Chainsaw chain sharpening methods

As stated above, there are several different ways to do this. The most popular are:

- file sharpening,

- grinder,

- electric machine

- and the so-called "manual" machine.

File

The file will do well with sharpening the chain

The file will do well with sharpening the chain

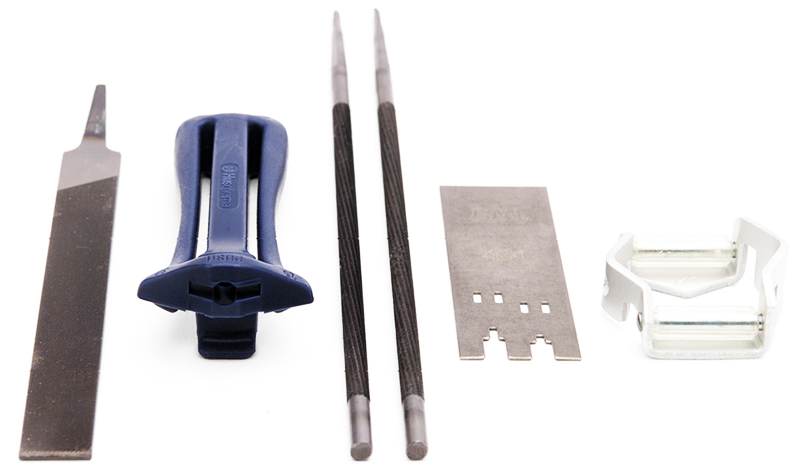

This type of sharpening is the simplest. This set includes a round and flat file, special tool holders, a gauge, a chip removal hook and more. And if the file sharpening tools may differ somewhat, they nevertheless have approximately the same logic and the same functionality.

The diameter of a round file is directly related to the size of the chain:

How to sharpen?

The sharpening process is divided into several stages:

Make sure the chain brake is on on the saw.

After that, you should firmly grip the tool in a vice.

The tooth from which sharpening was started should be marked with something so that you do not accidentally start sharpening the teeth again.

Before sharpening, pay attention to the special mark, with which the manufacturer indicated the maximum possible sharpening angle. Sharpening itself should be in the direction of the arrowheads.

In addition to the teeth, the limiter is also sharpened

This may become necessary over time as the sharpening reduces the height of the teeth. As a rule, the stop is sharpened after two or three sharpening of the teeth. If this is not done, then problems may arise while working with the tool.

Have you tried sharpening your chainsaw on your own?

There was a case!

Tips from experts

- In the absence of experience, it is best not to start with expensive chains.

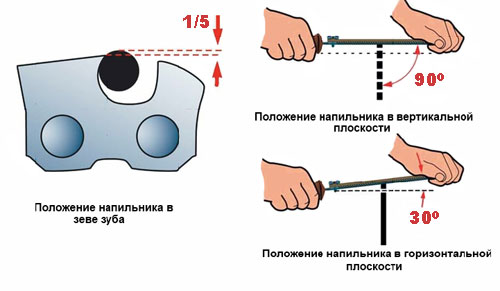

- Movements should be made only in one direction "away from yourself". Moreover, for each of the teeth, the same number of movements should be performed with approximately equal efforts.

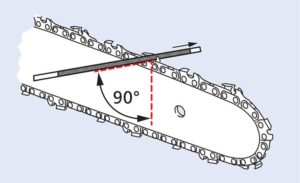

- For sharpening a vertical plane, the file must be located strictly at a right angle, and for sharpening a horizontal plane - at an angle of 20-30 degrees.

- If, before sharpening, it was found that not all teeth are of the same height, then the lowest of them becomes the guideline.

Pros:

Minuses:

Grinder

One way to sharpen your saw chain is with a grinder

One way to sharpen your saw chain is with a grinder

This method is not very well approved by professionals, since there is a high risk of damage to both the tool and the person who will directly sharpen the saw. At the same time, at first glance, many people like this method, but in practice everything is much more complicated than it seems.

However, the method is still valid.

- The chain must remain on the bar.

- A disc (preferably not new) with a thickness of one and a half to two millimeters is attached to the grinder.

- There should be a small obstruction in front of the chain and bar.

- The sharpening angle is the same as described in the first method.

- After the process, be sure to tighten the chain.

Professionals especially do not recommend this method to beginners, since there is a high risk of serious injury and injury.

Pros:

Minuses:

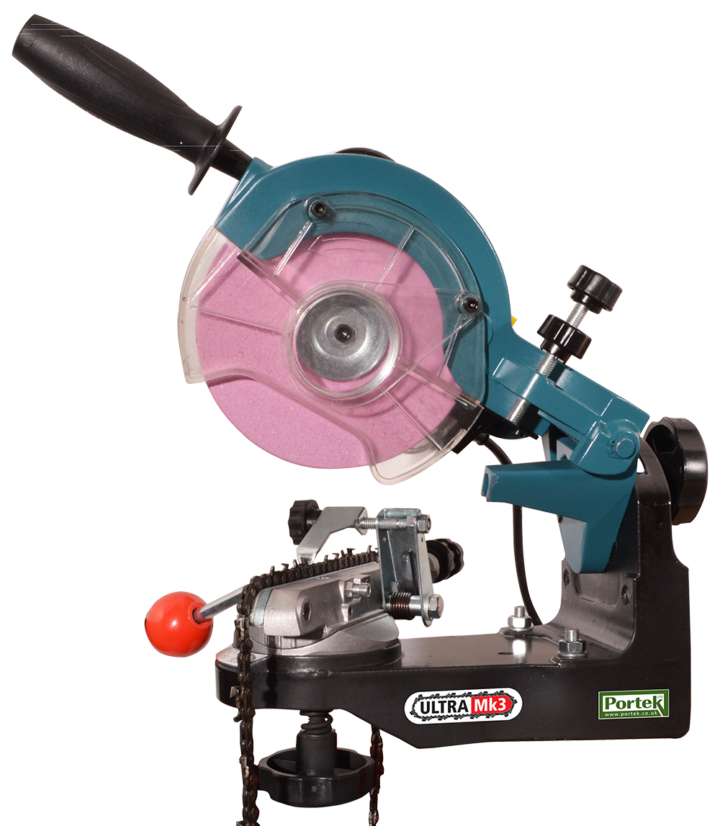

Electric machine

Electric grinding machines

Electric grinding machines

These machines are equipped with special functions for sharpening at a certain angle. Thanks to the machine, there is a guarantee that the disc will be brought to the chain with maximum accuracy and accuracy. There are also machines with special vices for clamping the chain. This method is most suitable for beginners, since convenience and safety are guaranteed. The cost of such a machine directly depends on its functionality.

Hand-operated machine

In appearance, the machine with a manual drive resembles a bow saw. Unless there is a file in the place where the blade of such a saw would be located.Such a machine makes it possible to sharpen and adjust the teeth of the chainsaw to the desired size. A mechanism is built into the machine, thanks to which you can build the desired size.

During the process, you need only two or three movements, after which you can move on to the next tooth. The same machine can also sharpen the limiter. The only difference is in the file itself, or rather, in its shape. Since when sharpening the teeth, a round file is required, and when sharpening the limiter, a flat file.

Pros:

Minuses:

Hand-operated machines

Hand-operated machines

Tips from professionals

- Before you start sharpening in any way, you need to turn on the saw for about a minute. This is done so that the lubricating oil gets on every part.

- Be sure to sharpen the chain from time to time and never put it off until later.

- Observe the chain tension during operation. If you find problems, you should immediately fix them. A loose chain is a dangerous object.

The above are the most common ways to sharpen a chainsaw. You should choose your own method based on skills, knowledge of safety rules and experience with the tool.

Sharpening signs

The first sign that a regular saw needs to be set and sharpened is to move away from the cutting line or clamp it in the material. A sharp chain saw allows for effortless cuts, while high heat combined with too small chips signals the need for adjustments. Experienced technicians can determine the need for sharpening by changing the sound.

Circular saws also heat up, build up carbon deposits and become more difficult to move.

The chain saw dulls extremely quickly after hitting the ground. Its further use leads not only to an increase in muscle effort, but also increases the load on the units of a gasoline or electric saw.

The chain may vibrate, fuel consumption will increase, and overall efficiency per unit of time will be significantly reduced. The detached shavings will resemble flour in size.

Deformation of the teeth can be determined visually. Thus, the urgency of the operation will be indicated by a general decrease in labor productivity, a decrease in accuracy, a change in the nature of the sound, rounding of the tops of the teeth, the withdrawal of the tool from the cutting line and the use of large physical efforts.

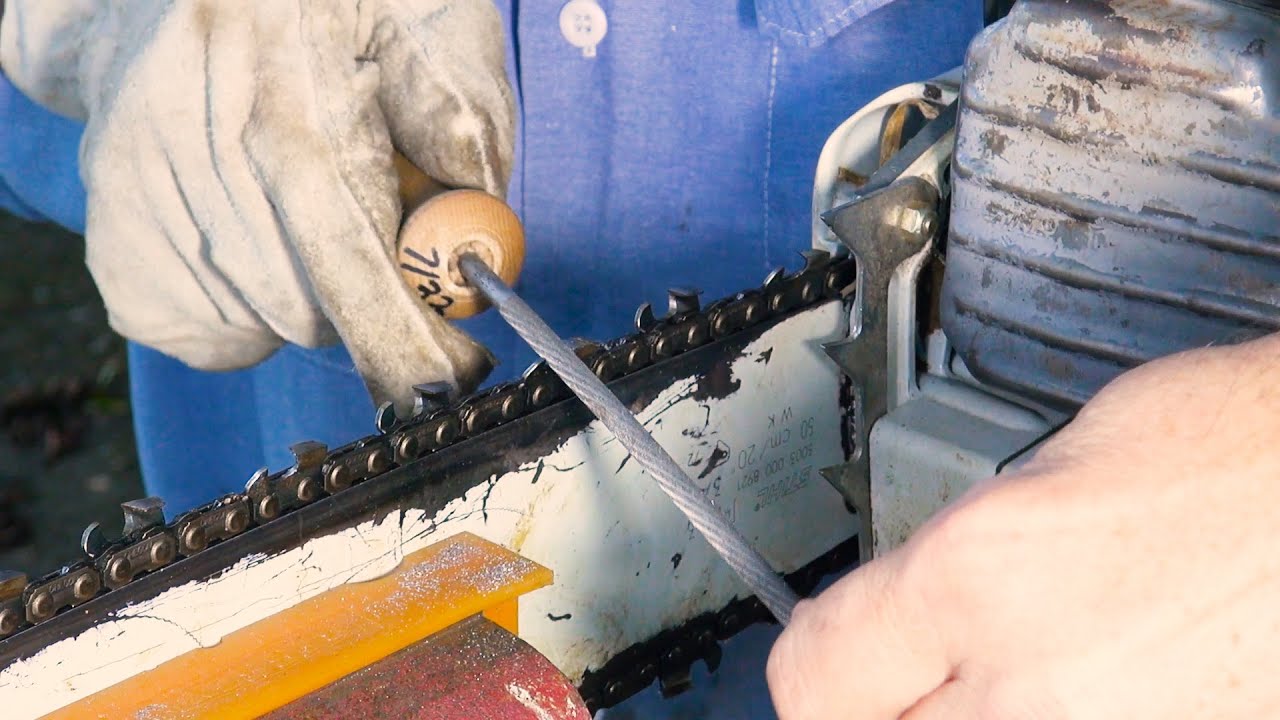

How to sharpen a chainsaw chain at home with a file

A tool with an exceptionally round section will help to properly sharpen the chainsaw chain with a file. File parameters are determined by the dimensions of the saw itself

It is important to know the pitch of the teeth. One round sharpener is not enough

For sharpening and dressing chains, two types of tools are used. The first is a file with a circular cross-section with a diameter corresponding to the diameter of the rounding of the working edge of the saw tooth. A flat file is required to cut the depth gauge on the guide tooth.

Sharpening can be done manually using a round file with a working diameter of 4 ... 5.5 mm

It is imperative that the tool is correctly positioned in relation to the tooth being sharpened. The upper edge of the working part of the file is located about a fifth above the upper edge of the workpiece

The tool is held perpendicular to the chain axis at an angle of 25º… 30º to the upper edge of the tooth.

For sharpening saw chains of household tools, round files with a diameter of 4 and 4.8 mm are used, since they have a small tooth. For professional models, use more powerful chains with a larger tooth. Therefore, files with a diameter of 5.2 and 5.5 mm are required.

You will need a flat file to sharpen the limiter, and a hook that removes the resulting sawdust to clean the work area. There are also commercially available special holders, on which the lines of the direction of movement of the file relative to the axis of the chain are graduated. The holder can be mounted on top of the tooth, resting on its upper edge.Since its height is adapted to a certain chain pitch, this device should be selected in relation to chainsaws of specific models and brands. The minimum required set in order to obtain the correct sharpening angle of the chain by hand is shown in the photo.

A set of sharpening tools and accessories

A set of sharpening tools and accessories

Manual sharpening saves material resources, allows you to work in the field. First, place the instrument on a level surface. If the work is done in the forest, trimming a large diameter log is a good choice. Next, you need to inspect the saw chain for any defects, it can be cracks, completely broken off teeth. After inspection, you need to set the brake in working condition, thereby blocking the movement along the chain bar, which must be tightened during sharpening with a file.

A file for sharpening chainsaws: types and tips for choosing

The diameter of the round file is selected according to the pitch of the saw chain. The pitch values of 1.3 and 1.6 mm correspond to files with a diameter of 4 and 5.2 mm. A flat tool will be required to reduce the height of the cutter link stops.

How to properly sharpen a chainsaw chain with a file

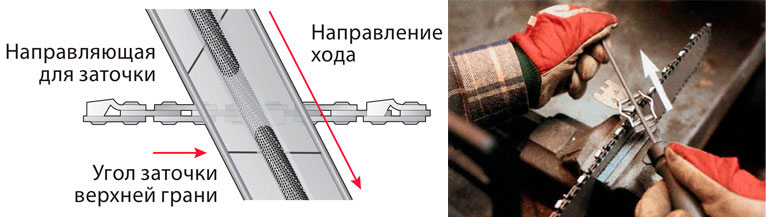

Templates and patterns must be fixed on the area to be treated. They will give the right direction to the file, making the process easier. When all the preparatory work has been done, you can proceed directly to sharpening the chain.

According to the rules, it is necessary to sharpen the teeth in one direction, then in the other. Work begins with light clicks with a file in the direction away from you, the pressure gradually increases. Reverse file movement - without pressing. The circular tool must be continuously rotated along its axis. The chain is sharpened by movements from the inside of the tooth to the outside. In this case, the file must be located parallel to a special mark on the chain, which is applied by the manufacturer to indicate the standard sharpening angle.

The sharpened tooth should be located approximately in the middle of the tire, this is necessary for ease of work. In the process of processing, you need to move the chain along the tire, not forgetting to set the brake to the working position every time.

The angle of inclination of the tool should be right, and the angle of sharpening of the chain of the chainsaw horizontally - sharp, while its changes are allowed in the range from 10º to 30º. The smallest tooth in the row should be taken as a basis. Turn the tire over and do the same job for the teeth that go in the opposite direction. The disadvantage of this sharpening method is the large time required.

Sharpening the chain with a file

Sharpening the chain with a file

You can insert a round file with a broken handle into the chuck of an electric drill or screwdriver. You will get a very convenient mechanized sharpening device.

Sharpening the chain with a drill and file

Sharpening the chain with a drill and file

How to sharpen a chain saw with your own hands?

To sharpen the saw body of an electric garden saw evenly, the owner has 3 options. The first method is manual. It consists in the use of two files - a round and a flat one, as well as the holder required for fixing a round-shaped tool. The round file must be matched to the chain pitch - the larger the pitch, the larger the diameter of the file used. A flat file is required to process the stopper, so it can be of any size.

The procedure for sharpening the chain with files is as follows:

- First, the holder with the round file previously fixed in it must be installed on the cutting chain of the electric saw. Arrows are marked on the bar, which should be parallel to the guide rail;

- Next, you need to check the sharpening angle. After making sure that the upper blade of the cutting tooth of the chain is located at an angle of 25-30⁰, you can start sharpening;

- Operator movements should be uniform and directed only forward.Each of the cutting teeth of the chain must be cut the same number of times.

The second method of sharpening the cutting bodies of an electric saw is to use a set of files and a special template. The required parameters are already marked on the template: angles of inclination and processing of teeth. In addition, sharpening the saw chain using a template allows the stop tooth to be machined evenly.

The second method of sharpening the cutting bodies of an electric saw is to use a set of files and a special template. The required parameters are already marked on the template: angles of inclination and processing of teeth. In addition, sharpening the saw chain using a template allows the stop tooth to be machined evenly.

During the restoration of the cutting teeth, the template is alternately applied to each of them. It is equipped with moving rollers on which the file slides when working with the chain. At the same time, the sharpening angle is not disturbed, which makes the restoration of each tooth uniform.

The only drawback of this method is the need to use a separate template for each specific type of cutting body, taking into account the chain pitch, the width of its shank, the leading link and other parameters.

The third sharpening method is using an electric machine. This option is considered the simplest, fastest and most convenient. Most machines are supplied complete with metric and graduated scales that allow you to restore almost any chain, regardless of its pitch and number of links.

The use of an electric machine is suitable for people who regularly cut wood and cut logs. In other cases, it is impractical to buy specialized equipment.

The use of an electric machine is suitable for people who regularly cut wood and cut logs. In other cases, it is impractical to buy specialized equipment.

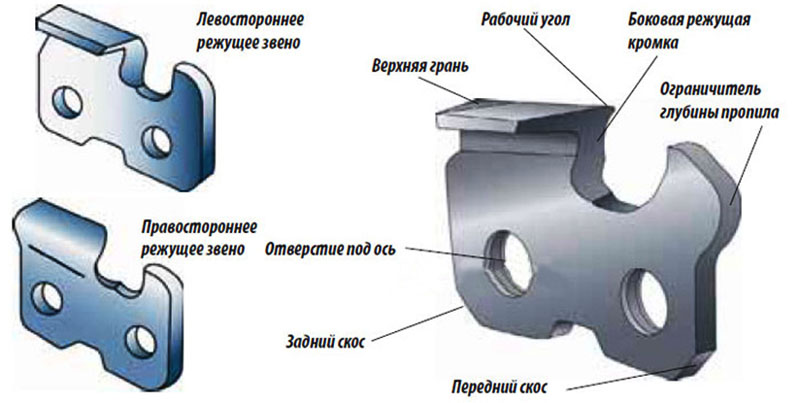

Geometry features

In order to sharpen correctly with your own hands, even if a machine is used, you should know the geometry of the tooth. Its constituent elements include:

- Scapula.

- The main link.

- Depth stop.

In this case, the scapula of the tooth consists of the following elements:

- End blade.

- Upper blade.

Sharpening correctly with your own hands is necessary, taking into account that the end and top blades must be located correctly relative to each other to ensure the best cutting performance. The back of the tooth forms a certain angle of the upper blade. A similar angle is formed to cut the blades into the material. Do-it-yourself sharpening should also take into account the fact that the back of the blade has a narrowing - this design feature forms the angle of the end blade. It is created to provide side cutting of the chips.

Chainsaw chain tooth

The sliding surface and the blade end form the rake angle. In this case, the angle has a fixed value, it varies from 60 to 85 degrees. If you sharpen the teeth with your own hands, it is worth considering that it is the upper blade that is the main one, and the angle formed by it is the most important angle. that the sharpening angle may vary depending on the application. The main rule that should be observed if you sharpen a tooth with your own hands is the following: the higher the angle, the greater the performance of the chainsaw, but a decrease in the indicator provides a smoother blade movement, reduced vibration and increased service life. Sharpening is worth considering that the indicator should be in the range from 25 to 35 degrees. An exception can be called the version of the blade, which is designed for longitudinal cutting - many manufacturers of the cutting element of the chainsaw can withstand 10 degrees.

How to sharpen correctly?

The tool sharpening process is quite simple. The blade is clamped in a vice and the teeth are sharpened alternately. First, this is done on one side, and then, turning the canvas over, the manipulations are repeated. Movements should be extremely accurate and monotonous.

Sharpen the saw from the inside towards the set

Naturally, in this case, it is necessary to observe precautions by wearing special gloves. The result is recommended to be assessed using the "control sawing"

The difference "before and after" should be significant: the resulting cut is smoother, much less effort is made.

Each saw tooth can be viewed as a small knife, and in the case of a chain saw, as a small plane that enters the material at different angles depending on the technological purpose of the tool.

Teeth can be straight and oblique, trapezoidal or conical. Oblique - the most common, conical, as a rule, perform auxiliary functions, in particular, they are used for cutting laminate.

Before sharpening round discs that are used for working on aerated concrete, you need to clearly understand what kind of alloy we are talking about. Not every abrasive material will cope well with the task: the harder the metal, the more difficult it is to sharpen it.

The wear of the stone and the cleanliness of the processing depend on the conformity of the abrasive material to the metal, including the grain size. When using machine tools, the speed of rotation also affects the efficiency of sharpening.

Electric saw

An electric or gasoline chain saw uses the chain as a contact cutting surface. It is sharpened in workshops using industrial equipment or do it yourself using a template. In the latter case, round (cylindrical) files with a small diameter are used, which are selected depending on the marking of the sharpened product.

In particular, the Stihl MS brand chain from 180 to 250 will require a file with a diameter of 4 millimeters, for MS 290 and further up to 440, a tool with a diameter of 5.2 millimeters is needed.

The round file only moves forward and nothing else. Direction perpendicular to the chain plane. In addition, when sharpening the chains, a flat file and a template are also used, after installing the template on the tooth, the cutting surface is sharpened.

Before starting work, the tire is clamped in a vice. However, the use of the machine in such a case is still preferable, although there are opposite opinions. If the wear is small, the matter can be corrected in manual mode, but one should not forget about the geometry of the cutting part.

With heavy wear, machine tools are necessary. Sophisticated equipment has a tuning system that allows it to work automatically.

It must be borne in mind that different chains differ in the shape of the teeth, so the tool used must correspond to this.

For manual sharpening of chain saws, the tool is sold in sets. Choosing it, you need to understand well which chains will have to sharpen. If, in the course of solving a problem, you have to choose between engine power and chain sharpness, the latter should be preferred.

By wood

Any wood saw works very efficiently if it is regularly checked and sharpened. A manual model can be sharpened by hand.

The machine is a good solution, however, if only a manual version is possible, the procedure will look like this. First you need to fix the product on a stand that will rotate. Mark the corners with a marker. The template can be a standard disc, taken "on the side" or previously purchased in pairs. If there is none, you will have to take care of your own hardboard template in advance.

Framed

The gang saw is a tool commonly used in sawmills. It serves for longitudinal cutting of wood into boards and beams. Its peculiarity is that the saws are rigidly connected in the form of a frame.

The undoubted advantage of the design is its high performance. When sharpening, it is necessary to take into account the parameters of the teeth, which are usually selected for interaction with a specific material.

Sharpening gang saws is considered to be more difficult than conventional similar tools for wood.

The width of the set of teeth for sawing fresh coniferous wood should not exceed 0.8 millimeters, the same figures for oak or beech - 0.6 millimeters. The operation is carried out in an industrial way, the grinding material is corundum.

At the end of the work, grinding is carried out.Sharpening gang saws is more difficult because the thickness of the material to be ground is not the same for different teeth. Both the front and back of the teeth are ground.

How and how to sharpen the chain teeth

The saw chain teeth are irregularly shaped. They consist of a base, a blade and a depth gauge. At the same time, the blade has a vertical blade and a horizontal blade that falls at an angle. It is thanks to these blades that the chainsaw cuts wood. They work on the principle of a plane, cutting off pieces, and the limiter regulates their thickness (the difference in height between it and the horizontal blade will be the thickness of the chips). You can sharpen the chainsaw chain manually or using a machine.

Sharpening kits

One of the most common methods is with a set of round and flat files, a holder, a stop template and a hook used to remove sawdust. For the correct positioning of the holder, special markings are applied to it, allowing you to determine the correct angle for sharpening. It is installed on the upper part of the tooth and the stop, while the round file remains under it and is located just next to the blade. Thanks to the holder, the file is at the correct height, or more precisely, protrudes 1/5 above the blade. For sharpening the cutting tooth, only round files are used, since the contour of the tooth has a rounded shape.

Before you start sharpening the chainsaw chain at home, the tire must be secured in a vice or with a clamp, the main thing is that the saw does not move during processing. Having installed the holder according to the markings, begin smoothly and without too much pressure, move the file strictly away from you 2-3 times. Similar actions are repeated with all other teeth. The file must be turned over from time to time so that there is no one-sided wear. The force of pressure and the number of movements for all should be the same, this is necessary for uniform sharpening of all teeth. If they are different, then cracks can form in the chain, which will lead to its breakage.

They start sharpening from the smallest tooth so that the length of all the others is the same with it. After the work on the processing of the blades is finished, proceed to the limiters. A template from the kit is installed on top of the chain in such a position that the stopper is in the hole. The protruding part is grinded with a flat file.

On this topic:

BACK

FORWARD

1 of 27

The video shows an example of how to sharpen a chainsaw chain with a file:

There is another set, which, instead of a holder, has one template, both for sharpening the blade and for grinding the stop. Install it so that the chain falls into the holes. Then the round file is placed on top of the rollers and fed under the blade. During sharpening, make sure that it is always parallel to the lateral edges of the template.

There are 2 separate holes for the stopper, labeled Soft for soft wood and Hard for hard wood. The protruding part from the slot is grinded with a flat file.

PowerSharp System

This system allows the chain to be sharpened in seconds without even removing it from the bar. Includes PowerSharp chain, abrasive bar, guide bar and sharpener. In order to sharpen the chain with them, you will need to take the following 3 steps:

- install the PowerSharp bus and chain;

- fix the bar inside the sharpening device, after which it is installed on the tire;

- the end of the chainsaw is pressed against an object and started for a couple of seconds.

Manual and electric machines

If the teeth are severely worn away and the cutting blade has lost its shape, it will take a long time to align them by hand. In this case, a manual machine or an electric one with a sharpening wheel is usually used. The first type of device looks like a bow saw with a round file. The machines are stationary and mobile, which can be installed directly on the tire.

To adjust the necessary parameters, start with the smallest tooth.After all the teeth are sharpened and aligned, the round file is replaced with a flat file to sharpen the stops.

The advantage of electric machines is that the disc is fed directly under the sharpened blade. In addition, the quality of sharpening in this case is guaranteed and all teeth will be the same size.

The video below shows an example of sharpening a chainsaw with your own hands using an electric machine.

The sharpening angle can be changed - it depends on the purpose of the application. A smaller angle is used for sawing hardwood, and a larger one for soft. In any case, it should be between 25 ° and 35 °. The 10 ° angle is used for chains intended for longitudinal cutting.