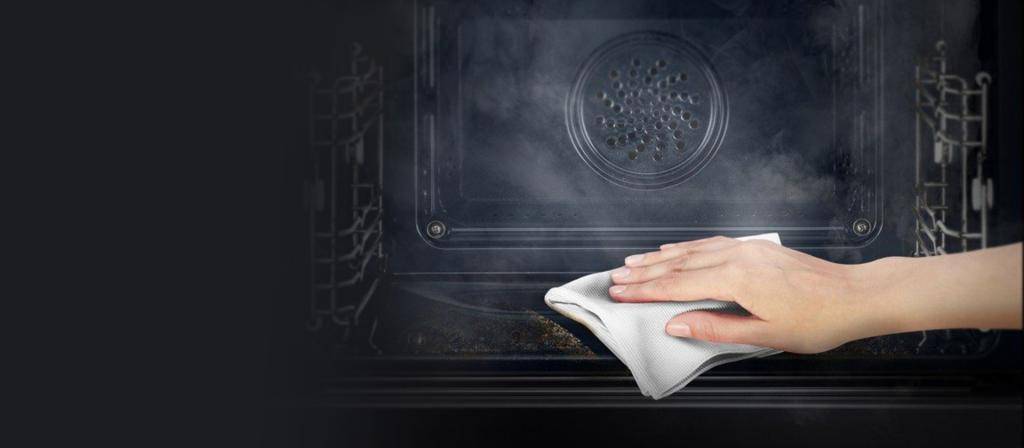

Hydrolysis oven cleaning - what it is and how it works

Another method of cleaning the inside of the oven is hydrolysis, or steam cleaning of the oven. What it is? The method involves the use of a special reagent called a hydrolysis fluid. It is poured into the drip tray and the oven turns on. The gradually generated steam begins to settle on the walls and leads to a softening of the fatty deposits. Further, the natural drainage of fat into the pan with liquid occurs.

IMPORTANT!

In case of severe contamination, this method is not enough, and the final cleaning will have to be done manually.

Steam cleaning is the third most effective oven cleaning method

Steam cleaning is the third most effective oven cleaning method

The main requirement for modern ovens equipped with a hydrolysis cleaning function is to manufacture surfaces from high-quality acid-resistant enamel to prevent fat from entering the device.

Advantages and Disadvantages of Steam Cleaning

Knowing what it is - cleaning the oven with steam, allows you to highlight the advantages and disadvantages of this method. They also need to be considered when choosing a new oven for the kitchen. The advantages of the method are:

- simplicity of the method;

- low cost;

- implementation of the process without the use of aggressive reagents;

- the cleaning procedure takes place at low temperatures, which allows you to preserve the surface of the oven.

If there is no tray for pouring water, you can use heat-resistant dishes

If there is no tray for pouring water, you can use heat-resistant dishes

The disadvantages of the process are:

- the need to use a rag or sponge to remove softened fat;

- self-cleaning of additional elements;

- inability to remove old fat.

How to properly carry out hydrolysis cleaning

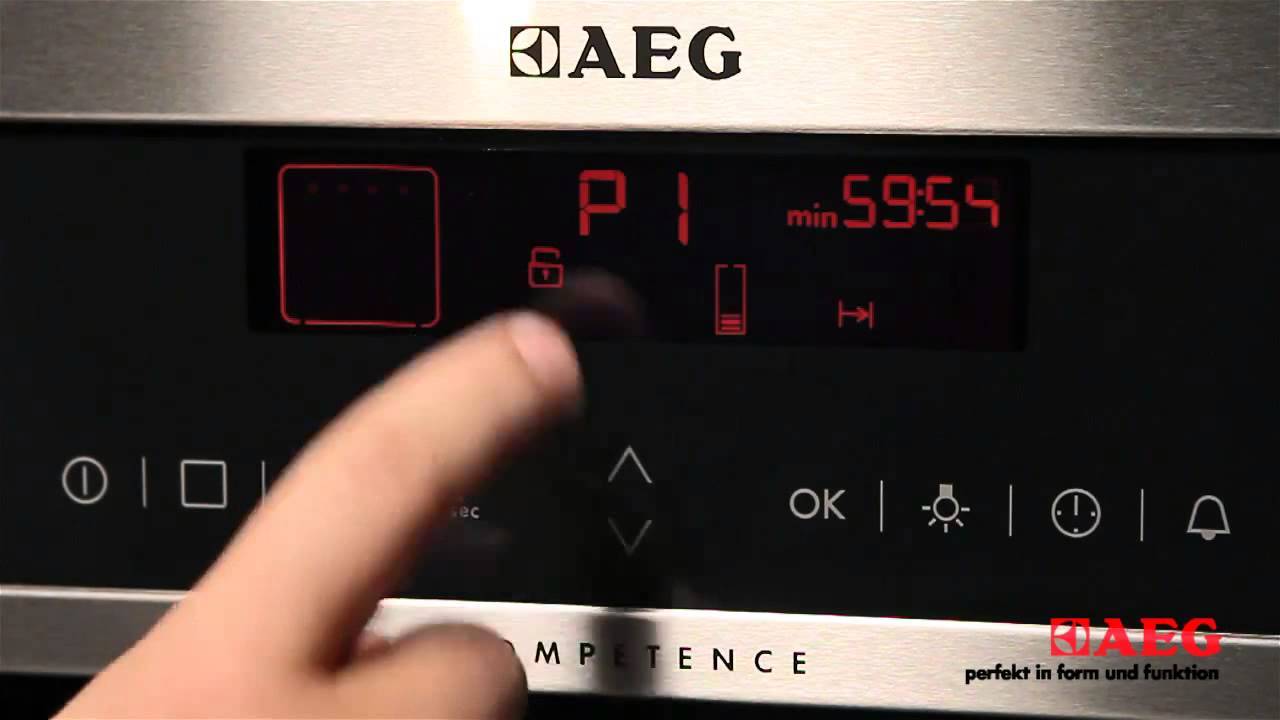

The process of hydrolysis cleaning of the oven, which is called AquaClean or AquaSmart, takes place in several stages:

- All additional elements, such as baking trays, racks, fasteners, should be removed beforehand.

- Further, the required mode is selected on the control panel and the cycle is set with the support of such technology.

- The required amount of liquid is poured into a tray or a special recess in the bottom of the oven.

- After the end of the vaporization process, allow the oven to cool slightly and clean the surface with a clean, soft cloth.

FOR YOUR INFORMATION!

Budget models of stoves are not always equipped with a special tray for water, so in them the steam cleaning process can be carried out by pouring liquid into heat-resistant dishes, which are installed on the grate.

Traditional methods involve the use of household chemicals and your own hands

Traditional methods involve the use of household chemicals and your own hands

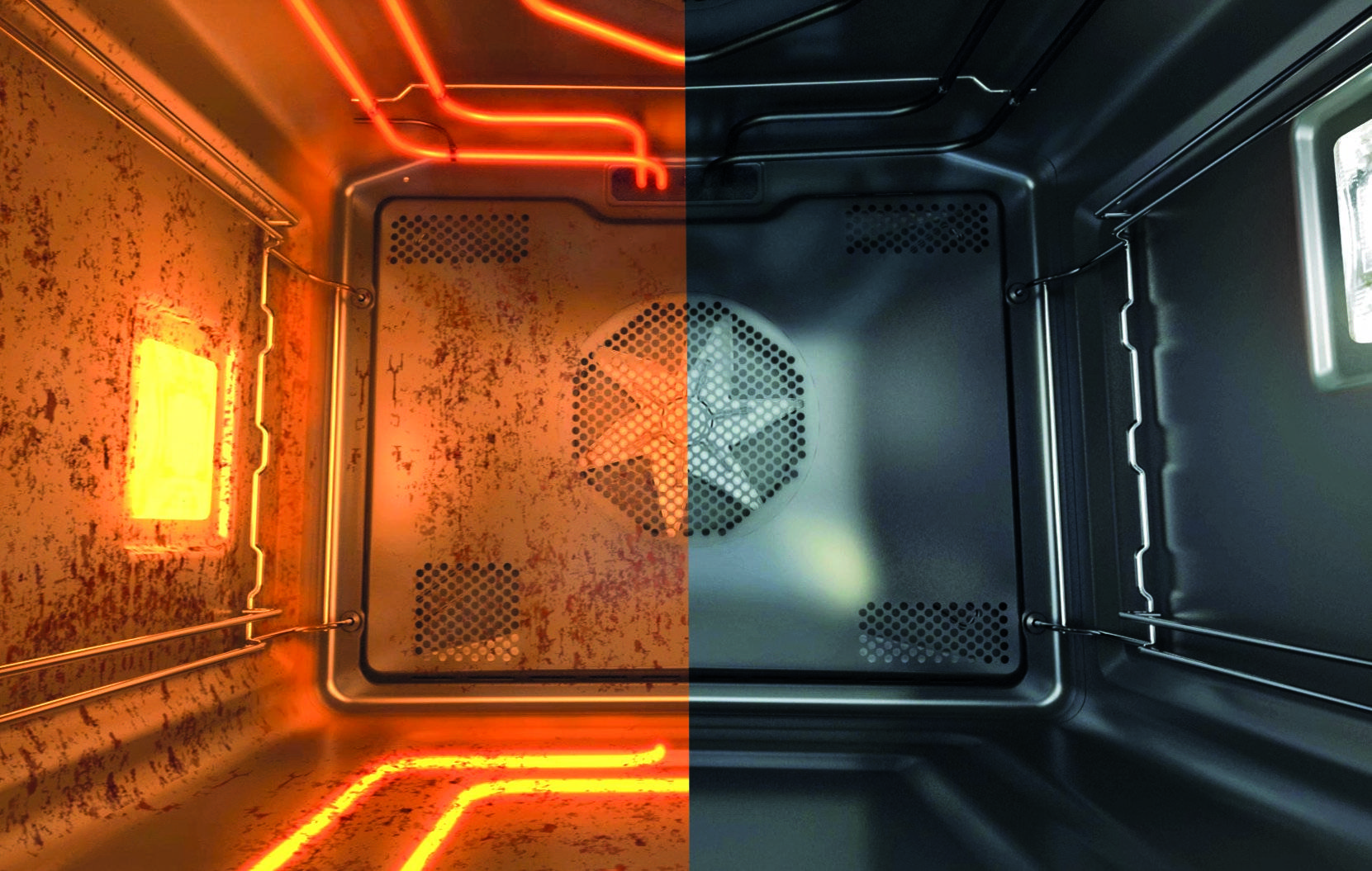

Pyrolytic oven cleaning - what is it

The next way to get a clean inside of the oven is the pyrolysis cleaning process. What it is? The essence of the method lies in the name itself, since in translation from Greek “feast” means “heat”, and “lysus” means “decay”. In other words, this technology is called thermal decomposition, since the inside of the oven must be heated to at least 450 ° C to remove the remaining fat. Under the influence of such high temperatures, all organic compounds simply burn out with the formation of ash, which is simply removed from the oven with a cloth after it has cooled down.

Even the most severe pollution can be dealt with by pyrolysis

Even the most severe pollution can be dealt with by pyrolysis

IMPORTANT!

The pyrolysis process is only possible in electric models, since gas devices are not able to heat up above 250 ° C.

Advantages and disadvantages of the method

This method also has a number of invaluable advantages, which are side by side with disadvantages. They should be taken into account if you want to become the owner of an oven with pyrolysis cleaning. The advantages of the method are:

high efficiency

When choosing which method of cleaning ovens is better, pyrolysis confidently takes a leading position, since through this technology it is possible to get rid of even the most old and strong contaminants;

versatility, allowing the removal of all types of plaque;

cleaning the entire area of the oven, which is especially important to remove dirt in places where, using another method, only manual cleaning would be required; Ovens for pyrolysis cleaning are equipped with special heat-resistant glasses

Ovens for pyrolysis cleaning are equipped with special heat-resistant glasses

Ovens for pyrolysis cleaning are equipped with special heat-resistant glasses

no need to use household chemicals, after which there is a plaque and an unpleasant odor that affects the quality of food.

The disadvantages of this cleaning method can be considered:

- higher cost of equipment with pyrolysis, which is due to the use of heat-resistant types of steel and specially tempered glass to withstand high temperatures;

- the duration of the cleaning process, which can last up to 2 hours;

- power consumption, the value of which depends on the degree of pollution, but on average varies from 4 to 7 kV;

- requirements for the surrounding furniture, which must also withstand higher temperatures;

- the presence of an unpleasant odor. The oven, equipped with a pyrolysis function, has special filters to trap odors, but with heavy pollution, they simply may not cope with the assigned task.

Gas ovens are devoid of the pyrolysis function, since they cannot heat up to the required temperatures

Gas ovens are devoid of the pyrolysis function, since they cannot heat up to the required temperatures

How to use pyrolysis correctly

In order for the pyrolysis cleaning process to be of high quality, a number of rules must be observed, which also ensure the safety of others during the procedure:

First, you should remove trays and grates from the oven, which are simply not designed for such temperature conditions.

When choosing a specific model, you should pay attention to the presence of a door lock function, which should be activated when the temperature rises to 200 ° C.

We recommend cleaning at least once a month to avoid significant carbon build-up. Many modern stoves are equipped with a special catalyst that determines the degree of contamination and notifies the owner of the need for cleaning.

IMPORTANT!

IMPORTANT!

Even if there is a blockage in inexpensive models, significant heating of the glass is observed, therefore, it is advisable to keep children away from the stove during cleaning.

During pyrolysis cleaning, keep children away from the stove, as the door can become very hot.

During pyrolysis cleaning, keep children away from the stove, as the door can become very hot.

How to use

The procedure itself is carried out automatically after manually starting the function. Before starting this option, remove all additional items, namely: baking sheet, wire rack, guides and pull-out parts that deform when exposed to high temperature conditions.

Some manufacturers produce components made of heat-resistant materials, thereby making it easier to use the cleaning system so that the hostess does not have to spend time removing foreign elements.

Important!

Before using the self-cleaning mode, remove all cookware from the oven to allow for unforeseen circumstances.

The phased pyrolytic cleaning consists of the following steps:

- Assessment of contamination, selection of the most suitable program and activation of the function;

- When the temperature reaches 300 degrees, the door is locked to avoid burns.The control system avoids injuries and ensures complete safety for children and adults;

- At the end of the procedure, when the temperature in the oven drops to 200 degrees, the lock is automatically unlocked;

- Open the oven and wait for the device to cool completely;

- Residues that have turned to ash are removed with a soft cloth or brush;

- The device is ready for further operation, looks like a new unit;

- Baking trays, racks and other accessories can be put back.

If cooking in the oven is carried out regularly, this procedure should be applied every week.

Security measures

Compliance with standard rules will help extend the life of the kitchen units and ensure safe use for all family members.

When applying pyrolysis, you must follow these recommendations:

- The oven is used strictly for its intended purpose - for cooking. Drying of mushrooms, herbs and premises is strictly prohibited;

- It is contraindicated to cover the bottom and inner walls of the cabinet with aluminum foil;

- Baking trays should not be placed on the bottom, such a moment can damage the enamel and prevent high-quality air circulation;

- It is forbidden to place dishes on an open door;

- The ventilation openings must not be blocked.

The health of consumers and the safety of using the unit depend on compliance with this list of rules.

Pros and cons of cleaning types

Pyrolysis is the most expensive and most effective. At a high heating temperature (up to 600 ° C), only a heap of ash remains from any contamination, which can simply be brushed off with a cloth. But this requires high energy costs - the network must be designed for at least 6 kW. During the process, an unpleasant odor appears and the room requires high-quality ventilation. High heating of the door can cause burns. The option cost is in the "above average" price bracket.

Pyrolysis is the most expensive and most effective. At a high heating temperature (up to 600 ° C), only a heap of ash remains from any contamination, which can simply be brushed off with a cloth. But this requires high energy costs - the network must be designed for at least 6 kW. During the process, an unpleasant odor appears and the room requires high-quality ventilation. High heating of the door can cause burns. The option cost is in the "above average" price bracket.

In order to understand which oven cleaning is better - catalytic or hydrolysis, it is necessary to consider their advantages and disadvantages.

Catalytic cleaning is carried out using a special porous coating that works as a catalyst and contains copper, cobalt, cerium oxide and manganese. The process consists of three main stages:

- Start an automatic program.

- When heated to 200 ° C, a chemical reaction begins, during which the fat breaks down into water and soot.

- Removal of residual substances after cooling.

The process is safe, can take place during cooking and does not require additional energy consumption. However, the special coating is designed for a certain number of cycles and requires periodic replacement of the entire panel. Some manufacturers go to meet consumers and make the panel double-sided - after the expiration date, you can simply turn it upside down.

Hydrolysis oven cleaning is the ideal way to keep your kitchen oven clean. It's simple, inexpensive and safe. Even if the “helper” is not equipped with a special automatic system, it can always be put in order using ordinary steam and detergent. Among the disadvantages is the application of some effort and the use of difficult-to-wash chemicals. In order to reduce the intensity of dirt and protect the inner surface from the ingress of fat, you need to use a lid, foil and a baking sleeve.

Pros and cons of hydrolysis cleaning

The hydrolysis method has several distinct advantages:

- Versatility. The hydrolysis method is suitable for cleaning all ovens. Only traditional stain removal methods have this versatility. But hydrolysis speeds up the cleaning process.

- Simultaneous cleaning of every surface. Steam affects all parts of the oven, as well as baking trays, pans and other utensils.This allows you to immediately remove grease from both interior surfaces and pots and pans.

- Cheapness. To clean the oven, just pour and heat water. In other cases, you will need to purchase specialized tools. And if we talk about ovens with catalytic surfaces, then these devices are much more expensive.

- Security. The oven is cleaned with minimal human intervention.

- Gentle effect on surfaces. At a temperature of 90 degrees, neither the inner parts nor the installed dishes, which are intended for the oven, are damaged.

The disadvantages of the hydrolysis method include the fact that such cleaning takes a long time. To sufficiently soften traces of dirt, it is often necessary to heat the oven for 10 minutes or more. The oven cleans faster with catalytic and pyrolytic methods. The duration of the steam exposure depends on:

- degree of pollution;

- characteristics of the cleaning agents that are added to the water;

- features of spots.

The hydrolysis method does not help with old traces of fat. In this case, you will need to carry out this procedure several times in order to soften all the stubborn stains.

In addition, if chemicals are used in the cleaning process, a persistent, pungent odor is generated. In this case, you need to run the hood at maximum power. A similar disadvantage is characteristic of the pyrolytic method, due to which, under certain conditions, smoke can occur in the kitchen.

Pyrolysis, hydrolysis or catalysis - which is better?

Oven cleaning comparison table

Each type of cleaning has its own advantages and disadvantages.

When making a choice in favor of a particular technology, you should consider:

- how often the device will be used;

- what price segment is acceptable;

- what should be the quality of the materials used;

- Is it essential to fully automate the process or allow minor manual cleaning;

- what is the power of the wiring;

- is there a powerful hood at home.

The pyrolysis model is convenient if there is an opportunity to purchase expensive equipment, a wire with a power of at least 600 W is installed, the kitchen is equipped with a powerful hood.

Hydrolysis does not require large energy consumption, the possibility of burns is excluded. The method is quite simple and cost effective, but additional manual work is required to remove the remaining burnt fat.

If the priority is to save money, then a gas stove with a catalytic type of removal of old contaminants would be the best option, although this type of equipment is less functional than electric ovens. Catalysis is suitable for frequent use of the stove and will greatly facilitate the removal of old grease and stains.

How good are pyrolysis ovens

If we compare them with cars, then these are premium Mercedes.

If we compare them with cars, then these are premium Mercedes.

... And it's not just about the high cost of pyrolytic cleaning ovens.

In order for them to function at full capacity, their quality must be very high, which means that their operational life is quite long.

Steel for them is used of the highest quality, which is not afraid of high temperatures of prolonged exposure. The interior of the oven is covered with heat-resistant enamel, and all components are high-tech items.

For example, an electrolux oven with pyrolytic cleaning has 4 heat-resistant glasses that can easily withstand such a temperature load. Additionally, they are equipped with external surface cooling systems.

Important!

The procedure should be carried out in the absence of children and pets in the room. Safety of use is ensured by:

Safety of use is ensured by:

- automatic door locking systems;

- highly sensitive temperature sensors, carbon monoxide;

- a system that prevents the ignition of fatty deposits in the combustion chamber;

- grease filters on the convector grill.

Modern technology has a presentable and expensive appearance, which makes it an adornment of any kitchen

It doesn't matter if it's an expensive restaurant's cuisine or homemade

Other types of oven cleaning - pros and cons

In addition to those listed, there are other types of cleaning ovens. They have pros and cons. Let's consider them in more detail so that you can more consciously choose the right option for your home.

There are other ways to achieve perfect cleanliness.

Enamel for easy cleaning of the oven - what it is and why it deserves attention

If you do not like cleaning oily surfaces, pay attention to the oven with an easy-to-clean enamel. To do this, we propose to learn in more detail what it is, so that you can appreciate the benefits of such models.

The absence of pores will not allow grease to penetrate into the coating

Process features

The main feature of this cleaning method is the application of a special coating that does not have pores on the inner surfaces of the device during the production process. The structure of the material does not allow the absorption of fat.

Dirt is easy to wipe off

Cleaning instructions

To remove the resulting dirt, you must use a regular rag. When grease and soot appear on the surface, they are simply wiped off. The result is significant time savings, but all work is done manually.

You need a rag to clean

The service life of such a coating is limited. On average, after five years, the side panels have to be replaced with new ones.

Traditional oven cleaning - what it is and what is the main advantage

The lack of a self-cleaning function significantly reduces the cost of the oven. Traditional methods are used to clean these ovens. Let us dwell in more detail on what it is and what means can be used.

Chemicals and different sponges are used for cleaning

Process features

A distinctive feature of this method is the ability to remove even the most difficult contaminants without using electricity. This significantly reduces the cost of not only the initial cost of the oven, but also its subsequent operation.

A large assortment will allow you to choose the right composition

Refusing to use electricity, you have to spend your time. The grids and pallets will be cleaned separately from the interior. In addition, an incorrectly selected product can cause mechanical damage to surfaces.

Folk remedies are in high demand

Cleaning instructions

Knowing what methods of cleaning ovens exist, many believe that the traditional option is still better. How cleaning is performed depends on the chosen product.

To obtain a high-quality result, you should:

- remove all racks and trays from the oven;

- apply the composition to the surface to be treated. If it is in the form of a spray, spray over the surface. If in a liquid state or in the form of gruel - carefully distribute along the walls, bottom of the oven, as well as on baking sheets and a wire rack;

Spray on the surface to be cleaned

- wait for the allotted time;

- rinse off the composition thoroughly.

Metallic and hard sponges should be used with extreme caution

The main types of self-cleaning ovens

Consider the types of cleaning enamel from fat deposits.

Catalytic cleaning

The main features of this type are:

- The oven walls are covered with a thin layer of enamel and a special material (copper, manganese or cerium oxide).

- Enamel layers are filled with pores that contain catalyst particles, accelerated decomposition of fatty deposits into water and carbon occurs.

- The catalysis process takes place at fairly low (140-200 degrees) temperatures.

- Advantages of catalytic cleaning: it is found not only in gas, but also in electric ovens, the cleaning process itself occurs during cooking, which does not require additional energy consumption.

The disadvantages include a short period of use of catalytic panels (about 300 hours), they must be replaced, special enamel covers only some part of the oven, the door is not covered with enamel at all, the price is very high.

Pyrolytic cleaning

This is the most aggressive, but also the most effective cleaning. During such cleaning, the remaining fat in the oven burns out completely at a temperature of 500 degrees, forming ash.

In this process, the oven door is locked until the fat is completely burned out. The advantages of pyrolysis cleaning are that the entire oven is cleaned.

Cons - additional costs for power cable and electricity. Some Western manufacturers have created a multilevel pyrolysis cleaning system at a temperature of 250 degrees.

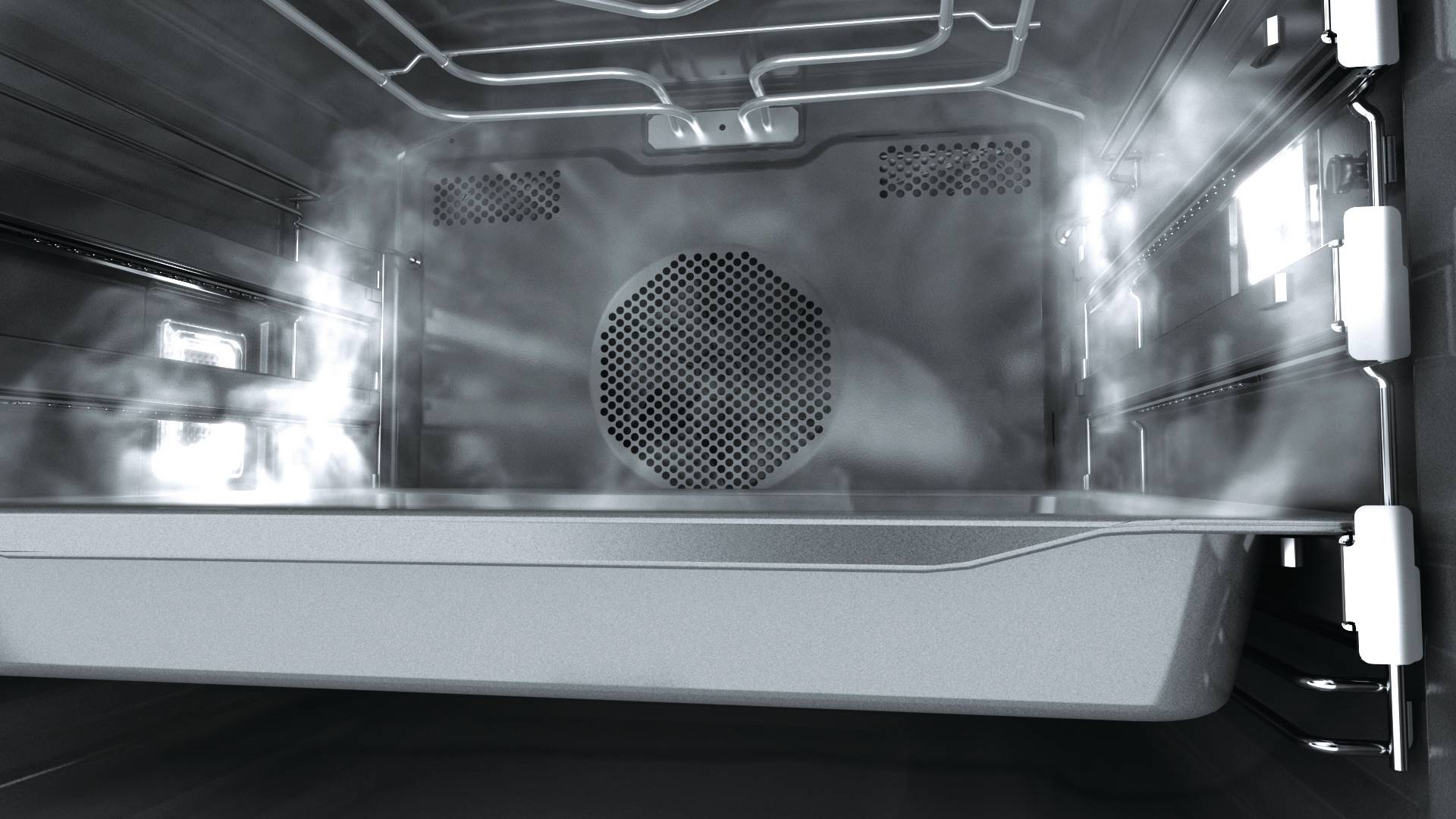

Hydrolysis cleaning

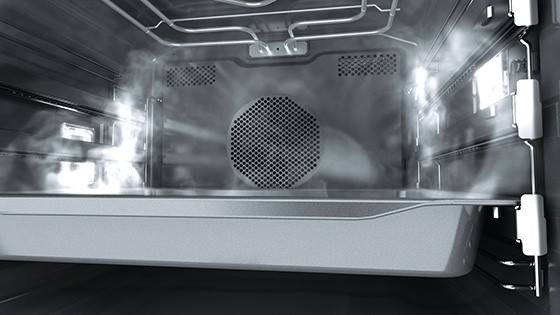

Literally, it is cleaning the oven with steam at elevated temperatures. The very principle of operation - water is poured into a baking sheet and installed in the oven at the very bottom.

The required program turns on for half an hour, the oven heats up to 90 degrees and the dissolved fat flows down the walls onto a baking sheet. Remains can be wiped off with a damp sponge.

Pros - the sufficient availability of the method, it can be applied without a special program. Minus - the method can only be used if the oven is used irregularly. Old fat cannot be removed in this way.

Do not use abrasive substances and agents for cleaning - this may render the oven surface unusable. Make it a rule to wipe the cooled oven with a sponge and detergent after every cooking. And then you don't need complicated cleaning methods.

Pros and cons of catalytic cleaning

- Having understood what catalytic cleaning is, we can highlight its main positive features:

- starts automatically during cooking;

- saves you time and energy;

- suitable for use in any ovens (both electric and gas);

- practically does not increase the cost of equipment;

- catalytic enamel has the same quality in models from different manufacturers;

- such ovens are produced by almost all manufacturers, so you can easily buy your favorite brand that has this function.

- Of course, this function has certain disadvantages:

- it is less effective than pyrolysis;

- involves manually cleaning the bottom of the oven, its door and baking sheets;

- requires careful attitude to removable plates, cannot stand the touch of rough rags or abrasive powders;

- when dairy or sweet products get on it, special enamel loses its properties;

- effectively breaks down fat only with regular use of the oven;

- requires periodic replacement of specially coated plates.

Taking into account all the details considered, we can conclude that such a technique is ideal for housewives who quite often use the oven and do not have the ability or desire to purchase expensive models of ovens with pyrolysis function.

Sometimes manufacturers do not install special panels on the walls before selling, and they simply lie inside the device along with grates and trays - this should also be noted.

Advantages and disadvantages

- Catalytic cleaning has the following strengths:

- all chemical processes take place automatically under the influence of high temperature and catalysts in the pores of the enamel;

- it is possible to reduce energy consumption, since cleaning takes place directly during cooking;

- for the human body, catalytic cleaning is absolutely harmless;

- slightly increases the cost of the oven.

As for the cons, they are as follows:

- it is necessary to manually wash baking sheets, grills, wire racks;

- the bottom and inner surface are not treated with an enamel coating, so they will also have to be cleaned manually;

- sweet and dairy products quickly destroy the protective coating on the side walls;

- effectively breaks down fat only with constant use;

- there is a need to replace the plates after 4-5 years of operation, since they lose their properties.

Recommendations for use

- So that over time, catalytic cleaning does not lose its speed and efficiency in splitting fats, it is worth observing the following recommendations:

- take good care of the catalytic surface, refusing to use hard sponges for cleaning fat after oxidation;

- if sugar accidentally gets on the catalytic surface during cooking, it should be cleaned in the classical way, that is, using a gentle detergent and a soft sponge;

- for manual cleaning, abrasive detergents should be completely abandoned, as they will destroy the enamel.

It should be noted that the abundant fat is completely burned after several cleaning cycles, therefore, after the first catalysis, you should not immediately grab onto the rag to manually remove the fat.

Oven cleaning systems

Pyrolytic

The essence of pyrolysis is the combustion of any organic pollution at high temperatures (up to 500 ℃). The pyrolytic system is considered the most reliable and effective, since all internal surfaces (including the door glass and the convection fan) are cleaned, and after a cycle of oven operation in self-cleaning mode, all that remains is to wipe off the settled soot.

Pyrolysis (from ancient Greek πῦρ - fire, heat and λύσις - decomposition, decay) - thermal decomposition of organic compounds without air access

Pyrolysis (from ancient Greek πῦρ - fire, heat and λύσις - decomposition, decay) - thermal decomposition of organic compounds without air access

According to user reviews, the disadvantages of pyrolytic ovens include:

- high cost (justified by the quality and durability of materials);

- the presence of an unpleasant odor during the combustion of organic deposits;

- high energy consumption (such ovens are only electric, and cleaning is carried out as a separate operation cycle and requires up to 7 kW).

Read more about pyrolytic oven cleaning in this article.

Catalytic

In catalytic ovens, the walls have a special coating (porous and rough to the touch) containing chemical oxidants: cerium dioxide, manganese, cobalt, copper oxide. These substances enter into an accelerated reaction with fats and decompose them into carbon (soot) and water.

In catalytic ovens, self-cleaning takes place during the cooking process. The chemical reaction of fat breakdown begins at 140 ℃, and reaches its maximum efficiency at 200 ℃

In catalytic ovens, self-cleaning takes place during the cooking process. The chemical reaction of fat breakdown begins at 140 ℃, and reaches its maximum efficiency at 200 ℃

Fat accumulating on the walls of the oven breaks down into carbon and water each time the oven is used for its intended purpose, that is, during cooking. Residual contaminants are absorbed by special sorbents with nano-particles. Catalytic ovens have obvious advantages of the cleaning system, but also some special features of use:

- the bottom and inner surface of the door must be cleaned manually, since they are not coated with catalytic compounds;

- panels with grease-absorbing enamel should be replaced (or turned over the other side, if they are double-sided) every 4-5 years - during this time, oxidizers gradually lose their properties;

- it is better to use the oven often, because a large amount of fat may not dissolve at a time;

- care must be taken that no sweet or dairy products get on the panel, because they lead to deterioration of the coating (therefore, the bottom is not covered with catalytic compounds).

Hydrolysis

Hydrolysis is the decomposition of fatty and other organic deposits under the influence of water, more precisely, water vapor.

During the hydrolysis cleaning of the oven, dissolution and softening of dirt occurs due to the creation of the effect of a steam bath inside the working chamber

During the hydrolysis cleaning of the oven, dissolution and softening of dirt occurs due to the creation of the effect of a steam bath inside the working chamber

The steam is gentle and does not damage the enamelled finish of the oven. The softened deposits are better removed from the inner surfaces, without requiring hard scrubbing and the application of great efforts. Many modern ovens have an automatic steam cleaning function, but even if it is not in your model, you can create the conditions necessary for steaming yourself.