Trash can requirements

To collect waste, containers with certain characteristics are used:

- Resistance to repeated mechanical loads during waste disposal. For this, the design provides for the required wall thickness and upper edge. Metal products should have stiffening ribs at the corners to avoid deformation and loss of tightness.

- Anti-corrosion properties.

- Tight fit to the upper edge, without distortions and gaps, if equipped with a cover.

- Wheels must be able to withstand the declared weight of the waste during the pre-service life.

Containers should be equipped with areas for unimpeded loading and disposal of garbage.

Classification

As mentioned earlier, there are a large number of specialized furnaces that are created to operate and incinerate a certain type of waste. They use some engineering features and technological solutions that not only simplify the process of burning materials, but also significantly reduce the cost of maintenance!

- Recycling and incineration of hazardous waste. A medical waste incinerator is a fairly vivid example of a type of device that works with hazardous materials. Medical waste is a biological and chemical hazard, so all items must be properly disposed of. In the working chamber, the temperature reaches 1200 degrees Celsius, which is quite enough to reduce the mass and volume of waste, destroy microbiological residues, as well as residues of pharmacological agents.

- Utilization and incineration of mixed waste and garbage. This type of device works with a wide range of materials, which explains its popularity. The average temperature in the chamber is about 1000 degrees. Thanks to the availability of modern engineering solutions, it is possible to achieve high energy efficiency.

- Disposal and incineration of animal corpses. The system is actively used on farms and other livestock farms. The average efficiency is about two tons of waste per hour. The stove has a rotary mechanism that ensures uniform combustion of objects, as well as a large number of air filters to clean the outgoing air from any impurities and sediments.

- Recycling and incineration of mixed waste (and garbage) with increased productivity. The model of this type has the following technical characteristics: Volume of waste incinerated: about 350 kg per hour; The amount of energy released from combustion: not less than 6250 kcal / kg; Ash content: 9.5%; Humidity: no more than 50%.

- Furnaces for the combustion of phenol and formaldehyde formed during the production of plywood, chipboard. A fairly simple device that maintains an elevated temperature regime for the elimination of phenolic and formaldehyde compounds from materials. The furnace is a double-circuit device, and elevated temperatures are achieved due to the active combustion of diesel fuel and natural gas.

- Furnace for thermal neutralization of liquid waste from polypropylene production (mineral oil containing TEAL and ATMER). Devices of this type are installed in refineries to neutralize oils and other substances that contain polypropylene. Despite the modern structure, the unit must be installed outside the working areas where the company personnel are located.

Varieties and purpose

An auxiliary household tool resembles a shovel in appearance.Over time, its shape and size changed, the modern industry promotes the manufacture of practical, lightweight products.

> Models differ:

- handle length;

- container capacity;

- color;

- material;

- design.

Long handle reduces stress on the back. With scoops with a short handle, it is convenient to collect garbage from the kitchen, hallway, room. For industrial premises, it is more expedient to use metal tools with a long handle. The material of the handle is metal, wood, plastic. On some models, a rubberized insert is installed for convenience so that your hands do not slip during cleaning.

A specially designed model - a scoop-trap reduces the load on the hands. It is equipped with a capacious container for collecting waste, a comfortable handle, which reduces the burden on the hands. A household tool allows you to use it without bending over while working.

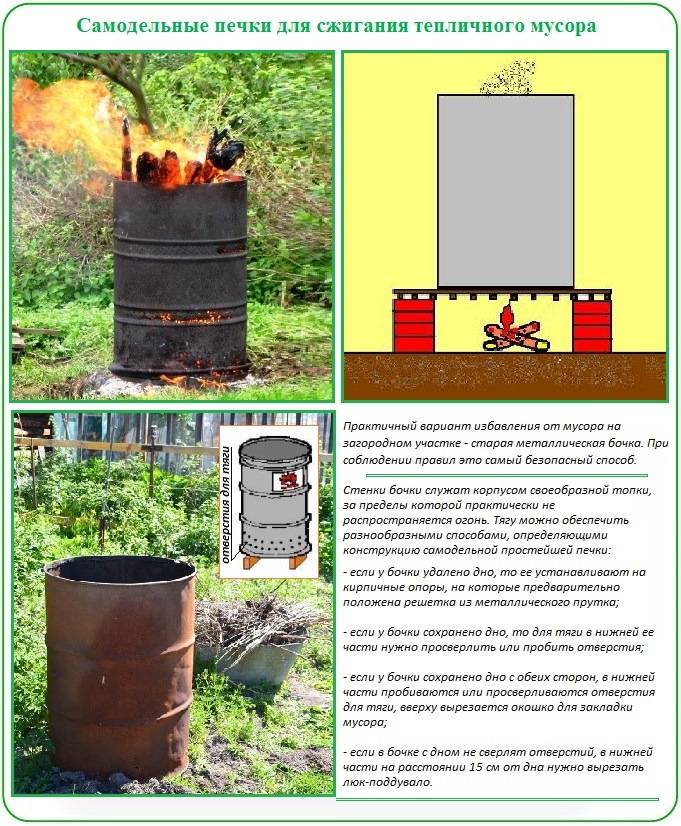

Features of a homemade recyclers

Homemade designs attract attention with simple maintenance and low cost. With a metal barrel, manufacturing costs can be minimal.

For the construction of such a stove, you can literally do with a grinder, drill and hammer. However, at home, it will not be possible to assemble a functional device.

Factory heat exchangers allow you to use the generated heat for cooking or heating your home. Such products have good build quality, attractive appearance. Some variants are equipped with filtration systems, which reduce the level of harmful emissions into the atmosphere. The devices are more durable than the barrel, but their cost is also quite high. Therefore, such a purchase for use in the country is not always justified.

How to burn garbage in a barrel

The design of the stove must be made in accordance with safety regulations. Before you start burning waste, you need to prepare fire extinguishing agents (water and sand).

For disposal, you should use organic waste, which, after burning, turns into ash and can be scattered in the garden as fertilizer.

Despite the fact that anyone can build such a stove, you need to be aware of the advantages and disadvantages of such a device.

The pluses include:

- the ability to move to any place on the site;

- compactness;

- lack of scorched soil.

Disadvantages:

- improper location and lack of control can lead to fire;

- frequent use contributes to metal burnout and failure of the container.

What can't be burned

Waste of inorganic origin must not be disposed of by incineration. Such waste includes: plastic, glass, metal, electronic boards, synthetics. It is strictly forbidden to burn aerosol cans from paints and other substances. Also, do not burn chipboard, various posters, painted boards, since they emit toxic substances during the combustion process. An exception is a tree covered with water-based emulsion.

Safety engineering

Before embarking on the disposal of street waste, you should consider the following points:

1. The barrel must be located at a distance of 25 m from buildings, trees and bushes and 50 m from the forest.

2. There should be no dry grass, branches and other easily flammable materials nearby.

3. In strong winds, waste incineration is not worth it.

4. Be sure to control the combustion process.

5. It is necessary to prepare a sheet of metal to cover the tank.

Pros and cons of waste incineration

The problem of recycling affects all states. In some, up to 70 percent of the waste is incinerated; in our country, the average rates vary within 3 percent. In the capital alone, an increase of up to 10 percent is planned. The benefits of burning include:

- liberation of a large space from accumulated waste;

- residual weight in the range of 5 to 10 percent;

- minimal harm to the environment;

- the ability to generate heat and energy at a minimum cost;

- saving time for transportation, taking into account the construction of incinerators near the city;

- reduction of waste intended for storage in landfills and burial.

The advantage will be the complete absence of unpleasant odors. Air pollution from the emitted methane during the decomposition of garbage does not occur. Among the disadvantages are:

- inevitable emission of carbon dioxide, affecting the development of the greenhouse effect;

- the release of toxic elements into the environment (sulfur, nitrogen, dioxins, furans);

- problems with the disposal of waste after incineration containing harmful impurities.

There is no need to use ash and ash as fertilizer. Disposal in a regular landfill is prohibited, and the waste should be taken to a special landfill.

How to make a do-it-yourself incinerator

To make a garbage shredder with your own hands, you do not need to be a furnace master - any man can build this simple device.

Country stove from a metal barrel

A waste metal drum is an ideal material for a recycling oven. With the help of simple actions, it is easy to turn it into a container for the safe burning of garden waste and household waste. There are many options for transforming a barrel into a furnace, invented by folk craftsmen, below are the simplest and most effective ones.

The second life of an old barrel

The second life of an old barrel

Option one: a barrel without a bottom

- Remove the bottom of an old metal barrel with a grinder or chisel.

- Drill several holes in the lower part - they will provide traction during combustion.

- Dig a shallow oblong hole about a meter long, about 20 cm wide and one shovel bayonet deep.

- Before disposal, a fire is kindled in the groove from dry twigs or paper, then a barrel without a bottom is installed on top so that air from the ditch can freely enter the lower hole.

- Debris should be stacked gradually, long branches do not need to be sawed - thanks to good traction, they will quickly turn to ash.

Option two: installation on bricks

- Drill or punch many holes in the bottom of the thick-walled barrel. Make similar holes in the lower part of the vessel, approximately to the middle of its height.

- Prepare the base of bricks, providing gaps for air intake.

- Place the barrel on a brick pedestal, put the trash in it and light the fire.

You can extend the life of a home-made stove from a barrel by strengthening the walls with steel sheets or placing a smaller container in it. After the internal parts have burned out, they can be replaced with new ones.

Barrel on a brick pedestal

Barrel on a brick pedestal

Waste incinerator made from an old stove

An old sauna stove should not be scrapped, even if it is burnt out and rusted. A broken stove can be turned into a good waste disposal unit in the garden. To begin with, with the help of improvised tools, you need to get rid of the internal parts, leaving only the body and the grate. Inside, the structure is reinforced with sheet metal, welding it to the base.

Waste can be loaded directly from the top, but it is recommended to light the flame using paper or dry twigs before loading large parts. When burning garbage, it is advisable to cover the stove with a metal sheet, placing a stone to ensure the escape of smoke.

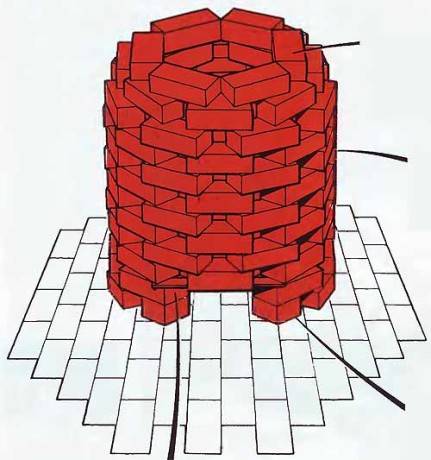

Brick Waste Incinerator

A capital brick oven will last longer than a metal barrel, and its appearance will not spoil the design of the garden plot. For a small recycler, 115 bricks will be required, if necessary, the size of the structure can be easily increased.

First of all, they prepare the base for the furnace - they clear a section of 70 * 100 cm and cover it with a layer of sand at least 5 cm thick.The first row is laid around the perimeter without mortar, leaving gaps of about 15 mm between the bricks - they are important to ensure traction. In total, there are 8 bricks in the first row: three at the bottom and at the top, and one at the sides.

For the construction of the furnace, refractory bricks are taken

For the construction of the furnace, refractory bricks are taken

Next, they put a lattice or strong rods, previously welded to each other or connected with a wire. For the construction of the proposed size, 14 lobes and three transverse rods are sufficient. The ash pan can be made of bricks, made of steel sheet or poured from a cement-sand mortar.

The second row also consists of 8 bricks, but two bricks are laid on each side, observing the dressing. All subsequent rows are laid without mortar with small gaps. The last 12th row is made continuous. A metal cover is installed on top.

Instead of a square stove, you can lay out a structure in the form of a cylinder. In this case, air gaps for traction are also provided and a grate is laid, which can be taken as steel reinforcement or a strong metal mesh.

Round Brick Waste Incinerator

Round Brick Waste Incinerator

Safety regulations

Burning waste is hardly a safe pastime, as there may be trees, bushes or wooden buildings on the site. If there is a strong wind, sparks can fly apart and cause a fire. In a word, when burning garbage, it is imperative to adhere to safety requirements.

Regardless of how high-quality your oven is, always be there when it is working. Do not burn garbage if it is hot or windy outside. Place a container filled with sand or water next to the stove.

Note! Puffs of smoke that rise when burning garbage not only harm the atmosphere, but are also dangerous to the human body. Therefore, be prepared for the fact that you may be issued a fine.

For the same reason, it is unacceptable for children to be near the structure.

If you follow all these requirements, you can get rid of the accumulated garbage as safely as possible for yourself and those around you.

As a conclusion. Factory stoves

If you do not want to make a garbage oven for your summer cottage with your own hands, then you can purchase a ready-made version. Such structures will differ in that, in addition to the elements known to us, they are also equipped with a box for collecting ash.

They can be rectangular and round in shape. For the manufacture of the case, durable steel is used, it is also covered with refractory enamel. But we are talking about simple containers, and there are also more complex designs on sale. So, for example, you can buy one of the multifunctional models with which you can also heat water.

Note! When buying, be sure to pay attention to the volume of the combustion chamber, compare it with the volume of waste. Finally, install and use such equipment only in accordance with safety regulations!

Finally, install and use such equipment only in accordance with safety regulations!

Barrel for incineration of garbage in the country

In practice, three variants of such oven devices made from barrels that do not have a bottom have found application.

- In the first version, first a small fire is made from some dry waste (birch bark, wood chips, etc.) on a metal pallet. After our fire is kindled, bricks or stones are placed next to it, on which our barrel-pipe without a bottom is installed on top. From below, air enters the formed holes, which helps combustion. The combustion of waste is intense and it is necessary to constantly monitor that our flame does not rise too high and does not throw sparks on the site. But there is also a drawback in this option, with each use it is necessary to put and remove the barrel.

- The second option, based on the same barrel, is simpler, it has no shortcomings of the first option. For its device, you first need to prepare the site.Pour a layer of sand 10-15 centimeters thick on the selected place, lay a metal sheet on it, on which a fence-support is made of bricks in the shape of the letter P. We put a metal grate-grate on top, and at the end we install our barrel (of course, also without a bottom) ... So we fill our stove from above with waste, and we arrange a fire from below, between the bricks. The resulting ash, after burning out the waste, we calmly rake out from below. During rains, so that the ash does not get wet, the barrel must be closed with a lid on top.

- The third version of our device is a little close to the second, only it is necessary to cut out a window with a size of about 450x200mm at the bottom of the barrel, and also additionally punch several side holes for blowing air. The bottom of the barrel also rests on bricks with a grate, which can be made from a metal perforated sheet. Unlike the second option, here 40x60mm holes are cut on top of the barrel and a metal lid is installed, where you can pre-dry the garden waste. All of these minor additions provide more favorable conditions for burning waste than the first or second option. And here the combustion is more uniform and intense. At the same time, the time required for waste incineration is significantly reduced.

Anyone who wants to tinker can make it more functional and more beautiful. If you do it well and for a long time, you can use a piece of used water pipes of large diameter and weld a reliable stove that will serve you for many years. One but - it turns out a little expensive!

Garden fireplaces and waste incinerators (garden waste)

I would especially like to note that these are garden fireplaces, which can be found more and more often on our garden plots. Such fireplaces perform not only a utilitarian function, but also a decorative one, thereby decorating the recreation area. The designs of such fireplaces are very diverse, but, as a rule, each of them has three nodes that ensure safety in operation. It is a site for waste burning, well protected from different winds, an arched roof and a high chimney that reliably extinguishes sparks.

In conclusion about incineration of garbage in the country

By the way, in many regions the employees of the Ministry of Emergency Situations often began to carry out raids and fine for the burning of household waste in the garden emitting TOXIC substances! Remember this and be careful!

However, it is better to dispose of garden waste in other ways, for example:

- branches, foliage and other organics are perfect for warm beds;

- diseased plants or with signs of damage can be buried in a separate hole, if possible, then outside the site;

- cardboard, paper - can be used for mulching the beds;

- well, and polyethylene, plastic, cans and other trifles can be taken to the city, in a bag and disposed of in a garbage container.

These garden tricks are used by our gardeners to get rid of garden waste.

And remember, NEVER BURN PLASTIC PRODUCTS, as they emit toxic substances that are very harmful to the environment, and your body too!

How do you get rid of all the garbage in your plots?

Calculation of sizes and quantities

For residential areas, the number of containers is calculated by the waste disposal companies.

The main indicators are:

- the average annual volume of waste accumulation (in cubic meters) for an apartment building;

- dimensions of the waste bin;

- the frequency of waste removal during the day.

To calculate, use the algorithm:

- The volume of 1 container is multiplied by the frequency of waste disposal during the day.

- The average annual volume is divided by the resulting product.

- The result is corrected (multiplied) by the coefficient of uneven filling with garbage and the coefficient of validity.

The coefficients are const .: Knzm = 1.25; Kg = 1.05.(The expiration factor takes into account the breakdown of containers and the need for replacement).

Selection Tips

Inconsistency of household equipment makes cleaning difficult, leads to a decrease in efficiency in work

Therefore, it is important to choose the right scoop for removing litter indoors or outdoors.

When choosing a reliable assistant, they pay attention to the material of manufacture. Products made of thin plastic or metal will not last long, they are easily deformed during operation

When choosing metal scoops, the presence of a protective layer is taken into account. To prevent the negative effects of moisture and other factors, the scoops are covered with a layer of paint or galvanized. Such products are not afraid of exposure to water, corrosive environments, easily tolerate temperature extremes.

Products with a short handle are compact, easy to use, do not take up much space during storage. Such equipment is not picky about care. It is optimal to choose a scoop with a container where the edge rim is slightly raised. This feature of the structure will allow you to keep garbage in the container. Often these scoops are sold with a stiff brush for easy cleaning.

The size of the container is selected depending on the purpose of the inventory. For use in an apartment, house, a small container is enough. For cleaning garden, sidewalk paths, on construction sites, it is better to choose a model with a wide and voluminous capacity.

Choosing a dustbin is easy if you rely on the tips and tricks above. A correctly selected product will facilitate labor, and will allow you to quickly cope with the cleaning task.

p> Share link:

Method three. We use an old heater for waste disposal

If you have an old sauna stove lying around, then do not rush to send it to the landfill. Even if it is badly rotten or rusted. A stove, which has long become unusable, we can turn into a fairly good waste disposal unit by installing it in our summer cottage. We do it as follows. First, using the tools at hand, we remove all internal elements from the heater - we only leave the grate and, of course, the body itself.

After that, we take sheet steel and weld it to the base from the inside, thus strengthening the entire structure.

In this case, we will be able to load garbage directly from above, although before loading large elements, it is recommended to ignite the flame in advance with the help of dry branches and paper. Directly during the combustion process, it is advisable to cover the furnace with an iron sheet, placing pieces of brick under it - this will ensure the unhindered exit of flue gases.

How to make a tank with your own hands

You can use a barrel to make a stove. Moreover, there may even be leaks in it. The door should be made at the end. To do this, it is recommended to cut it in a circle. Then attach loops and a handle to the fragment. Make holes on the other end. Through them, air will enter the firebox. The stove can be fixed using stands. To do this, you can use metal corners. They are fixed in the form of a parallelepiped. It is also permissible to do it crosswise.

It is worth placing a grate inside the structure. There should be a little space under it for the ash pan. On top of the barrel, it is recommended to make a hole of the same diameter as the chimney. The circle should be divided into 10 equal sectors and cuts should be made. After that, the resulting triangles should be bent up and the chimney welded to them.

It is also permissible to use the barrel in another way. Burning waste in it, dumping them in a heap, is prohibited. This is due to the fact that air will not enter the lower layers. Therefore, it will not be possible to get rid of a large amount of garbage.

To solve this problem, it is recommended to make holes at the bottom of the barrel. They should be performed not only in the bottom, but also on the walls. It is forbidden to leave the barrel on the ground.It should be placed on bricks. It is recommended to fold them in the form of a firebox.

A brick oven is an excellent option for waste disposal. It can be made from scratch or you can use the sauna hearth. It is permissible to cover a metal barrel with a brick. This will help make it safer.

Brickwork should be organized with a refractory mortar. When constructing a small kiln, the blocks can be folded without cement. However, you should use it carefully. To make a stove, it is allowed to use the following types of bricks:

- fireclay - capable of heating up to 1500 degrees;

- red - transfers temperature parameters up to 1000 degrees;

- graphite - used for finishing the inside of the firebox, since it is permissible to heat it up to 1700 degrees.

Refractory blocks are quite expensive. Therefore, they are mainly used for the construction of the firebox. Red bricks are more affordable. A stove made of bricks is considered safer than metal structures.

Conclusion

Garbage disposal is hard to imagine without incineration. Storing tons of materials in a landfill is irrational and dangerous for the environment. Recycling is not always possible.

The first waste incinerators used antediluvian technologies and polluted the environment. Today, they began to build unique complexes that can get rid of a lot of waste and calmly bury the remains that do not pose any harm.

Incineration is of course not the most ideal waste disposal option. There are more advantages, given the receipt of heat energy at a low cost. High productivity will save you from arranging new landfills, part of the residues will be reused and useful material will be produced.