Working with mixed saws

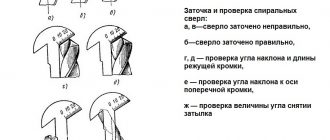

Preparation of the hacksaw for work: a - set of teeth; b - sharpening.

A mixed saw for wood cutting should be sharpened with a file that has a coarse cut, alternatively a diamond file that has a fine cut can be used. When sharpening, you can use one of two ways, the first is called oblique (90 °), the second is straight (75-80 °).

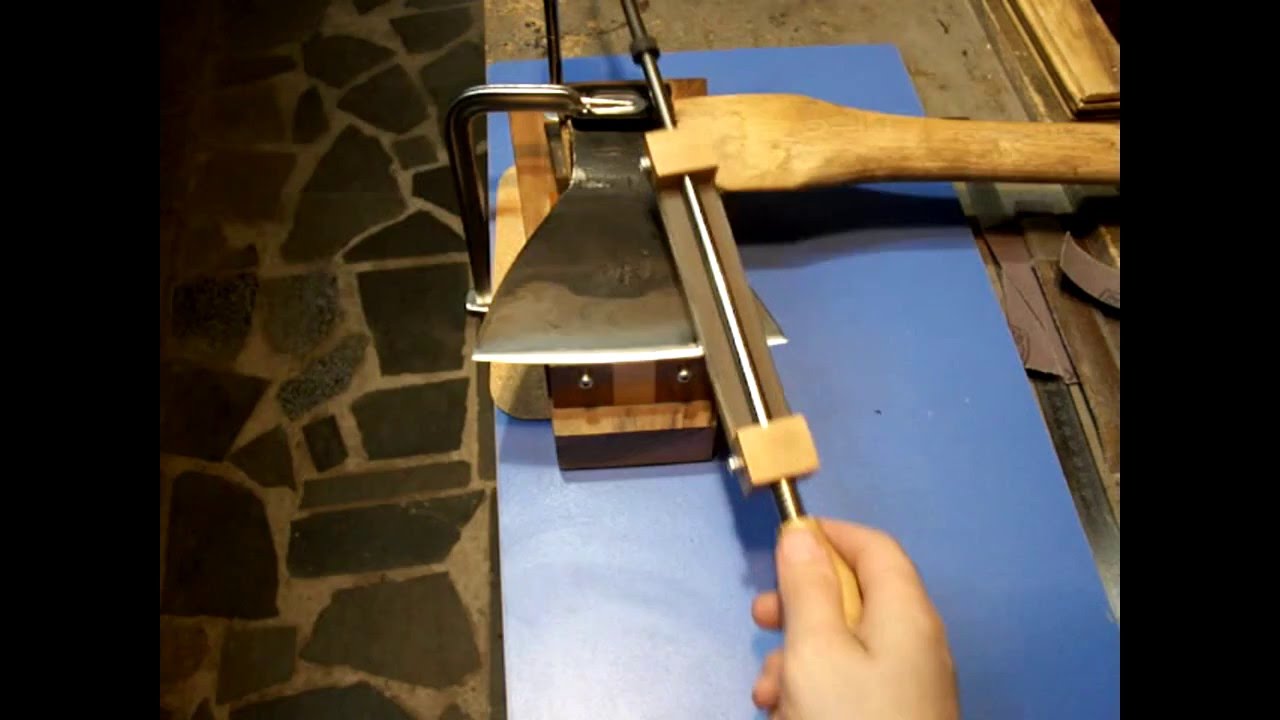

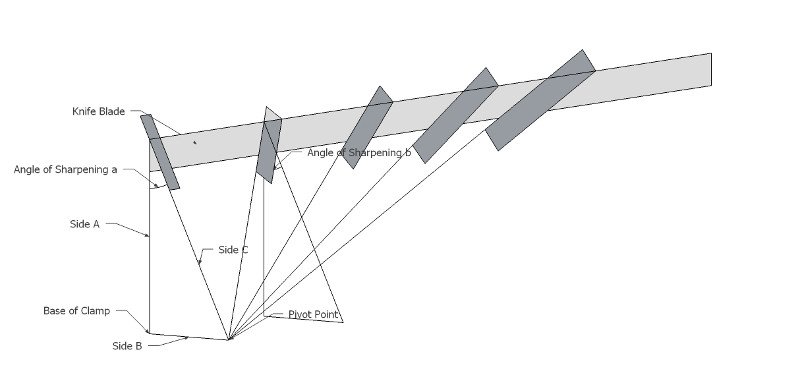

The clamping unit consists of a plywood base with dimensions of 550x200x20 mm. Two steel guides are mounted on the base.

Sharpening begins after setting the tool so that the teeth protrude 20 mm above the surface of the clamping bar.

There are clamping machines designed for working with large tools and two-handed saws. They are based on two transverse strips, the length of which is 550 mm, and the section is 40x30 mm. The device has 1100 mm posts, the cross-section of which is 60x40 mm, and clamping blades with dimensions equal to 450x150 mm, the latter are made of 15 mm plywood. The joining of the crossbars and racks is made with screws.

The installation must be installed, taking into account a certain sequence. From the floor surface at an insignificant height, you need to strengthen the crossbar to the uprights, then you need to install your right leg on it so that it becomes possible to mark the level of fixation of the upper crossbar, while the knee should rest on the latter. This allows you to obtain the stability of the rack, mated to the workbench. In order to sharpen the tool, it must be positioned between the clamping bars so that the teeth are facing up. The fastening can now be done using the wing nut bolts. As soon as it was done with the sharpening of the teeth on one side, the tool should not be removed from the clamps, the device must be turned over, and then continue to work with the teeth on the other side.

In order to produce, you need to stock up on such materials and tools as:

- wiring;

- file;

- file;

- clamping device.

How to sharpen a shovel correctly

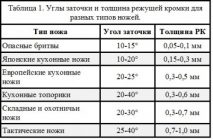

In the process of work, it is necessary to maintain a sharpening angle of up to 20 °, while achieving a cutting edge thickness of no more than 0.5 mm. When using an electric tool, do not apply excessive force, as this can lead to a defect in the metal, or breakage of the grinding wheel.

You can use a piece of paper or a piece of wood to check the quality of your work. Cut off the edges with the edge of the shovel, if you have to apply effort, then the straightening process is repeated. The working surface should be free of jams, chips and burrs. Poor quality metal, even after sharpening, cannot return to its original sharpness.

Sharpening your shovel correctly

File sharpening

The advantages of the method:

- High quality cutting edge. The same result cannot be achieved with an electrically powered tool. The file is used to adjust the thickness of the metal both on the working edge and on the side edges.

- There is no heating of the metal surface. When using a grinder and emery, overheating occurs, which leads to a change in the properties of the metal part of the shovel.

- Convenience when carrying. The ability to edit the tool anywhere without the need to find a source of energy.

When sharpening it is necessary:

- Fix the metal part securely. It is recommended to use a locksmith's vice. Do not exceed the force when tightening the lips, this may lead to deformation.

- Rough processing.First of all, the editing is carried out with a file with a large notch. Move from front to back, reverse order is prohibited.

- Precise processing. Editing is carried out with a file with a fine notch, while achieving an edge thickness of no more than 0.5 mm.

- Removing sharp edges. A square file is used, with its help they remove the edges sharpened with a smaller angle.

Editing a shovel with a grinder

The disadvantage of this method is:

- The need for the presence of a source of electrical power.

- As a result of critical heating of the metal, the technical characteristics of the edge decrease. This phenomenon leads to the fact that the edge subsequently becomes blunt.

- The difference in the thickness of the edge of the shovel. High rotational speeds do not allow maintaining a thickness of 0.5 mm along the entire length of the tool edge.

- After processing, the metal must be additionally straightened with a file with a fine notch. This will help prevent injury when transporting the shovel.

Advantages include only editing speed. When machining, the grinding wheel must be guided towards the holder. Only the front of the tool is sharpened.

Sharpening a shovel with a grinder

Sharpening with an emery machine

For a high quality edge, it is necessary to use machines with adjustable speed of rotation of the abrasive wheel, as well as a large weight of abrasive. This will avoid vibration during processing. You can sharpen the shovel by following the instructions below:

- Clamp the workpiece securely. In this case, the master needs to press the working part of the shovel against the stop on the machine.

- Initially, it is recommended to remove a layer of metal no more than 0.3 mm thick. Thus, cracks and dents on the edge of the shovel are smoothed out. Subsequently, the angle of the workpiece is changed relative to the surface of the grinding wheel. During operation, to cool, the edges must be watered with water. Dark spots will appear on the edge, which, however, will not affect the characteristics of the metal.

- Finishing is done with a hand file. Burrs and microcracks are removed. Areas with excessive sharpness are removed.

How to sharpen a sapper blade

You can sharpen a sapper blade, like a regular bayonet, in any of the three main ways. It is preliminarily recommended to beat off the edges of the metal part, which in the future will help to reduce the loss of time for straightening the edge with the help of the tool. Movements are carried out on the front side, only burrs are removed from the back.

Compliance with the instructions and safety requirements will help keep the tool in working order for a long time, reduce efforts when digging soil in the personal plot.

Sharpening process

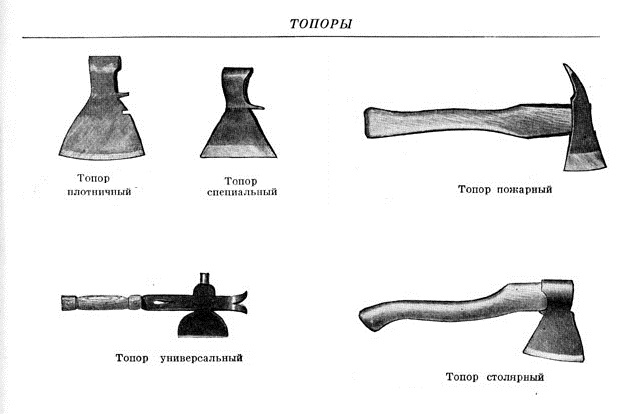

In order to properly sharpen an ax at home, it is important to choose the right way to process the cutting blade. It will depend on the following factors: what kind of wood they have to cut - in this case, the stiffness of the fibers, and their twist, and their other parameters must be taken into account;

what kind of wood they have to cut - in this case, the stiffness of the fibers, and their twist, and their other parameters must be taken into account;

it is important whether the wood is wet - then the blade will need to go deeper;

the type of carpentry is taken into account - whether the ax will be used for felling trees, chopping wood or cutting logs;

- the width of the chamfer is always taken into account - this indicator should allow the blade to plunge into the material being processed;

- the angle at which the sharpening is carried out is important.

During work, it is important to observe several safety rules so as not to harm your health.

Grinder

Sharpening an ax with a grinder is not recommended by professionals for the following reasons:

- the procedure is dangerous and difficult for people with low physical fitness;

- the metal heats up quickly, which leads to a deterioration in its quality characteristics.

Bruscom

In addition to a measuring bar or protractor, a set of abrasive stones, differing in their grain size, rough cloth, water, as well as a leather belt as a rule, are needed. Using a measuring bar allows you to find out at what angle the sharpening will be carried out. This device will need to be made with a bevel corresponding to the angle of the planned sharpening. The tool is placed on a straight, stable surface, such as a table or stool, after which the blade begins to be cut with a bar. In this case, the stone moves along a curve, creating half rings.

It is necessary to hold the block at the angle of the required sharpening. Thanks to a stone with a coarse grain, it will be possible to provide the required slope and width of the chamfer. The second side of the cutting blade is processed in a similar manner. At the next stage, sharpening occurs using a bar with an average grain size. Last of all, with the smoothest stone, all burrs are removed and all uneven fragments are corrected.

If everything is done correctly, the bevel will be evenly smooth tactilely. After straightening on a leather belt under tension, you can complete the job. Residual debris or dust can easily be removed with a piece of cloth. By the way, during the work, it is periodically recommended to moisten both the stones and the ax.

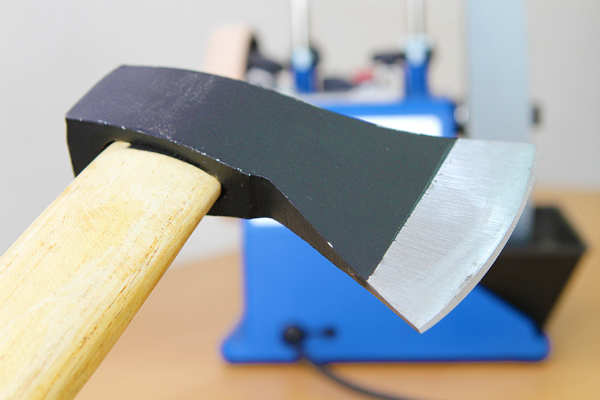

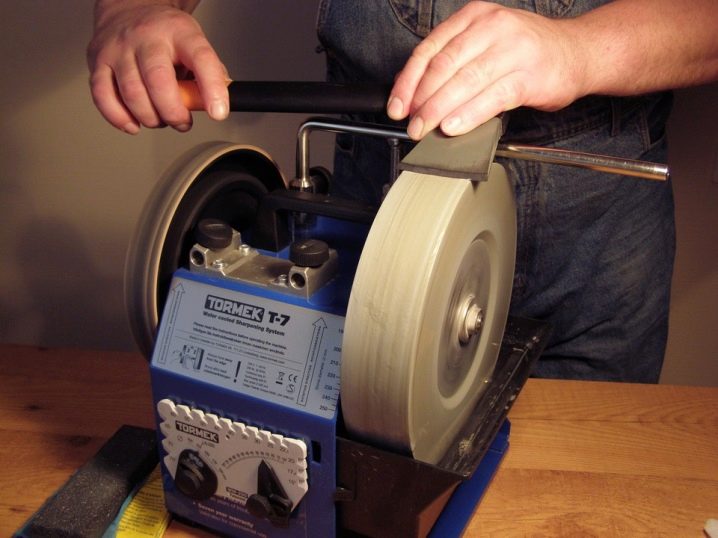

On a grinder

Specialized machines are usually used by professionals. In addition to the electric drive, they are equipped with a device that allows you to sharpen axes at a certain angle. Direct sharpening is carried out using an abrasive disc. Since the ax is mounted on a cylinder, it will not move from side to side and disrupt the workflow. In addition to the machine itself, for sharpening it is also necessary to prepare a hand sharpener with two sides, a marker, a polishing agent, an inclinometer, as well as the master's protection: gloves, glasses, closed clothes and shoes.

First of all, the chamfer is covered with a marker, then the ax is fixed on the machine. The point is brought to the grinding wheel, and the required cutting angle is selected using the sharpening angle. To check the circle, you need to turn it yourself and see if the paint has worn off where the blade and the stone came into contact. Ideally, they should disappear completely. When finished with the settings, you can turn on the sharpener. The chamfer is processed until all the irregularities disappear, and everything is brought to mind with a hand sharpener.

File

If you wish, you can also use a file to sharpen an ax with your own hands, having done everything on emery. Completing the task will require the following tools:

- rust converter;

- wire brush;

- sandpaper of three types (from hard to velvet);

- polishing paste;

- a piece of cloth;

- locksmith vice;

- files;

- measuring ruler;

- grinding wheel with two working sides;

- a fragment of technical wax;

- mineral oil for lubrication.

First of all, the blade is cleaned from the effects of corrosion and any contamination. Then sandpaper is passed over it. Further, sanding is carried out using a medium-grained sandpaper. The next step is polishing with a special paste. The ax is fixed in a vice or between the squares, with the help of a file, sharpening of the chamfer begins. The surface of the abrasive must be moistened with water.

How to sharpen an ax correctly

You will soon notice that iron particles begin to collect on the blade. Do not brush them off - they will help sharpen the ax. Flip the blade over and do the same operation on the other side, then repeat the entire procedure again until it becomes very sharp.

Stage 4

Now you can start editing. Use the smooth side of the whetstone. Make circular movements, only now counterclockwise, from right to left.

Date Added: 2015-05-30; views: 457; Does the published material violate copyright? | Personal data protection |

Didn't find what you were looking for? Use the search:

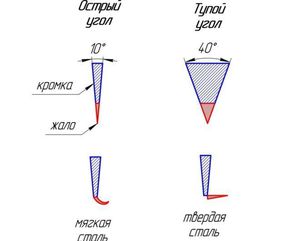

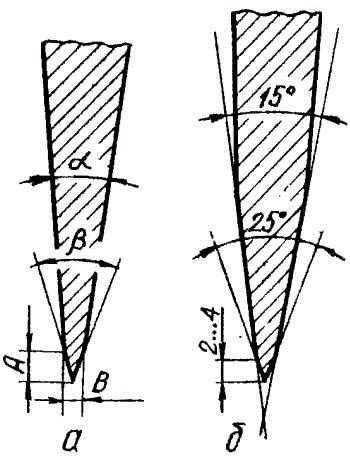

First of all, pay attention to the fact that different types of operations in woodworking require different axes: for cutting logs (carpentry), for carpentry and others. The sharpening angle of a carpenter's ax is 35 degrees

If it is made smaller (the blade is sharpened thinner), then the blade will get bogged down in the wood - you will have to apply significant effort to pull it out. A finely sharpened blade on knots, especially spruce, crumbles and bends (depending on the quality of the metal). A properly sharpened blade will not get bogged down in the wood as it breaks the wood chips to be separated from the main log. As a template for sharpening an ax, you can use a piece of tin and make a cutout on it with scissors at an angle of 35 degrees

The sharpening angle of a carpenter's ax is 35 degrees. If you make it smaller (the blade is sharpened thinner), then the blade will get bogged down in the wood - you will have to apply significant force to pull it out. A finely sharpened blade on knots, especially spruce, crumbles and bends (depending on the quality of the metal). A properly sharpened blade will not get bogged down in the wood as it breaks the wood chips being separated from the main log. You can use a piece of tin as a template for sharpening an ax and cut it out with scissors at an angle of 35 degrees.

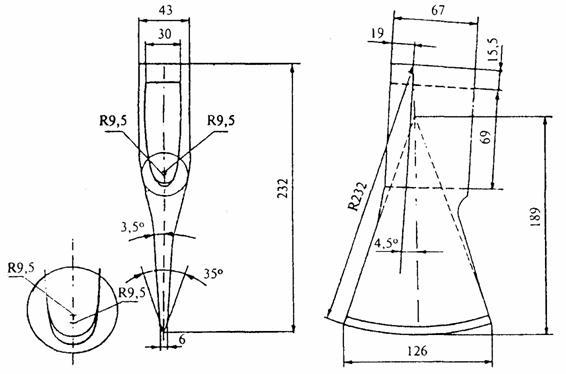

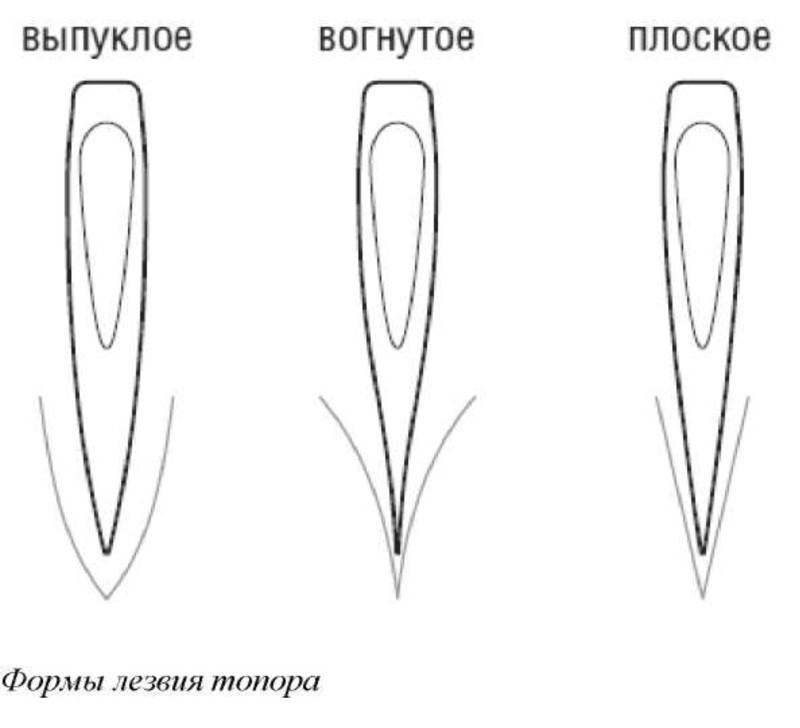

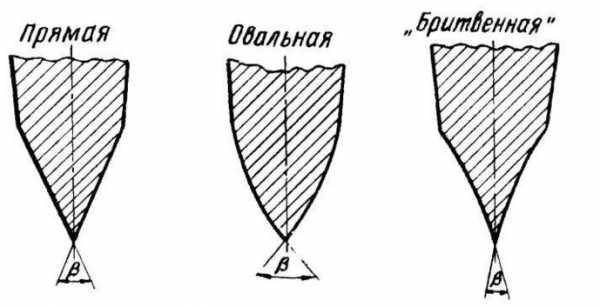

As a rule, axes are on sale with a straight blade. Working with such an ax is hard and unproductive. This is because a straight blade penetrates the wood over its entire width, and it takes a lot of force to operate with such a tool. With a rounded blade, the ax works like a scherhebel - the blade breaks down the chips being separated. With such an ax, it is easier to level irregularities on the edge of the log. The radius of curvature of the blade should be about 250-270 mm.

The optimum weight of a carpenter's ax is about 1.5 kg. Light axes require a lot of physical effort when handling logs. But it is difficult to operate with a heavy ax with one hand (for carpentry work).

A little about the choice of stones

Sharpening stones are of the following types:

- Ceramic;

- Diamond;

- Natural;

- Japanese water stones.

Optionally, once you get the hang of it, you can buy some solid and expensive diamond or Japanese water stones. However, it is better to start with ordinary ceramic bars (such as "Boat"), which are sold in every hardware store. They are hardwearing, durable and affordable. Of the shortcomings, only their uneven abrasion can be called.

Here are some tips to help you find the right mate:

- What size should the bar be? Ideally, it is 1.5-2 times longer, or at least not shorter than the blade of a knife. The width and shape of the bar is not critical.

- When buying a block, make sure it is flat and free of chips.

- To get started, you can buy one medium-hard universal whetstone. But if you want, buy one block with two sides of different grain size or two stones with a large and less grain size twice. A couple more stones may be added to your collection in the future.

- It is best to try to get a couple of Soviet-made donkeys, say, at flea markets or from your grandfather. Bars marked "Made in USSR" have uniform grains and high quality binder.

To bring the knife to razor sharpness, in addition to sharpening stones, you can buy GOI abrasive paste, which we will also talk about working with.

Description of the stages of the work performed

In the house, every owner always has tools that may be needed at any time. The ax is one such tool.

Use small circular motions and work around the edge. Count how many strokes you use on one side of the bevel so you can reflect your technique on the other side of the bevel. After completing the first side, switch to the other side.

Using the rough side of the washer. This process may take a while, just work on one side of the bevel and then on the other. This can take 3 to 5 alternating strokes on each side. Now it's time to flip the washer and repeat the process on the shallow side. Make sure your edge is sharp before moving on to the finer sand. At this point, your ax should be able to cut the paper.

How to sharpen an ax correctly?

This product is indispensable when performing various works in the country, during the construction of buildings, greenhouses and hotbeds. Any instrument loses its sharpness over time. How do you do it yourself? For proper sharpening, you can:

- Make a template from a piece of tin, from another material.

- Choose a sharpening angle.

- Make a cutout on the template.

- Attach it to the blade.

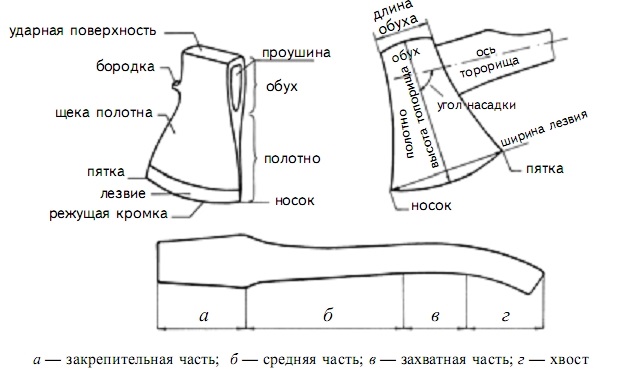

Carpenter's ax device.

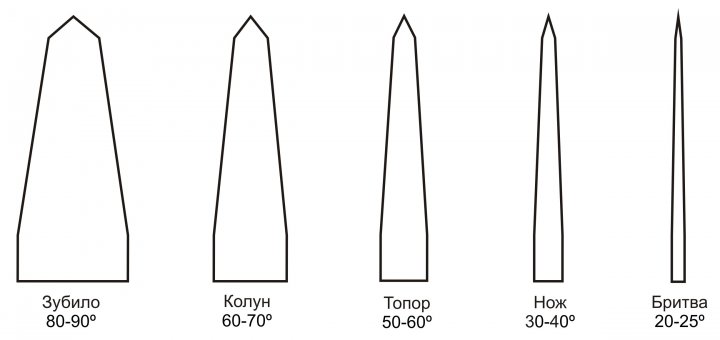

The angle of sharpening of a construction ax blade is usually 20-30 °. Carpentry tools are sharpened at a 35 ° angle. The sharper it is, the less effort you need to apply when doing any job.

But at a low angle, the tool is able to dull very quickly and get stuck in the workpiece.

Therefore, cleavers are sharpened at an angle of 35-40 °, and logging axes at an angle of 25-30 °.

You can sharpen the ax yourself by hand; you can use an electric sharpener for this operation, which is a rotating circle. For proper sharpening you will need:

- axe;

- fixture with a template;

- grindstone;

- finishing paste;

- special device for setting and dressing the circle;

- marker;

- goniometer;

- glasses and gloves.

The procedure for using an electric grinder is something like this:

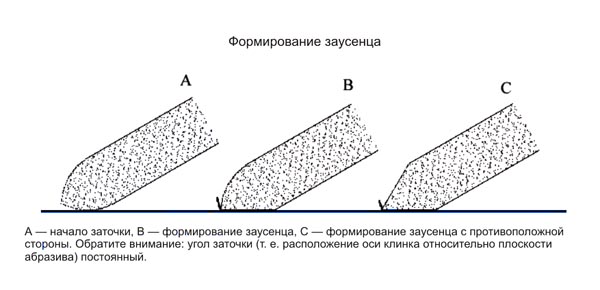

Sharpening an ax - shaping a burr.

- The machine must be installed on a solid and fairly level surface.

- Check the abrasive wheel for defects.

- If necessary, sharpen the working wheel with a special sharpening stone until the surfaces are completely leveled.

- To renew the sharpening at the same angle, paint over the surface of the blade with a black permanent marker.

- The product to be sharpened is fixed directly against the grinding wheel.

- The blade must be lowered to the circle.

- Fix the set sharpening angle.

- Make manually 2-3 turns of the working circle.

- Remove the ax from the machine and check the cut left under the marker layer.

- Repeat the procedure until the correct angle is found.

- Fix the tool and sharpen it until all irregularities and cracks have been removed.

- Smear the leather circle with lapping paste.

- Polish the blade by sliding it along the surface of the circle.

- Apply a rust preventer to the metal part.

Special tools for hand sharpening axes can be purchased. The Smith's 50118 sharpener has proven itself to be excellent. In a few passes, it makes any blunt ax sharp. It is completely safe to use this device. It uses premium carbide elements as an abrasive. The kit includes a special brush for cleaning the instrument. It is stored in the handle.

The simplest device used for manual sharpening is an ordinary abrasive wheel. You can use a bar. To perform such a sharpening you will need:

Ax sharpening angle.

- brush (preferably metal);

- means for protecting metal from rust;

- emery cloth with different grains;

- protective glasses;

- polishing paste (RA-70);

- vice;

- burgundy file;

- whetstone (SP-650);

- machine oil.

Operating procedure:

- Remove rust from the blade with a metal brush.

- Grind the surface of the blade first with coarse, then fine sandpaper.

- Polish the instrument with paste.

- Place the product on the table so that the point hangs over the edge. You can fix the ax in a vice.

- Sharpen it along the chamfer with a baking file.

- Remove metal chips and dust.

- Continue sharpening with the double-sided stone in a circular motion. The bar must first be treated with liquid.It can be water or machine oil.

- Repeat the operation on the other side of the ax.

- Treat the blade to protect it from rust.

Sharpening process

In order to properly sharpen an ax at home, it is important to choose the right way to process the cutting blade. It will depend on the following factors: what kind of wood they have to cut - in this case, the stiffness of the fibers, and their twist, and their other parameters must be taken into account;

what kind of wood they have to cut - in this case, the stiffness of the fibers, and their twist, and their other parameters must be taken into account;

it is important whether the wood is wet - then the blade will need to go deeper;

the type of carpentry is taken into account - whether the ax will be used for felling trees, chopping wood or cutting logs;

the stronger the steel from which the cutting blade is made, the more difficult it will be to sharpen it by hand, but the result will be more durable;

- the width of the chamfer is always taken into account - this indicator should allow the blade to plunge into the material being processed;

- the angle at which the sharpening is carried out is important.

During work, it is important to observe several safety rules so as not to harm your health.

Grinder

Sharpening an ax with a grinder is not recommended by professionals for the following reasons:

- the procedure is dangerous and difficult for people with low physical fitness;

- the metal heats up quickly, which leads to a deterioration in its quality characteristics.

Bruscom

In addition to a measuring bar or protractor, a set of abrasive stones, differing in their grain size, rough cloth, water, as well as a leather belt as a rule, are needed. Using a measuring bar allows you to find out at what angle the sharpening will be carried out. This device will need to be made with a bevel corresponding to the angle of the planned sharpening. The tool is placed on a straight, stable surface, such as a table or stool, after which the blade begins to be cut with a bar. In this case, the stone moves along a curve, creating half rings.

It is necessary to hold the block at the angle of the required sharpening. Thanks to a stone with a coarse grain, it will be possible to provide the required slope and width of the chamfer. The second side of the cutting blade is processed in a similar manner. At the next stage, sharpening occurs using a bar with an average grain size. Last of all, with the smoothest stone, all burrs are removed and all uneven fragments are corrected.

If everything is done correctly, the bevel will be evenly smooth tactilely. After straightening on a leather belt under tension, you can complete the job. Residual debris or dust can easily be removed with a piece of cloth. By the way, during the work, it is periodically recommended to moisten both the stones and the ax.

On a grinder

Specialized machines are usually used by professionals. In addition to the electric drive, they are equipped with a device that allows you to sharpen axes at a certain angle. Direct sharpening is carried out using an abrasive disc. Since the ax is mounted on a cylinder, it will not move from side to side and disrupt the workflow. In addition to the machine itself, for sharpening it is also necessary to prepare a hand sharpener with two sides, a marker, a polishing agent, an inclinometer, as well as the master's protection: gloves, glasses, closed clothes and shoes.

First of all, the chamfer is covered with a marker, then the ax is fixed on the machine. The point is brought to the grinding wheel, and the required cutting angle is selected using the sharpening angle. To check the circle, you need to turn it yourself and see if the paint has worn off where the blade and the stone came into contact. Ideally, they should disappear completely. When finished with the settings, you can turn on the sharpener. The chamfer is processed until all the irregularities disappear, and everything is brought to mind with a hand sharpener.

File

If you wish, you can also use a file to sharpen an ax with your own hands, having done everything on emery. Completing the task will require the following tools:

- rust converter;

- wire brush;

- sandpaper of three types (from hard to velvet);

- polishing paste;

- a piece of cloth;

- locksmith vice;

- files;

- measuring ruler;

- grinding wheel with two working sides;

- a fragment of technical wax;

- mineral oil for lubrication.

First of all, the blade is cleaned from the effects of corrosion and any contamination. Then sandpaper is passed over it. Further, sanding is carried out using a medium-grained sandpaper. The next step is polishing with a special paste. The ax is fixed in a vice or between the squares, with the help of a file, sharpening of the chamfer begins. The surface of the abrasive must be moistened with water.