Description - what is it, what types are

Cleaners on the street and indoors always remove garbage in PPE

Cleaners on the street and indoors always remove garbage in PPE

Reliable gloves protect the skin of the hands from harmful effects:

- chemical reagents;

- harsh cleaning agents;

- dust;

- water;

- abrasions, cuts and other injuries to the skin of the hands.

For your information. Such protective equipment is created from a wide variety of bases, which causes a difference in their properties and scope.

Varieties by material of manufacture:

- Vinyl. Obtained by mixing polyvinyl chloride and plasticizing substances. A polyurethane coating is applied from the inside. The technology is complex, but justified: such models are durable, stretch well and can withstand the effects of aggressive oil substances.

- Latex. Extracted from the sap of the rubber tree. However, the rubber itself is not particularly durable (if stretched, it breaks easily). Therefore, products are made from latex - a water dispersion of rubber.

- Nitrile. Obtained as a result of processing petroleum products. It is a new material that is a combination of budatiene and acrylonitrile, which has undergone a polymerization process under industrial conditions. The reaction results in a nitrile elastomer. The cleaning equipment made of nitrile is distinguished by its greater (in comparison with latex) elasticity, density, qualitatively protects hands from accidental cuts or punctures, and does not cause allergic reactions. Used as an interlayer in snow removal models.

PPE is firmly integrated into everyday life

PPE is firmly integrated into everyday life

Vinyls differ:

- ergonomic shape, close to the hand and easily acquire the shape of the hand.

- have a high density, do not stretch, can be easily put on and off;

- hypoallergenic;

- suitable for reuse;

- low cost product.

Features of natural:

- talcum-treated and untreated;

- sterile and non-sterile;

- anatomical and suitable for both hands;

- with relief on the palm and fingers, and smooth;

- with cotton, animal or synthetic lining.

Features of nitrile:

- resistance to punctures and cuts.

- can be used when working with technical fluids (automobile oils, greases and solvents - the Freken model);

- wide scope of application;

- increased strength;

- hypoallergenic.

For your information. Nitrile rubber gloves for cleaning (the price is the highest of those listed) are unprofitable.

Decoding of marking and technical characteristics

In accordance with the requirements of the standards, the following symbols are present on the palm of your hand:

- MI - means protection against abrasion;

- MA - such products provide vibration protection;

- MP - the product is protected from cuts and punctures.

Foreign models differ in different markings. In this case, the English letter denotes the protection class. There are such designations:

- A - speaks of abrasion resistance;

- B - indicates resistance to cuts;

- C - speaks of resistance to mechanical rupture;

- D - confirms puncture resistance.

A number is located near the letter, which indicates the level of operation. In addition to the listed characteristics, the quality of gloves depends on the following parameters:

- anatomical shape;

- the use of breathable environmentally friendly materials;

- elasticity;

- lack of seams;

- the presence of cuffs.

1 Technical requirements

1.1 Gloves should be manufactured in accordance with the requirements of this standard. The recipe for the mixture for the manufacture of the layer of gloves in contact with the skin of the hand must be agreed with the Ministry of Health of Russia.

1.2Basic parameters and dimensions

1.2.1 Depending on the purpose, gloves are produced in two types:

I - for rough work;

II - for delicate work.

1.2.2 Gloves are manufactured in the following numbers:

1, 2, 3 - for type I;

1, 2, 3, 7, 8, 9, 10 - for type II.

1.2.3 Length of gloves L must be at least 300 mm. Other dimensions should correspond to those indicated in the figure and in table 1.

Table 1

| Glove type | Glove number | Width at the fifth metacarpophalangeal joint b, mm | Wall thickness S, mm |

|

I |

1 |

110 ± 5 |

0,6 — 0,9 |

|

2 |

120 ± 5 |

||

|

3 |

130 ± 6 |

||

|

II |

1 |

88 ± 5 |

0,2 — 0,4 |

|

2 |

100 ± 5 |

||

|

3 |

107 ± 6 |

||

|

7 |

101 ± 8 |

||

|

8 |

108 ± 8 |

||

|

9 |

119 ± 8 |

||

|

10 |

126 ± 8 |

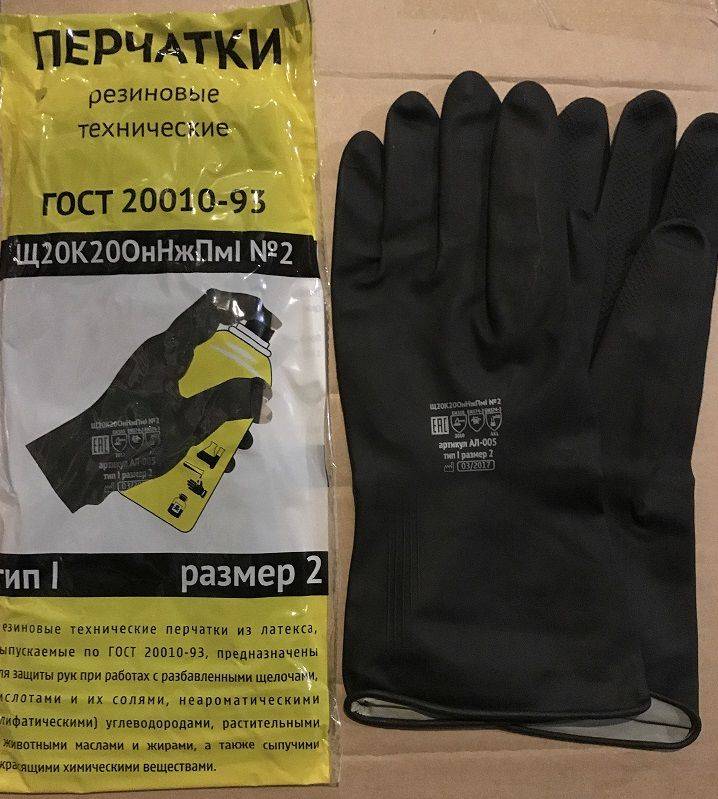

An example of a symbol of type I gloves No. 2:

Sch20K200nHfNSmI №2. GlovesrubbertechnicalGOST 20010-93

1.3 Features

1.3.1 Gloves must be five-fingered, seamless, shaped to match the volumetric model of the hand and made for right and left hands. The fingers can be straight or curved.

1.3.2 Gloves should be made in two layers.

1.3.3 Gloves can be made in any color.

The inner and outer layers of two-layer gloves should be different in color. Protrusion of the inner layer along the edge of the glove guard is allowed.

1.3.4 In terms of physical and mechanical parameters, gloves must comply with the standards specified in Table 2.

table 2

|

Indicator name |

Norm |

|

1 Conditional tensile strength MPa (kgf / cm2), not less |

16 (160) |

|

2 Relative elongation at break,%, not less |

800 |

|

3 Relative residual elongation after rupture,%, not more |

12 |

|

4 Tear resistance, kN / m (kgf / cm), not less |

20 (20) |

|

5 Acid-alkali permeability, pH, no more |

1 |

|

6 Change in mass after exposure to a 20% alkali solution or 20% sulfuric acid solution for (24 ± 1) h at a temperature of (23 ± 2) or (27 ± 2) ° С,%, no more |

10 |

|

Note. - Indicators for PP. 1 - 4 are determined after exposure in a 20% solution of sodium hydroxide or potassium hydroxide at a temperature of (45 ± 2) ° С for (24 ± 1) h. |

1.3.5 On the surface of the gloves there should be no defects exceeding those indicated in Table 3.

Table 3

|

Defect name |

Checked part of the glove |

|

| Fingers (working surface), interdigital spaces, palmar part | Back, leggings | |

|

1 Holes |

Not allowed | |

|

2 Foreign inclusions of a non-rubber nature |

Also | |

|

3 Bubbles on the face of the glove with a diameter of more than 1 mm or the absence of a protective layer on the face with a total area of more than 10 mm2 |

Not allowed | Allowed |

|

4 Inclusions of coagulum on the seamy side of the glove |

Not allowed with a height of more than 3 mm | Allowed |

|

5 Smears on the seamy side of the glove |

Allowed |

Notes (edit)

1 To control the appearance of gloves, it is allowed to use control samples agreed between the manufacturer and the consumer.

2 Transmission of the relief pattern of the protective layer on the inside of the glove is not a defect.

1.4Marking

1.4.1 The face of each glove must be marked with the glove number.

1.4.2 Each packaging unit must be marked with:

trademark and (or) name of the manufacturer;

product name;

type and number of gloves;

number of pairs;

date of manufacture (month, year);

designations of this standard;

gloves designation in accordance with GOST 12.4.103;

guaranteed storage period.

It is allowed to apply additional or informational inscriptions.

Each packing unit must be supplied with rules for the use and storage of gloves (attachment).

1.5Package

1.5.1 Gloves of the same type and numbers, matched in equal quantities for the right and left hands, are packed in an amount of not more than 150 pairs in boxes or packs of cardboard in accordance with GOST 7376, GOST 7933, GOST 9421, GOST 12303 or cardboard boxes in accordance with GOST 13511, GOST 13512, GOST 13513, GOST 13514, GOST 13515, GOST 13516 or in another container that ensures the safety of products as agreed with the consumer. Each box must be bandaged, overtightened, or sealed.

9.3. Information provided by the manufacturer

Information should

accompany gloves and provided upon request. Information should

include:

a) name and full

manufacturer's address or

an official representative;

b) product marking in

in accordance with 9.1.2 b);

c) link to

the corresponding standard;

d) available sizes and, c

if necessary, information on;

e) in case

necessary, as indicated in 9.2.2, a pictogram indicating protective

properties, indicating the characteristics of harmful factors. Further should be

explanation of the performance characteristics of hand PPE

and references to relevant standards;

f) a list of substances

contained in a glove that can cause allergies;

g) instructions for

application;

i) care instructions

(washing or dry cleaning conditions) and storage;

j) type of packaging for

transportation and storage;

k) shelf life for

gloves and packaging with a significant decrease in protective properties as a result

storage.

Appendix A

(reference)

Determination of personal protective equipment for hands only for minimal risks

This category belongs

only hand protection designed to protect against:

- mechanical

surface influences (garden gloves, etc.);

- detergents of weak

actions (gloves protecting against dilute solutions of detergents and

etc.);

- risks arising from

handling objects, the temperature of which does not exceed 50 ° C, not subject to

human danger of serious burns;

- atmospheric influences

non-exclusive and non-extreme characters (seasonal clothing);

- weak blows and

vibrations that do not affect the vital functions of a person and are not able to cause

irreparable damage to health.

Appendix B

(reference)

Pictograms

|

Pictogram |

Hazard category, purpose |

Pictogram |

Hazard category, purpose |

|

From mechanical stress |

From low temperatures |

||

|

From cuts |

From high temperatures and open flames |

||

|

From ionizing radiation |

From radiation contamination |

||

|

Chainsaw cuts |

From chemicals |

||

|

For firefighters |

From chemicals |

||

|

Information |

From biological factors |

Bibliography

1. Instruction

on the application and testing of protective equipment used in electrical installations.

Approved by Order No. 261 of the Ministry of Energy of Russia dated June 30, 2003.

Keywords: funds

personal protection of hands, gloves, quality indicators, test methods,

marking

Materials (edit)

Knowing what gloves are made of is necessary for the correct selection of products appropriate to the operating conditions. The main materials used in the manufacture of hand protection are:

- cotton fibers used for the manufacture of materials of various weights and grades of knitting. They are hypoallergenic and have excellent air permeability;

- split, which is the lower part of sheets of leather cut through the thickness. Combines high temperature resistance, fire resistance with high strength;

- latex, which provides gloves with a snug fit and reliable protection for hands due to elasticity;

- neoprene with high resistance to humid environments;

- vinyl resistant to acids, alkalis, alcohol. With high tear resistance, the material is highly breathable;

- nitrile with high puncture resistance.

In the manufacture of gloves, materials are often combined to improve performance.

How to care for rubber gloves

A product made of rubber can serve you up to 12 months. Improper use of the gloves will shorten their lifespan by several days.

When the work is completed, it is worth taking off the gloves and rinsing them with water. Then the product is thoroughly dried and sprinkled with talcum powder so that it does not tear or stick together. The storage conditions for gloves should be special. The room temperature should not exceed 15 degrees.

Pay particular attention to the humidity in the room where the product is stored. This figure should not exceed 85%

In the modern world, not only the functions of rubber gloves, but also their design come to the fore.Of course, most often these products are bought by women, so they are decorated with flowers and hearts.

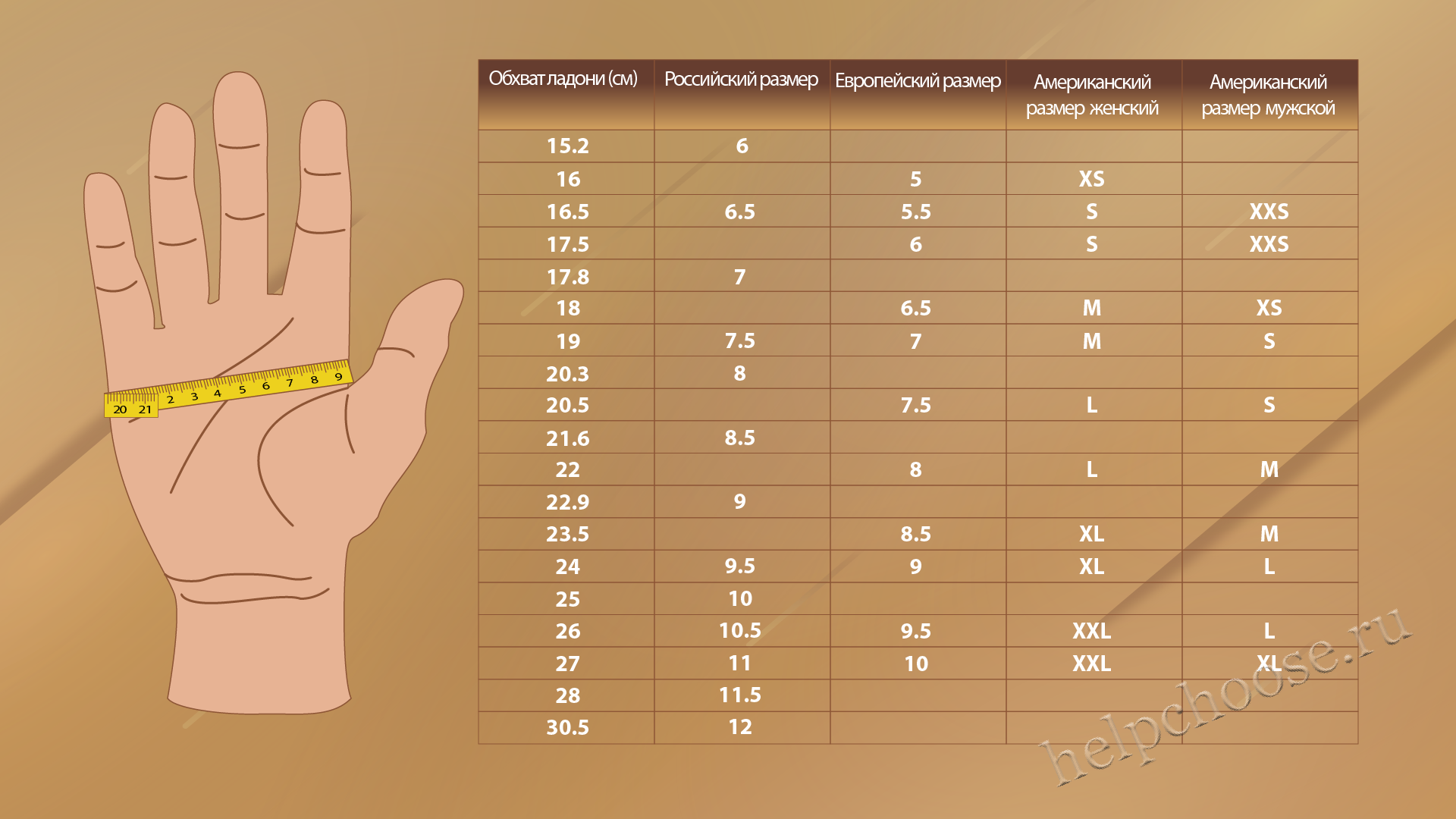

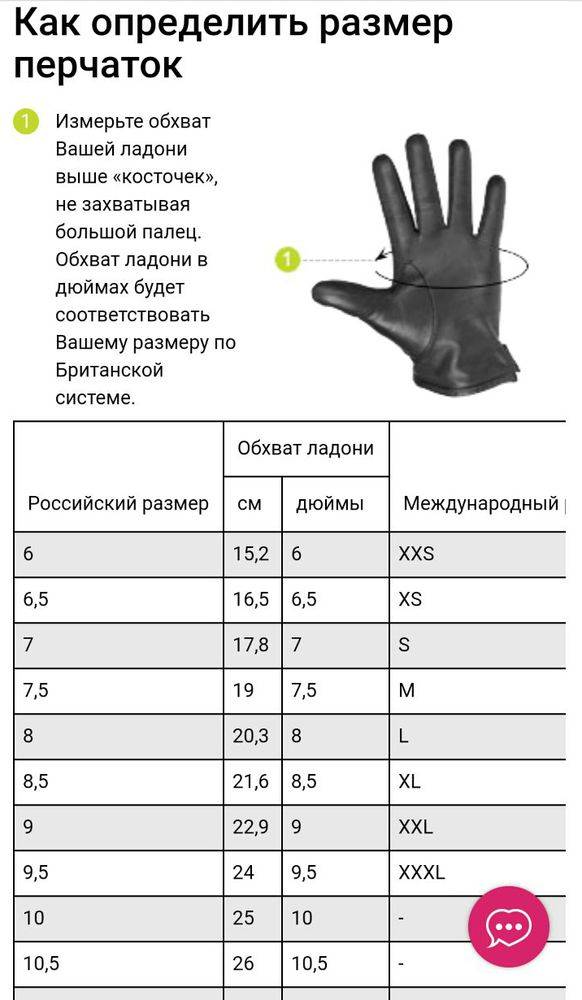

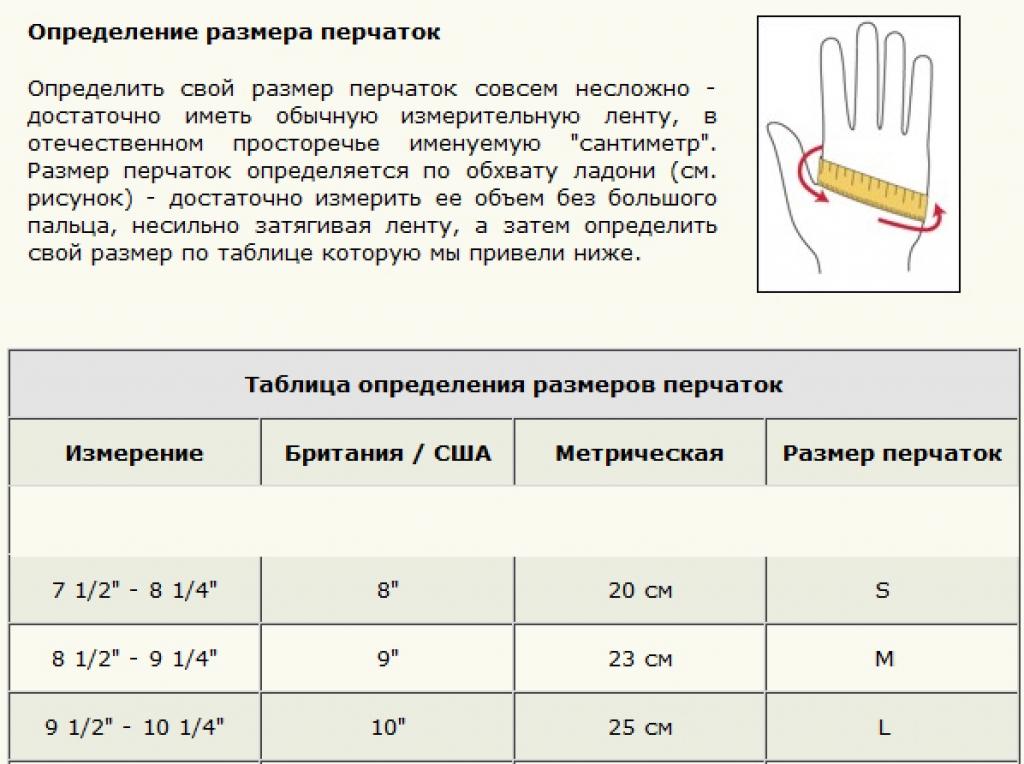

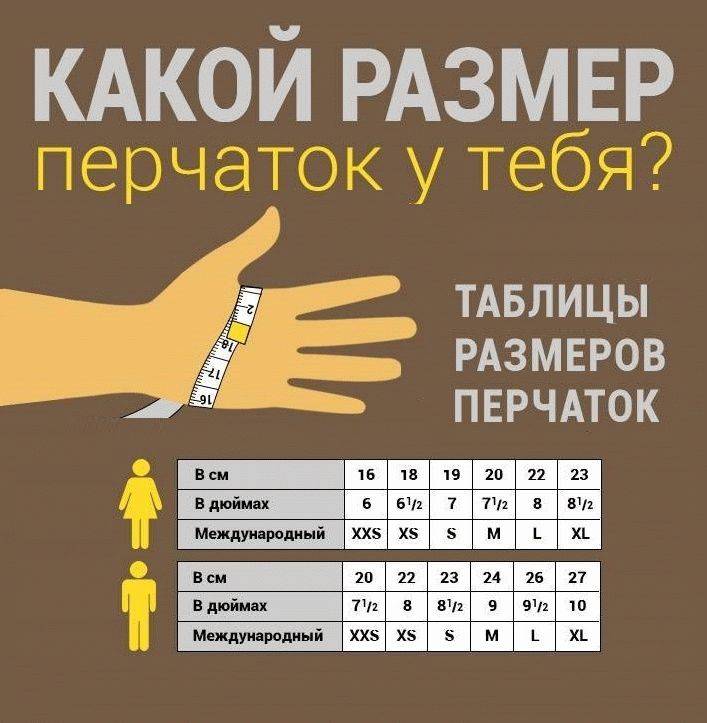

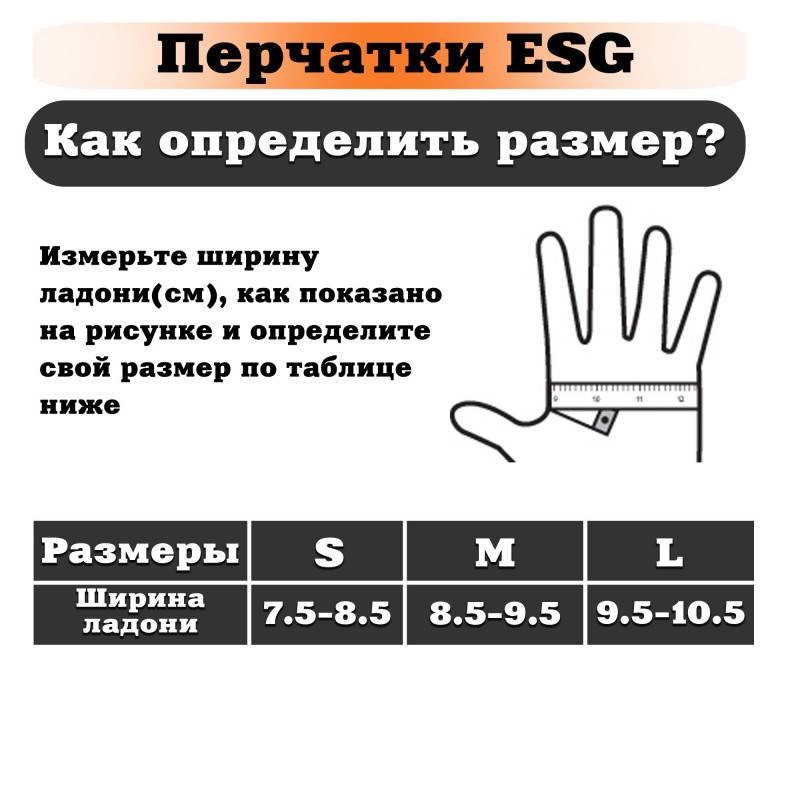

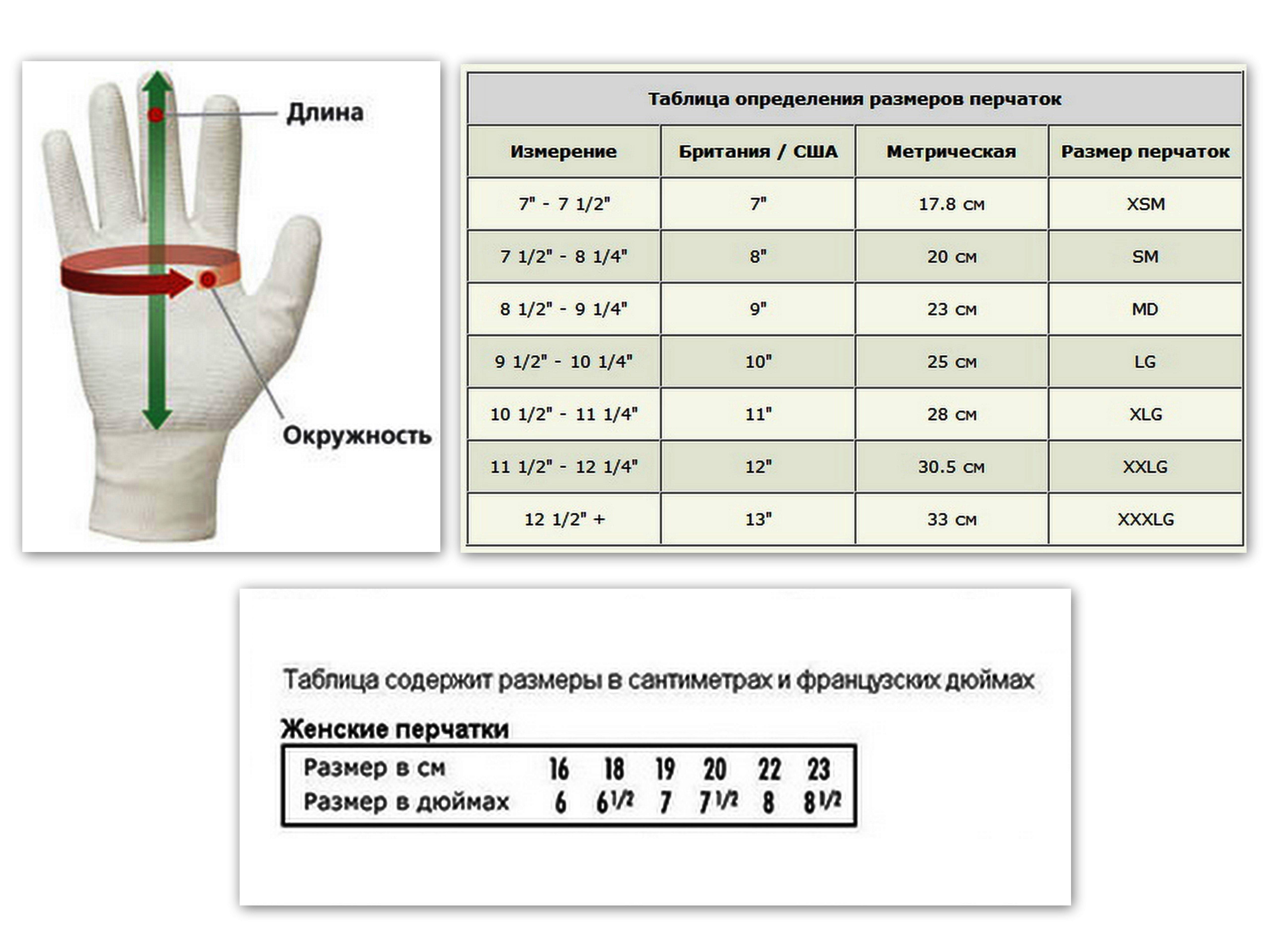

How to determine your size of gloves, see the video:

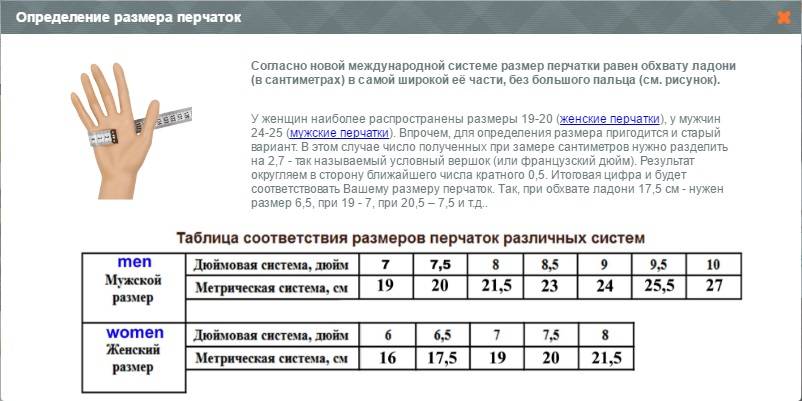

The size of the gloves for both men and women is of great importance, especially if they are cleaning gloves, rubber or medical gloves. If the glove on the hand "sits" too freely, then during work it will bring inconvenience: rubbing, falling off the hand, etc. In addition, there is a high risk of dirt, dust or chemicals getting under the glove while doing work. A tight glove will restrict hand movement and may pinch blood vessels.

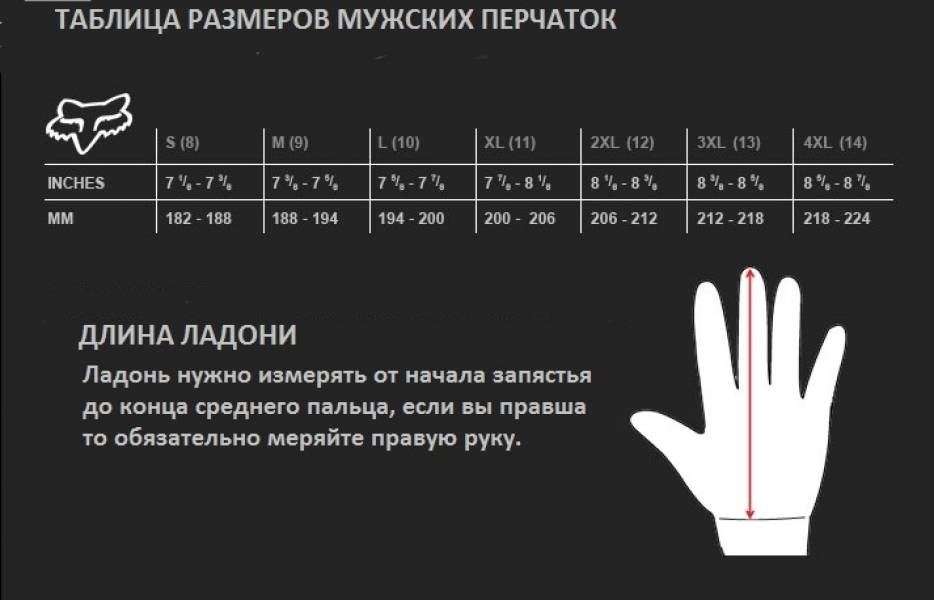

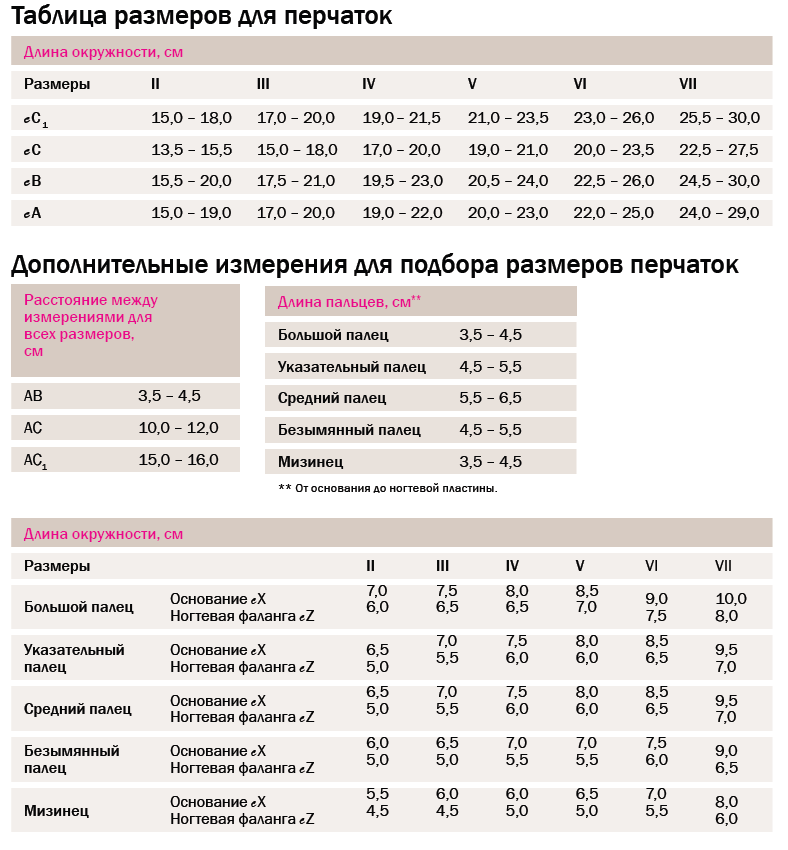

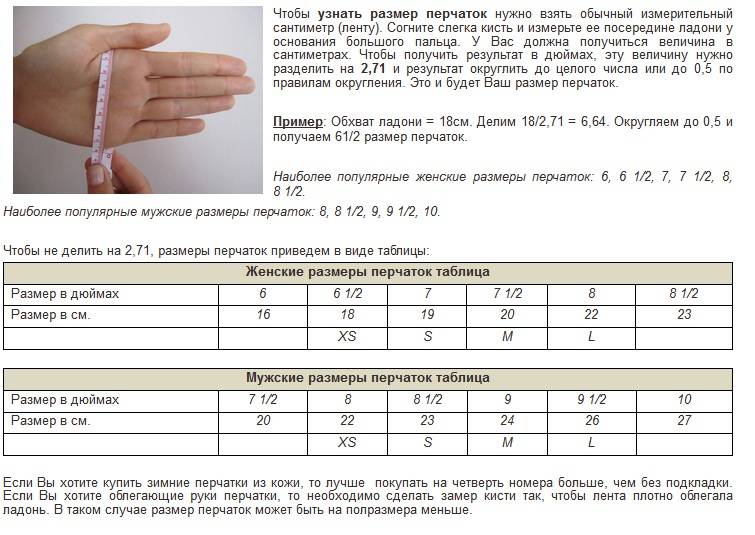

How to measure your hand and determine the size of gloves

Use a flexible tape measure. First, measure the circumference of the right hand (for left-handers - left) above the thumb (in the area of the "bones"), without tightening the tape, but simply applying it tightly to the skin. For a more accurate result, you can gently squeeze your hand into a "half fist". Then measure from the pad of your middle finger to the base of your palm.

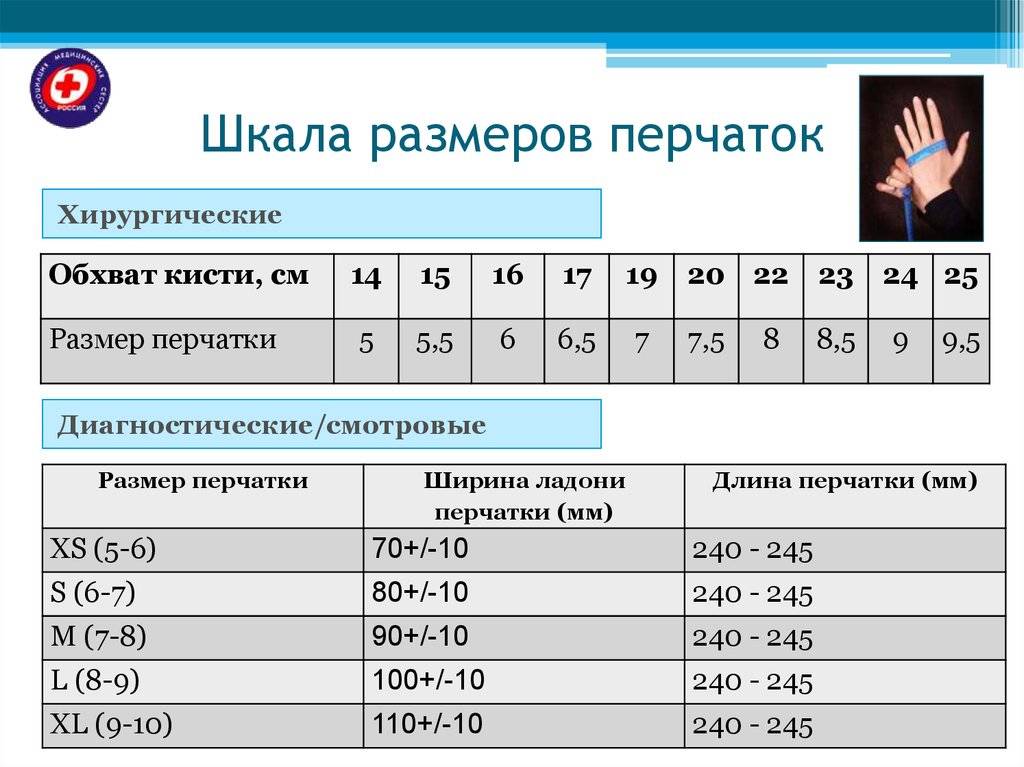

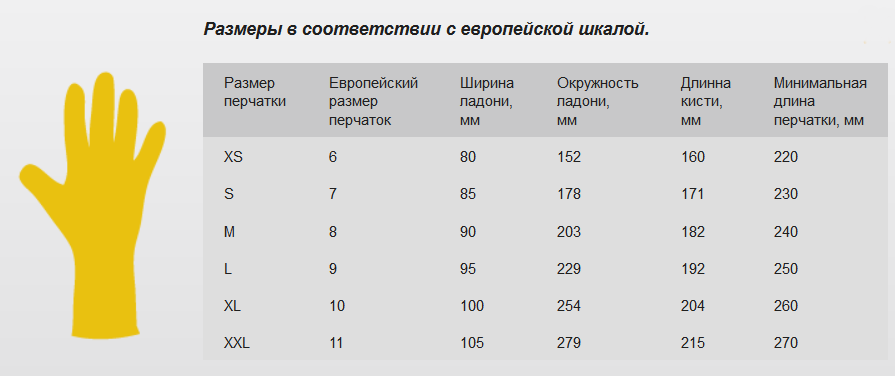

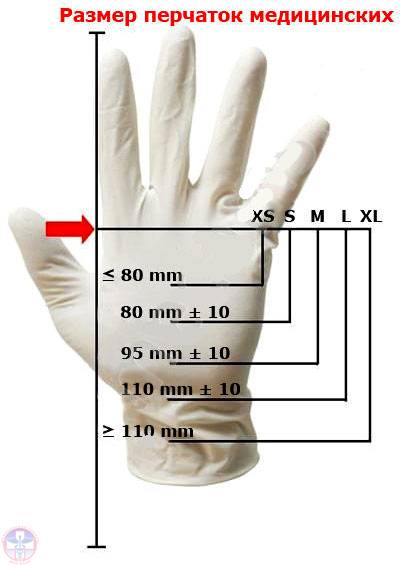

European size range of gloves

The smallest European size is considered to be # 6 (palm circumference 152 mm, palm length 160 mm). Glove # 6 must be at least 22 cm long to completely cover the wrist. The largest European size is No. 11 (palm circumference 279 mm, palm length 215 mm). Sizes 6 through 9 are best for a woman's hand, 9 through 11 for a man's. Nevertheless, when choosing gloves, both men and women need to be careful, because the hands of both are completely different.

American size range of gloves

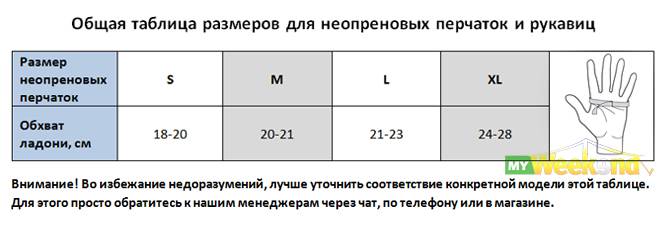

The US size of the gloves is expressed in letter codes. The 6th European corresponds to the American XS, and the 11th is equal to the XXL size. Latex, rubber and specialty gloves are labeled in just four sizes: S, M, L and XL.

When choosing gloves, it is necessary to take into account the specifics of the work. For example, when working with aggressive environments or in the cold, it is better to buy looser gloves, because when working, they can become stiffer and harder, creating a feeling of tightness in the hands.

You can buy latex, nitrile, rubber and cotton gloves through our catalog or by contacting our managers directly.

What are they made of

Gloves are made from a variety of materials.

Household rubber gloves: technical characteristics

Gloves made of natural rubber - latex. Indispensable when you need increased sensitivity of the fingers when performing work, as well as protection against contamination of the skin of the hands and exposure to the aggressive environment of household chemicals and constant contact with water.

- thin and light, do not weigh down the hand, while maintaining the sensitivity of the fingers;

- resistant to tearing under tension, stretch well;

- in case of punctures or cuts, the place of damage does not creep away, making it possible to complete the work with minimal damage to the hands;

- perfectly protect the skin of hands and nails from pollution.

- not resistant to cuts / punctures, and therefore their service life can be reduced to one day;

- poorly resistant to highly concentrated chemicals;

- may be uncomfortable to use if the size is incorrect: pinch the vessels, contribute to the occurrence of edema;

They are used for wet cleaning at home, washing dishes (fruits and vegetables), can protect hands when carrying out paintwork, are useful when working with glass or ceramics that require high tactile sensitivity.

Latex Household Gloves

Artificial rubber - nitrile, vinyl. Due to the addition of artificial fibers to the composition, such gloves acquire greater wear resistance, increased resistance to mechanical damage.

Advantages of nitrile and vinyl gloves:

- resistant to aggressive chemicals;

- greater resistance to punctures / cuts in comparison with latex;

- less slippery than latex ones, especially when additional relief is applied to the palmar part.

- in case of mechanical damage, the puncture or rupture site creeps up;

- sit on the arm more freely, while losing tactile sensitivity;

- they do not stretch well, they break easily with diligent pulling.

They are used in cleaning sanitary rooms, cleaning tiles, taps, plumbing; cleaning of common areas in institutions; it is possible to use it when carrying out gardening works: transplanting plants, harvesting; spraying seedlings, etc.

Note! All types of rubber gloves can cause allergic reactions, as they are quite tight on the hands, and also do not allow air to pass through, preventing the skin of the hands from breathing. In these conditions, there is a high risk of allergies, prickly heat, skin irritations in especially sensitive people.

Rubber gloves for cleaning

Household textile: technical characteristics

Textile gloves: knitted and cotton. Produced from cotton threads of various thicknesses and quantities. Their wear resistance and their field of application depend on the knitting class:

7th class of knitting: rough work, high importance of protection from mechanical damage;

10th grade: work with high tactile sensitivity (assembly, small fasteners);

13th grade: high-precision work (electronics, jewelry).

Knitted mittens of the 7th class are often equipped with a point or continuous polyvinyl chloride (PVC) coating, which increases the number of useful performance characteristics.

Advantages of PVC knitted gloves:

- resistant to mechanical damage (especially with continuous PVC spraying);

- have a high tenacity with inventory;

- ensure the supply of oxygen to the skin of the hands;

- wide functionality due to the PVC coating, which increases the protective properties.

- not designed to protect hands from water;

- in the absence of PVC spraying, they lose most of their protective properties.

The scope of application of textile mittens is great: carpentry, horticultural work; warehouse, loading work, packing, cosmetology, auto mechanics, installation and various types of work in production.