Introduction

Professional sharpening of circular saws is carried out as on a specialized machine, according to a given program. The entire technological process can be either from the beginning of sharpening to the end automatically or semi-automatically. The operator only prepares the workplace, puts the discs into the washer and fixes them on the machine bed. The robot manipulator performs the rest of the operations itself. Very convenient and efficient. After such a repair, the blade looks like new and continues to perform well without losing its performance during the sawing process.

The question will follow - where to sharpen a circular saw with victorious soldering, which workshops work in the region? I do not provide any advertising, all information is provided for informational purposes only and to help you. I ask you to ask all questions by contact information or in personal messages on the blog.

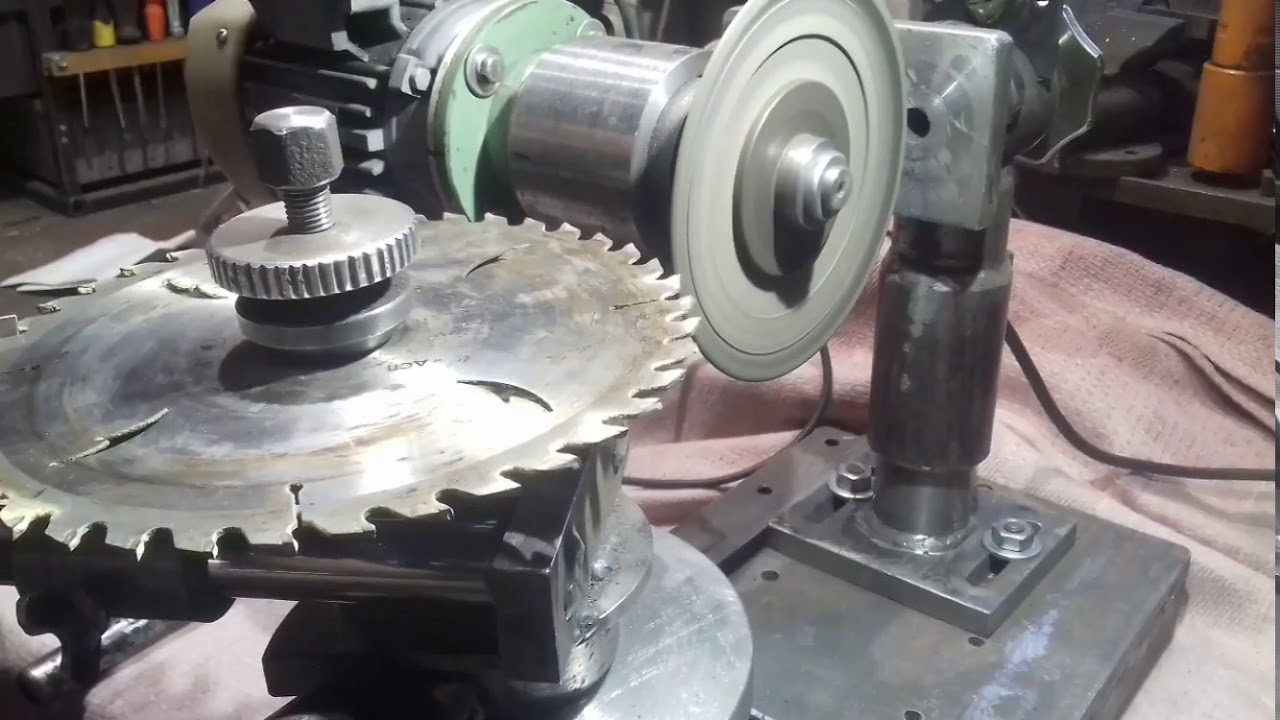

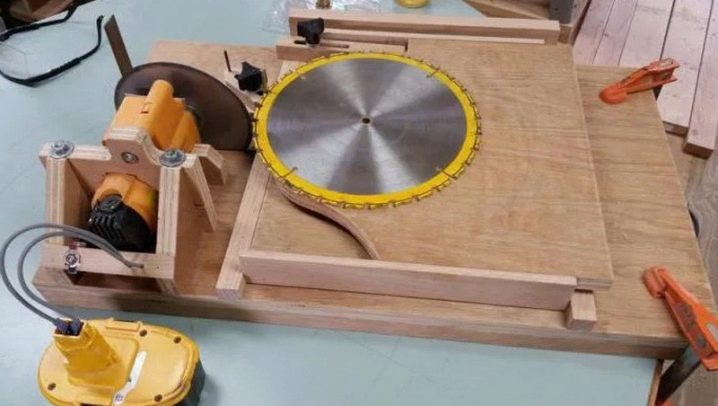

This is what a specialized workshop with equipment looks like.

Before the operator starts work, he must make a preliminary diagnosis of your discs, as well as check the wear and runout of the disc. Only after carrying out these measures is the sharpening program of the circular saw with victorious solders selected, if any.

Drank varieties

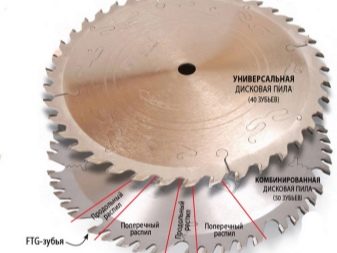

If the disc is correctly sharpened and the teeth are set according to the template, then it can process the workpiece in any direction relative to the wood fibers.

There are such types of tools:

- saw with carbide discs;

- discs made of solid metal;

- discs with hard-toothed teeth;

- discs with heavy-duty brazed teeth.

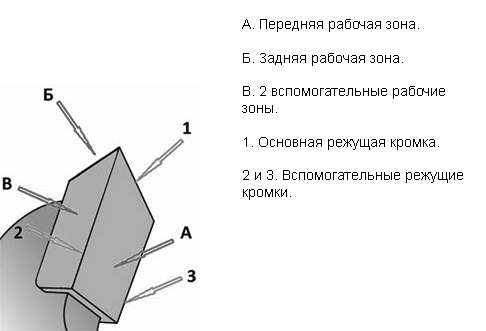

Hard woods are processed with discs that have special grooves. Technological breaks prevent deformation of the tool, do not allow it to overheat during the production cycle. And also vibration, noise background is significantly reduced, the quality of the line formed by the cut is improved. The saw has teeth that are cut at a certain angle, each tooth has several cutting edges.

There is a main edge, additional ones mate with it, and intersecting planes are formed:

- A;

- V;

- WITH.

The planes themselves also vary in different mates.

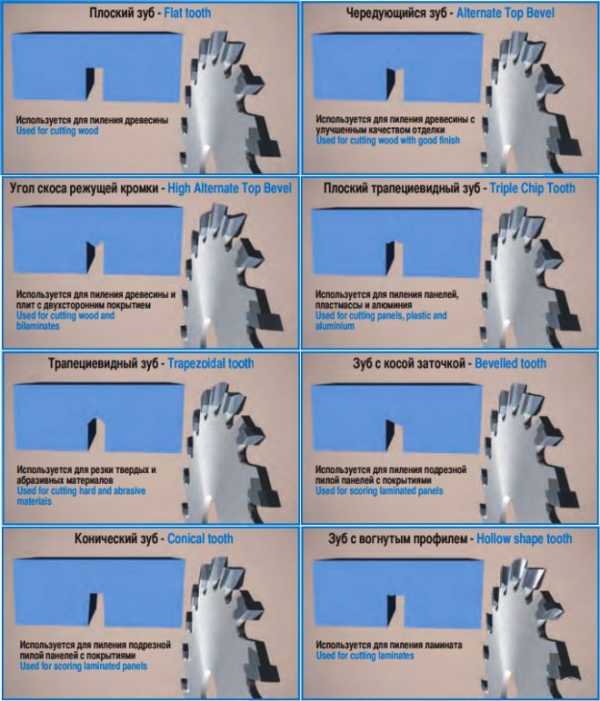

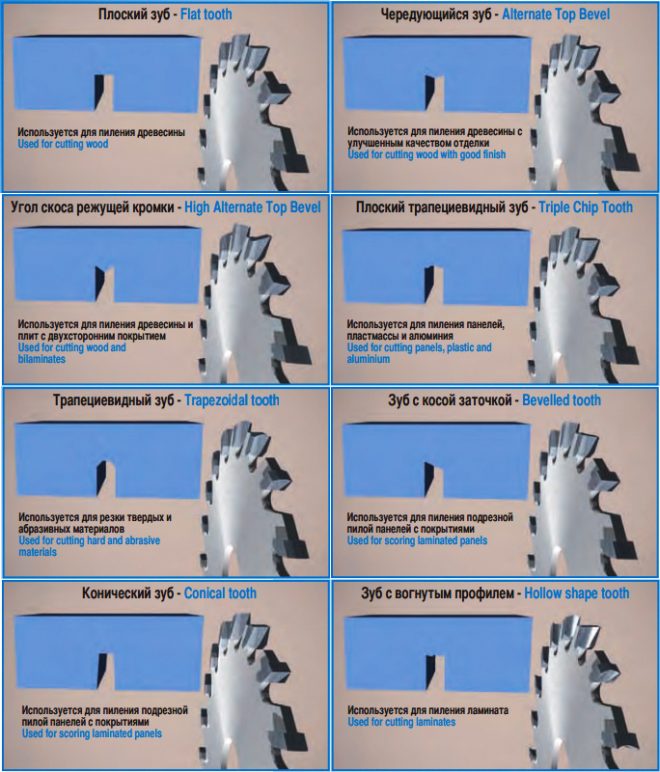

The teeth can be straight and are usually used for pre-cutting the material. These teeth provide a low cut. However, the performance of such teeth is quite high.

Beveled teeth provide a more accurate line and are suitable for materials such as:

- plywood;

- PVC sheets;

- Chipboard;

- Fiberboard.

The teeth provide a smooth cut without crumbling the material.

There are also discs in which there is a bevel at the leading edge of the cutter, there is also a bevel with a trailing edge. Variants of alternating different teeth with different bevels are possible. Such tricks ensure a clean cut, but remember: the denser the material, the faster such teeth become blunt.

Trapezoidal tooth - This tooth configuration ensures long tool life. A complex design is often used when trapezoidal and straight teeth alternate. The second ones carry out the primary cut, which makes it possible for the straight teeth to "polish" the cut produced.

Cone-shaped tooth - these teeth are auxiliary and are designed to work with materials on which a laminated surface is present.They ensure a correct cut without any chipping.

Sickle-shaped tooth - in this case, the teeth are bent, which makes it possible to accurately cut the material across the wood fibers.

Required tools

With your own hands, discs for a circular plate can only be sharpened with special tools. There is also a machine that allows you to automate the process and make it more efficient.

To carry out work on sharpening a disc with your own hands, you can use the following tools:

- assembly vise;

- file;

- block of wood.

It is also possible to use a circular saw sharpener, which does not require the above tools.

When do you need to rebuild your circular saws?

Quite an important issue can be called the determination of when the sharpening of circular saws should be carried out. Heavy wear and tear can lead to the inability to carry out such work. There are three clear signals that determine the need for sharpening the circular saw blade:

- The appearance of smoke, heating of the protective casing. The device usually has a special protective cover that can get hot if the disc is dull. It should also be noted that in special cases the appearance of smoke occurs due to the strong heating of the cutting zone.

- Also, with a mechanical feed, when the pressure is adjusted by hand, great effort should be made to obtain the desired result.

- When processing wood or other material, traces of carbon deposits and a corresponding odor appear in the cutting area.

In the above situations, it is recommended to sharpen the circular saw blade.

Do-it-yourself sharpening at home

Figure 4. In order for the sharpening to be correct and fast, the disc should be well secured.

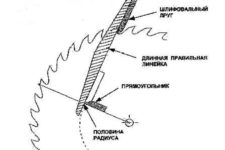

You can also sharpen the saw at home. To do this, it is not necessary to have a specialized grinding machine in your own workshop, which costs a lot of money and is rarely used for its intended purpose.

But just holding a disc in your hands and sharpening teeth on a grinding wheel is irrational. No amount of hand hardness and an excellent eye gauge is enough to make the cutting element flawlessly sharp and suitable for efficient work. For this purpose, care should be taken to manufacture the simplest fixing device (Fig. 4).

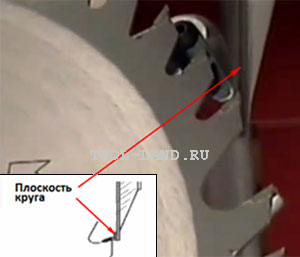

Its surface should match the level of the sharpening wheel axis. The toothed wheel itself is placed on a stand so that the sharpened planes of the teeth are perpendicular to the saw blade. For sharpening beveled teeth on the front and rear surfaces, the specified device is made with a movable hinge.

However, in this case, it is difficult to maintain the same size of the front and rear sharpening angles. To eliminate this problem, the center of the saw blade is rigidly fixed in the desired position in relation to the abrasive disc. This is done either with the help of a groove for the mandrel, which is mounted on a stand to place the sharpened saw on it, or by installing special stops on the stand that fix the saw blade at the required angle to the grinding wheel.

If you fulfill all the requirements for the sharpening technology of carbide circular saws, then they will serve a person for a long time and effectively.

Sharpening of circular saws is a mandatory measure during the operation of this equipment. Woodworking requires the craftsman to have tools with appropriate cutting properties at his disposal. Like chainsaw sharpening, circular saws require extra attention. If the shortcomings are not eliminated in time, over time the tool will begin to blunt much faster.

How to sharpen: basic methods

There are two methods available for sharpening circular saws - manual and machine.In order to sharpen the disc correctly at home, you need to take into account some of the nuances.

Manual way

Special saw blade sharpening machines are rarely used in a domestic environment, because their cost is high. Therefore, in the absence of such a device, you can cope with sharpening with improvised devices, for example, a grinder. In this case, it is forbidden to hold the circle in your hands without fixing it with anything. Otherwise, it will not be possible to achieve a sufficient cutting angle for further work with the material.

To securely fix the circle in the correct position, use a flat stand.

Some features:

- the surface of the stand coincides with the level of the axis of the grinding wheel;

- on it, the gear wheel is placed in such a way that the sharpening plane becomes perpendicular to the saw blade;

- the design of the device is complemented by a swivel joint.

The stand will help to comfortably position the saw blade for processing against the abrasive material. Before starting work, clear markings are carried out. For this, a colored marker is used. They draw lines that will allow them to sharpen the element at the desired angle. The vise will help secure the disc to the surface.

Video of sharpening a circular saw blade with a grinder:

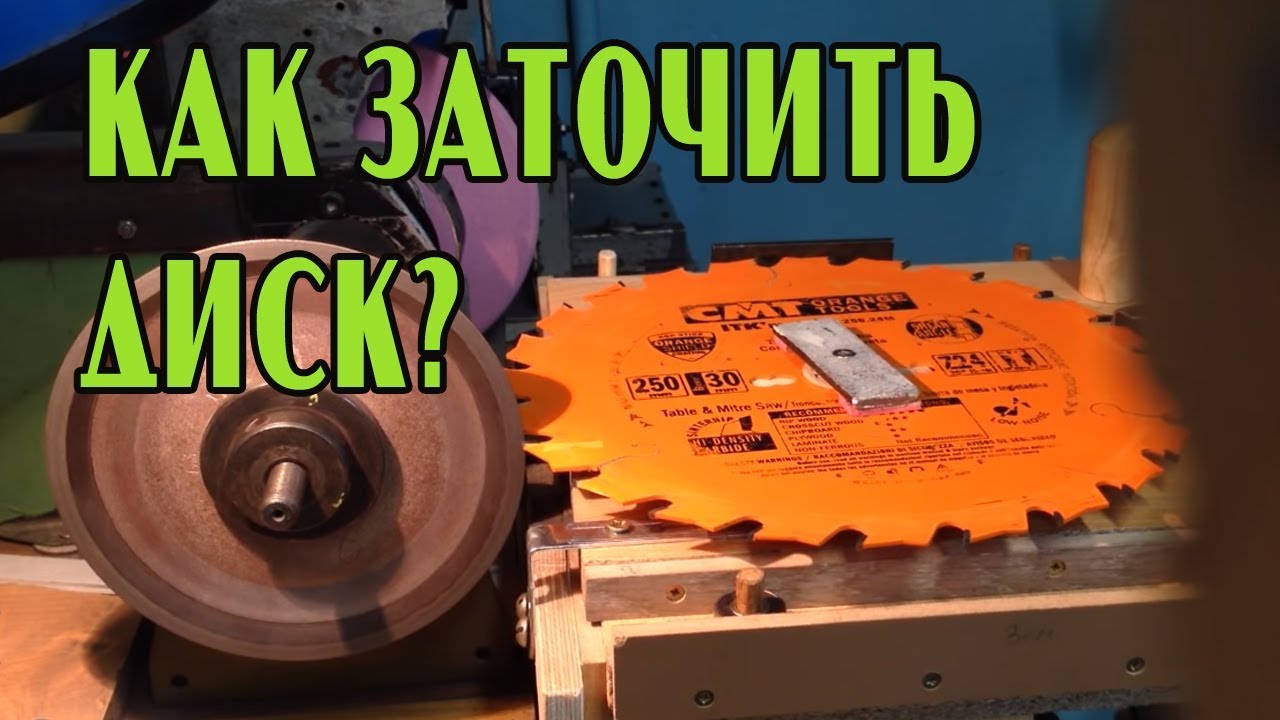

Using a machine

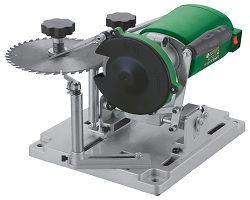

When the craftsman has access to a special grinding machine, the elements are processed quickly and efficiently. This device is small in size, so it is comfortable for a beginner to work with it. There will be no problems even when used in a domestic environment.

When buying such a device, they look at the abrasive wheel. To select it, certain nuances are taken into account:

- It is best to purchase a wheel made from diamond-coated CBN or green silicon carbide;

- If the carbide wheel is sharpened, problems may arise even with the machine tool.

The very process of using a sharpening machine is extremely simple. The operator should comfortably position the disc on the device and clamp it using the special retainer. Before starting work, it is recommended to mark the first tooth with a marker. This will help you avoid getting tangled while sharpening and not checking teeth that have already been cut. To select the sharpening angle, a special meter is provided on the device. The required angle should be set on it, after which the device will complete the task on its own.

The circular saw is a useful tool that you cannot do without during construction. It helps to make cuts in surfaces, as well as change their shape and size. For sharpening discs, use special machines or materials at hand. It is not so difficult to do the work with your own hands, you need to adhere to the listed recommendations and not be afraid.

Sharpening a disc with victorious solders:

Determination of the degree of wear and the angle of sharpening

Circular saws, sooner or later, lose their performance characteristics during operation, it is possible to effectively extend the service life of the tool if it is properly sharpened again. This operation is simple, in many cases you can do the work yourself.

First of all, you should have an idea: what parameters does the working disk of the unit have?

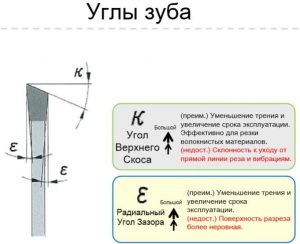

The second most important parameter is the sharpening angle, what parameters does the tooth itself have

Before you start working, you should test the tool, understand how relevant its recovery is. The disc should be inspected by removing it from the machine. An important indicator is the change in size, this can be seen even with a cursory examination.

The knobs themselves are made of ultra-strong steel of the brand:

- 9HF;

- 50 HVA;

- 65G.

And also some other grades of steel are used.

This material stands out for its strength and wear resistance, but it also requires preventive treatment.

The teeth themselves have a standard prescribed in GOST 9768-78, however, each manufacturer has a differentiation in the angles of inclination and shape.

In the absence of a template, it will be necessary to determine the parameters of the teeth yourself. For this there is a tool - a pendulum goniometer. With this tool, you can precisely align the sharpening angle.

Another option is to take a new disc and use it as a template. You should take a sheet of thick cardboard, draw precise outlines on it with a pencil. Then, using a pendulum angle meter, the exact configuration of the soldering should be established. It is recommended to save this sample, it will be possible to work with it in the future, using it as a reference.

After the end of the work, it will be necessary to test the obtained sample by comparing it with the standard. The angle of inclination in such saws ranges from 15 to 25 degrees.

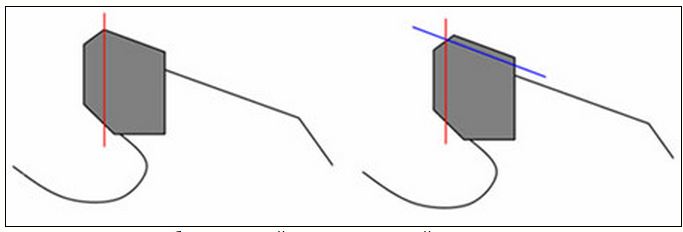

Consider when starting work: the rake angle can be negative. Such models are used for working with PVC sheets, as well as with soft metals.

The need for a procedure

Circular saws are needed both in private households and in production. When building a house, creating furniture, cutting boards, beams - a similar tool is required everywhere. Sharpening a circular saw correctly requires practical skills and knowledge.

Circular saws compare favorably with other cutting tools:

- chain;

- saber;

- longitudinal.

Disc circular devices have significant performance, and their service life is also much longer. Sharpening circular saws is an important necessary step; without it, the tool will not work fully. Thanks to the various carbide-tipped nozzles, as well as victorious coatings, cutting can be carried out both with wood and with metals.

To sharpen discs with different attachments, special equipment is required. If the processing of the disk is done "according to science", it will greatly extend its service life.

Timely sharpening of circular saws is performed with several obvious signs.

- The engine begins to experience unnecessary stress. The reason is simple - the teeth are dull, and additional resources are required to process the material. There is a danger: if the disk is damaged, if the engine shutdown relay is missing, the machine may fail.

- If chipping and chips form on the cut, and the cut itself becomes too wide, then this is a sure sign - the tool should be repaired.

- An extraneous smell of burnt material appears, and dark spots are also visible on the cut line.

- The time it takes to process the part increases.

How to sharpen: basic methods

There are two methods available for sharpening circular saws - manual and machine. In order to sharpen the disc correctly at home, you need to take into account some of the nuances.

Manual way

Special saw blade sharpening machines are rarely used in a domestic environment, because their cost is high. Therefore, in the absence of such a device, you can cope with sharpening with improvised devices, for example, a grinder. In this case, it is forbidden to hold the circle in your hands without fixing it with anything. Otherwise, it will not be possible to achieve a sufficient cutting angle for further work with the material.

To securely fix the circle in the correct position, use a flat stand.

- the surface of the stand coincides with the level of the axis of the grinding wheel;

- on it, the gear wheel is placed in such a way that the sharpening plane becomes perpendicular to the saw blade;

- the design of the device is complemented by a swivel joint.

The stand will help to comfortably position the saw blade for processing against the abrasive material. Before starting work, clear markings are carried out. For this, a colored marker is used. They draw lines that will allow them to sharpen the element at the desired angle. The vise will help secure the disc to the surface.

Video of sharpening a circular saw blade with a grinder:

Using a machine

When the craftsman has access to a special grinding machine, the elements are processed quickly and efficiently. This device is small in size, so it is comfortable for a beginner to work with it. There will be no problems even when used in a domestic environment.

When buying such a device, they look at the abrasive wheel. To select it, certain nuances are taken into account:

- It is best to purchase a wheel made from diamond-coated CBN or green silicon carbide;

- If the carbide wheel is sharpened, problems may arise even with the machine tool.

The very process of using a sharpening machine is extremely simple. The operator should comfortably position the disc on the device and clamp it using the special retainer. Before starting work, it is recommended to mark the first tooth with a marker. This will help you avoid getting tangled while sharpening and not checking teeth that have already been cut. To select the sharpening angle, a special meter is provided on the device. The required angle should be set on it, after which the device will complete the task on its own.

The circular saw is a useful tool that you cannot do without during construction. It helps to make cuts in surfaces, as well as change their shape and size. For sharpening discs, use special machines or materials at hand. It is not so difficult to do the work with your own hands, you need to adhere to the listed recommendations and not be afraid.

Sharpening a disc with victorious solders:

The disc tool for sawing wood is always useful in construction. The circular saw is convenient in that it allows you to quickly cut the material with minimal effort and time. As for the quality of the cut, we can say that it is perfect, but only when the saw is in good working order and well sharpened. Otherwise, it is even dangerous to work with such a tool, therefore, you should sharpen the circular saw.

It is not difficult to determine the need for a sharpening operation: a blunt tool cuts the workpiece poorly, which immediately catches the eye. There are two options here: either send the disc to the workshop, which is not always profitable in terms of time and money, or sharpen the circular saw with your own hands. This may seem daunting at first glance. But if you delve into the essence of the saw device in more detail, it will not be difficult to perform maintenance of the tool at home.

Expert advice

Experience is a useful thing, thanks to which you can avoid a number of mistakes that are common for beginners.

Therefore, paying attention to the advice of specialists is very useful if you want to achieve a positive result for yourself when turning a circular saw

- Always use safety glasses. For some reason, many ignore this rule, which is why the masters themselves suffer later. Therefore, before starting sharpening, be sure to put on all the necessary protective equipment;

- Do not try to remove more metal than is required. Remove just enough to remove any cracks, burrs, and unevenness;

- During turning, be sure to keep the disc in a constant position;

- If the disc has not been sharpened for a long time, you will have to remove a larger layer of metal;

- Observe the identity of all teeth in shape and height.

Initially it seems that sharpening is a technologically complex process. But with a little experience, you will be able to easily sharpen the circles of circular saws.

It is most convenient to sharpen on a special production machine. However, many home craftsmen make their own design for this purpose, which significantly saves time and money.

Saws made of high-quality materials are less blunt, which means they rarely need sharpening. However, if the discs are made of low-quality material (and this happens quite often, and even an experienced craftsman can not always "by eye" determine the quality of the metal), most likely, they will have to be sharpened often.Therefore, any DIYer who uses a circular saw should know how to sharpen it.

The ways

You can sharpen the tool with your own hands (if it does not have a winning coating) at home on your own. And also in such cases, you can use a simple machine on which you can successfully sharpen any edges.

It is very important to choose the right circle.

They are of the following types:

- corundum;

- diamond.

Grinding equipment for soldered discs is not cheap and can only be found in specialized technical centers.

Recovers to move the sharpening independently:

- it costs extra work;

- manual movement accuracy will be poor;

- if there is no skill in sharpening circles, then it is recommended to contact the professionals.

There are rules:

- the main defect occurs on the edge from above, that is, the edges are rounded within 0.11-0.31 mm - this is the starting point from which sharpening should be started;

- both the front and rear parts should be processed, this should be done at least 26 times;

- the size does not exceed 0.051-0.151 mm;

- front and back faces are processed identically;

- after the end of the cycle, the finishing process should be implemented, that is, clean the surface with "zero" sandpaper.

The work on creating a new configuration requires adherence to regulations and has its own complexity.

- Read the requirements, in particular, check the number of revolutions. It is clear that for metal this figure will be noticeably lower. Wooden elements are processed at a high speed.

- The material from which the solders are made can withstand heavy loads, its service life is significant, but even it sooner or later gets defects, chips and cracks appear.

- A sure sign that the material is beginning to "get tired" is the appearance of micro-burrs and roughness on the surface. After a while, defects will appear in these places.

To correctly implement sharpening, you should know what teeth are:

- straight;

- a bevel tooth from the back;

- trapezoidal;

- in the form of a cone;

- concave.

How to sharpen:

- clean the disc thoroughly using alcohol or chemicals;

- all work planes are processed;

- removing metal is permissible 0.051-0.151 mm;

- sharpen, perhaps no more than twenty-five times;

- you can sharpen with a special file, if there is practical experience;

- It is recommended to sharpen carbide teeth on separate equipment;

- victorious solders can be "taken" only using a special machine, in which there is a diamond wheel.

There are several types of tooth settings.

- Wavy, each tooth is straightened at a certain angle of inclination, thus, a semblance of a wave appears.

- Protective, two teeth have tilt angles, the third tooth is present without tilt. This method is effective even when working with mahogany and oak.

- The classic, when the teeth are variable - the angles of inclination to the left and right.

- Frontal.

- Rear.

- A slope is made at the frontal plane.

- A slope is made at the back plane.

There is one more parameter - this is the angle of sharpness, but it usually "works" as an additional tool.

For manual sharpening you will need:

- wooden blocks (2 pieces measuring 52x32 mm);

- drill, screwdriver;

- screwdriver crown;

- a hacksaw for processing ceramics;

- marker;

- ruler;

- screws or screws.

The surface of the stand is the same as the surface of the disc. The circle lies on a stand, the sharpening plane should be at an angle of 90 degrees to the saw blade. Such a simple device is equipped with a swivel unit. This secure fixing allows all the teeth of the tool to be machined evenly. With the help of a marker, you make markings, which makes it possible to correctly determine the angle of inclination.

The main sharpening angles of circular saws

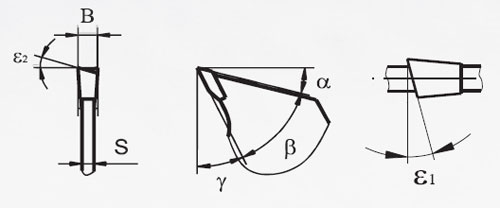

The circular saw tooth, which is usually made of carbide metal, has a complex structure.It has three cutting edges as standard, so you need to sharpen the teeth so as to sharpen these edges. But the main thing when sharpening is to observe the angles at which the planes of the tooth diverge from the edges, and the angles of attack between the plane of the tooth and the workpiece. The last point is important to maintain the performance of the saw blade.

The front face, the one that first cuts into the workpiece in the direction of the saw movement, forms the main cutting edge with the rear face. The angle at which the leading edge meets the material is called the Y-angle (angle of attack). The angle between the back face and the front face is the taper angle. If you subtract the rake angle and the taper angle from 90 degrees, you get the clearance angle.

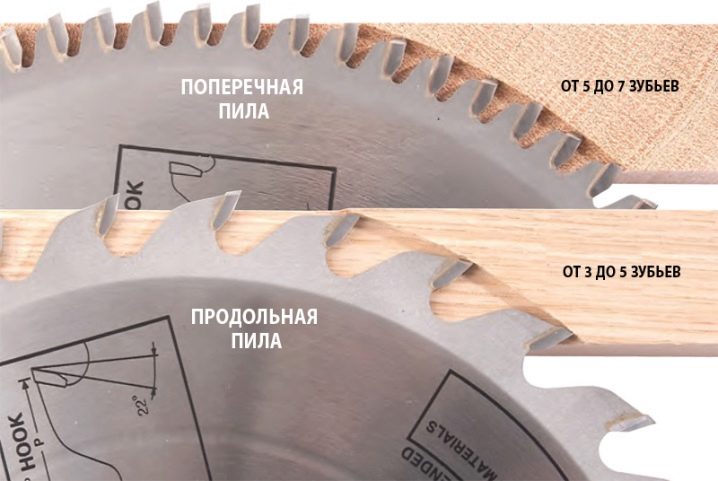

In practice, it is important to observe these angles when sharpening for each type of disc. It is according to the front angle that the saws are divided into types:

- Longitudinally cutting, where the rake angle should not go beyond 15-25 degrees.

- Transverse cutting, where it is permissible to sharpen the front edge of the tooth at an angle of 5-10 degrees.

- Universal discs, which are easy enough to cope with both longitudinal and transverse cuts, their rake angle should be maintained in the region of 15 degrees.

The angle of the bevel of the rear and front planes is also important: the sharper it is, the easier it is for the saw to enter the material, but wear is faster.

Cutting geometry

The working element of the saw - the tooth - has a certain geometric shape with the presence of not one, but several cutting edges. There is always one main edge and additional ones formed by the intersection of planes "A", "B" and "C" in certain combinations. To work with different materials, it makes sense to select discs with the most suitable cutting teeth shape.

Straight tooth

A saw blade with such a working area is intended for rough cutting of sawn timber. The cut is rough, of low quality, with relatively fast operations.

Beveled tooth

The leading plane of the cutting edge, made in this shape, ensures that cuts are obtained with an accurate and straight line. The saw is ideal for working with composite material: plywood, chipboard (single-sided and double-sided lamination). After cutting the blanks from solid sawn timber, it is chipped, practically no chips are observed.

There are discs with a beveled leading edge of the cutter, there are also discs with a beveled trailing edge, or a variant with alternating teeth (alternately beveled blade). In the case of working with a tool with a beveled surface of the trailing edge of the cutting element, when cutting hard wood species, a clear high-quality cut is observed, but a quick bluntness of the saw.

Trapezoidal tooth

The main advantage of such a saw is the slow wear of the disc due to the absence of the need for frequent sharpening on a grinding machine. Usually the entire blade line consists of alternating cutting elements - straight and trapezoidal teeth, working in tandem. The taller trapezium tooth creates a rough cut, allowing the main straight edge to cut more easily. The tool can be used for cutting plastics, hard laminates.

Conical tooth

An auxiliary type of tool designed to cut materials with a laminated surface in advance of the felling cut. The operation is carried out to avoid the appearance of chips on the front of the product. Such a saw blade is not used as an independent working unit.

Crescent tooth

It is convenient to cut the material in the transverse direction of the cut with respect to the location of the fibers with blades with a concave tooth shape.

- The movement of the workpiece on the working table during cutting occurs with the use of great physical effort;

- Cracks and chips are observed along the cutting line;

- During operation, the engine overheats;

- There is a burning smell in the air;

- The material burns, which shows up as dark spots along the cut line.

If you find any of these signs, you need to urgently start sharpening circular saws with your own hands. Also, before carrying out work, you can check the sharpness of the saw, focusing on tactile sensations or visually using a magnifying glass. The permissible radius of rounding of the cutting corner should correspond to a value of 0.1-0.2 mm. When cutting large workpieces, all working edges wear out.

Sharpening carbide-tipped saw blades

Victory solders are sharpened using a special machine or a homemade device for a grinding wheel. The device is a retainer in which the disk is clamped, observing certain sharpening angles relative to the emery. A diamond wheel is considered the best for sharpening a victorious circle.

Any point is marked with a marker as a reference point. Position the main working surface of the tooth to the grindstone so that they are in the same plane. Each tooth is ground in turn until the entire circle is passed. Rearrange the disc with the auxiliary plane to the grinding wheel. Already a different plane is ground at each tooth. This is how the carbide-tipped discs are completely sharpened step by step.