Rules for the purchase of personal respiratory protection

Before buying a product, you need to make sure it is of quality and size. Smooth stitching, durable fittings, reliable seams are the main signs that a respirator is made soundly

It is important that the mask fits snugly to ensure a tight seal. The slightest gaps will render the device useless.

A reliable respirator should not create discomfort, obstruct breathing, or pinch your head.

The main working element of a protective mask is a filter. It must correspond to the type of hazardous substances with which you will have to work. It is also necessary to take into account their concentration in the air. All the necessary parameters are indicated in the accompanying documentation for the product. With information about the technical specifications, it is not difficult to decide which respirator is best for a particular purpose.

Loose filters with large meshes will only handle relatively large particles. For example, when processing wood with coarse sandpaper, it will be quite enough to use a cotton-gauze bandage. If you have to work with cement mortar, cut concrete or gouge a wall, you will need a respirator capable of trapping the smallest particles of dust that are in suspension. Before purchasing a means of protection, you need to determine for what kind of work it will be used. A filter that is too loose will be useless in most cases, and an excessively tight filter will interfere with normal breathing.

Popular models

The most common dust mask is a single-use product called the Petal. They are made from specially manufactured filter material. However, it should be borne in mind that this is the simplest filtering system, it is not effective enough against highly concentrated abrasive dust particles.

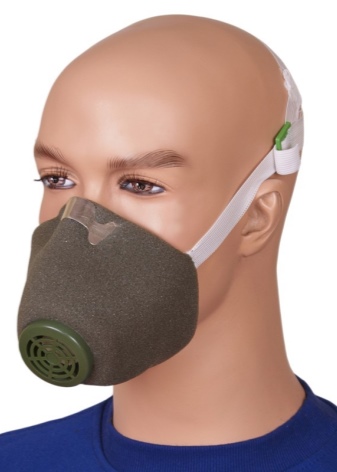

The U-2K respirator is more efficient, it has a pair of protective layers - the upper layer is made of polyurethane foam, and the lower one is made of polyethylene. A filter is placed between them, which fully protects the respiratory system from various types of industrial dust (cement, lime, as well as mineral and metal). The model is suitable for performing renovation work in the room - chipping, surface grinding and cutting ceramic dust.

Such a mask is not recommended to be worn in contact with substances emitted by highly toxic volatile vapors. If you have to come into contact with paints, as well as enamels and solvents, it is better to use combined models, for example, RU-60M. This model is indispensable for protection against industrial dust and aerosols, it provides a pair of breathing valves, in addition, replaceable filter blocks that absorb hazardous substances. Such a mask can work continuously for up to 60 hours. Nowadays on sale you can find more improved analogs of the product - this is "Breeze-3201".

Applications

With the existing variety of mask products, the basic principle of their operation is described as follows:

- they are needed to prevent contamination of the respiratory tract - the mask isolates them from direct interaction with external adverse factors;

- depending on the design features of the product, it either supplies a person with breathable air from a cylinder, or purifies the air inhaled from the atmosphere using filters;

- promotes the removal of exhaled air for its subsequent processing.

The main area of use of such masks is repair and construction, carpentry, as well as carpentry work, they allow you to protect the respiratory tract from small polluting particles and prevent the development of pathology of the bronchopulmonary system.

It should be noted that the use of masks is far from limited to the construction industry. Life in a metropolis dictates its own conditions, unfortunately, in our country the situation with cleaning cities is far from being the best. Utilities are in no hurry to do their job, the situation is aggravated in spring, when the snow melts and the sand that covered the roads against the ice in winter turns into huge clouds of dust. In European countries, this is fought, for example, in Germany, the streets are washed several times a year with shampoo, removing all the dirt and dust from the sidewalks. In Russia, rains are waiting for the water from the sky to help carry the sand to the side of the roads. Cars, which bring mud from lawns and dirt roads, also make their negative contribution to the environment, in addition, moving at high speeds, they lift this very sand into the air. All this leads to the fact that many people develop allergic diseases, as well as lung diseases - which is why they are forced to wear protective equipment in order to prevent their condition from worsening.

Views

All the variety of products on sale for protecting the face from dust particles can be conditionally subdivided into several categories. So, depending on the functional purpose, the following types are distinguished:

- medical;

- household;

- production;

- military.

By design features, models are distinguished with a valve, as well as without it. According to the operational period, one - and reusable models are distinguished. Disposable are designed for single use - after use they are immediately disposed of. Reusable ones include special dust absorbers, most often black carbon filters, so they are worn for a long time.

Respirator filters are usually made of artificial fine fiber cloth. Professional respirators are able to provide the highest level of protection against dust, which is why they are especially relevant during construction work, as well as any actions related to mixing and cutting concrete, using building mixtures.