Increased strength

- Heavy-duty gloves are used when performing some types of work under difficult conditions. There are two main types of products of this type:

- split-fork, used when necessary to protect hands from burns, punctures and blows, as well as during welding. Made from durable and coarse split wood;

- leggings, for the production of which they use split leather, tarpaulin and sheepskin. They have an elongated sleeve that completely covers the arms. Protection of this type is used when working in conditions of low or high temperatures, high levels of contamination, during welding.

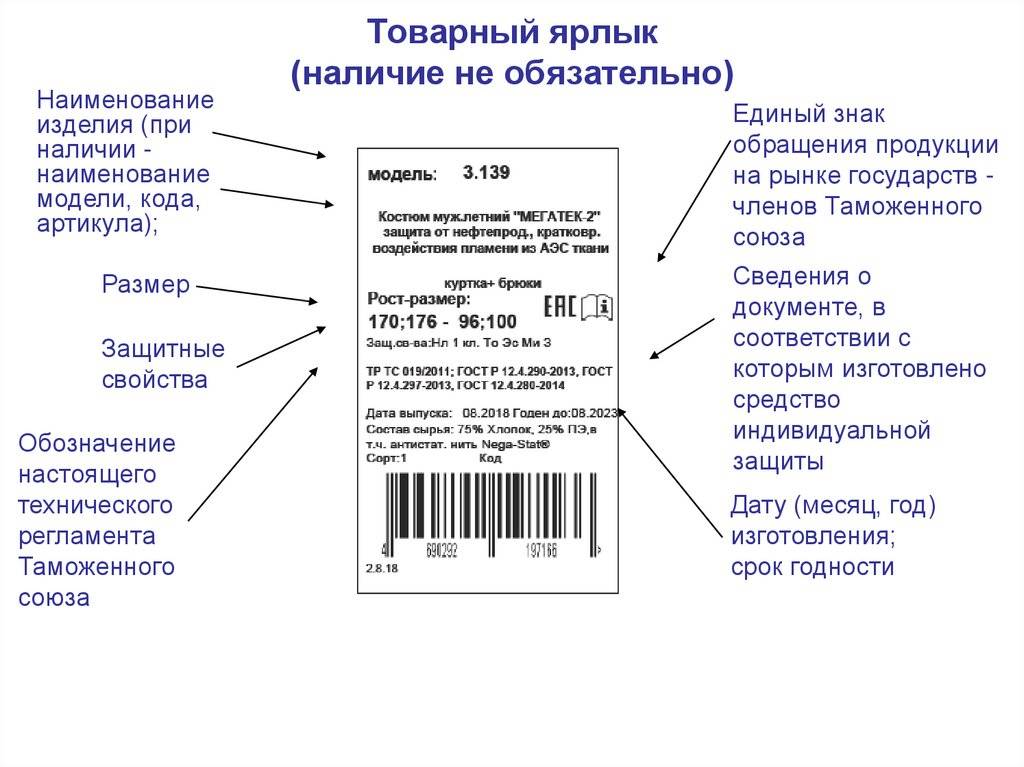

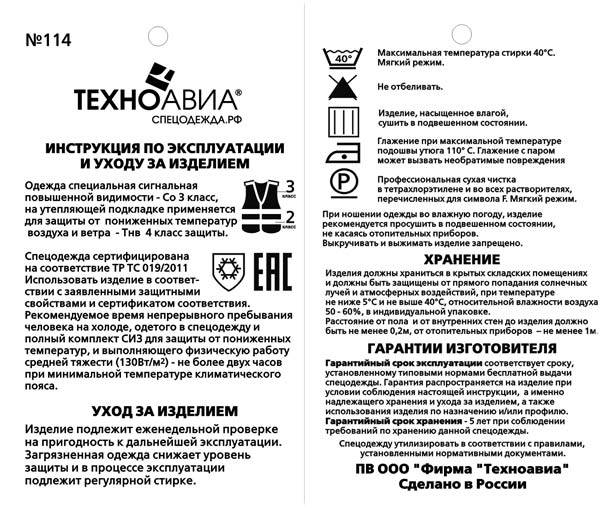

9.3. Information provided by the manufacturer

Information should

accompany gloves and provided upon request. Information should

include:

a) name and full

manufacturer's address or

an official representative;

b) product marking in

in accordance with 9.1.2 b);

c) link to

the corresponding standard;

d) available sizes and, c

if necessary, information on;

e) in case

necessary, as indicated in 9.2.2, a pictogram indicating protective

properties, indicating the characteristics of harmful factors. Further should be

explanation of the performance characteristics of hand PPE

and references to relevant standards;

f) a list of substances

contained in a glove that can cause allergies;

g) instructions for

application;

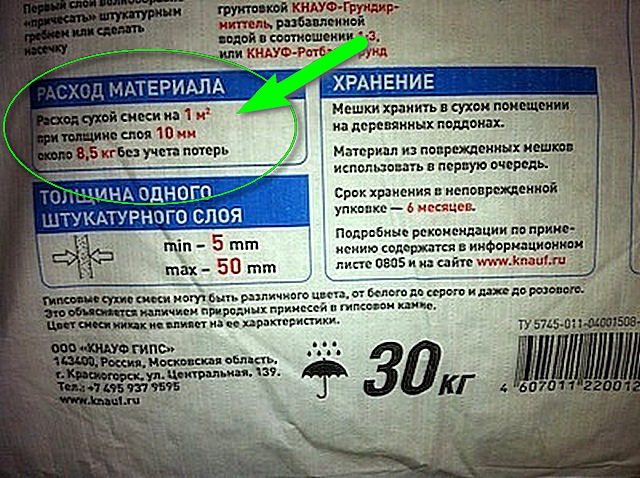

i) care instructions

(washing or dry cleaning conditions) and storage;

j) type of packaging for

transportation and storage;

k) shelf life for

gloves and packaging with a significant decrease in protective properties as a result

storage.

Appendix A

(reference)

Determination of personal protective equipment for hands only for minimal risks

This category belongs

only hand protection designed to protect against:

- mechanical

surface influences (garden gloves, etc.);

- detergents of weak

actions (gloves protecting against dilute solutions of detergents and

etc.);

- risks arising from

handling objects, the temperature of which does not exceed 50 ° C, not subject to

human danger of serious burns;

- atmospheric influences

non-exclusive and non-extreme characters (seasonal clothing);

- weak blows and

vibrations that do not affect the vital functions of a person and are not able to cause

irreparable damage to health.

Appendix B

(reference)

Pictograms

|

Pictogram |

Hazard category, purpose |

Pictogram |

Hazard category, purpose |

|

From mechanical stress |

From low temperatures |

||

|

From cuts |

From high temperatures and open flames |

||

|

From ionizing radiation |

From radiation contamination |

||

|

Chainsaw cuts |

From chemicals |

||

|

For firefighters |

From chemicals |

||

|

Information |

From biological factors |

Bibliography

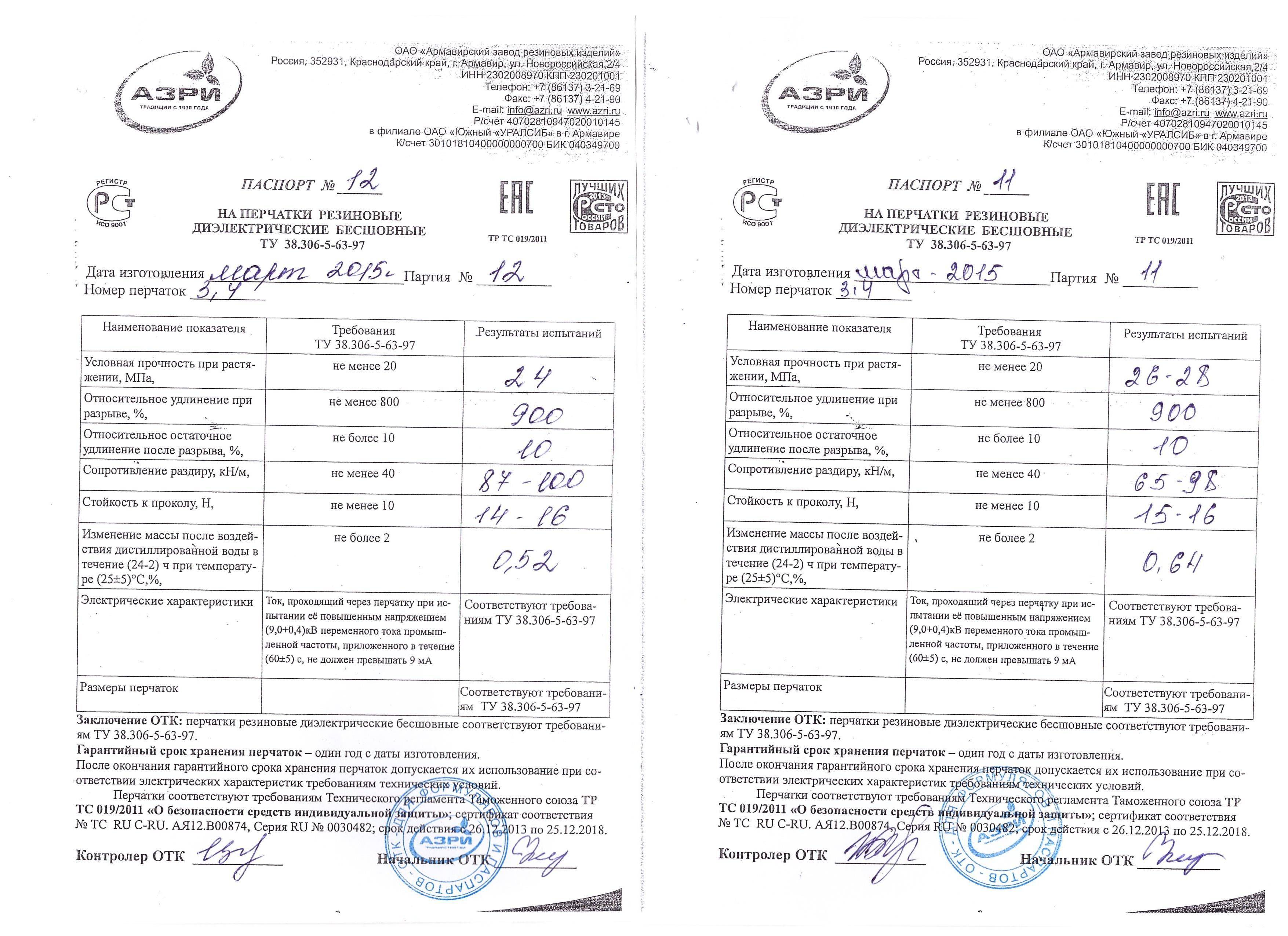

1. Instruction

on the application and testing of protective equipment used in electrical installations.

Approved by Order No. 261 of the Ministry of Energy of Russia dated June 30, 2003.

Keywords: funds

personal protection of hands, gloves, quality indicators, test methods,

marking

Device and principle of operation

This respirator model has a rather simple device - it consists of three layers of different materials.The first layer is polyurethane, which is characterized by a protective color, has the appearance of a film and does not allow dust contained in the air to pass through. The device also includes 2 valves, between which there is a second protective layer made of polymer fibers. The main task of this layer is additional filtration of the air inhaled by a person. The third layer is made of a thin air-permeable film, in which the inhalation valves are mounted separately.

The front of the protective device has an outlet valve. To make it convenient to use the respirator, manufacturers additionally equip it with a nose clip and soft elastic straps, thanks to which the device is securely fixed on the head and does not slip on the eyes or chin.

The inhaled air enters through the filters, being cleaned at the same time, and the exhaust air is discharged through a separate valve. Using such a device, a person almost completely protects his body from the negative effects of dust.

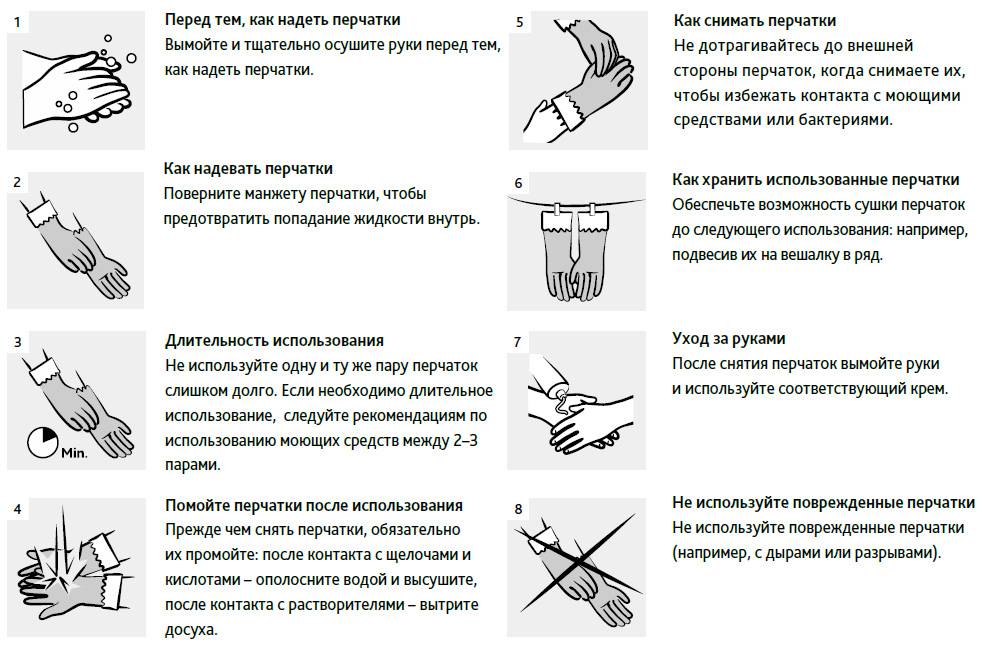

Household gloves care

The service life of rubber gloves is up to 1 year. With improper use and care, this period can be reduced to 1 day. In order for your hand protection to serve you for a long time, you need to follow simple rules:

- After finishing work, be sure to rinse the products with water, dry and sprinkle with talcum powder to prevent sticking and tearing.

- Store gloves at temperatures between 5 and 15 degrees, prolonged exposure to the sun or heating devices will shorten their service life.

- The air humidity in the room where the products are stored should not exceed 85%.

Today, glove manufacturers pay great attention not only to the quality characteristics of the product, but also to the design of the products. Since the users of these hand protection are predominantly women, in the manufacture of gloves, applications in the form of hearts or flowers are used, the products themselves have acquired bright juicy shades.

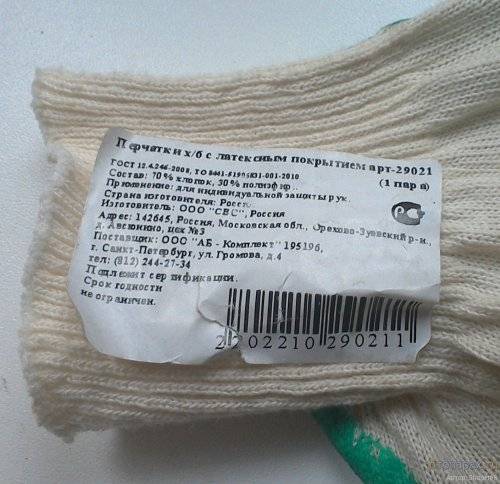

Oh, these different PVC gloves, or the Knit grade is an important detail

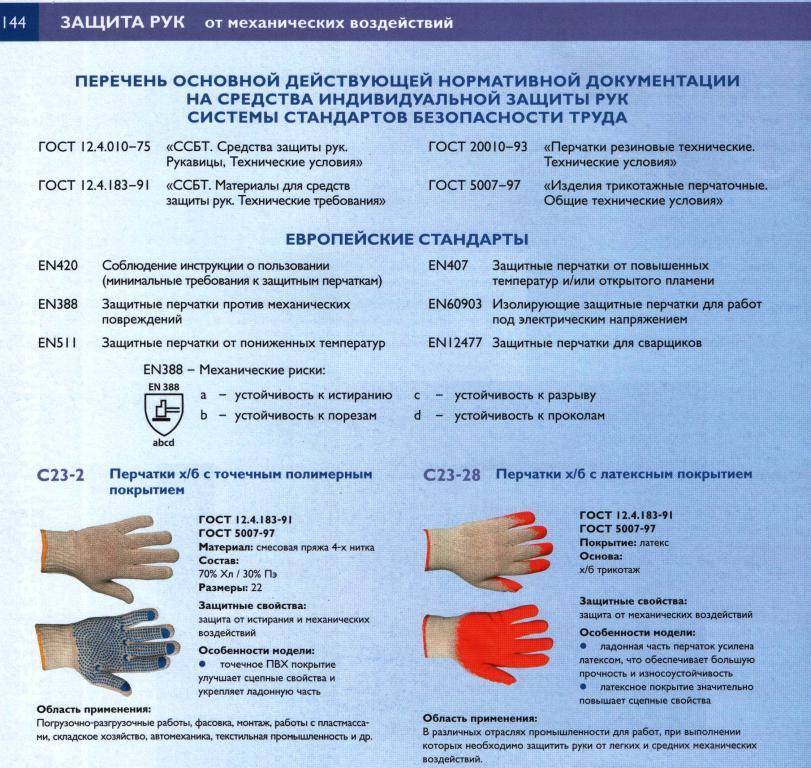

Various models are presented in the hb PPE catalog, but most buyers are lost not knowing which option to choose. How does one pair of gloves differ from another?

4-strand personal protective equipment - an economical option

The purchase of such goods is justified when it comes to "one-time" work. The knitting of the described gloves is looser. They are not as dense as their "brethren". As a result, they wear out faster.

Advantages:

- Provides good adhesion to the surface of the object.

- They allow air to pass through well, so hands practically do not sweat in them.

- Protects against corns.

- Protect hands from contact with dust and dirt.

- Who will benefit from: gardeners, warehouse workers.

PPE cotton 7,5 class - protection against mechanical damage

Standard density gloves presented. They look denser than "four-strings". They are more reliable and last longer.

Advantages:

- Protects hands from calluses and abrasions.

- Do not hinder movement when performing various types of work.

- Allows the skin to "breathe".

- Keep your hands clean.

- Easy to wash.

Who needs: loaders, farmers, builders, installers, housing and communal services workers.

PPE with grade 7.5 PVC protects against abrasions, calluses

HB PPE class 10 - high hand sensitivity

For the production of products, thinner cotton yarn is used. Since six threads are used, the knitting is denser, the loops are smaller.

- Protect from contamination.

- Well "fit on the arm" due to the elastic cuff, without squeezing the wrist.

- Provides a feeling of comfort even during prolonged work requiring increased tactile sensitivity of the hands.

- They serve for a long time.

Who needs: car service employees, workers of assembly shops.

PPE with PVC class 10 - long service life

LUXURY gloves - comfort and convenience in work

The manufacture of PPE requires 7 threads, due to which a high level of density is achieved. Such products are 1.5 times heavier than standard ones.They are usually called "male" because of their large size.

- Protects hands from cuts and splinters.

- Provide the ability to perform precise manipulations.

- They are distinguished by an increased durability resource.

- They have a good grip on heavy and slippery objects.

Who needs: glaziers.

Gloves HB LUX

Varieties

Due to the high prevalence of cotton gloves on the modern market, you can find several varieties of such goods (for example: insulated, working, thin, knitted, white, black, double winter, without and with PVC, etc.). In general, depending on certain factors, personal protective equipment is divided into several main categories.

Main classes

First of all, it is important to consider the existing classes of cotton PPE

- 7 (or 7.5) class. Gloves that fall into this category are characterized by a standard knit density. Of all the existing models, these models are the thickest and roughest. Among the main advantages is the fact that this particular variety will best protect your hands from mechanical damage.

- Grade 10. In gloves of this type, the threads fit more tightly, but at the same time they themselves are quite thin. Most often, this type is used in production during painstaking work (for example, repair or assembly of products). Hands in such gloves maintain a high level of sensitivity.

- Grade 13. The knitting density of these gloves is 4 times higher than that of the 7th class. Despite the fact that PPE is quite thin, it is very tight. This type is recommended for performing tasks that require high precision.

Types of drawing

In addition to the class, the most important characteristic of cotton gloves is the type of pattern. There are several varieties.

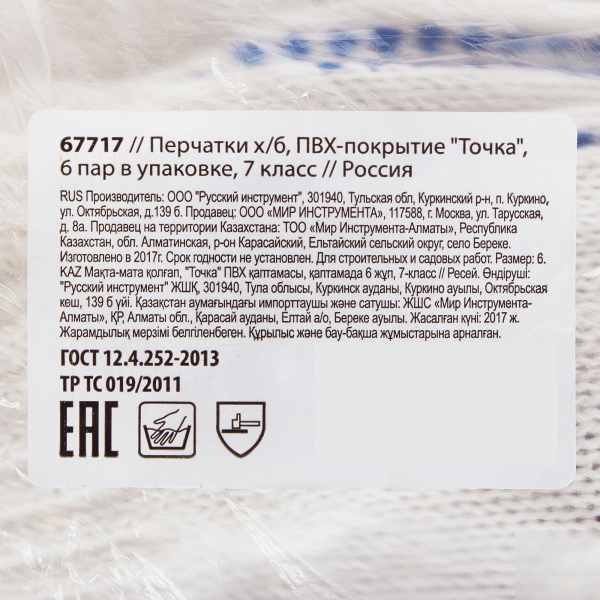

Drawing "Point"

If this pattern is applied to the gloves, then they should be chosen for performing light and medium jobs. So, this type will be relevant in the course of performing various kinds of repair tasks or for loading various objects.

Drawings "Herringbone", "Brick", "Protector" and "Wave"

These gloves are suitable for heavy work.

This is due to the fact that, thanks to the printed pattern, the PPE provides a high level of grip reliability (which is especially important if you are moving heavy loads)

Thus, we can conclude that the purchase of gloves must be approached carefully, because there are a large number of different models, each of which is designed to perform certain tasks.

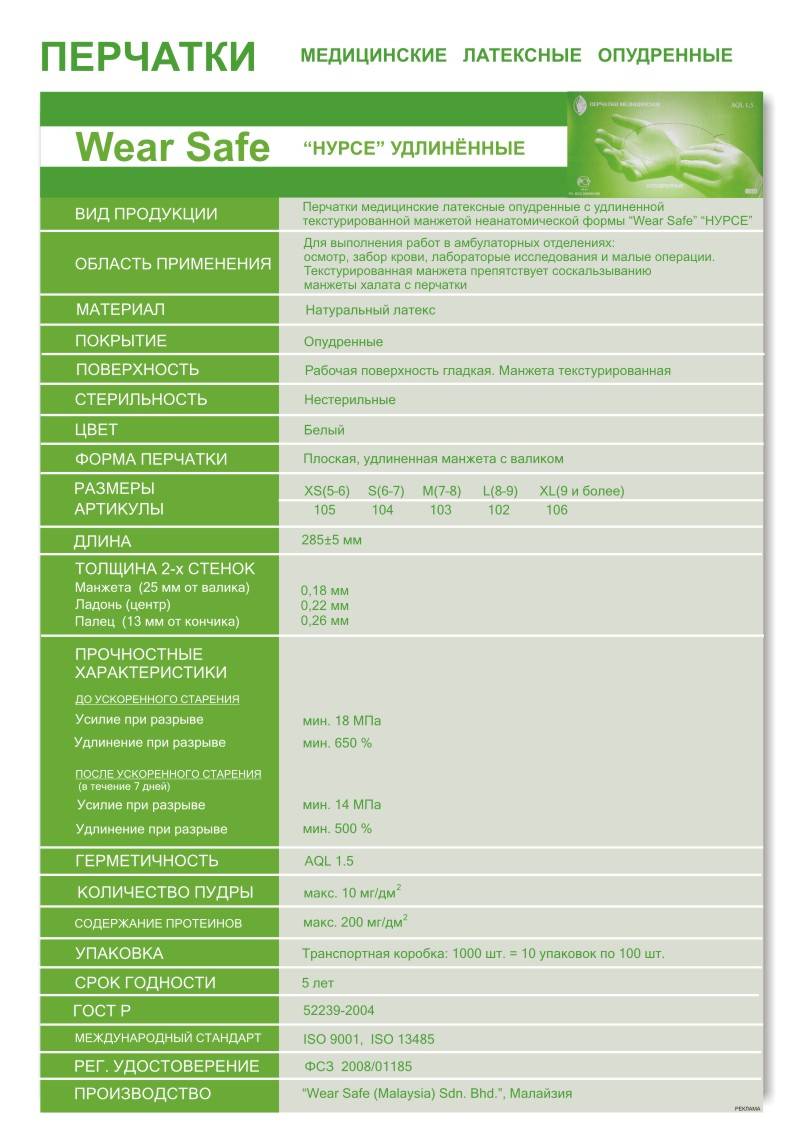

Main characteristics

Today, rubber technical gloves are made mainly of 3 types of material - latex, vinyl and nitrile. On the farm, they are a useful accessory when working with water, mud and chemicals. The scope of application of gloves is wide - they are used both in simple household chores and during repair and painting work.

According to the service life, technical gloves are divided into 2 types:

- disposable - after work to be disposed of;

- reusable - serve for several months, depending on the frequency of use.

Protective gloves are also divided into 2 conditional groups:

- universal - used in works where hand protection from mechanical damage is needed;

- special - designed for certain jobs, have an increased level of protection, differ in material and the principle of sewing.

There are special types of protective products such as anti-slip and fingerless. Various types are used in certain areas, however, the general requirements for all products are the same, first of all, this is protection.

Criterias of choice

It is necessary to select PPE by size

All works can be divided into three subgroups:

- Household. Washing dishes, taking care of house plants, with cleaning agents that are caustic or alkaline.

- Work on the personal plot.

- Industrial.Electrical work, painting, exposure to technical fluids.

Important! For work with electric current, special dielectric gloves are used, and they are usually worn over cotton ones. You also need to take into account personal characteristics - people with allergies should not buy modifications from natural rubber

Better to overpay a little, but keep health

You also need to take into account personal characteristics - people with allergies should not buy modifications from natural rubber. Better to overpay a little, but keep your health.

Another point - for working with deep containers (buckets, tanks or for cleaning the toilet), it is better to choose gloves with an extended arm to protect against water and cleaning agent getting inside.

It is recommended that you have a separate pair of gloves for every type of household work (washing the dishes, cleaning the bathroom or gardening). You can buy options in different colors so that you can easily determine what a particular pair is for.

Usually, manufacturers indicate the size grid directly on the pack. The correct size of gloves is the key to ease of use and wearing comfort. Four main parameters are most often presented on sale:

- S - suitable for people with a small palm (girth without thumb 17.5-19 cm).

- M - for a medium hand (19-20.5 cm).

- L - for those with a large palm (20.5-22 cm).

- XL - for people with a large hand (from 22 to 23.5 cm).

For your information. However, in specialized hardware stores you can find XXL gloves (23.5-25 cm).

Description and scope of knitted work gloves

PVC coated gloves are very popular with workers. The advantages of such products include the following:

- affordable cost;

- protection of hands from external influences;

- constant expansion of the range;

- decrease in muscle tension;

- the ability to perform precise work.

> Knitted PVC gloves are successfully used in loading and auto mechanics. They are actively used in light industry and construction. Also, such products can be used to perform various household chores. Such devices are used to work with polymers.

The density depends on the number of threads in the yarn. 5-thread gloves are considered to be denser. They provide the best protection against dust and dirt. The relatively thin fiber helps to increase the sensitivity of the hands.

Gloves with 4 strands wear faster. They are more often used by loaders or other people who are forced to work with heavy objects. Such products provide better surface grip. For good adhesion of the gloves to tools and work surfaces, the palm and fingers are treated with a PVC coating. Thanks to this, the grip of the hands becomes secure and strong.

It should be borne in mind that it is not recommended to use such products for contact with hot objects. In this case, it is recommended to use products in which cotton threads predominate.

Most often, such products are equipped with a dot coating. The most common types of drawings include the following:

- Herringbone - represents sharp corners that are applied to the surface of the palm.

- Dot is a common coating that is a dotted pattern across the entire surface of the gloves.

- Waves - in this case, a wavy coating is applied from the side of the palm with a small interval.

- Brick - in appearance it is an imitation of brickwork.

- Stripes - run parallel to each other with a small interval.

- Logo - used for advertising purposes.

Synthetic rubber

Artificial rubber models have undeniable advantages over latex positions. Of course, they are more resistant to aggressive chemicals. Less prone to mechanical damage, not as slippery as natural rubber options.

For your information.They do not cause allergies (the inner surface is specially coated with cotton or synthetic dusting, which does not allow the skin of the hands to come into direct contact with the rubber).

Rubber gloves are reusable.

Along with the advantages, synthetic models have a number of disadvantages. As the artificial rubber products are thicker, the finger sensitivity is reduced. This excludes the possibility of performing "fine and high-precision" manipulations. Such models are non-sterile, and the use of standard reprocessing methods causes significant changes in the structure of materials.

They don't stretch well and break easily. At the slightest damage, the products quickly deteriorate, and they have to be changed frequently. There is another unpleasant feature - the permeability of such gloves. Often in the area of the thumb or the tips of others, water can seep into the synthetics.

8.1. Measuring hands and gloves

8.1.1. Arm circumference

measured with a metal tape in accordance with GOST 7502

at a distance of 20 mm

from the bifurcation of the thumb and forefinger (see Figure 1).

8.1.2. Arm length

measured in millimeters as indicated in Figure 1.

8.1.3.

The length of the glove is measured from the top of the middle finger to the end of the glove on the back

side (see figure 2).

|

a - length Figure 1 - Measurement |

a is the length of the glove, Figure 2 - Measurement |

For measuring

the length of the glove must be freely suspended by the middle finger vertically

located ruler. Without stretching the glove must be smoothed by straightening

wrinkles and folds. The resulting minimum length is recorded with an accuracy of

millimeter.

8.1.4. If the glove

there is a sewn on cuff or it is made of elastic material, dimensions

indicate for the unstretched state.

Description and application

Rubber gloves are multifunctional products suitable for use in various spheres of life. The first thing that comes to mind is doing chores. Rubber products can be used for dishwashing, wet mopping, or plumbing cleaning. They are also needed in the garden during planting, weeding or other activities. You cannot do without them during repairs - gloves will keep the brushes clean during painting and other works.

Some housewives use gloves when preparing food: washing fruits with vegetables, processing meat or cleaning fish. Durable acid resistant gloves can be used in the chemical, pharmaceutical or car service industries. For example, they come in handy during the development of medicines, accompanied by possible contact with chemicals, when interacting with electrolytes, or even the manufacture of fertilizers.

Rubber gloves made of polymer materials are usually divided into disposable and reusable. The former are thrown away immediately after the end of the work, while the latter can serve a longer period provided they are thoroughly cleaned, sometimes up to a year. At the end of the work, such household accessories are washed with running water, dried and sprinkled with talcum powder. They should be stored protected from direct sunlight at temperatures from 5 to 15 degrees Celsius and, preferably, in their original packaging. Humidity should not exceed 85%, and all heating devices should be located remotely.

If we consider the characteristics of the product, then we can find that gloves perfectly protect against the negative effects of water, dirt, chemicals and reagents, detergents and objects that can lead to scratches. The adhesion to the hands is ensured due to the presence of the embossed surface. Rubber gloves should not be used for work involving interaction with electric current, for contact with particularly sharp elements or strong chemicals.

In the first case, we are talking about the use of nitrile and neoprene, and in the second - natural latex. The work is carried out using a seamless technology that makes the protective accessories denser and provides reliable protection for the skin. To achieve the best possible comfort, the inner surface of the gloves can be treated with cornstarch or talcum powder, and the outer surface can be coated with a special cotton dusting. In addition, chlorination of latex products makes it possible to lengthen their service life.

Wear rubber gloves only on dry hands

Before use, it is important to carefully inspect the accessories and find a replacement if any defects are found. If you have to work for a long time with strong chemicals, then it is better to alternate several pairs of gloves.

It would be good to bend the edges of the cuffs in order to precisely prevent the ingress of hazardous substances onto the skin surface. When finished, the gloves should be washed and dried naturally, both externally and internally. Before the next use, they will again have to be carefully inspected for cracks or breaks.

Distinctive features and purpose

Nitrile coated protective gloves are available in different types. There are thin disposable models and denser ones that are designed for heavy work. There are also varieties with a smooth or embossed surface.

Similar products differ in length and colors. The gloves themselves are made from different materials. They are often supplemented with cuffs. Depending on the variety, they are made hard or elastic. Then the gloves are treated with nitrile. Coverage can be complete or incomplete. Sometimes the pouring is done in two or three layers. It often contains antifungal or antibacterial components.

Selection Tips

When choosing household gloves, it is worth considering a number of criteria:

Comfort - the product must fit in length and width

It is important that it fits snugly around the cuff. Models that are too short or loose will topple and slide.

Base type - knitted models are considered more elastic

They stretch easily and fit the skin. However, such products contain more synthetics. Hands in such gloves sweat more. At the same time, the cotton base is better breathable. It is suitable even for those with sensitive skin.

Availability of certificates - only standardized products that have passed all the required checks are considered safe to use. It is important that the surface of the products has appropriate markings that indicate the type of coating, size and other key features.

Pairing - Dotted gloves are often sold in packs because they are affordable and quickly consumed. However, when buying, it is worth checking the pairing of the purchase. It is important that all products match.

Strength - the stronger the load on the surface is planned, the more dense the products should be. Otherwise, the protective equipment will have to be changed frequently.

Compliance with the listed recommendations will help you choose gloves for working in the garden, at a construction site or in other areas of economic activity.

8.5. Method for determining the peel resistance of a PVC dot coating

The real method

designed to determine the pull-off resistance of a polyvinyl chloride point

PPE covers for hands and materials for their manufacture.

The essence of the method

consists in determining the number of cycles when the PVC-point coating is torn off.

8.5.1. Sampling and preparation for testing

8.5.1.1. For testing

select two pairs of gloves.

8.5.1.2. From the palmar

the sides of the gloves in the longitudinal direction are cut out at least five beads.

The length of the test piece shall be (100 ± 5) mm.

8.5.1.3. As

use a strip of length 110

mm and width 35 - 40

mm from cotton tarpaulin according to ND, approved in

established order.The strip is cut so that the thread of the base of the kersey

located in the transverse direction, and inserted into the clamps of the desktop

device.

8.5.1.4. On indenter

fix a strip of waterproof skin in accordance with GOST

13344.

8.5.2. Equipment

The tests are carried out on

device AILP-1 for determining the abrasion resistance of latex and polymer

materials according to GOST

12.4.167.

8.5.3. Testing

8.5.3.1. Prepared

the test specimens are fixed in the clamps of the instrument. When fastening, the sample for

tests stretch 20% - 30%. Test piece working area

is (60 ± 5) mm.

8.5.3.2. By using

loading mechanism set the load on the sample equal to 0.5 kgf.

8.5.3.3. The indenter is lowered

on the sample and turn on the device.

8.5.3.4. Periodically

(after 20 cycles) turn off the device and visually inspect the sample for

tests.

8.5.4. Processing of results

8.5.4.1. Per indicator

pull-off resistance of PVC dot coating take the number of pull-off cycles

the first two points.

8.5.4.2. For the result

tests take the arithmetic mean of five measurements.

8.6. Availability of necessary

structural elements are determined visually.

8.7. Basic linear

dimensions and thickness are determined in accordance with ND for a given type of test

gloves.

8.8 Requirements for stitches,

lines and seams - according to GOST

29122.

8.9. Breaking load

seam - according to GOST

28073.

8.10. Efficiency

vibration damping - according to GOST

12.4.002.

8.11. Package thickness

materials - according to GOST

12023.

The load at which the

thickness, set in standards and other technical documentation for

textile materials depending on their purpose.

8.12. Acid and

alkali permeability - according to GOST

12.4.063.

8.13. Seam strength at

rupture of rubber gloves - according to GOST

270.

8.14. External species

defects in knitted gloves - according to GOST

8846.

8.15. Extensibility

knitted wristband - according to GOST

19712.

8.16. Irreversible

deformation of the knitted wristband - according to GOST

19712.

8.17. Resistance to

abrasion of knitted gloves - according to GOST 12739.

8.18. Resistance

cut knitted gloves - according to GOST

12.4.141.

8.19. Fire resistance

knitted gloves - according to GOST

11209.

8.20. Resistance to

burning knitted gloves - according to GOST

12.4.184.

5.5. Requirements for knitted gloves

Knitted gloves

must meet the requirements given in table 7.

Table 7 -

Quality indicators of knitted PPE hands

|

Group and subgroup of protection |

Level of quality |

Norm |

|

By * |

Appearance |

According to ND, approved in accordance with the established procedure. |

|

In finished products, the following are not allowed: |

||

|

through breakthroughs, |

||

|

darning with a total area of more than 1.5 |

||

|

skipping the overcasting seam, |

||

|

the difference in total length in the matched pair is more than 1 |

||

|

broken latex thread in the wristband |

||

|

Basic linear dimensions, cm, not less |

||

|

length |

21,0 |

|

|

width |

7,5 |

|

|

thumb length |

7,5 |

|

|

Elasticity of the wristband, mm, not less |

140 |

|

|

Irreversible deformation of the wristband,%, no more |

6,0 |

|

|

Abrasion resistance, number of revolutions, not less |

100 |

|

|

Resistance to separation of points, number of cycles, not less ** |

150 |

|

|

Cut resistance, N / mm, not less |

2,0 |

|

|

Fire resistance, s |

The sample should not burn or smolder after being removed from the flame |

|

|

Resistance to burning, s, not less |

50 |

|

|

* For all groups and ** For knitted |

6. Requirements for gloves from minimal risks

Gloves on their own

quality indicators that do not meet the requirements given in - 7,

can only be used to protect hands from minimal risks (see),

7. Requirements for the materials of gloves

In addition to the above

quality indicators of gloves, determined on products as a whole, should

establish quality indicators characterizing the main protective properties

materials from which they are made. Depending on the purpose of the gloves and

of the materials used, the requirements for quality indicators and their methods

definitions must comply with GOST

12.4.183.