Selection rules

The choice of special protective equipment is legally entrusted to the employer. The choice of insulated work gloves should be based on the specific conditions in which it is planned to use them. There are no glove models that are suitable for absolutely all types of protection. But in order to eliminate the risk of error as much as possible, you should adhere to some general recommendations.

- Checking the marking. Products must be certified and comply with Russian or international standards. For Russia, this is GOST 12.4.246-08 for technical requirements and test methods for gloves. For European manufacturers, this is EN407 for low temperature protective gloves. Employees responsible for the selection of PPE in enterprises should be well versed in reading pictograms and labeling symbols.

- The size should be appropriate for the worker's hand. When choosing a batch of products for an enterprise where there are many workers, it is necessary to buy gloves of different sizes (Russian sizes vary from 6th to 11th), so that workers can individually select the desired model. Too large gloves will slide off your hands, and small ones will create inconvenience. It is not uncommon for workers to ignore the use of protective gloves due to discomfort, resulting in frostbite.

- The required degree of mobility of the fingers in gloves depends on the specifics of the work being performed.

- The wrists should be protected by tight-fitting cuffs (elastic, gaiters).

- Insulation layer thickness. It should be borne in mind that the thicker the insulation, the more effective the heat protection, but the more difficult it is to work in such gloves. Thick gloves are not suitable for work at low temperatures in the high-precision mode; you should choose models with a thin layer of insulation.

Choosing the right warm protective gloves is not as easy as it seems at first glance. If in doubt, you should seek the advice of a specialist.

What are they?

To protect hands in industrial conditions, most often it is necessary not only from the cold, but also from other harmful factors, therefore, insulated gloves will be needed for combined protection. There are various models of winter gloves designed for different working conditions. They differ in a set of technical and operational characteristics, materials of manufacture, and a method of sewing.

Let's consider the main types.

- Warm cotton gloves made of thick cotton thread of dense double weaving or with the addition of woolen thread to cotton. The declared level of thermal protection during testing of some models made of cotton fiber double weave is -35? С. They are used both at enterprises and at the household level in simple work (load and unload bulky items, transfer something dry and not very dirty, work in the street with a broom or a shovel in winter, clear snow from paths). Most models have a dotted polymer coating for durability. The cost is low.

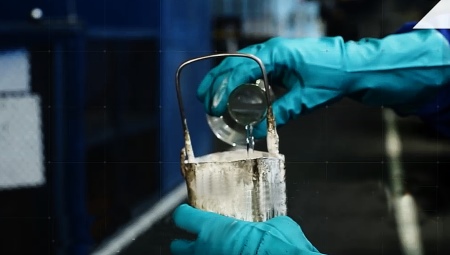

- Waterproof insulated gloves with a latex-rubber coating are indispensable in working situations with the repair of the water supply network in the winter or in the elimination of an industrial accident.

- Rubberized assembly gloves with an insulating layer or with a warm liner are used for electrical work of varying degrees of complexity, including high-altitude ones. They have a protective effect against electric shock and antistatic properties.

- Special frost-resistant gloves with a polymer coating (PVC, latex, nitrile) on a double-weave insulated cotton base are used for emergencies when the threat of chemical attack joins the cold.

- Combined insulated models with a complex protective effect are used in extended areas with different types of protection. Together with protection from cold, they are able to protect from mechanical damage, from the action of chemicals and aggressive media.

The materials for the manufacture of winter work gloves have frost-resistant properties. This is a double-weave cotton fabric of increased density, natural woolen yarn, fleece, split leather (the middle layer of leather when processing raw materials in the tanning industry), natural leather. Batting, natural or artificial fur, camel wool serve as insulation. The choice of camel wool for use as insulation is not accidental.

Camel wool inserts have a micromassage effect, as the hairs continuously tingle the skin of the hands and stimulate the intensity of blood circulation in the palms, from this the hands are warmed by natural warmth and will never freeze in the cold even without movement. To improve the properties of products, coatings made of latex, nitrile, and PVC are used.

Care Tips

Winter work gloves are a seasonal protection for long-term use. It is necessary to properly care for warm gloves in order to maintain their appearance and performance, to maximize their service life. In addition, it is necessary to keep the protective equipment clean in order to comply with hygiene rules in order to prevent the development of fungal infections and other infections on the skin of the hands.

Care methods directly depend on the material of manufacture and the scope of use, but there are general points that it is advisable to adhere to.

Keeping PPE clean is an immutable rule. At the end of the working day, gloves should be thoroughly cleaned of dirt and residues of substances that you had to work with during the day.

Lay out the gloves to dry on racks or on a shelf in an individual closet for storing workwear between work shifts. If the model has a removable insulating liner, remove it from the gloves, wash and dry if necessary.

When washing, strictly follow the manufacturer's recommendations for acceptable methods (indicated in the labeling) in accordance with the materials that make up the products

Be sure to pay attention that washing is unacceptable for some materials (for example, natural leather and fur can only be cleaned with special products).

Provide adequate storage conditions during the summer period (some insulated winter gloves are issued for several years).

Russia is a huge country. Several climatic zones pass through its vast territory. In the conditions of severe winters of northern latitudes and the far from mild climate of middle latitudes, insulated work gloves are a necessary element of work equipment and an effective help for those who work in frost or in a cold room without heating. Their high performance and affordable price make these personal protective equipment widely available in virtually all industries and households.

In the next video, you will find an overview of the Mechanix Winter Armor winter work gloves.

Do it yourself

Some fishermen do not trust modern materials and manufacturers, find it difficult to choose a product or, in order to save money, make gloves for winter fishing with their own hands, and also, based on their experience and needs, improve the already purchased ones.

How to improve or insulate existing gloves

It often happens that the purchase does not take into account some detail or the terms of use change.Some errors can be corrected by yourself, for example, by insulating the product or by making waterproof stripes on the palm of your hand.

Knitted items or a fur lining made from old leather gloves can serve as insulation. Inserts can be made from waterproof fabric, such as leather, by sewing them onto the surface in the desired place.

As a heater for fishing gloves, you can use an old unnecessary fur coat made of artificial or natural fur. To do this, you need to cut off its sleeve, taking into account the desired length, and trim the edge with braid to prevent shedding of the fur.

Such a clutch can be used while waiting for a bite by placing your hands in gloves or mittens there, which will make it possible to warm them even in the most severe frost. For convenience, you can sew on a loop and attach it to the button on the jacket.

How to make ice fishing gloves yourself

Gloves for winter fishing can be made independently, with the most basic sewing skills:

- You can cut out a product based on any used and suitable size.

- An old muton, sheepskin or even a soldier's greatcoat in combination with a construction mitten is used as a material.

- Parts can be sewn on a sewing machine, and in its absence it is possible by hand with small stitches, strong thread.

- The crumbling edges can be neatly hemmed, and additional insulation can be placed inside.

- Alternatively, you can use regular construction gloves, wearing several pairs at the same time, cutting off your fingertips.