Correct tool sharpening process

It has been proven in practice that over 80 percent of tool breakages occur due to improper sharpening of band saw teeth. The need for sharpening is determined by eye - by the condition of the cut walls

or the kind of teeth itself.

Grinding wheels for band saws are selected depending on the hardness of the tooth. For sharpening tools made of tool steel, a corundum wheel is used. Bimetallic saws are sharpened with diamond or borazon abrasive. The shape of the circle for the tool should be determined based on the parameters of the saws. It can be cup, profile, plate and flat.

Before using the saw in the work, it is necessary to hold it in a suspended, inverted state for about eleven hours.

Tool sharpening requirements

with your own hands:

- it is necessary to evenly remove the metal along the tooth profile;

- exclude excessive pressing of the circle (this can lead to damage to the tooth);

- mandatory use of coolant;

- to ensure the safety of the geometry of the tooth;

- avoiding the formation of burrs.

The standard instruction states that the sharpening of the tool should be carried out either along the front face of the tooth, or both along the back and front. In practice, many craftsmen and professionals sharpen exclusively along the rear edge - this is, in their opinion, more convenient.

This tool is enough unpretentious in terms of sharpening

, despite a lot of requirements and rules. Sharpening can be done both manually and using a special sharpening device; apply for processing circles of different material and shape, etc.

Before sharpening the tool, you need to familiarize yourself with the basic types of implementation of this operation. You can also watch a video on the Internet.

Sharpening types

If you have neither an engraver nor a machine tool, then you can sharpen the tool using the old-fashioned usual method - using a file

... With diligent and regular execution of the operation, the skill of manual high-quality sharpening will very quickly appear.

- When sharpening a tool on a machine, before starting sharpening, you need to make sure that the sharpening disk is correctly positioned relative to the saw.

- It is necessary to remove such a layer of metal from the sinuses in order to guarantee the elimination of all microcracks.

- If the saw was operated without high-quality maintenance, longer than the manufacturer's prescribed, the layer of metal removed in one sharpening must be increased.

- Always use a new tool as a reference to check the sharpening results.

- The shape of the saw blade is a parameter verified and developed over the years. Therefore, it is not worth displaying your parameters and hoping for a good quality of work.

- Subject to the rules of operation and the requirements of the manufacturer, the band saw will last you until its width is reduced to 65 percent of the original crimp. The width decreases as the teeth are re-sharpened.

- It is imperative to remove burrs when sharpening the tool, otherwise it will lead to the formation of microcracks during the cutting of materials.

- After finishing work, the tool must be immediately cleaned of sawdust and resin, and before sharpening, the saw must be carefully inspected. Otherwise, chips will clog the sharpening wheel, which will result in improper sharpening of the saw band.

Video: Setting Up a Band Saw Grinder Video

It is quite difficult to choose a high-quality grinding machine, but more and more really high-quality tools appear on the modern market. With the advent of automatic tools for sharpening dust, the quality of the process has also improved, since the human factor in this process is minimized, which means incorrect angles of the pointed teeth or clogged sinuses.

Among the high-quality cars, models of several brands can be distinguished.

"Cedar". One of the most widespread and well-known brands. This tool belongs to fully automatic machines using work thanks to the installed program. This also includes constant monitoring and use of the coolant for normal operation. Cedar is quite easy to use and is suitable even for beginners. Adjusting the angle manually is not difficult either, just unscrew the two special screws located on the back of the tool and adjust the angle using the screw on the base. And also on the tool there is a blade speed regulator.

More modern options allow the use of diamond grinding wheels.

"Taiga". The brand is no less famous than the previous one, it has almost the same characteristics, it is even easier to manage it. The blade angle and feed rate can also be easily adjusted on the tool.

This machine can be used for both wide and narrow band saws.

AZU-02. The most modified of all previous cars. All models have a special device for automatic coolant supply. The tool has several switches that allow full control over the operation of the grinder. And all models use diamond discs that speed up the workflow and improve its quality.

AZU-02 is still capable of regulating high-speed internet traffic, which also greatly simplifies the process.

PSLL 30/60 Pro. A modern fully automatic machine with a high sharpening speed. A special cooling oil is used to cool this machine. This machine does not require any professionalism and you only need surface control as the machine shuts down when grinding one circle of saw blades.

"PZSL 10/2". Narrow band saw machine, suitable for both wood and metal saws. This unit, like the previous one, is oil-cooled. The process is fully automated, the task of the master is only to establish the desired process and bring the canvas onto the machine, then the machine itself will do all the work.

Astron (A-1). Full bore machine with borazon, the process of working with such a unit is fully automated. The machine cuts the entire saw in 1 full pass. The sharpening disc is used for sharpening, which is of high quality and durability. Setting up the process is very simple and does not require high professionalism.

In the modern tool market, there is a huge variety of grinding machines, the simplest and most popular grinding machines.

hints

If you want to sharpen the tool efficiently and easily, then the following must be observed when working:

- fully automatic devices must use a special liquid, otherwise the device will overheat and break;

- remove the same layer of material from each nail during sharpening;

- after work, there should be no burrs or burrs on the teeth;

- all work must be carried out with the same pressure on the tool and at the same angle;

- the workplace must be cleaned and nothing interferes;

- there should always be a first aid kit;

- Protective clothing must be worn during work.

Some difficulties may arise when doing work without special education and experience, so it is best to hone at least some knowledge and skills in this area.

Summing up, we can say that the use of special grinding machines for band saws greatly simplifies and speeds up the work process, but it is important to follow the instructions and all recommendations, and also not to forget about safety rules. Watch how to sharpen a band saw on a sander in the following video

Watch how to sharpen a band saw on a sander in the following video.

All rights reserved, 14

The use of any material without our prior written consent is prohibited.

Sharpening recommendations

During the work of the canvas, its rupture is very often observed. This is due to the fact that it is poorly sharpened. This is due to the concentration of stress in the blade profile, if the sharpening is carried out at a low-quality level. The need for the procedure is determined by the condition of the band saws. If the surface roughness of the cut increases, then this leads to a bluntness of the tool.

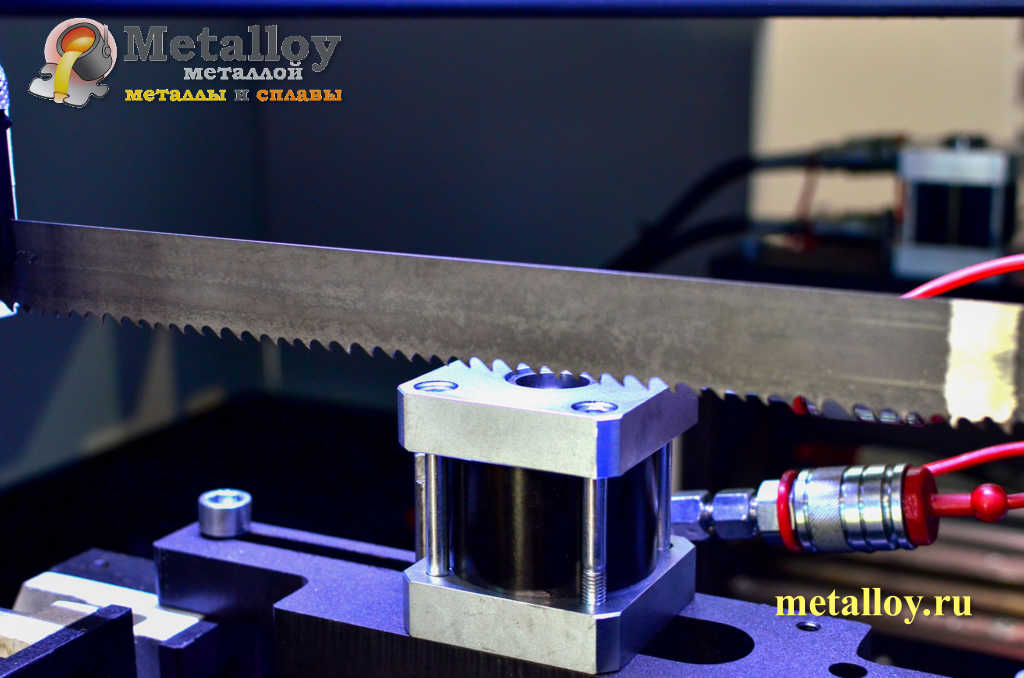

Tool sharpening is carried out using diamond, electrocorundum, CBN discs. Their choice directly depends on the characteristics of the material being processed. The sharpening of the blade, the material of production of which is tool steel, is carried out with corundum wheels. The procedure for bimetallic tools is carried out correctly if a diamond or CBN wheel is used. The instructions will tell you how to carry out this procedure. The most important thing is that the angle does not change in the process.

Wheels of various diameters can be used for sharpening. The choice of one of them is determined by the parameters of the device. For this purpose, profile, flat, dish-shaped, cup circles are most often used. Sharpening is correct if the peripheral speed is 20 to 25 meters per second.

The principle of sharpening tape blades

If there are chipping on the tool, chipping will be observed on the edge of the workpiece. That is why it is imperative that sharpening is carried out correctly. During this process, it is necessary to work not only with the front, but also with the back of the canvas. Sharpening of devices can be carried out in different circles. In this case, it is necessary to take into account the angle of the canvas. If you want to carry out the procedure correctly, then you need to learn it from a specialist.

In order for the band saw equipment to work efficiently, it is necessary not only to select it correctly, but also to sharpen it in a timely manner. For this purpose, special circles are most often used. This procedure is as simple as possible, which allows it to be easily performed by a master without appropriate experience.

If you find an error, please select a piece of text and press Ctrl + Enter.

Perhaps, like any commonly used tool, the band saw has its own field of application, where it has almost no equal. In this article, we will make sure of this by considering the various parameters of the tool. And, most importantly, we will learn the features of band saw sharpening.

So, I'll start with a general description of the band saw.

The band saw is in the form of a saw blade having a serrated edge connected to form a continuous band. Simply put, this tool is nothing more than a closed belt with teeth.

And to make sure that the band saw is a very significant cutting tool, I propose to consider its main advantages.

Types of sharpening machines

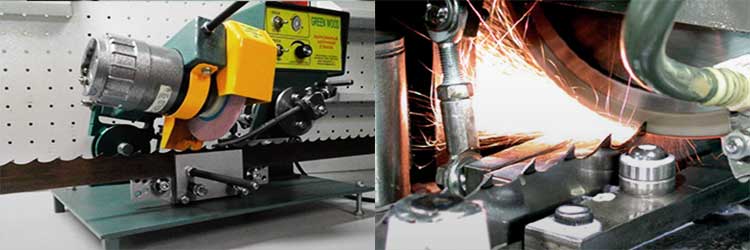

Grinding machines are classified according to their technological purpose and are divided into two main types: universal and specialized. On the first, you can sharpen almost any kind of carpentry, locksmith and many types of machine tool cutting tools. Such grinding machines have a horizontal spindle and are used for single and small-scale works, and sharpening on them, as a rule, is carried out in manual mode.This type of equipment also includes the most common grinding machine, which is commonly called "electric sharpener".

Specialized sharpening equipment is structurally much more complicated and is produced for sharpening multi-blade machine tool cutting tools: various milling cutters, circular and band saws, reamers, countersinks, taps, as well as drills and cutters in mass production. In addition, there are various types of combined grinding equipment on the market, in which the sanding machine is combined with other devices. A typical example of such devices are grinding machines with a drive on a flexible shaft (see the left photo below) or with a grinding belt on the second drive (see the right photo below). The first ones are equipped with a high-speed electric motor with speed control, which allows them to be used, among other things, for engraving work. Therefore, the common name "engraver machines" was assigned to them.

Characteristics

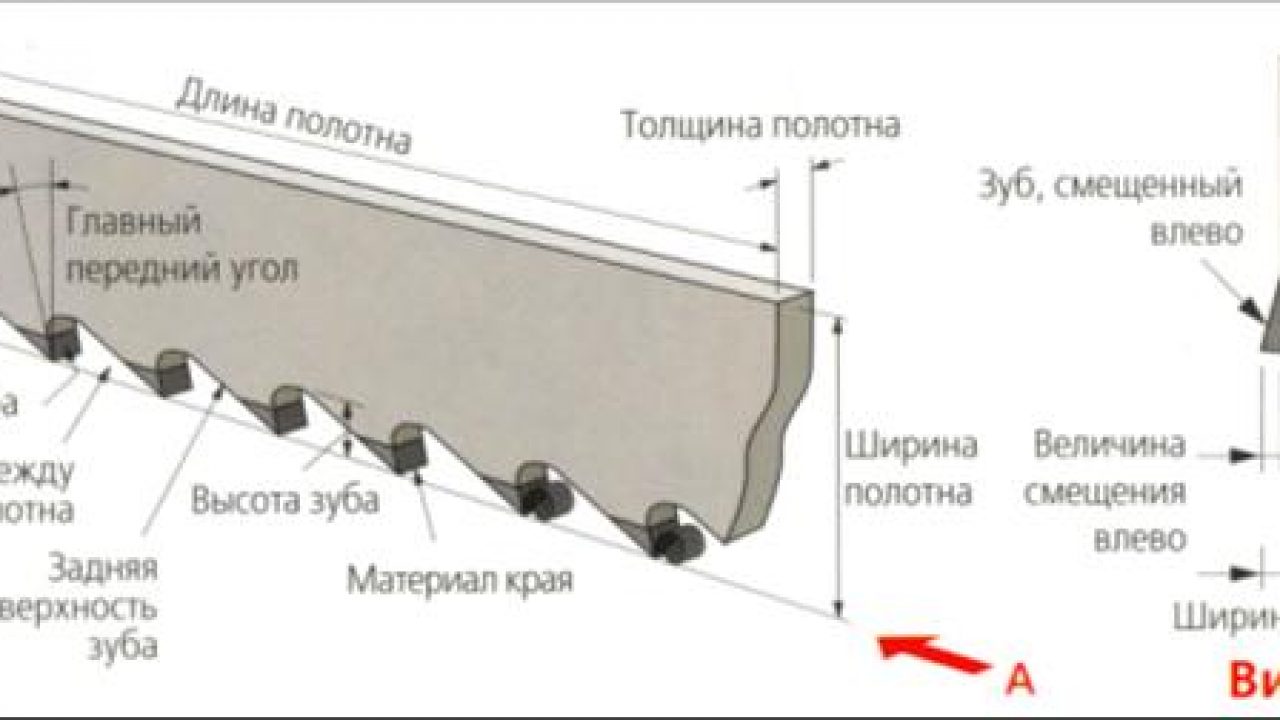

Band saws have three distinctive features. They are made only of special grades of tool steel, which ensures high strength and wear resistance of the teeth. Russian manufacturers usually use steel grades 9HF and B2F, foreign companies prefer the C75 series. In any case, the hardness of the material must be at least 45 HRS.

The cutting width of the band saw blade is much narrower than that of circular counterparts. As mentioned above, this is a fundamental factor in the processing of precious woods and industrial woods.

The saws are able to handle workpieces of any length and diameter without any problems. At the same time, a properly sharpened band saw ensures high production productivity.

It should be clarified that the reliability of closed saws is due to the heterogeneity of the material used to make the blade.

In particular, the body of the saw tool is usually made of spring steel, which has incredible tensile and dynamic resistance. Steel grades with a high tungsten and cobalt content are used for the manufacture of cutting edges. Individual parts of the web are welded together by high-frequency currents. Tools made using this technology can be used for cutting metal.

This is interesting: Grinding machine - we explain in all the details

What can you sharpen?

A small blade with small teeth can be sharpened with a special file or the usual nozzle of the machine. However, such sharpening is very long and ineffective, and also very often causes a number of saw breakdowns. Given these problems, many craftsmen have long been using an electric sharpening machine, which sharpens all the teeth of a band saw quite quickly and equally evenly.

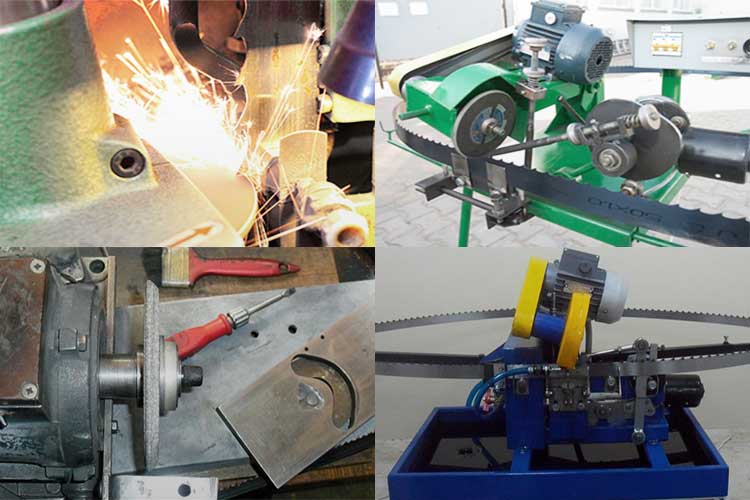

Such machines are divided into several groups.

- Fully automatic centers, they use a specialized feed and sharpening program, such machines are mainly used by large workshops for sharpening or restoring large and massive band saws. The process is carried out with the use of cooling chemical liquids and under strict control.

- Semi-manual machines with special tool consoles.

- Small automatic centers, in which the step of moving the web is adjusted and the process is monitored.

A sharpening machine is an aggregate that helps to sharpen the saw with high quality using a sharpening wheel. Most often, a certain unit is selected for a certain type of saw.

The machine includes:

- base and external structure;

- tool holder;

- special drives used to move the blade and rotate the grinding wheels.