Heat exchanger cleaning methods

Removal of scale and soot can be done mechanically or with the use of special chemicals.

Mechanical cleaning

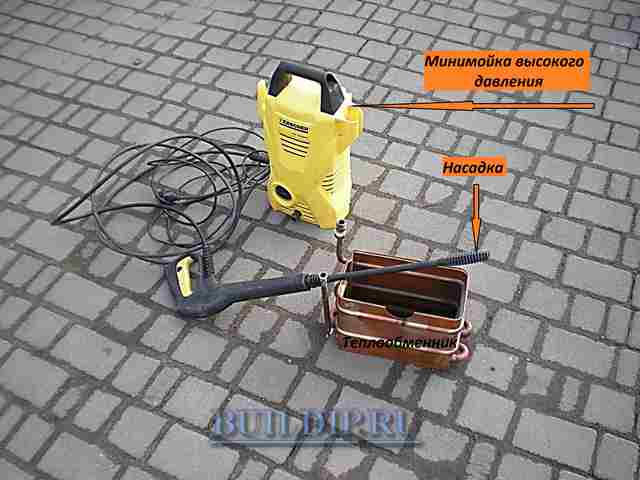

The cleaning process takes place with a foam sponge, a soft bristled brush, a mini high pressure washer. The most effective of the listed tools, allowing you to quickly remove plaque and broken layers of scale, is a mini high pressure washer.

Before cleaning, for a high-quality reaction, it is advisable to apply a special liquid to remove carbon deposits on the radiator fins, or treat the surface with a dishwashing detergent. You can combine the two ways to remove dirt and fill the coil with descaling fluid. After 30 - 40 minutes, and with the combined method, after 30 - 180 minutes (depending on the type of reagent used), perform a high-quality rinsing of the elements of the flow-through radiator with water under pressure.

Cleaning with chemicals

Dry cleaning can take place at a static or dynamic rate. When using the static method, the heat exchanger is removed from the water heater and filled with an active substance:

- Hydrochloric acid (H2SO4) with additives from active reaction with metal (inhibitors). When acid comes into contact with a metal surface, the protective layer is broken and the thickness of the coil wall becomes thinner, therefore inhibitors are added to it, which prevent corrosive wear. After flushing the radiator, the spent acid residues from the coil must be neutralized with an alkaline solution, for example, soda dissolved in water, before pouring into the sewer.

- Phosphoric acid (H3PO4). Neutral agent, reacts well with carbonates, does not harm the metal components of the system. An effective reagent is obtained by mixing H3PO4 and water in a 1/6 ratio.

- Aminosulfonic acid (NH3SO3) - iron oxide removal agent. To prevent the metal parts from being subject to premature wear when cleaning the boiler heat exchanger, a liquid consisting of corrosion inhibitors, water with a concentration of NH3SO3 in an amount of 2-3% is used.

- Citric (C6H8O7) or acetic (C2H4O2) acid. These substances are less hazardous to metal and humans than hydrochloric, phosphoric and aminosulfonic acids. But the decalcification reaction lasts several times longer than when treated with hydrochloric or orthophosphoric acid. If 30 - 40 minutes is enough to react with the same amount of H2SO4 scale, then for citric and acetic acid the time increases to 3 - 4 hours.

- Special liquid for descaling. In specialized stores, certified substances are sold, for example, Detex, Boiler Cleaner E, which easily cope with scale. After some concentrates, it is necessary to additionally treat the cavities with a neutralizer of acidity, while others may not be treated with a neutralizer, since they are neutral to the components of the system. Only certified fluids should be used in service centers. If this rule is observed, the company is guaranteed to be protected from the claims of the owner, the heat exchanger of which, after chemical cleaning, leaks.

The dynamic method of removing carbonates is carried out with special boosters. A booster is a device designed to circulate a liquid active for scale, both through the heating system and through its individual units. The flushing liquid is used in the same way as for static cleaning.

The use of H2SO4 causes premature corrosion of the metal parts of the booster.

All events are held outdoors or in a well-ventilated area, using personal protective equipment (goggles, rubber gloves) in clothes that cover well parts of the body in order to prevent acid and fumes from entering the human body. To improve the catalytic reaction and reduce the processing time, the contacting liquid should be 50 - 60 ° C.

What are the differences between cleaning a double-circuit gas boiler?

How to flush the secondary heat exchanger of a gas boiler with your own hands? There are no fundamental differences between flushing the DHW circuit and the heating heat exchanger. It's just that in the case of a two-circuit model, you will have to clean not one, but two elements.

Double-circuit gas boilers can be equipped with two types of heat exchangers:

- removable secondary;

- bithermic.

The first option is cleaned in the same way as the primary circuit using manual or dry cleaning using a booster:

- connect the hoses of the booster with nozzles for cold water supply and hot water outlet;

- the apparatus is put into operation with heating of the reagent (t = 50-55ºC).

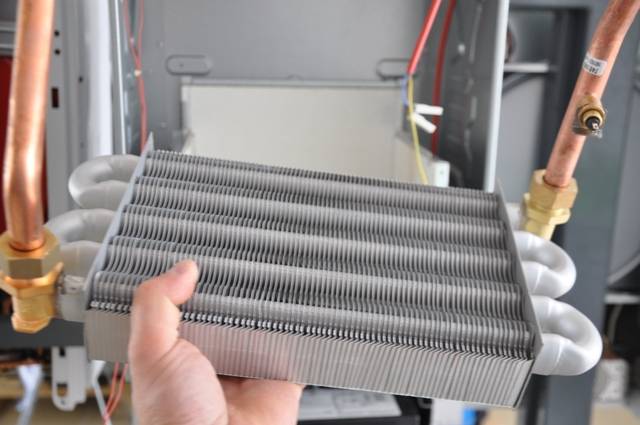

For manual cleaning, the secondary circuit is dismantled and immersed in a citric acid solution. Then brushed outside and dried.

A bithermal heat exchanger consists of two pipes inserted into one another: a coolant moves along one of them, hot water flows along the other. Its cleaning is much more difficult to carry out, especially since such a circuit cannot be dismantled as a separate analogue. Therefore, flushing of the bithermic circuit can only be performed using a booster. If such an element is heavily contaminated, then it is simply impossible to clean it. Then you will have to buy a new bithermal heat exchanger and install it instead of the old one.

Procedure: how to clean the boiler from scale, carbon deposits and soot

If you decide to do the procedure for cleaning the structure with your own hands, before doing any work at home, you need to turn off the electricity, turn off the gas, close all the valves of the heating system and the boiler.

All actions should be performed carefully, disassembly and assembly requires special care:

- The boiler cover is removed;

- Next, remove the gas burner, remove carbon deposits from the electrodes, you can rinse the surface with water and detergent, rinse;

- Clean the injector and nozzles with a soft-haired brush;

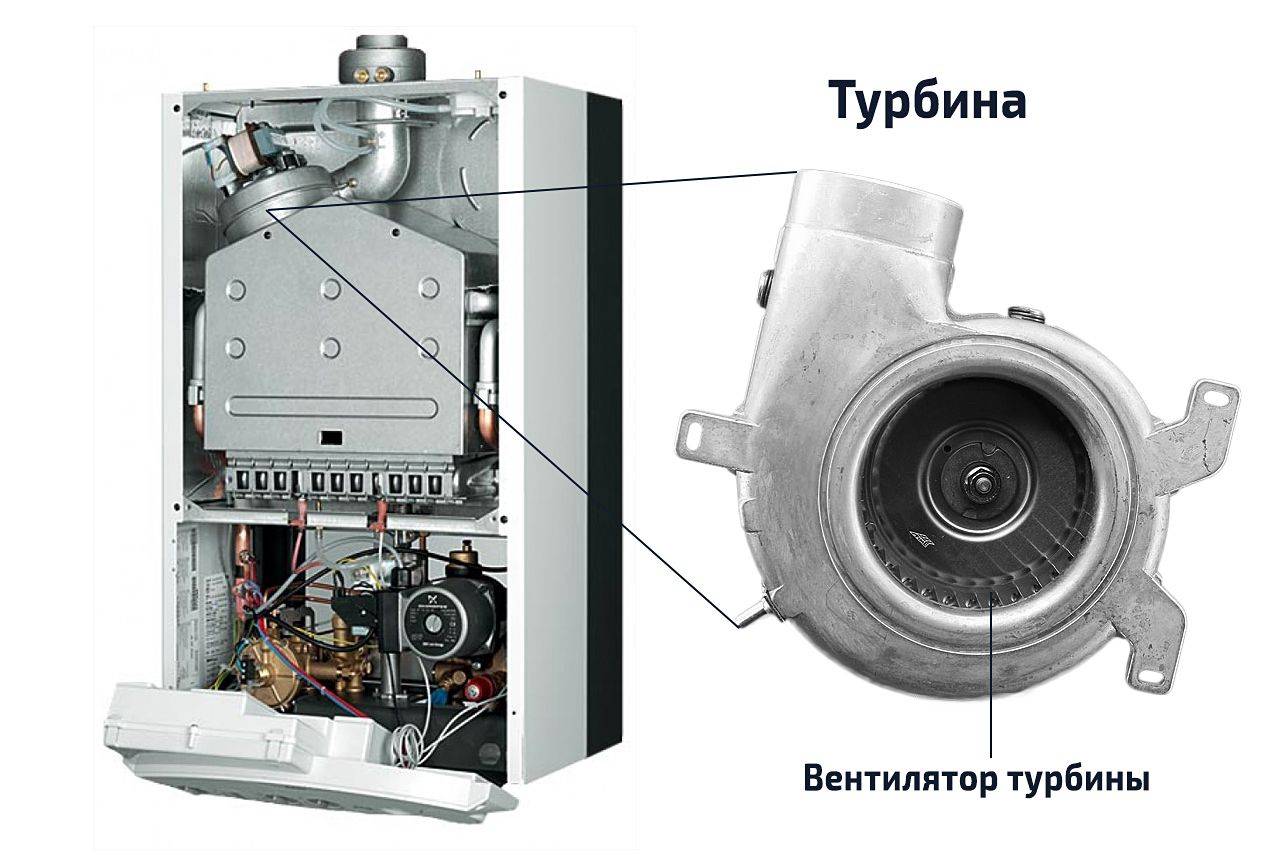

- Next, the fan is removed, and its blades are cleaned;

- The wall of the AGV combustion chamber is removed;

- The heat exchanger should be cleaned of soot, rinsed from limescale with citric acid or a special compound;

- After dismantling the coil, it is necessary to clean the bottom of the boiler;

- Then the filter intended for cold water is cleaned, blown and rinsed with clean water;

- All parts are returned to their places;

- The tightness of the AOGV is checked.

After completing all the necessary procedures, you can open the gas valve and turn on the electricity.

When the boiler has been running for a long time, soot deposits will gradually form on the burner. When it accumulates in large quantities, it can cause equipment malfunction. Therefore, you must periodically remove it.

For mechanical cleaning with small accumulations of dirt, you will need:

- Brush;

- Brush;

- Thin needle.

The gas duct is wiped without fail. The surface of the nozzles is cleaned with brushes or a brush. A needle is used for the holes. In no case should the hole be enlarged, as the combustion process may be disturbed.

If there is a lot of carbon deposits, acidic solvents can be used.

How to clean the heat exchanger of a floor-standing gas boiler

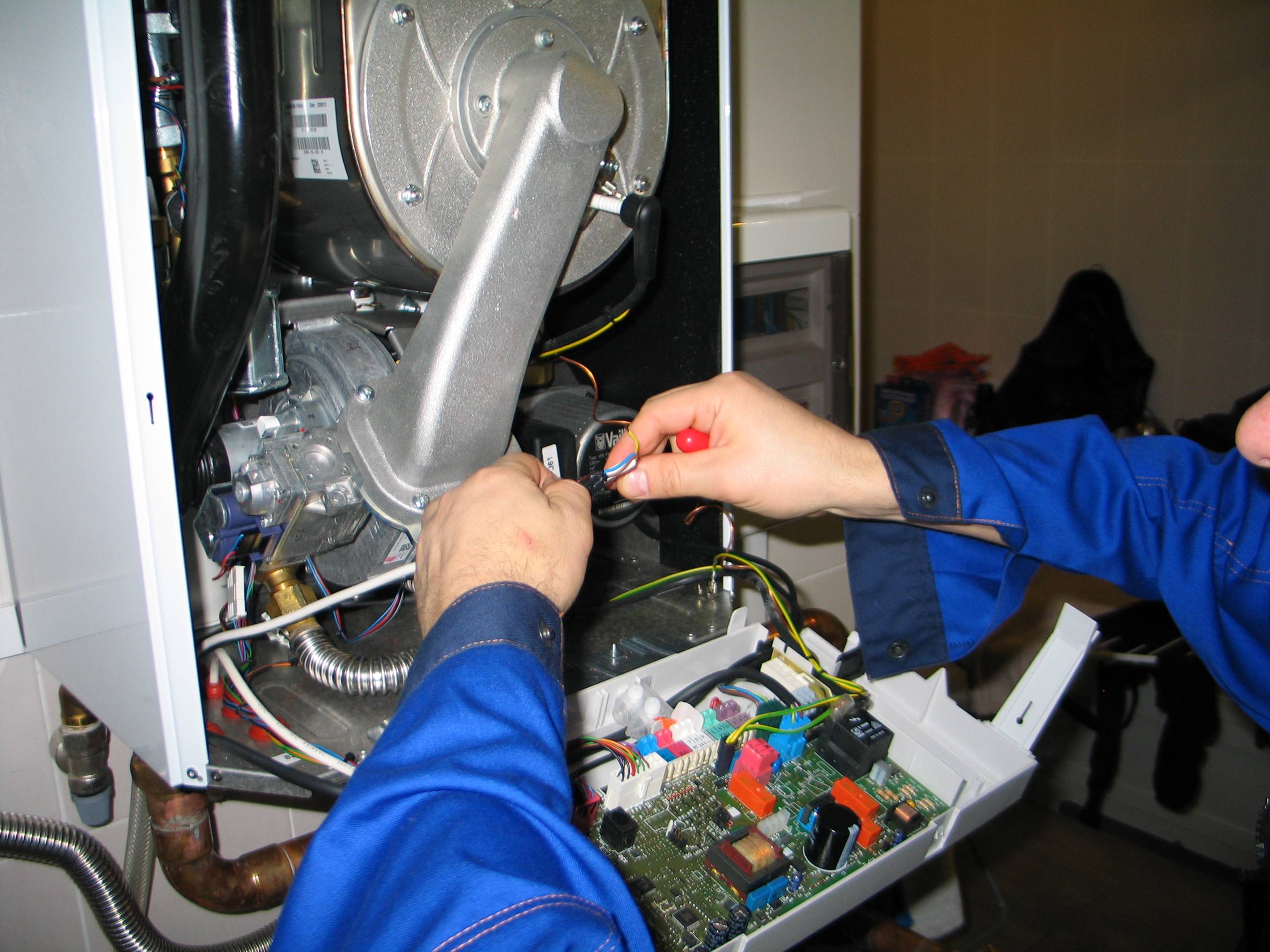

To disassemble the heating unit at home, you do not need any special tools, a simple set with screwdrivers, keys and pliers is enough. Preventive cleaning of the heat exchanger from soot and scale is carried out in the off-season, when the heating of the house is turned off.Having previously shut off the gas supply, we begin disassembling the boiler by removing the burner in the following sequence:

- Disconnect all wires from the gas valve.

- Remove the thermocouple from the combustion chamber, connected to the gas valve with a capillary tube.

- Disconnect the gas inlet.

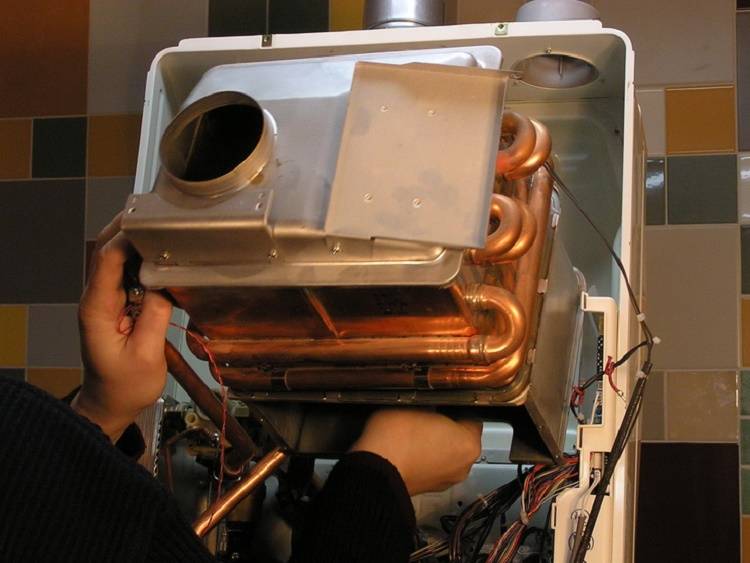

- Remove the 4 nuts (or bolts) holding the burner plate. Pull the assembly outward as shown in the photo:

The burner can be removed together with the safety valve and mounting plate

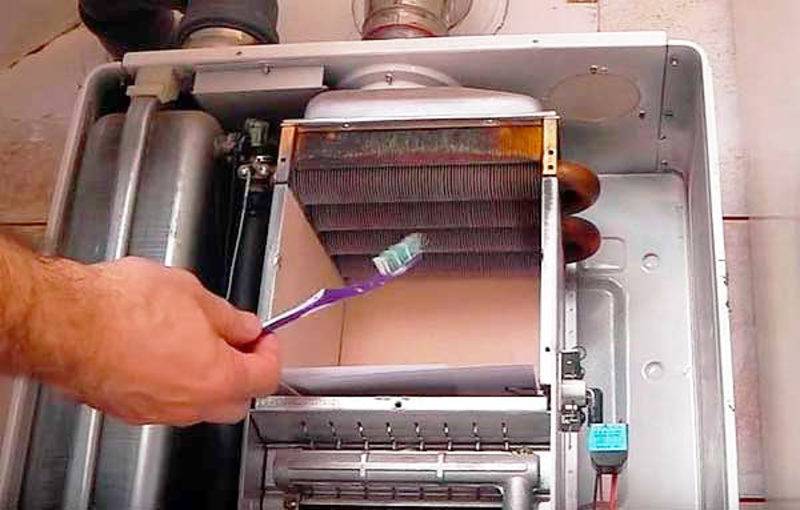

The gas boiler burner is cleaned without further disassembly using an old toothbrush. The igniter, piezoelectric ignition device and flame sensor (if present) should also be cleaned of soot. Now you need to get to the heat exchanger, for which you need to remove the top cover of the boiler, disconnect the draft sensor and the chimney.

In the opening that opens, you will see insulation covering the chimney casing. Carefully remove the insulation, and then unscrew the screws securing the casing and remove it. Under it is a heat exchanger, from which steel turbulators need to be removed, as shown in the photo:

When removing the turbulators from the heat exchanger, the soot spills down, so the first thing to do is remove the burner

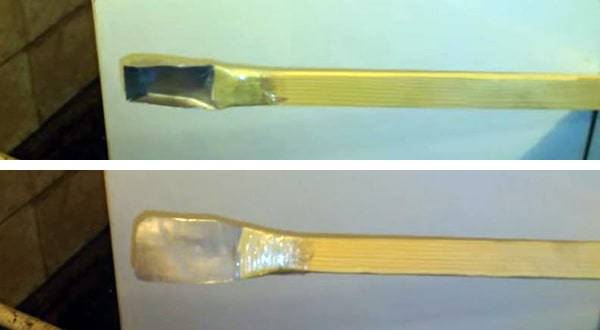

It is not difficult to clean the turbulators; this is done with a regular metal bristle brush. But cleaning the heat exchanger of a floor-standing boiler is best done with the help of simple tools, made by hand according to the size of the smoke tubes. If they have a rectangular cross-section, then you need to bend a comfortable flat spatula and a small scraper in the form of a scoop out of thin metal, then nail it to a wooden handle.

For round flame tubes, the same tools are made slightly curved. First, the pipe walls should be cleaned with a scoop, after which the soot remaining in the corners should be removed with a spatula.

At the end of the work, all surfaces of the heat exchanger can be swept with a brush screwed to a long handle. The last step is to remove soot from the bottom, where it was poured when cleaning the smoke tubes. This is what a clean heat exchanger of a heating unit looks like:

You can take a closer look at how to clean a gas boiler at home in the video:

How to clean the fire-tube heat exchanger of a single-circuit boiler?

Cleaning floor-standing boilers with a flame tube heat exchanger is different from the same procedure for attachments. Here, for the procedure, the heat exchanger is not removed, but only access to it is provided.

To complete the work, you will need the following tools:

- open-end wrenches;

- metal brush-ruff;

- hand brush for metal;

- screwdriver;

- a brush made of natural bristles or nylon.

The first required action is to turn off the gas supply valve. Next, you need to perform three stages of work - providing access to the heat exchanger, cleaning the parts, assembling the boiler. Disassembly / assembly steps depend on the specific model. How the boilers of the MAYAK-12 KS model are cleaned can be seen in detail in the video.

Methods for cleaning a gas boiler

There are several options. These include traditional methods: mechanical and chemical methods. In not the most difficult cases, hydrodynamic cleaning is chosen. Serious help is sometimes needed.

Mechanical

This method involves using the simplest tools. Manual cleaning avoids wasting money and time, but its effectiveness is low. The mechanical method does not guarantee an excellent result at all, so its use can be called a half-measure. Actions with "crazy" hands will only help if cleaning is carried out regularly.

The usual tools act as tools - brushes, brushes, toothbrushes, and a vacuum cleaner is also used in the struggle for cleanliness. All mechanical devices must not have sharp edges, since it is very easy to damage the parts of the unit with them.The required element is disconnected from the system, carefully brushed, taking care not to damage the surface. To clean the inside, use a brush, or blow through the parts with a vacuum cleaner.

Sometimes the mechanical method is combined with the chemical one. In this case, before "manual work", small units are soaked in a container containing a weak acid solution. Use citric or hydrochloric acid: 100-200 g is enough for a bucket of water. After such a preliminary half-hour preparation, it is easier to remove scale, as it softens.

Chemical

This method is more efficient than manual work. Chemicals allow you to remove blockages in places where tools simply cannot reach. This option is not only more effective, it saves a lot of time. However, there were some drawbacks here. You have to pay for reagents, and for high-quality work you will need special equipment. It will either have to be bought or rented from familiar craftsmen.

Cleaning with drugs

This option is suitable for small local pollution, but in this case, you need to be extremely careful. Personal protective equipment required

Excessive contact of elements with chemicals can lead not only to the elimination of soot, but also to the destruction of the metal. Therefore, it is better to carry out processing very carefully.

Heat exchanger cleaning booster

Booster is a water pump with a reagent tank. For maximum efficiency, the units are supplemented with heating elements. Instead of ordinary water, aggressive substances are used for cleaning. For example, solvents, phosphoric or hydrochloric acid. Heating them increases the cleaning efficiency of the gas boiler.

The booster is connected to a heat exchanger. When the device is started, the liquid begins to circulate continuously inside it, gradually corroding all deposits. It is recommended to change the reagent, since it loses its properties, and all deposits enter the tank and accumulate there. To neutralize the remains of a caustic liquid, after cleaning, a special (alkaline?) Solution is run through the pump. Or clean water.

Hydrodynamic

Such flushing does not require disassembling the gas boiler, but a booster is also required for the procedure. This operation is pumping water (in exceptional, difficult, cases - with an abrasive filler), followed by increasing the pressure in the system. The accelerated movement of the liquid provokes the destruction of deposits, and then their safe removal from the equipment. However, this option is fraught with serious consequences.

If there is a critical increase in pressure indicators, then it can provoke pipe rupture. Because of the potential danger of independent work, such "water procedures" are best left on the shoulders of professionals working with gas equipment. In this case, the owners of the gas boiler can avoid all problems.

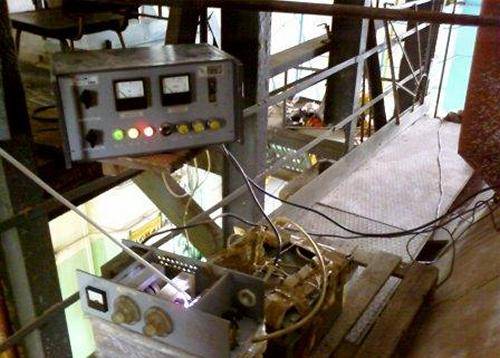

Electric discharge

This is another way to clean a gas boiler, but it requires serious equipment - a whole complex. In this case, the scale is exposed to a liquid through which an electric discharge is passed. Such a formidable treatment causes splitting of the deposits and their subsequent washing away.

The advantages of the method are a high degree of cleaning, no negative impact on the metal parts of the equipment. Disadvantages - more time for processing, noisy procedure, expensive and bulky equipment (Streamer complex). Such boiler flushing is usually done only in service centers.

How often should the heat exchanger be cleaned?

The frequency of cleaning the heat exchanger of a gas boiler is usually indicated in the operating instructions. If there is a filter on the water inlet pipe, then cleaning can be done less frequently. If there is no filtration and there is hard water in the region, then the heat exchanger will clog up faster.

Usually, without a water filter, cleaning is done once a year or two.If the tap water is filtered, it is sufficient to take care of the heat exchanger once every 4 years.

There are signs that an urgent circuit cleaning is needed:

- Fuel consumption has increased - with a clogged circuit, gas consumption can increase by 15-20%.

- The performance of the heating system has decreased. Signs of this may be as follows: weak heating of the batteries, the unit cannot reach the required temperature and works continuously.

- Weak water pressure from the DHW system or insufficient heating.

- Noises in the heat exchanger.

- An increased load on the circulation pump is created.

If at least one such "symptom" appears, the heat exchanger should be cleaned as soon as possible, otherwise inaction will lead to costly repairs.

How to clean

There are two main methods of descaling the boiler:

- collapsible;

- indiscriminate.

When using the collapsible method, you can sequentially dismantle parts that are contaminated with scale with your own hands. Then these parts are placed in a container with a reagent for several hours. After that, these units are thoroughly rinsed with water, and then reinstalled in place.

The name of the CIP method speaks for itself, in other words, the boiler is flushed from scale on the spot - without dismantling the contaminated parts. In this case, descaling of the boiler unit is carried out using a special device called a booster.

This device consists of the following components:

- container for a chemical solution;

- electric heater for liquid;

- circulation pump.

Flushing the boiler from scale using a booster is carried out in the following order:

- the boiler is disconnected from the fuel supply or, in the case of a solid fuel option, the device is allowed to cool down;

- water is drained from the boiler;

- disconnected from the heating system;

- a booster is connected;

- this device starts pumping the reagent through the boiler for 5–6 hours;

- the waste liquid is drained;

- the boiler is flushed and connected to the heating system.

It is also worth knowing that for effective descaling with booster rinsing, the entire volume of operations must be repeated several times.

You may also be interested in an article on how to clean a gas boiler.

Read an interesting article about the features of flushing the heat exchanger of a gas boiler here.

Physical cleaning methods

If we are talking about cleaning the boiler from scale in a complex, then initially mechanical cleaning is performed, and only then chemical

Among the main disadvantages of the physical method, one can single out the fact that the inner surface of the boiler is exposed to negative effects, therefore it quickly deteriorates, especially if, through carelessness, too sharp tools are selected

As soon as the cleaning of the boiler is completed, it is important to thoroughly rinse all the removed parts with water and reassemble them correctly.

Hydrodynamic cleaning of the boiler heat exchanger involves the removal of impurities by means of a high pressure water jet. This method differs from the mechanical one in that it excludes any kind of damage to parts. Although fluid dynamics are very efficient, they are not used very often due to their high cost.

There are two ways of physical methods for cleaning boilers from the formed scale

Both options require the analysis of the system without fail, which means that it is extremely important for everyone who is interested in such work to acquire the necessary tools and provide full equipment. Since limescale forms mainly on the inside of the boiler, it is impossible to interact directly with the contaminated areas.

Since disassembling a system is a time consuming and complex process, the cost of physically descaling devices is also high.

In private houses with a central water supply, decontaminated and roughly purified water is used as a heat carrier for hot water supply and heating. This coolant contains a large amount of various suspended substances, including Ca and Mg, which, under the influence of high temperatures, more than 65 ° C, due to a malfunction of the gas column modules, unsatisfactory water pressure, precipitate into carbonate sediment (CaCO3, MgCO3). These deposits are called limescale.

The scale adheres firmly to the metal surface inside the heat exchanger, piping, etc.

Low thermal conductivity of scale, and good adhesion leads to:

- overheating of tubes and plates of the heat exchanger, up to its damage;

- overexpenditure of energy resources;

- a decrease in water consumption due to overgrowing of the internal channels of the pipeline and elements of the water heater;

- clogging of valves, taps and other system elements;

- decrease in the thermal power of the device.

Over time, the outer part of the heat exchanger becomes covered with fuel combustion products. The formation of soot is facilitated by the intense flame of a gas burner, poor draft in the chimney, an unsatisfactory ratio of gas and air, an increased content of additional impurities in the fuel, the ingress of contaminated condensate from the chimney. Soot affects the violation of heat exchange, leads to an increase in gas and water consumption.

Why does scale appear

This type of pollution is the main problem in the operation of the boiler. Scale forms wherever hot water is circulated.

This type of pollution is the main problem in the operation of the boiler. Scale forms wherever hot water is circulated.

In other words, it settles as a hard layer on the inner walls of the boiler equipment.

What triggers the appearance of scale? The reason for this clogging is very commonplace - the use of hard water as a heat carrier, which is well saturated with magnesium ions, calcium carbonate, iron oxide, and other various impurities.

When these elements interact with the inner walls of the heat exchanger, salts or bicarbonates are formed, which are the source of scale formation. It is also worth noting the important fact that on the walls that are covered with this contamination, scale will appear even faster and faster.

The result of such an increasing action will be a narrowing of the channels for the circulation of the coolant, and this, in turn, leads to a loss of heat transfer and to a decrease in pressure.

Important information:

1 mm of scale increases fuel consumption by 10%!

Also, the negative effect of this pollution is that scale particles move freely through the heating system and, getting into the heating elements, can take them out of working condition.

Therefore, the following recommendation is very important: the scale removed in time will protect your heating boiler from breakdowns and failures.

How to flush the heating

Various reagents can be purchased in the retail network, offered in 3 types:

- liquid concentrate;

- powder;

- ready-made solution.

The concentrate and powder must be diluted with water, following the manufacturer's instructions. As a rule, the water is heated to 40… 60 ° C before cooking. Ready liquid for flushing the heating system is poured into a barrel, after use it is disposed of.

We will give a number of recommendations, the better to flush the heating pipes:

- The active ingredients of the reagent should not damage the elements of your system, for example, interact with aluminum radiators. Select chemistry based on the materials used in the metal parts and fittings.

- It is better to buy flushing with various useful additives - corrosion inhibitors, biodegradable additives.

- According to their composition, the reagents are divided into 2 groups - acidic and alkaline. The former act faster, but are considered more aggressive towards equipment and hazardous to health. Better to choose an alkaline concentrate.

We do not recommend using various folk remedies for washing, in particular, citric acid. Firstly, it is effective only against scale, which is only found in boiler heat exchangers. Secondly, a high concentration of an acid solution is required; with a large amount of water, it will not work.

When is cleaning possible?

In any case, it is inappropriate to wait for the moment when the device turns into a grimy "Cinderella", therefore, cleaning the gas boiler from soot is carried out at a certain time. There are three options.

- Periodic maintenance. It is a necessity. Owners are advised to do preventive cleaning of equipment at least once every 2 years. Better - once a year.

- Such a "cleaning" operation is mandatory, when the efficiency of the gas boiler decreases: the heating of water for hot water supply is worse, the heating does not work well enough. Usually, under such circumstances, the name of a professional is called.

- Cleaning the gas boiler from soot during repair work. When the heat generator breaks down during the heating season, the foreman, who came to fix it, at the same time does the preventive maintenance - cleans the heat exchanger.

The first 2 cases are not very attractive for equipment owners, since they imply a waste due to the invitation of the "alien" master. Cleaning can often be done on your own, but almost every rule is not without exception. For example, it is better not to experiment with a condensing boiler with a closed combustion chamber. If the owner is completely unfamiliar with such a unit, then professional help is already a necessity.

Preventive cleaning of the gas boiler from soot - flushing the heat exchanger - is a simple operation, moreover, it is performed quite quickly. This procedure can be carried out without much difficulty on your own.

There are certain symptoms that signal the need to clean the equipment. These include:

- increased gas consumption due to blockage of the heat exchanger;

- atypical hum inside the device due to pump overloads;

- decrease in the water pressure in the DHW circuit;

- insufficiently hot radiators;

- constantly working burner.

All these signs may not only be symptoms of a blockage in the unit, therefore, other possible causes of malfunctions must also be taken into account when self-diagnosing the equipment.

Dismantling and removal of soot from the inner surface of the boiler

In order to clean the entire system at home, you will need the following tools:

In order to clean the entire system at home, you will need the following tools:

- screwdriver;

- metal brushes (soft and for metal);

- brush;

- open-end wrenches;

- rags or any cotton cloth.

Stages of work:

- Shut off the gas.

- Remove the boiler door and disconnect the wire leading to the piezoelectric element.

- Unscrew the thermocouple, ignition electrode and pilot tube one after the other.

- Replace with a new gasket under the pilot burner.

- Remove the nozzle, copper pipe, burner.

- Carefully take out the thermometer sleeve and then remove the boiler lid together with the insulating sheet.

- Disconnect the terminals from the traction sensor and take out the gas duct.

Before cleaning, turn off the gas supply, wait until the structures have completely cooled down and only then disassemble.

After removing all the parts, you need to:

clean with a brush and metal brushes.

The channels should be cleaned with a vacuum cleaner.

Particular attention should be paid to the burner, as the inner channel can be easily damaged, it must be wiped carefully.

Wood-fired boilers are often used for heating in homes. And only a few people think about what kind of firewood should be chosen for kindling. Usually they use whatever they have. Resin firewood is especially harmful to chimneys. It settles on the walls of the boiler and the chimney pipe. Mechanical cleaning is required. In this case, the chimney must be cleaned of tar and soot residues from the roof, so it will be easier to remove the combustion residues from the inside.Observe safety measures!

Reasons for clogging the heating system

The main source of pollution that disrupts the operation of heating circuits is the coolant. Most often tap water acts as such. When filling the system, small debris from the water supply system can easily get into it. As the water circulates, this debris is transferred to the radiators, where it accumulates.

Another source of pollution is scale. It is formed in the boiler, where water is in contact with the hot walls of the heat exchanger. Gradually, the inside of the boiler is covered with a layer of scale, which has a relatively low thermal conductivity. The scaled heat exchanger transfers energy to the heat carrier much worse. With a thickness of salt deposits of several millimeters, the boiler efficiency can decrease by almost a third. In the process of cyclic heating and cooling, the scale crust is destroyed. Detached particles enter the pipeline and are deposited both on the inner walls of the pipes and in the radiators. Accordingly, their heat transfer decreases and there is a reason to think about how to flush the heating system in a private house with your own hands.

In addition, due to the oxygen contained in the water, rust gradually occurs in the metal elements of the system. Like scale, rust increases the hydraulic resistance of pipes and is an additional source of contamination.