How to use gloves for coronavirus

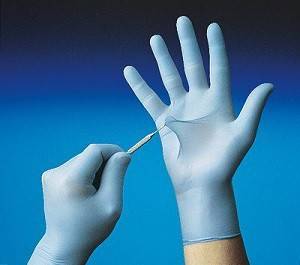

So that gloves do not pose a danger during a coronavirus epidemic, you need to use them correctly, namely, to shoot according to a clear algorithm:

- With one gloved hand, you need to pinch the edge of the glove on the other hand and remove it by twisting it, pulling the brush out.

- The removed glove remains in the protected hand.

- With the fingers of the "open" hand, grasp the inner edge of the glove on the other hand and remove it, too, by twisting and simultaneously folding both into a "knot", "lump".

- Immediately place the gloves for disposal - in a plastic bag and close tightly. Or place it in a disinfectant solution.

- Wash hands with soap and water for 20 seconds or treat with an antiseptic.

Gloves do not protect against coronavirus 100%, they should only be used if you are going to visit public places or contact with many people, as well as medical workers.

It is important to wash your hands frequently with soap and water, remove used gloves correctly and properly dispose of them or disinfect them for reuse.

Which gloves to choose: nitrile or latex?

Step 1. Decide what you need protective gloves for

In some cases, only nitrile or special rubber KShchS gloves are suitable, and for many jobs, basic protection of latex PPE workers is sufficient (besides, this is a cheaper option).

Step 2. Decide on functional features

When it comes to purchasing disposable gloves, one decides what characteristics are required: sterile (for various invasive procedures) or examination (diagnostic) gloves, powdered or not.

Looking for coated cotton or nylon gloves? Work involving immersion of hands in oils or chemicals, or the possibility of splashing, requires complete protection - only full dousing. When interacting with objects covered with these substances, it is enough to protect the palms and fingers - incomplete dousing.

Step 3. Find the right size

Thin medical gloves have the widest size range (5 or more variations are possible), thicker work gloves are often presented in a universal size or several basic ones.

What are they for?

Nitrile gloves are used in medicine. They do not cause allergic reactions, bacteria and microbes cannot penetrate through the material. Special medical gloves cover the hands up to the forearm, and are anatomically made for both hands.

These gloves do not break even at maximum stretch due to the correct structuring of the material.

There are rollers along the edges of the cuffs of the gloves so that they fit snugly and do not slip. Gloves are absolutely versatile and fit all hands. They are part of medical special clothing and are disposed of after use.

AQL1 Special Gloves

Designed for employees of chemical laboratories, they are especially durable and dense. Nitrile options are three times thicker than vinyl and latex options. Hands are reliably protected from chemicals and acids, which are often used in pharmacological and anatomical institutions. Nitrile is an excellent protector when working with refined petroleum products.

You can find out more about AQL levels and tolerances in our guide to choosing surgical gloves.

In production, the thickness of the gloves can be increased from 0.75 to 0.90 mm for resistance to chemical elements. Such options are used when working with highly concentrated acids and alkalis.

Although base acids and alkalis are only 40-50% concentrated, gloves can withstand up to 80%. There are lightweight models made of thin material that can withstand only 10-20%. With nitrile gloves, you can easily grip a slippery object covered with corrosive substances.

Although base acids and alkalis are only 40-50% concentrated, gloves can withstand up to 80%. There are lightweight models made of thin material that can withstand only 10-20%. With nitrile gloves, you can easily grip a slippery object covered with corrosive substances.

Fines are what employees in various industries work with on a daily basis. They are safe for the environment, but their sparse structure helps them easily penetrate the skin and respiratory tract. For example, powder polymer paint is used in many industries. The best protection for paint professionals is workwear with a respirator, mask, goggles and nitrile gloves.

Views

Anti-static gloves can be classified in several ways. For example, they are white, gray and even black in color. These products are very durable and can withstand up to 50 washes without losing their performance. However, they vary in the type of manufacture and design.

Gloves are made from nylon and polyester. In order for them to neutralize static energy, thin carbon fibers are added to the base material. This increases the wear resistance and durability of products. Knitted lint-free gloves are used in microelectronics, surgical departments and pharmaceutical companies.

The simplest anti-static nylon models are characterized by a uniform texture. They neutralize static electricity and protect the entire palm. According to the type of manufacture, the products are knitted from nylon or polyester threads or sewn from these materials. At the same time, knitted models are considered the best, since they fit the hand more tightly and provide better tactile sensitivity of the fingers.

Products differ in the value of the surface resistance of the material. Based on this, they are dissipative and conductive. Products of the first type dissipate the charge, the second - conduct it. Models of the first type use an artificial thread saturated with carbon fiber. Conductive varieties are produced by adding thin copper wire to synthetic filament. In order to avoid slipping during work with small parts, the base material is coated with a special polyurethane compound. Depending on the variety, they can cover the areas of the fingertips or completely of the palms.

Nitrile gloves

Nitrile gloves are made from synthetic rubber. They are latex free and have the best protective properties of any disposable glove. They are the most durable and difficult to puncture or damage. These gloves provide excellent resistance to a wide variety of chemicals. Keeps out isocyanates, the most toxic chemicals found in two-component hardeners. Good for people who are allergic to latex.

The disadvantage of these gloves is that they do not fit as well on the hands as latex gloves. They reduce the sensitivity of the hands and make it more difficult to perform actions that require high tactile sensitivity. Nitrile gloves should not be stored in high temperature and bright light. From these factors, they are destroyed. They have the highest cost of disposable gloves. Since they are made from petroleum products, the cost fluctuates depending on the cost of oil.

Description

Nylon is durable and thin. The work gloves are comfortable and lightweight, providing maximum finger sensitivity.

There are many benefits to nylon products.

- Ease, thanks to which a person does not get tired of them.

- Resistance to aggressive external conditions.

- High strength and long service life even with regular heavy loads.

- High elasticity that cotton counterparts do not have.

- Easy care consists in washing the garment at a water temperature of 30 ° C.

- Resistant to chemicals such as alkalis and acids.

- Large assortment of types and colors. White, black and blue models are especially popular.

- Fit the hand, completely repeating its shape.

It is worth noting that nylon reacts poorly to high temperatures and chlorine-containing substances. When gloves are modified, some types lose their breathability. In this case, hands will sweat during prolonged continuous use of the product. Elastic cuffs prevent the items from sliding off the hands, processing with double cotton thread ensures a secure fit.

Synthetic rubber

Artificial rubber models have undeniable advantages over latex positions. Of course, they are more resistant to aggressive chemicals. Less prone to mechanical damage, not as slippery as natural rubber options.

For your information. They do not cause allergies (the inner surface is specially coated with cotton or synthetic dusting, which does not allow the skin of the hands to come into direct contact with the rubber).

Rubber gloves are reusable.

Along with the advantages, synthetic models have a number of disadvantages. As the artificial rubber products are thicker, the finger sensitivity is reduced. This excludes the possibility of performing "fine and high-precision" manipulations. Such models are non-sterile and the use of standard reprocessing methods causes significant changes in the structure of materials.

They don't stretch well and break easily. At the slightest damage, the products quickly deteriorate, and they have to be changed frequently. There is another unpleasant feature - the permeability of such gloves. Often in the area of the thumb or the tips of others, water can seep into the synthetics.

Nitrile and Vinyl Gloves: Disadvantages and Benefits

- Details

- Views: 24578

Nitrile and Vinyl Gloves: Disadvantages and Benefits

In many different fields of activity, synthetic gloves are used as personal protective equipment for hands. Gloves are made from various materials; The most popular latex-free types of gloves are currently nitrile and vinyl. Both types have advantages and disadvantages, but when used correctly, they are irreplaceable.

Nitrile base of gloves

Nitrile gloves are made from a synthetic polymer called acrylic, which is vulcanized, thereby releasing rubber-like properties. To obtain the desired characteristics, nitrile is treated with sulfur, butadiene and other chemical accelerators to give it strength, durability and elasticity. The use of a synthetically produced polymer avoids latex allergy problems. Finally, nitrile gloves are usually blue or purple in color.

Vinyl base of gloves

Similar to nitrile gloves, vinyl gloves are also made from a synthetic polymer material - polyvinyl chloride, more commonly known as the abbreviation PVC. Again, like nitrile gloves, this polymer relieves manufacturers of the complications associated with latex allergy. Another advantage is that the PVC polymer is relatively inexpensive. The underside of vinyl gloves is often treated with cornstarch or other light powder to make it easier to pull on the hand.

Both nitrile and vinyl gloves provide reliable hand protection. But when you choose between the two, nitrile gloves provide more strength and protection thanks to the chemical properties of nitrile.In addition, nitrile gloves are more flexible and fit better than vinyl gloves. The advantage of vinyl gloves over nitrile, despite the lower level of protection, is their relative cheapness both to manufacture and to purchase.

disadvantages

The main disadvantage of nitrile gloves is their price. While they are more durable than vinyl, this does not negate the fact that they are also intended for single use; the buyer makes the final decision whether to overpay for durability. Vinyl gloves are less durable, less elastic, and generally provide less protection than nitrile gloves. In addition, vinyl gloves are less hand-shaped. But vinyl gloves are very cheap.

Application

How do you choose between the two types? Decide how high the level of protection should be. Many glove manufacturers have simplified the selection process by calling nitrile gloves “medical” and vinyl gloves “household”. In the United States, nitrile gloves that are advertised for purchase by health care providers (such as hospitals) must undergo a series of tests to prove their durability. Tests are conducted by the US Food and Drug Administration. Vinyl gloves, on the other hand, are very often used in the food industry, where high strength and protection are not so fundamental. The American Society for Testing Materials USA sets less stringent standards for the manufacture of vinyl gloves.

-

Back

-

Forward

Criterias of choice

Nylon gloves will be useful to anyone whose activities can lead to injury. They provide hand protection and maximum control over the situation thanks to their tactile sensitivity. Product selection criteria vary by industry.

- Electronic industry. For engineers who come into contact with small parts during the manufacture of microcircuits, gloves with antistatic agents are suitable. Maximum sensitivity will allow you to clearly control the process. In case of contact with chemicals or solder, the worker will not be injured.

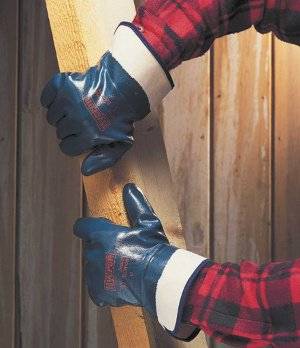

- Construction. Excellent application area for PVC nylon gloves. They can be in contact with any finishing materials, even those that have chemical activity. And also gloves are comfortable when cleaning construction debris. Varnish-and-paint work will become much easier, because the substances do not have to be wiped off by hand with solvents. What's more, gloves protect against cuts, splinters and other injuries that often accompany construction activities.

- Medicine and Pharmacology. Suitable for laboratory staff who are forced to come into contact with various reagents. It is also a great way to protect your hands when servicing equipment.

- Agriculture. Used when working with fertilizers, protect hands from chemicals. Gloves will come in handy during the maintenance of various units.

- Car service. This work is closely related to chemicals and petroleum products. Gloves make it much easier to work with oiled parts, ensuring a secure grip. Nylon does not react to gasoline, its contact with the product does not spoil the material.

It is important for the builder that gloves protect hands and do not interfere with the full grasp of objects. When working with various electronic parts, you will need very thin anti-static nylon products

How to choose and use?

The choice of ESD gloves is not easy. For them to be effective, when buying, it is necessary to take into account the specifics of the purpose and type of work. For example, electronics models should be lint-free and suitable for the specific environment. In addition, you have to rely on the price.

For example, models with cut protection cost about 1160 rubles on average.The price of nitrile antistatic gloves today exceeds 7,000 rubles. The most budgetary - simple models, on average, their price varies from 114 to 185 rubles. Conductive gloves made of polyester and carbon fiber cost 185 rubles.

In this case, the measurement system can be either metric or inch. In addition, the European size is also on sale. The size range is variable, so you can choose the exact size for high-quality and full-fledged work.

It is necessary to choose this or that product correctly. For example, models with a thread have their own specifics. These models are not only anti-slip: they dissipate the charge, preventing possible destruction or damage, for example, of the microcircuit. Their advantage is their resistance to dust and the ability to dissipate a 5000 charge in 3/10 seconds.

To work with oily and greased surfaces, it is worth using products with a polyurethane coating. Antistatic models with a covering of the entire palm part are good for working with electrical appliances (including smartphones, computers). They are characterized by a high capture rate.

If repairing, handling or cleaning small parts is planned, antistatic gloves with a coating on the finger area are required. They are also indispensable when working with carrying materials with a sliding surface type. Others try to purchase products with goatskin inserts. These gloves are made in white and blue.

You need to buy a pair in a trusted store with a good reputation. Products of famous brands are of high quality. They are distinguished by a dense structure and minimal thickness, no visible defects and high elasticity.

Gloves should be worn on clean, dry hands. Do not work in wet and dirty products. Depending on the type of work, in addition to wearing gloves, it is necessary to use grounding means for users. The resistance between the person and the ground can be provided by wearing special shoes.

You can get acquainted with anti-static gloves in the video below.

Selection Tips

The defining criterion for purchasing is the purpose of the product. The nature of the work dictates the requirements for personal protective equipment:

- For washing dishes, it is recommended to purchase medium-strength household gloves. On some models, special anti-slip pimples are made to prevent the dishes from slipping out of the hands.

- For work in the garden or vegetable garden, work products of increased strength are purchased.

- When working with chemicals or industrial use, it is recommended that you choose shoulder-length products that protect the garment well.

It is not recommended to purchase oversized pairs. If the product is large, even when washing the dishes, water may get inside. If the glove is small, then when pulled on the hand, it can tear at the slightest load.

Selection criteria for protective gloves

To choose the right mittens, you need to take into account the conditions under which they will be used.

Protection functions are the determining factor. Depending on the required purpose, models are selected to prevent mechanical or chemical harm.

Air temperature. If the ambient temperature is comfortable, standard gloves can be used. When working in the cold, you need insulated gloves that have a fur lining.

Strength indicators

When purchasing gloves, pay attention to the EN 388 ratings, which indicate the classes of protection against cuts, abrasions, tears and punctures. The higher the indicator, the higher the degree of protection.

For example, if you need to protect your hands from acetone, the packaging should be labeled with the letter B, from methanol - A, and so on.

Hand protection area. When using gloves with knitted cuffs, the hand is free to move, but the gloves do not protect the wrist.The safety gaiters protect the wrist from mechanical damage, and the long, covered gaiter also protects against chemical influences.

Glove size. Choosing the right size will provide reliable protection and comfort at work. You need to be guided by the girth and long arm, as well as the required long gloves. These parameters are indicated on the packaging of gloves in millimeters.

Applications of nitrile gloves

Nitrile gloves were patented by Neil Tillitson and Luc de Becker in 1997. Since that time, the production of nitrile gloves has long been put on stream, and the products themselves have found wide application in all areas of industry, medicine, and cosmetology.

Nitrile gloves were patented by Neil Tillitson and Luc de Becker in 1997. Since that time, the production of nitrile gloves has long been put on stream, and the products themselves have found wide application in all areas of industry, medicine, and cosmetology.

Synthetic rubber gloves do not fit the hands as tightly as latex gloves, so nitrile surgical gloves are not widely used. However, medical nitrile gloves are 3 times more puncture resistant than latex gloves. Therefore, sterile and non-sterile powder-free nitrile gloves are used for ambulance, dentistry, serology.

For many years, disposable gloves were considered useless in the automotive industry due to the fact that natural latex simply dissolved in contact with oil, diesel or gasoline. Currently, car manufacturers and service centers are wholesalers of chemically resistant nitrile gloves. These gloves can withstand high temperatures under the hood, are resistant to almost all chemicals and provide sufficient tactile sensitivity when working.

Due to their high resistance to petrochemicals, nitrile gloves are actively used in the oil refining industry.

In cosmetology, gloves with a texture on the fingers are often used, this provides the specialist with a good grip of the instrument, while at the same time not preventing slipping. It is very convenient to carry out some procedures in them ׃ peeling, applying masks, cleansing the skin, etc.

Nitrile gloves are used not only in industries, but also in everyday life by ordinary residents. They are convenient for cleaning the apartment, working in the garden, minor repairs because they perfectly protect the skin of the hands from dirt and chemicals, without causing irritation or drying out of the skin. Nitrile glove manufacturers offer varieties such as nitrile cuff gaiters (partial or full coverage) and full nitrile coated gloves.

Selection Tips

When choosing household gloves, it is worth considering a number of criteria:

Comfort - the product must fit in length and width

It is important that it fits snugly around the cuff. Models that are too short or loose will topple and slide.

Base type - knitted models are considered more elastic

They stretch easily and fit the skin. However, such products contain more synthetics. Hands in such gloves sweat more. At the same time, the cotton base is better breathable. It is suitable even for those with sensitive skin.

Availability of certificates - only standardized products that have passed all the required checks are considered safe to use. It is important that the surface of the products has appropriate markings that indicate the type of coating, size and other key features.

Pairing - Gloves with dots are often sold in packs because they are affordable and quickly consumed. However, when buying, it is worth checking the pairing of the purchase. It is important that all products match.

Strength - the stronger the load on the surface is planned, the more dense the products should be. Otherwise, the protective equipment will have to be changed frequently.

Compliance with the listed recommendations will help you choose gloves for working in the garden, at a construction site or in other areas of economic activity.

Benefits of nitrile gloves

- Nitrile is a synthetic analogue of latex: if latex is made from natural rubber, then nitrile is made from oil refining waste. However, the properties of these materials differ markedly.

- The main advantage of nitrile is that it does not cause allergies, therefore nitrile gloves are indispensable for workers suffering from an allergic reaction to latex.

- Due to the absence of internal dusting of talc or powder, nitrile gloves do not cause dry skin and irritation.

- Nitrile protectors provide reliable protection against bacteria and viruses while allowing air to pass through. Gloves N101 MT-R (TACH-TAF-L) are widely used in medical institutions, in the food industry, in laboratories; company SOYUZSPETSODEZHDA.

- The model of nitrile gloves is not only resistant to alkalis, acids, alcohols and high temperatures, but also has remarkable elasticity: the possibility of stretching exceeds 500%! Disinfectants, acetates, hydrocarbonates, glycol ethers, oils and fats do not violate the integrity of nitrile products, therefore they are in great demand, both in chemical laboratories and and in beauty salons... Chemical resistance and a comfortable smooth surface with fine grooves for easy grip of the instrument - an excellent combination for cosmetic procedures.

- Nitrile gloves greatly facilitate precision operations in electronics and electrical engineering due to the texture on the fingertips, and the mechanical memory effect prevents hand fatigue, even with prolonged wear.

- The antistatic properties of nitrile also contribute to the precision of small jobs.

- Nitrile is a strong compound, thanks to which gloves made of it are distinguished by a long service life, as well as resistance to punctures and cuts.

- It is difficult to find a worthy analogue of nitrile gloves for work in car service centers and auto repair shops. Unlike latex, nitrile perfectly withstands the effects of gasoline, fuel oil, kerosene, oils, does not suffer from hot air under the hood, and in comparison with canvas gloves, nitrile gloves gain in convenience and elasticity, providing the necessary level of tactile sensitivity during work. For the same reasons, nitrile safeners are widely used in the petroleum and refining industries.

- And finally, nitrile gloves are well cleaned and washed from dirt, which allows them to be used repeatedly.

Nitrile protectors provide reliable protection against bacteria and viruses. Photo: courtesy of Soyuzspetsodezhda

GOSTs

The main characteristics of nitrile gloves must correspond to:

- GOST 12.4.010-75;

- GOST 12.4.183-91;

- GOST 38.106140-81.

The Europeans made a different testing system and their standards are different, but nitrile gloves received the second category EN388 and the third EN374: this means that during testing they turned out to be the most reliable.

Even the winter versions comply with the EN388 and EN 511 categories. The simple version of the nitrile-drenched gloves, resistant to oil and gasoline, complies with the EN 420 standard.

Powderiness

Gloves are a synthetic powder-free product designed for people who are sensitive to rubber latex. Since items are coated with cornstarch powder, powder-free nitrile options are best used for medical purposes. Starch can cause irritation if it gets into a wound or damaged surface.

Gloves are a synthetic powder-free product designed for people who are sensitive to rubber latex. Since items are coated with cornstarch powder, powder-free nitrile options are best used for medical purposes. Starch can cause irritation if it gets into a wound or damaged surface.

Household versions of gloves are common, but they are characterized by a complex composition of components.Vitamins and lanolin are added to them, sometimes covered with aromatic mixtures. The main purpose of these gloves is to protect hands from aggressive elements in cleaning products. Disposable options are worn before washing dishes to keep hands soft. In some gloves, you can even handle food freely.

Sterility

Sterility of nitrile gloves is ensured by complete sterilization, which removes bacterial spores, fungi, prions and proteins. Gloves are sterilized by heat treatment, radiation or chemical elements, filtration methods are used, nitrile gloves for surgical operations are sterilized using chemical treatment or gamma radiation.

The best types of sterilization are gas and radiation, they are absolutely safe for the body.

More often than not, the same manufacturer sterilizes gloves chemically and with ethylene oxide. To confirm the level of sterility, look for a special indicator on the package.

How to choose?

Gloves, like other products, have quality standards. Product information is displayed on the label with special symbols in the form of numbers and letters. There is a marking for Russian products:

- MI - resistant to abrasion;

- MP - dense products, resistant to cuts;

- MA - protect against vibrations.

Imported products have their own markings indicating the protection class:

- A - resistant to abrasion;

- B - dense products, resistant to cuts;

- C - resistant to tearing;

- D - dense products, puncture resistant.

The size range of gloves has classic designations:

- S is the smallest size, suitable for a small female hand;

- M - suitable for medium sized hands and arms;

- L / XL - wide gloves, mainly used by men.

These are the basic characteristics that are sufficient for the correct selection of the right technical gloves.

About what kind of rubber technical gloves to use, see below.