How to make at home

If your yard is covered with snow, and you did not have time to buy a cleaning device in time, then you will have to make it yourself

It is important to initially decide what to make a shovel from. The simplest option to quickly arm yourself in bad weather is a plywood structure.

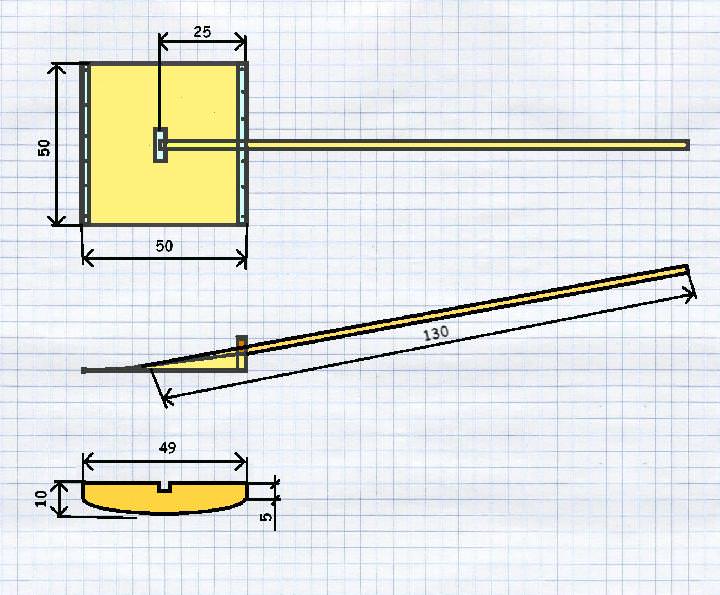

First, you need to build the back surface of the bucket from a piece of board. In advance, an arcuate mark is made on the workpiece with the following parameters:

- center height 100 mm;

- height at edge level 50 mm

A workpiece is cut along the contour with a planer and cuts are made for the handle in the central part with a hacksaw. Use a chisel to cut a rectangular hole in this place. The handle will be inserted into it.

A stalk made from a board is inserted into the hole. Moreover, its surface should go flush with the lid, go under the plywood and then adjoin it closely.

Then the plywood should be placed over the back cover and secured with nails. Prepared steel plates, corresponding to the parameters of the bucket, are folded over the edges of the bottom and fastened with screws to its surface. Using a small plate, they strengthen the attachment of the handle to the plywood.

A snow shovel is a useful tool on the farm. In snowy winters, you can clear the territory of the site, prepare access roads. To do this, you need to purchase any model made of plastic or metal, choose the desired design or make the simplest version of plywood inventory.

Photo of a snow shovel for home

We also recommend viewing:

- Correct repair of petrol cutters with your own hands

- Review of the best generators for home

- What hoses are better for giving

- How to choose a gasoline lawn mower

- How to choose a brush cutter for a summer residence

- DIY composter

- How to make a garden wheelbarrow with your own hands

- How to choose a garden pruner

- How to choose a garden sprayer

- How to choose a garden rake

- Choosing the best garden shredder

- How to choose a good ax

- How to find and tension a saw chain

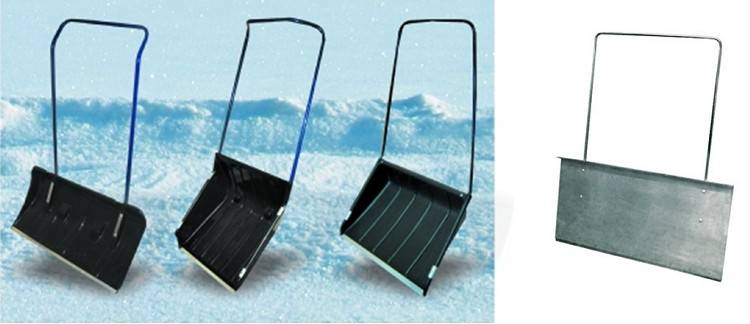

Types of cleaning tools

Snow shovels can be of various modifications. But all models can be divided into two large groups:

- Hand shovels with a handle;

- Mechanical tools.

The simplest solution for giving is hand tools with a bucket and a long handle. You can make it yourself from wood or plywood. In the store, you can buy plastic or metal counterparts. The strength and durability of the tool depends on the type of material. However, the shape of the bucket is even more important. You need to choose a shovel with a spacious working surface, which easily picks up and dumps the snow mass.

The option with an ergonomic working plane angle is also convenient. It is recommended to choose models with a rectangular or trapezoidal bucket shape. Moreover, the presence of the sides will increase the amount of snow taken.

Mechanical devices do not exceed 15 kg in weight, they are set in motion by a person, and the snow mass is collected using a special mechanism. They are used to clean the area near a country house, as well as in other areas with a small area.

No special knowledge and skills are required for work. There are two types of inventory for sale:

- hand auger tool;

- electric models.

2 What to look for when choosing a snow blower tool?

When choosing a snow shovel, you need to know a few points, because if you make the wrong choice, cleaning snow even on a small area will take a lot of time and effort.

2.1 Weight

One of the main criteria when choosing a tool is its weight.Working with a light snow shovel will be easy and enjoyable. The lightest scoops are made of plastic.

2.2 Shaft and bucket length

This criterion is important when choosing snow removal equipment, especially if it will be used by a teenager or a woman. After all, a long handle affects the fatigue of the muscles of the back and arms, and the large size of the bucket can rake in a lot of snow, and therefore it will be difficult to remove it.

The ideal bucket size is 360 x 40 mm. The handle should be attached to the scoop at a certain angle, acting as a lever. This simple solution allows you to reduce the strain on your back. A good item in your inventory will be rubber handles that prevent the scoop from slipping out of your hands.

Plastic shovels for snow

When you often have to drive a car in the winter snowy season, it is advisable to purchase a folding snow shovel. The car snow shovel is equipped with a removable or folding handle (telescopic shovel), which allows it to be stored compactly in the trunk of a car.

The most popular snow cleaners are:

- Snow shovel Bogatyr.

- Snow shovel Finland. Finland also produces scoops for cars.

- Snow shovel Knight.

- Snow shovel Berchouse.

- Snow shovel Shustrik.

2.3 When is a snow blower used instead of snow removal equipment?

A snow blower is needed when the snow plow is no longer able to cope with its function and the size of the cleared area exceeds the usual sidewalk paths or small garden areas. Do not forget that for such work, it is better to choose a self-propelled snowplow. Otherwise, it makes no sense to waste energy on such a cleaning of a snow-covered area.

Snow removal with a Stiga snow blower

Nowadays, the electric snow shovel is becoming popular. The electric shovel has a telescopic handle, with which you can adjust the length of the equipment to your height.

The lower electrical part is called the auger and has a rubberized appearance. The electric shovel is powered by an electric motor, which is connected to a 220 V network. Such a snow plow is suitable for those who want to be replaced by an electrician or, more simply, a snow shovel on wheels.

Also, when cleaning large areas, mechanical shovels are used. Such a mechanical shovel is called auger. There are several types of shovel with auger:

- Single stage. The screw mechanism of such models rotates at a certain frequency.

- Two-stage. Here, snow is thrown out by means of a rotor, and capture by means of an auger.

- Manual. It is used for cleaning a small area.

- Mechanical. Also, using this technique, you can remove the leaves in the fall.

- Self-propelled.

- Non-self-propelled.

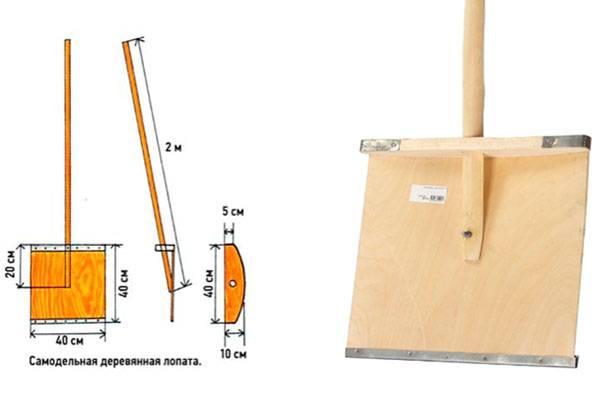

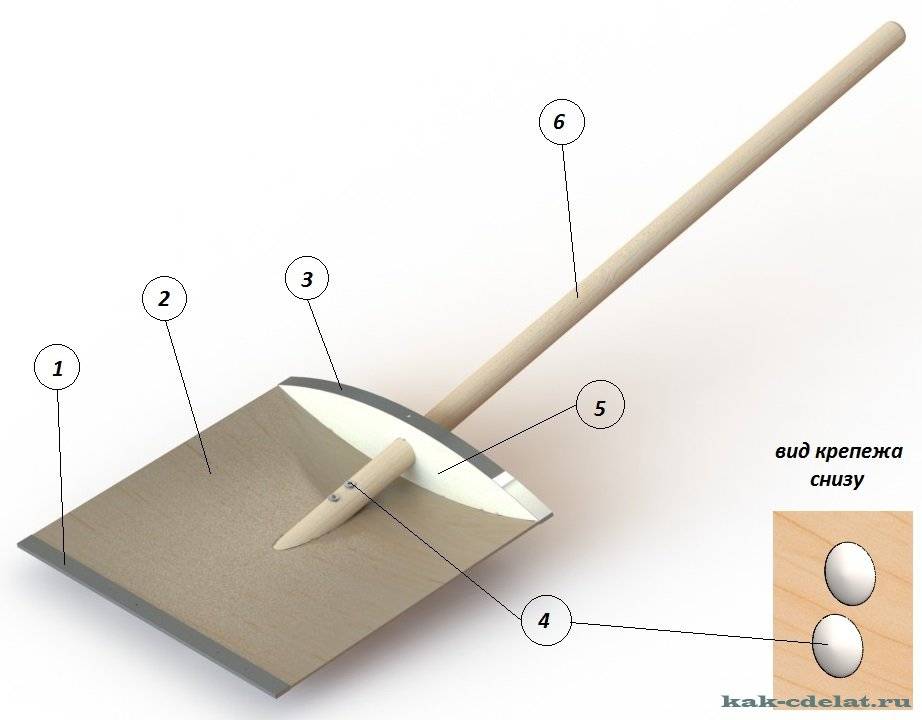

2.4 DIY snow shovel

It won't take long to make a snow shovel, but it will last 5-6 years. The cost of this inventory is low due to the fact that almost all the elements must be found on the farm.

Homemade snow shovel

In order to make a snow shovel with your own hands you will need:

- Plywood, 6 mm thick.

- A blank for a cutting 2 meters long.

- Board - 2.5 cm thick, 45 cm long.

- Tin strips

- Nails, screws.

A do-it-yourself snow shovel means that first you need to make a handle-holder 2.5 cm by 4.5 cm in size, 2.5 m long from the workpiece.The handle is sanded with sandpaper and cut to the desired length. The next step is shaping the end of the scoop. It is made from a board measuring 45 cm in length and 8 cm in width. It is necessary to cut out an arc with a height of 8 cm in the center and 5 cm on the sides in the workpiece.

A cut is cut in the center of the end, where the made handle will be attached. You need to fix it at an angle. The working part of the scoop is cut from an 8 mm plywood sheet measuring 45 cm by 45 cm. After all the preparations, the scoop can be assembled.The handle is installed at the end at an angle, the scoop is nailed to the end and screwed to the handle with self-tapping screws.

Homemade aluminum snow shovel

It is necessary to nail galvanized strips to the edge of the bucket with nails to protect the plywood from mechanical damage. Then you need to bite off the carnations and bend them. For the strength of the inventory, it can be reinforced with a galvanized strip of the scoop joint.

Done right and use durable materials, you get a super snow shovel that will last for years with careful use.

1 942

Auger construction

This is a more advanced modification of a conventional hand held device. Shovels with auger operate as follows. When a person moves the device over the section, the auger touches the ground with its edge and begins to rotate. Thanks to this rotation, the snow begins to be thrown away from the shovel.

The snow mass is thrown up to 300 mm to the side. This value depends on the speed at which you will move the tool.

This type of tool is preferable for picking up loose material. It is not suitable for clearing the area from compacted and packed snow. Among the well-known models are, for example, Forte QI-JY 50 or Patriot Arctic.

The main varieties and their features

There is a wide variety of snow shovels, from the simplest to the mechanical ones. Each type has its own advantages and disadvantages. Let's take a closer look at them. While everything is relatively simple with conventional hand shovels, there is no specific standard for separating mechanical shovels from snow blowers.

Auger

An auger shovel is a combination of a shovel with an auger - a special device shaped like a screw. Usually the auger in shovels has 2-3 turns. The principle of operation is quite simple - when the shovel is pushed forward, the edges of the auger, from contact with the surface, begin to rotate and push the snow to the right or left of the direction of travel.

Manual

If the setting in motion of the auger shovel or its direct work occurs only due to the muscular strength of a person, it is referred to as hand tools.

Mechanical tool

This category includes shovels, in which the mechanism is engaged in removing the snow, and the worker only pushes the shovel forward.

Mechanical non-self-propelled

If the auger shovel does not have a means of moving it during operation, it is called non-self-propelled. Usually, a similar mechanism is equipped with skis to reduce slip.

Self-propelled

If the auger shovel has wheels or tracks, it is considered self-propelled. It is much easier to push such a shovel.

Electropath

In fact, it is a kind of auger, more precisely, its mechanized version. The shovel is driven not by the muscular strength of the worker, but by an electric motor. Connecting the tool to electricity is traditionally carried out using an extension cord. There are also cordless shovels, in which the energy source is located on the shovel itself. Their power is slightly less than that of shovels powered from the mains using an extension cord.

Such devices are a wide scraper with a long handle. Their stalk consists of 3-4 rods, folding into each other. The length of such a handle in working condition can reach 9 m. In addition to removing snow from roofs, such devices are used to knock down icicles.

Device and characteristics

The snow shovel is designed to capture as much snow as possible.

The classic winter tool consists of two main parts:

- The bucket (scoop) is the actual working part with a wide and even raking surface. The presence of the sides allows you to capture the snow layers without the possibility of their sliding to the sides and, as a result, slipping. However, there are options without them.Many snow shovels are equipped with a special bucket bar - a steel plate mounted on the end of the bucket. It not only strengthens the structure, but also allows you to "bite" into frozen layers.

- The handle is actually a snow shovel holder, not much different from those that are installed on ordinary shovels, except perhaps in material. On the one hand, it attaches to the bucket, on the other, it often has a V-shaped handle for easy handling. Some units are equipped with two handles, which is very convenient in some cases.

Fastening the bucket to the handle in most cases is carried out with several self-tapping screws, like ordinary shovels, by means of a tulle.

Sometimes the so-called combisystems are used, in other words, standardized mounts that allow you to quickly change the handle to another, or simply remove it while storing the snow shovel.

The combisystem is a pin located on the bucket with a groove cut in a circle.

The handle, in turn, has a reciprocal longitudinal hole, through which the two elements of the shovel are connected.

Fixation takes place by screwing in a transverse screw through the handle body so that the first goes into the groove until it stops.

Of no small importance for a snow shovel is the slope angle, that is, the angle of inclination of the handle relative to the raking flat part of the bucket.

The raking shovels (engines) have a greater inclination, while the models intended for carrying and throwing snow are less.

In general, this angle is different for each model, selected optimally for the convenience of work.

As a rule, it is 20 - 25 degrees.

In addition, some manufacturers equip their products with a tilt adjustment function.

Bucket and shank material

For the manufacture of the cutting, wood of different species is used, from expensive to the simplest.

In addition, shovels with aluminum and plastic handles in the form of a tube are popular, since they have sufficient strength and low weight, which plays an important role during work.

To make a bucket, use:

- Wood, or rather plywood. It is often used to make a shovel bucket. The peculiarity of this tool is that the bucket has a width of 1 - 1.5 m. In addition, a wooden snow shovel is capable of performing the functions of a kind of wheelbarrow, which is very convenient when cleaning large areas. Low cost is characteristic of wooden models due to the cheapness of the material itself and the ease of manufacture. At the same time, wood does not have such an important quality as moisture resistance, and therefore degrades naturally over time.

- Plastic - is in great demand due to its extremely low weight, a huge range of colors and relative cheapness. Plastic snow shovels are reinforced with fiberglass. It is quite resistant to frost, partially retains its elasticity, however, when working with compressed snow, it is possible to break off the raking edge. Models with a galvanized strip are devoid of this drawback.

- Metal. Aluminum is often used in production, again because of its strength and low weight. Stiffening ribs prevent bending of the bucket leaf under load, and the sharp edge easily cuts into the frozen mass. In case of deformation, it can be easily straightened with an ordinary hammer. Models made of galvanized sheet steel are no less popular.

The combination of plastic-wood such specimens have a plastic bucket and a wooden handle, they are simpler and cheaper. At the same time, they perform their functions quite well and are popular with consumers.

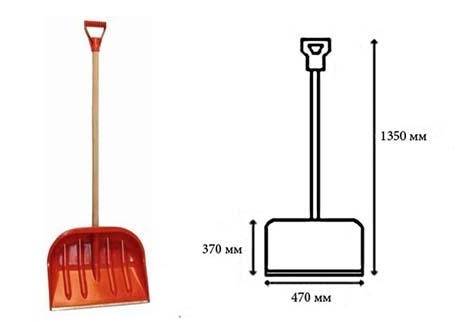

Dimensions and weight of snow shovels

A classic snow shovel is equipped with a square bucket with sides of about 400-500 mm, or a rectangular working part, where the wide side is 450 mm and the narrow side is about 370 mm.

The weight is usually 1 - 2 kg, depending on the materials and the length of the cutting.

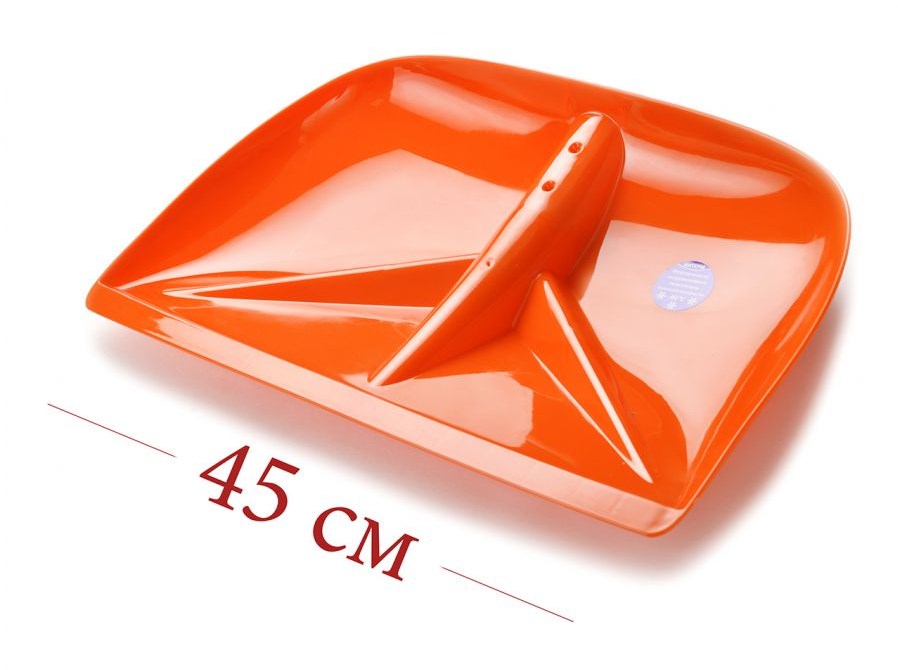

Plastic shovel

It is a more comfortable and lightweight model with a comfortable handle. Among the main advantages are:

- equipping with comfortable bumpers that trap snow on the working surface;

- the presence of wide ribs gives better gliding;

- frost-resistant flat bucket surface, especially if composite plastic is used that is resistant to mechanical damage;

- gentle effect on the coating of paths and lawns.

Of course, the standard plastic is not very strong, the scoop area of the structure wears out quickly enough. However, high-quality specimens may well last up to 4-5 seasons. Moreover, such a shovel will not get wet and rust. Many models are salt-resistant, equipped with additional attachments and convenient attachments.

Popular manufacturers of plastic shovels include GARDENA, Fiskars, etc. On sale you can find models with a telescopic handle, compact car designs. Special plastic scrapers with arched handles are popular. The latter option is used mainly for wet and loose snow.

Criterias of choice

The criteria for choosing a device for snow removal depend on the type of snow (fresh or packed), the area of the surface to be removed, and the material of execution. Let's consider them in more detail.

Snow type

The main parameter by which the selection is made. Mechanical shovels should be used to remove fresh or packed snow with a height of 15 cm. Some types of snow blowers can be used for fresh snow cover up to 25 cm high.

Cleaning area

The use of different types of shovels is recommended depending on the area of the surface to be cleaned. This is due to the fact that the width of the tool, and, consequently, the number of passes, will be different. A wide shovel will cover a larger area at a time, and, as a result, the work will be completed faster.

In addition, when using mechanical cleaning equipment, they may have different throwing distances of the removed snow. Therefore, manual and mechanical tools are recommended to be used on areas of no more than 50 square meters. m.

Storage space

The storage space for the device does not have any special requirements. It can be stored in any room. The best option is a garage or a barn.

Possibility to connect to electricity

If a mains powered electrical device is used, a method of connection must be provided. For this purpose, an extension cord with a length of at least 30 m is required, as well as an external socket on the wall of the room.

Employee skills

You do not need any skills to work with a snow blower tool. It is quite easy to learn and does not require qualified personnel.

Execution material

Depending on the material from which the device is made, it is able to withstand different amounts of loads, and, accordingly, work with different types of snow. A conventional plastic shovel can be used to remove fresh snow, since there will be no additional force when separating the layer of snow from the ground. Frozen and packed snow will require the use of aluminum or metal shovels.

Polycarbonate tools have intermediate characteristics between plastic and metal. Often in its manufacture, polycarbonate is used in the construction of the case, and reinforced metal inserts are used in the manufacture of the working edge (knife).

Is it possible to do it yourself

You can make a mechanical auger shovel yourself, but this will require basic skills in working with metal and plastic. If the goal is to make not just a tool, but a full-fledged mechanized assistant, then you will have to use some kind of engine (internal combustion or electric).

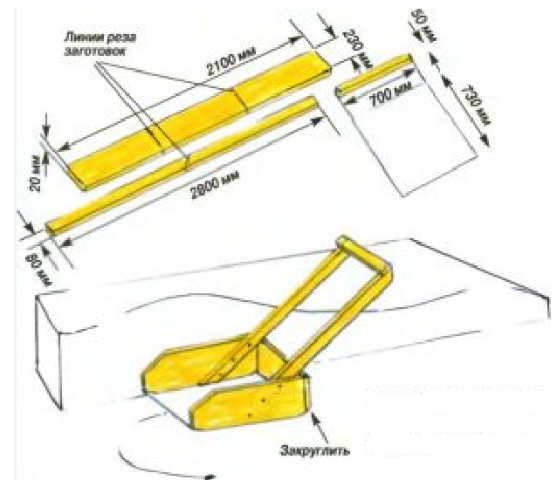

Naturally, in the second case, the device must have a solid metal structure, therefore, it is recommended to use welding for its manufacture. Consider how to make a mechanical auger snow blower without an engine with your own hands:

- A camera is made for receiving snow. It has a semicircular shape and is made of galvanized steel. A hole is made in the upper part for the outlet pipe. Its sides must be made of durable material (thick plywood, plastic, acrylic) so that they can hold the shaft. A tube with a diameter of 20 mm is used as a shaft.

- Slats are attached to the shaft. Blades made of dense rubber or thin steel are attached to them.

- To ensure the rotation of the shaft on the sidewalls, it is necessary to fix the hub mechanisms.

- In the hubs, the shaft is mounted on bearings.

- Install the outlet pipe.

- Attach a handle.

This completes the process of creating a snow blower.

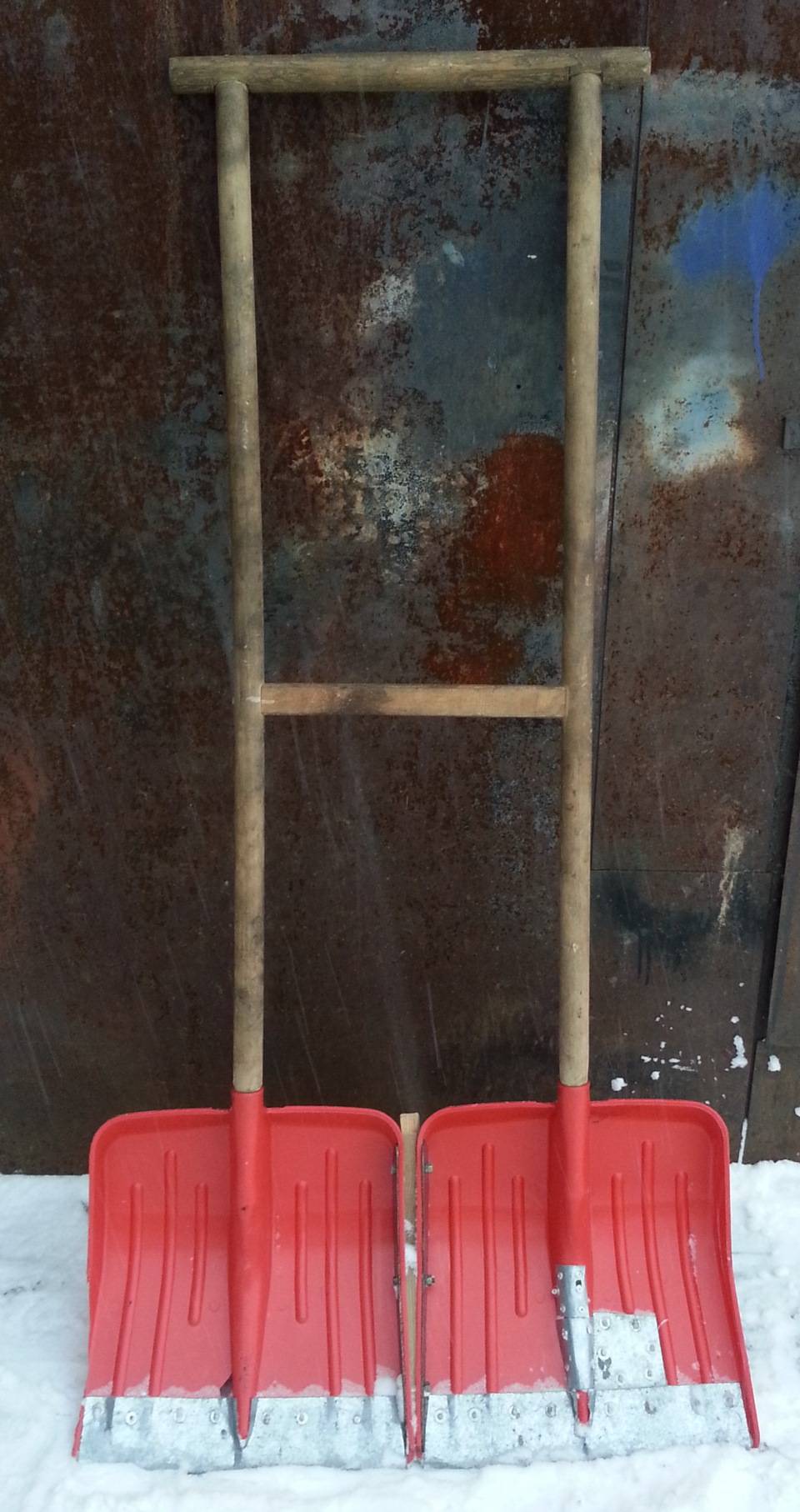

The simplest do-it-yourself snow blower

To create such a snow blower, you need handles, 2 small wheels and a bucket blade. You can use handles from an old baby carriage or, for example, a utility carriage, popularly known as "kravchuchka". If there are no such devices on the farm, you will have to bend a metal pipe or, for example, assemble a handle from thin plastic pipes using fittings. The latter is easy to implement and cheap.

Wheels can be taken from an old children's bike, scooter, stroller, etc.

It is better to make the working blade of the snow blower wide. A piece of thick plywood, plastic, or metal is suitable for this. Fastening of parts by bolts or by welding. A plywood or plastic blade is installed obliquely - this is more convenient for cleaning snow, the metal blade is usually bent.

If you need to clear snow from winding garden paths, it is better to mount the shovel not on two small ones, but on one large wheel (for example, a bicycle). It is better that the mechanism be movable, that is, the shovel can be lowered-raised, and also turned on its side to throw snow onto the side of the track.

You can install the scraper shovel not on the wheels, but on the runners. For example, attach a handle to a children's sled on the one hand, and a shovel blade on the other. It is also quite possible to make an easy-to-move snow blower from two old skis fastened in parallel.

However, the snow blower will slide in the snow not only on sled runners or skis, but also simply on a metal frame. A scraper bucket on skids is very convenient - we use it to collect snow. Although you can install such a bucket on wheels.

Another option for creating a homemade, powerful enough and comfortable snow blower is to attach a sturdy metal sheet to the front of your garden wheelbarrow. The attachment will help to shovel the snow, which can be immediately thrown into the wheelbarrow and taken out. With the onset of heat, we unfasten the canvas, and continue to use the wheelbarrow for its intended purpose.

Additional selection criteria

In order to remain completely satisfied with the tool for cleaning snow, there are a number of other criteria must be taken into account when choosing it. Special attention should be paid to such characteristics as the presence of sides, the length and weight of the handle, the angle of roll, the size of the working blade. But the most important thing is that the purchased product is as convenient as possible.

Composition and application of the drug Fitosporin for plants

Tray dimensions

When determining this parameter, you must proceed from your physical capabilities.

Be sure to take into account the shape of the scoop. Traditionally, shovels are made in a square shape with a side of about 40 cm.

But sometimes you can find improved models in the form of a rectangle, in which the largest side has a size of 40 cm. It will be much more convenient to remove snow with such a tool.

For cleaning large and flat areas from sediments, it is best to purchase a wide model.Due to the presence of a wide working surface, such a model will be able to capture the maximum amount of snow at a time. But this can also be called a disadvantage: the more snow fits on the scoop, the greater will be the load on the back and arms.

Slope angle

A model that has an optimal slope angle may be more comfortable to work with. The tilt of the working base can be used as a lever. This will significantly speed up and facilitate snow clearing. It is best to choose models with an inclination angle of 20-25 degrees.

Shaft length and weight

When choosing a tool for cleaning snow, you need to pay attention to the length and weight of the handle. To less often get tired during work, it is necessary to throw snow from the cleared area while standing, without bending

Such an opportunity can be provided by a model with a long and light handle. When choosing a suitable product, it is recommended to do it a few strokes while still in the store so that you can choose the optimal length and weight of the handle. Shovel shanks can be made of various wood species. To make them suffer less from moisture, manufacturers treat them with moisture-proof varnish.

The presence of sides

Since during cleaning it is important that as little snow as possible falls from the surface of the shovel, when choosing the most tool, you should pay attention to the presence of special bumpers. Thanks to them, the snow will crumble less from the working surface. Also, the bumpers will allow you to transfer much more snow at a time than in the absence of them.

Also, the bumpers will allow you to transfer much more snow at a time than in the absence of them.

Depending on the location of the sides, shovels can be single-breasted or double-breasted. In order for the snow clearing work to be most effective, it is best to purchase a wide shovel with deep sides. Thanks to the increased volume of the scoop, it will be possible to transfer a large amount of snow in it at one time.

Growing and caring for balsamic fir nana

How to choose a snow shovel: which material is better

A snow shovel, first of all, should be light and comfortable. The most convenient tool is a small shovel made of plastic. However, each type of shovel is designed for different situations. A plastic shovel is suitable for light, freshly fallen snow. A strong metal shovel is needed to remove a dense layer of snow. For regular home use, a wooden or plastic plow is best. The metal shovel may be too heavy.

Important! No matter how ideal the surface of the shovel handle is, it is necessary to clean the snow with gloves. This will protect your hands from frost and blisters.

Plastic snow shovel and how to make it yourself

The easiest option is to take a plastic bucket from the store and attach a homemade shank to it yourself. The cost of such a hand-made will be about 300 rubles, but it will have much more advantages than a wooden stump. Let's consider them.

- The weight is much less than OSB and fiberboard (about 150-250 g instead of 450-650). A plastic snow shovel is much more convenient, due to which the employee does not get tired and can perform much longer work. It is easy to transport.

- Not corrosive. Plastic serves for decades, unlike wood, metal, and other materials. It can be left in the sun, rain or any other aggressive environment. It is not necessary to store the shovel indoors.

- Relatively low cost. Compared to aluminum or steel, plastic is much cheaper. Thus, you get a tool with good characteristics inexpensively.

- Availability. You can find a plastic shovel bucket in almost every hardware store, and there are a variety of shapes and sizes!

If you want to make a plastic shovel with your own hands for throwing snow, then you need to get creative. The cost of such a product will depend on how correctly you select the materials and how well you know how to dig in the summer cottage garbage. All items can be found at home or from neighbors, at least. Let's take a closer look at the process.

Step 1We are looking for materials.

First you need to find a plastic bowl made of hard but flexible plastic. You can not use brittle material - it will quickly deteriorate even with little effort. You can check the "professional suitability" of the material in one simple way - try to break it. If you put in a lot of effort and the plastic bent during the process, this is ideal.

Step 2Making a bucket.

Cut out the correct shape. The ideal size is 45x45 centimeters. You can cut it with an ordinary jigsaw with a fine nail file or just a hacksaw for metal. An even seam is not required, you can do it as it happens, because the edge will sharpen on the snow in literally 1-2 days.

Step 3We attach the holder.

The simplest way is with wire. We heat the nail over a fire and make 4 holes with it, into which we push the wire. 2 holes at the point where the handle touches and 2 at the point where it comes to the end of the plastic plate. A slightly more complicated way is the aluminum mount. If the plastic is thick enough, you can drive a self-tapping screw into it. Take the cordless screwdriver and screw on the aluminum plate that will hold the handle. We attach a similar plate at the point of contact of the end of the handle with the plastic plate.

Our shovel for the snow war is now ready. It remains to wait for the beginning of snowfalls and test it in practice, perhaps make some adjustments regarding the strength and ease of use.

How to choose a snow shovel?

The winter tool is selected based on individual preferences, however, there are prerequisites that it must meet:

Strength. The snow shovel should not break on the first day of operation. This is especially true of plastic products, which, despite all their positive aspects, are fragile. It is necessary to check the elasticity of the bucket by placing it on the floor and leaning slightly on the handle. Too soft material will not cope with compressed snowdrifts, and too hard plastic will simply break under pushing load or burst from frost. Therefore, the plastic must be frost-resistant. The presence of a galvanized edging along the end and stiffening ribs is mandatory. Perhaps moisture resistance can also be included here. Wooden versions do not have it. The plywood surface will last long enough only if all adhered snow is removed from it with a broom or a brush after work.

- Lightness is perhaps the most important criterion. A good snow shovel weighs no more than 2 kg. Otherwise, it will be extremely difficult to unleash the potential of a large scoop, due to the rapid fatigue when working with a heavy tool.

- Convenience of work. The decisive factor here is the length of the cutting, which is selected individually. A holder that is too short when working will put a serious strain on the back, which will be constantly bent. Too long will create inconvenience. The comfort of using a winter tool is increased by a plastic handle at the end of the handle, made in the shape of a T or V.

You should also focus on the expected range of tasks.

For example, cleaning a roof made of metal tiles should be done with a plastic tool without metal edging, while breaking up frozen snowdrifts - preferably with a steel shovel.