Universal models with a lot of advantages are made of metal. They are lightweight, durable, reliable, non-corrosive and easy to use. Aluminum folding sectional ladders are very popular. The simplest model is a single-section staircase. Using a system of hinges, a two-section staircase is obtained. The number of sections usually reaches four.

Hard polyurethane and plastic are less commonly used. Of these, mainly low, lightweight step-ladders (up to 0.7 m) are made. Such designs are reliable when made from high quality, certified materials.

Stepladder as part of the interior

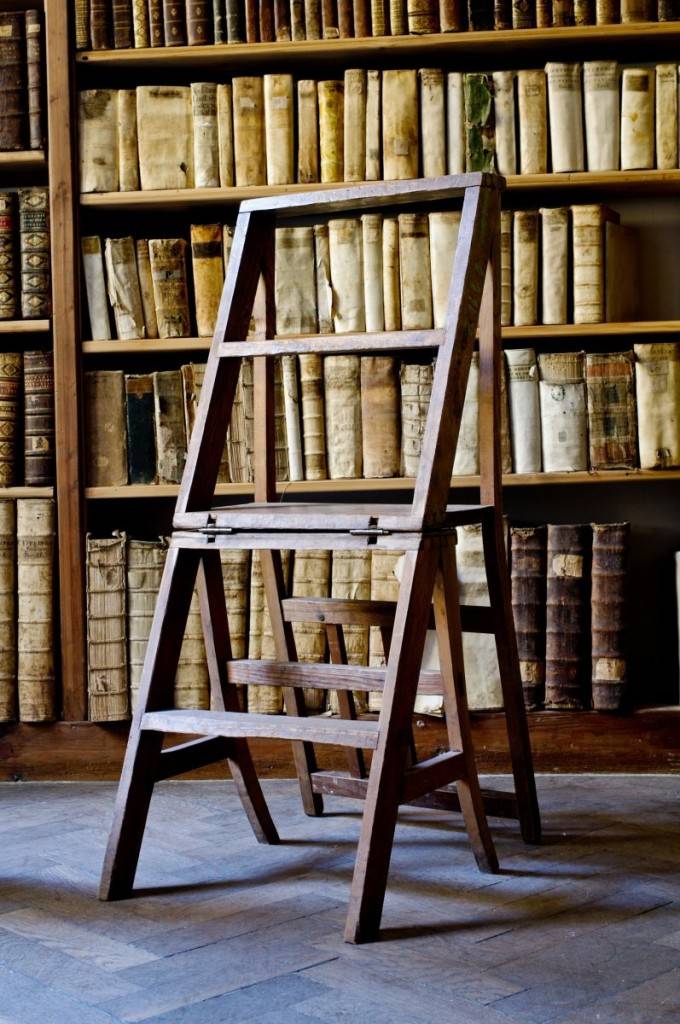

Portable stepladders are as popular as folding ladders. Most often they are used in private libraries or offices. Massive, full-fledged steps of such ladders are made of precious wood. Carved or curved bowstrings. Rounded handrails, carved balusters. Everything is like a real big staircase.

Portable ladders are often used in libraries.

Portable ladders are often used in libraries.

The main quality of both graceful folding and portable ladders is mobility. Portable ones are not often moved around the room or moved from floor to floor. Miniature or massive, with or without wheels for moving, they resemble an airdrome ladder. The same ceremonial, durable and mobile. The beauty of wood, the smoothness and shine of the finish, safety in use, everything is subordinated to its main purpose - to serve properly and be always in sight. A non-folding model is always a piece of furniture and a part of the interior. Lines, shape, color of decoration, general composition of wooden portable stairs can not only fit into the interior, but also create a mood in the room. The next design masterpiece of wooden and furniture architecture can be a stepladder that can transform into a stool, chair, armchair, ottoman or coffee table. Depending on the final idea, the steps when unfolding are steep or flat. But in any case, it's brilliant. And these ingenious ideas are suggested by the material itself - wood.

There are many ideas for transforming a stepladder into a decoration.

There are many ideas for transforming a stepladder into a decoration.

Criterias of choice

It is worth choosing a design, firstly, according to the material.The aluminum step-ladder has very good characteristics. This is explained by the fact that the aluminum material is very light.

If we compare it with a ladder made of steel, then an aluminum step ladder will undoubtedly be easier. For example, a steel ladder will weigh six kilograms, while an identical aluminum structure will only weigh four.

It is important to note that an aluminum ladder will cost slightly more than a steel ladder. Maximum load for structures - 150 kg

There are duralumin ladders on the market. They have practically no differences from an aluminum ladder, except that there is less aluminum in the alloy. But the price for their purchase is lower.

Aluminum stepladder is selected based on the configuration.

The last version of the ladder is suitable for working with large surfaces, since it is very convenient to rearrange it. Especially if the structure has an aluminum material. As a rule, it provides the ability to climb to a height from two sides.

The L-shaped design of the ladder, although equipped with a working platform, is a less convenient option for working at height. Although among its obvious advantages is greater compactness compared to L-shaped stairs.

The number of sections is another indicator that affects the ease of use and safety when working with it.

The two-section design is a versatile option that can be used both as a step ladder and as an extension ladder.

The three-section stepladder from the side resembles three separate ladders. It is also distinguished from other models by its maximum working height. In this case, not just the material aluminum is used, but a special alloy, which, for all the size of the structure, will not allow its individual elements to bend. Such stairs are most often used for high-rise work in production, but they may also be needed in everyday life if the height of a private house is too high.

Criterias of choice

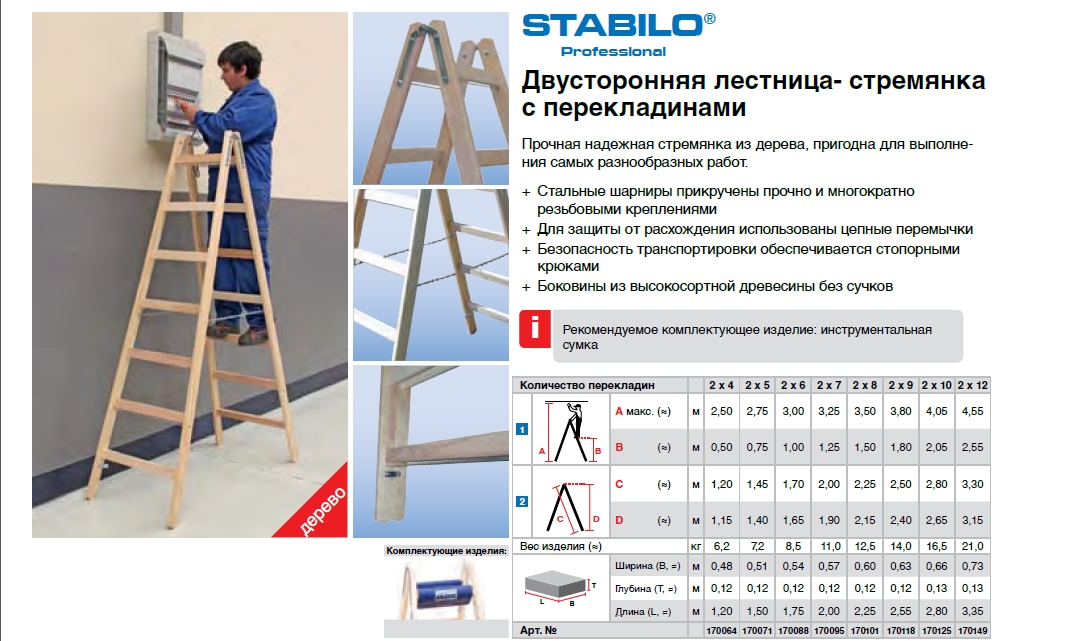

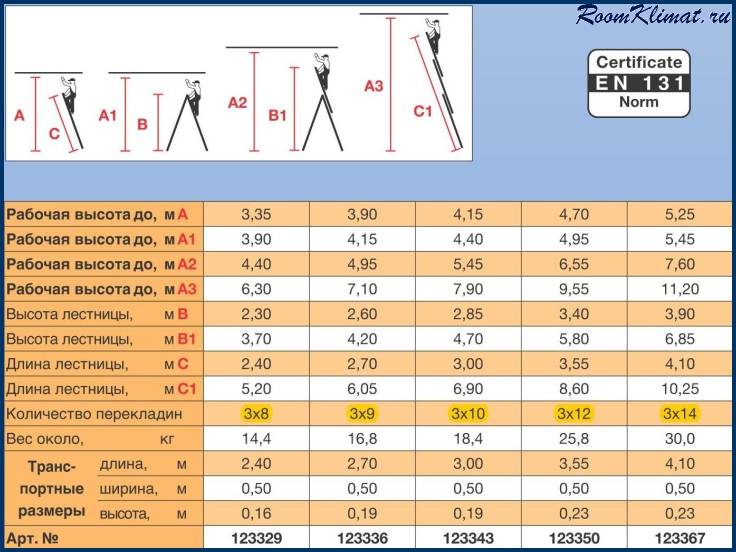

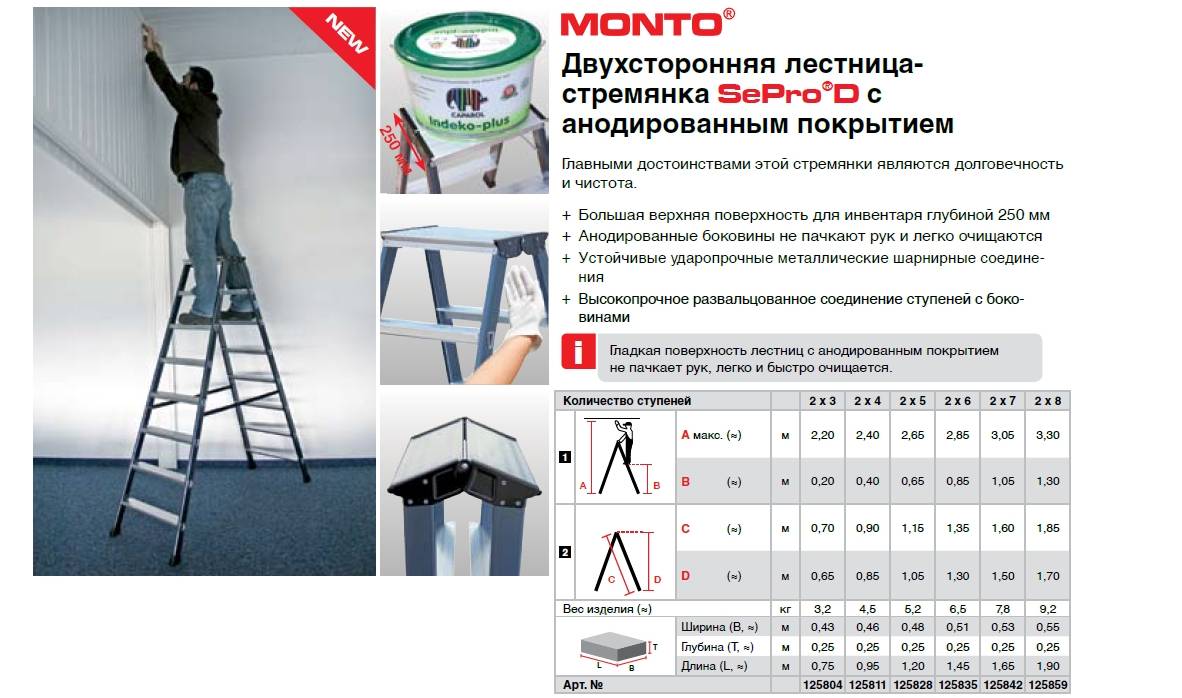

Manufacturers of step-ladders indicate in the brochures the main parameters that the buyer can be guided by when choosing a device.

Dimensions and height

How to determine the required step ladder height? Too tall or too small will be inconvenient to work with. The dimensions of the stairs are selected depending on the height of the ceilings in the house / apartment

The main indicator that you should pay attention to is the working height of the ladder

It is defined as the sum of two values: RV = RVP + RF, where:

- РВ - working height;

- RVP - height from the floor to the top of the stairs;

- RF - the height of a person in full growth with a raised hand (is a constant value equal to 2 meters).

Thus, if the instructions for the ladder indicate a working height of 3 meters, then the maximum rise above the floor level (RVP) is 1 meter.

By RVP (size), devices can be divided into 3 types:

- The distance from the floor is up to 0.6 meters. Products are convenient for painting. The ladders have a stool construction with 2-3 steps and a wide upper platform.

- Distance - 0.6 to 1.5 meters. Stepladders for interior decoration and renovation.

- Distance from 1.5 to 1.8 meters / 1.8 - 2.5 meters. Ladders for outdoor use are not folding / folding.

People whose height is less than 170 centimeters should take this into account when choosing a step-ladder. In order to be able to safely reach the ceiling, it is necessary to have a stock of 30-40 centimeters for the RVP.

Manufacturing material

In the manufacture of ladders, steel, metal alloys, plastic, wood are used. The materials have been tested in practice, which makes it possible to choose the appropriate option. Wooden ladders are made according to individual orders. Due to the original design and texture, the products are also used as part of the home interior. Low devices, 2-3 steps, are disguised as high stools, stands.In terms of durability, they are not inferior to metal ones if they are used inside an apartment.

Ladders made of aluminum alloys, duralumin, silumin are the most popular home ladders. The advantages of such products are low weight, no corrosion, and ease of repair. Insufficient strength of the material is compensated by the thickening of the steps and bowstring. Nodal connecting elements, corners are made of steel or stainless steel. The size of plastic ladder stools does not exceed 0.7 meters. Lightweight products are used for painting.

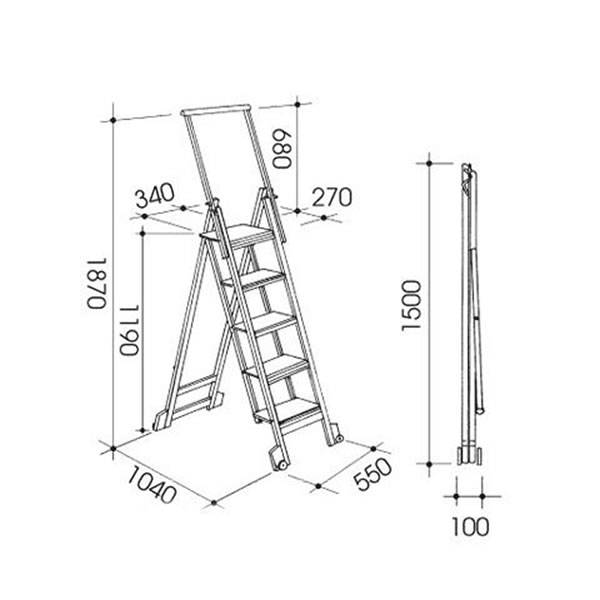

Technical specifications

In addition to the working height in the advertising attachment, indicate:

- the width of the foot bar;

- the distance between the crossbeams in height (step height);

- section width.

Comfortable and safe when working on a stepladder are considered to be steps wider than 12 centimeters, a step - up to 20 centimeters, a platform width - at least 35 centimeters, a frame width - more than half a meter.

Additional design features

A sliding ladder can be:

- in the form of a stand with 2-4 steps (on one or both sides), without an upper limiter;

- with a safety arc at a device height of 0.7 meters and above;

- combined (ladder-scaffold, with a retractable section).

Changes in the design are designed to solve specific problems, the main goal of which is convenience and safety in work.

Optional items

Ladders can be equipped with additional equipment to make their use more reliable and comfortable. Rubber heel pads are installed on the legs of metal products, which exclude slippage after installation on the floor. The metal steps have a rubber / rubber-plastic / plastic anti-slip coating. Stands, hooks or loops for the tool are installed on the safety arch.

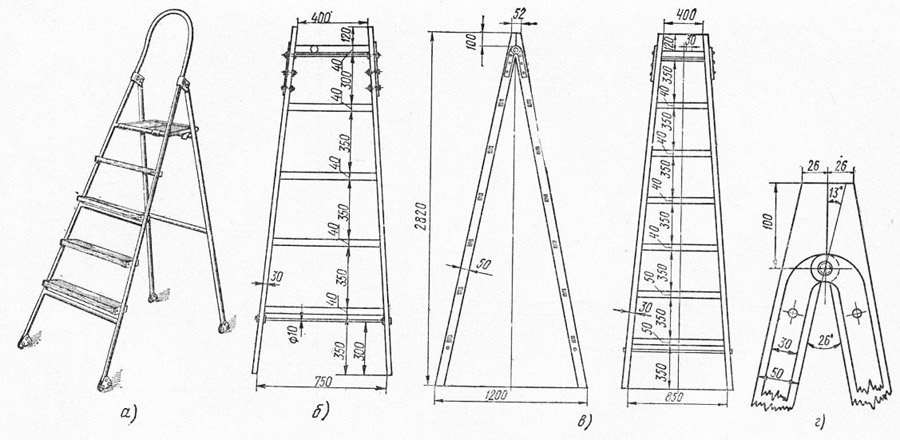

How to make a simple wooden step ladder with your own hands

A person who is familiar with the basics of construction can make a stepladder out of wood with his own hands. To do this, you need to select the type of stairs in advance, select materials and make all the necessary measurements.

Reference! To build a ladder, you will need a set of construction tools.

Determination of the configuration and size of a homemade step ladder

Before starting the step-ladder manufacturing process, it is necessary to calculate the input parameters. The first step to the calculation is to estimate the height of the future product.

The number of steps is often calculated based on how you plan to use the ladder. If the staircase is a decorative element, then it is enough to plan the construction of three steps. For repair work in houses with high ceilings or garden work, high stairs are constructed from 6 or more steps. Garden stands are most often designed as double-sided ladders, so that it is more convenient to work on them, and then fold and store.

Notches are made on the vertical support of the stairs, which imply the location of each successive step. One of the nuances of the correct approach to preparation is taking into account the tread indicator. A step is the distance between the edges of one step. The 45 shoe size is taken as a sample calculation. In this case, the length of the steps becomes shorter, the higher the step is.

Reference! It is customary to leave a distance of 20 to 30 centimeters between the steps.

The choice of the section of the bar

The cross-section of the bar can be square and rectangular. For the manufacture of stairs, both types are used. Most often, a bar with a total indicator of 60 by 40 millimeters is taken for the support posts, and a bar with a section of 60 by 30 millimeters is used for steps and crossbars.

Reference! Section standards take into account the type of wood species: for coniferous and deciduous species, the indicators may be different.

Choice of additional components

To make the staircase stable, beautiful and durable, additional elements are selected:

- Metal knitting needles or screws.These elements are necessary for a more reliable fixation of the steps. The knitting needles are inserted under the step, secured with nuts and bolts. The thickness of the needles should not be less than 8 millimeters, as otherwise the needles will begin to bend under the influence of the load. Screws can be used instead of metal spokes.

- Iron chain or nylon cord. These elements are designed to connect the two sides. They help to hold back the stairs, prevent the sides from sliding together.

- Nozzles or retainers. Pads are used to prevent damage to the flooring. They are put on the legs of the stairs and removed if they are used on the ground. Clamps are necessary for rolling structures.

- Swivel castors. This element is required for rolling structures. Builders recommend using 360-degree rollers. This design allows you to use the ladder on any surface, even to climb the steps without much effort.

Assembly: step by step instructions

To make a step-ladder with your own hands, you must strictly follow the step-by-step instructions. All work can be conditionally divided into stages:

- The necessary parts are cut or cut out according to the prepared templates.

- Where it is planned to install fasteners, holes, grooves, and recesses are made.

- The surface of the wood is treated with special compounds and dried.

- Self-tapping screws are installed in the places of fasteners, fasteners are fixed.

- The surface is re-grinded, errors made during processing are corrected.

- The final stage is the assembly of the stairs.

Advantages and disadvantages

Stepladders, especially made of wood, have many advantages over their competitors.

- They are lighter than steel.

- Compactness and stability of the structure. They do not scratch tiles, linoleum, parquet.

-

Smooth surface of bowstrings, steps. Preliminary sanding before painting or opening with varnish excludes the presence of chipping, roughness.

The polished and painted step ladder has an aesthetic appearance.

- Ease of processing with varnishes and paints. Ability to give any color shade, color combinations or multiple recoloring.

- Easy repair of worn out elements.

-

Possibility of choosing steps of any width from 30 to 200 mm, depending on the model.

On a stepladder with wide steps, it is easier to maintain balance.

- It is not difficult to make at home with the availability of space and tools.

- Availability of material for manufacturing.

-

The ability to choose the design of the ladder for the style of the room.

Small and stylish stepladder.

Wooden miniature step ladders also have some disadvantages:

- unable to withstand a load exceeding 120 kg;

- wood, as the main material of manufacture, does not tolerate increased moisture content in the room;

- have a slightly higher weight than aluminum or fiberglass.

A miniature step-ladder, and a wooden one in particular, can serve not only as a decorative element. Fragile in appearance, but strong, its design provides a person with a stable position during work.

The most durable and not large folding ladder can be considered a wooden step stool.

The most durable and not large folding ladder can be considered a wooden step stool.

Standard step ladder design

Here you can change the height of the platform

The construction of a building staircase involves not only an ascending row of steps, but also the obligatory presence of a support-retainer, which is necessary to give stability.

The grooved rungs on the ladders help to better maintain balance and are needed to create friction between the sole and the surface of each rung. Rivets or bolted joints can support about 150 kg, but some manufacturers insist on double the weight.

The main parameters that make up the cost of equipment are the number of steps and the width of an individual element, purpose and material.

The popularity of the manufacturer adds zeros to the price of the stairs - European companies sell their products at an order of magnitude more expensive than domestic ones.

The material of construction influences the price, weight and size of the stairs. The most practical are the combined models of aluminum and other metals.

Distinctive features of the double-sided stepladder

Lifting equipment is required to access the mezzanines and top shelves of shelving at home, in a library, office, store, construction or industrial site. To replace a burnt out light bulb, put curtains on the cornice, carry out repair and installation work at a height, harvest fruit, you also need stable steps.

> This type of model differs from ladders and one-sided ladder structures by the presence of steps on both sliding stable racks. On such a ladder, the possibility of performing labor-intensive work by two workers located simultaneously from different sides is allowed. The technician can also use the opposite side to place the instruments.

Useful equipment is made of wood, metal, aluminum and combined materials. The number of steps for models from different manufacturers varies depending on the application, load, height and other parameters.

Features of a wooden structure

It is difficult to list all the options where this wooden helper is applicable. Such a ladder can be found in pharmacies, offices, hotels, libraries and even apartments. What is the main secret of her popularity? To answer this question, let's first look at its design features.

Wooden stepladder is effectively used in offices.

Wooden stepladder is effectively used in offices.

First, the ladder is a very stable accessory. This type of ladder is able to maintain a stable position without additional support on a wall, rack or other vertical strong support. The essence of its design is that it relies on its own four anchor points. Secondly, a stepladder with bowstrings and steps made of wood does not create noise. No squeaking or clanking metal sounds are heard when folding / unfolding.

The safety belts prevent the step ladder from folding inadvertently.

The safety belts prevent the step ladder from folding inadvertently.

Thirdly, the strength of such a ladder is achieved not only by the reliability of the fasteners, but also by the massiveness of the bearing bowstrings. And so that the structure is not heavy and cumbersome, it is made in 3-5 steps. Fourthly, thanks to the wood, comfortable deep steps can be made. The foot is very confident on their horizontal plane. Homemade Stepladder Review

Materials and additional components

Increased safety design

For construction with a working height of 6 meters or more, aluminum is the optimum material. Ladders can withstand a decent load (about 150 kg), but they remain quite mobile. Wooden and steel with such dimensions, it becomes problematic to budge alone.

The functionality of the equipment can be expanded with the help of various auxiliary elements, such as:

- Rubber pads. Self-adhesive surfaces are suitable for covering steps or reinforcement. They significantly reduce the risk of slipping and impart dielectric properties to the supports.

- Additional sections. For most ladder models, you can increase the working height by attaching a few more steps.

- Safety supports. Usually not included in the standard package, but can be purchased separately. Legs increase stability by eliminating staggering.

Components can significantly increase the price of products. Most of them are easier to do it yourself or buy separately.

The best side ladders

These ladders resemble an ordinary ladder that can be installed against the wall at different angles.Usually they are used for washing windows and carrying out minor repairs at a height of up to 3-5 m. They are made of steel or aluminum, this category includes the 3 best models of this type.

Eiffel Granite

This step-ladder is designed for short-term work at a height of up to 3.5 m. The design has proven itself well both in production and in households. The product has 7 steps located at a convenient distance from each other for the user. They have a stable surface on which the feet do not slip, which reduces the likelihood of falling. Also, its corrugation is very useful here, which eliminates the risk of slipping legs. The product is made of an aluminum profile that lasts a very long time and is resistant to corrosion. Its width is optimal - 34 cm, there is room for "maneuvers".

Advantages:

- Rolling of the steps into the guides;

- Weight is only 3.36 kg;

- Thick profile;

- Withstands weight up to 150 kg;

- Compactness;

- Can be installed at any angle of inclination.

Disadvantages:

- Does not stack;

- No stabilizers included.

New height

This ladder is as simple as possible in execution and use. It consists of one section, so it does not take up much space in the room. With a length of 3.15 m, the working height is more than 4 m, which allows it to be successfully used for repair work. Thanks to its strong frame, the product can withstand people weighing up to 150 kg. The structure consists of 12 steps spaced 26 cm apart. Thanks to this, it is much easier to use, which is also facilitated by the low weight of the product at 4.4 kg.

Advantages:

- Thick profile;

- Materials do not rust in high humidity conditions;

- Good stability;

- 3-year warranty;

- Corrugation on the steps;

- Easily becomes at any angle.

Disadvantages:

- Rounded steps;

- With a large foot on the platform, there may not be enough room for it.

Ladder "New height" is not suitable for applications away from walls, for example, when a lamp needs to be replaced

In this case, you should pay attention to the stepladder with support from our rating

Alumet P1 9110

It is a good choice for work in the garden and construction sites, as well as in the home. It has a compact size and does not take up much space in the room. The width of the structure is 42 cm, the height is 2.97 m. The product is equipped with 12 steps, which, like the frame, are made of corrosion-resistant aluminum. Due to its low weight of 6.5 kg, it is easy to carry it even in one hand, including a woman. Anti-slip foot protection ensures safe ascent and descent, but it is best not to use it in wet shoes.

Advantages:

- Compact for storage;

- Lightweight crossbars;

- During the ascent and descent, it is convenient to hold on to the profile with your hands;

- The palms do not slide on the surface;

- Strong, high quality connections.

Disadvantages:

The price is above average.

The Alumet P1 9110 structure in the ladder rating is distinguished by a long service life and good stability on the surface, but it is still not recommended to install it in sand and other loose types of soil.