Principle of operation

The charger should not be taken as a simple cable that allows you to power the battery from an electrical outlet - this device is always somewhat more complicated. Depending on the exact set of functions of a particular instance, it can be arranged in different ways, however, in general, the methods for achieving the goal are always approximately the same. Since it is impossible to charge the battery of a screwdriver directly from a 220 V outlet, a key part of any charger is a step-down transformer, which provides a significant reduction in voltage. He himself, as a rule, does not lower the voltage down to the desired value - the current acquires the necessary characteristics only later, passing through diode bridges and microcircuits.

So that the entire filling of the charger, not to mention the battery or the screwdriver as a whole, does not burn out from too high a voltage in the power supply network, a fuse is installed at the very beginning of the circuit. Charge limiting is usually achieved in one of the two most common ways - either the microcontroller measures the current in the battery, or the charging time is limited by a timer. The first option is good in the case of lithium-ion batteries, since they can be charged at any time, which means that the exact charging time cannot be determined.

In this case, overcharging threatens an explosion, therefore it is very important that the microcontroller is able to determine the charge level and turn off the electricity supply in time. The timer is good for recharging different types of nickel batteries - they are not afraid of overcharging, moreover, they must be completely discharged before the procedure, because the charging time is always about the same

For the sake of increased ease of use, some expensive models of chargers are also equipped with indicators, which are usually ordinary LEDs. Often they perform different functions - one can demonstrate the fact that the device is connected to the network, the other shows that the current is not lost anywhere in the microcircuits and enters the battery, the third can even indicate the approximate level of charge, highlighting only a certain part of the line in which they are built.

Varieties of batteries

A charger for a screwdriver is created taking into account the characteristics of an autonomous power source. The following sections cover popular rechargeable batteries

In the course of studying the compatibility of the functional components of the screwdriver, it is recommended to pay special attention to the charge recovery modes

Nickel-cadmium

These batteries are different:

- reasonable cost;

- good energy performance;

- long service life.

Unfortunately, big problems arise at the disposal stage. Harmful chemical compounds in Ni-Cd batteries cause great harm to the environment. For this reason, the use of such products is gradually being phased out in many countries.

Unless otherwise indicated by the manufacturer, select the operating mode together with a suitable charger circuitry for the screwdriver according to the following data:

- to extend the service life, it is recommended to "train" 2-6 full working cycles before the start of operation and thereafter every 6-8 months;

- long-term storage in a discharged state is permissible;

- pre-discharge voltage - from 0.9 to 1 V;

- the nominal capacity is maintained only at a positive temperature;

- overheating is unacceptable during the recovery process (no higher than + 40 ° C);

- the end of the cycle is indicated by a slight decrease in voltage;

- the charge current is calculated by the formula:

2 * C.

Important! The letter "C" denotes the capacity indicated in the battery passport. If C = 2.5 A * h, you can use a charge with a current of 5A = 2 * 2.5

Sulfuric acid batteries for screwdriver

Products in this category are created on the basis of lead cells with an acid-type gel electrolyte. Advantages:

- simplicity;

- affordable price;

- the ability to operate in any position.

The main disadvantages of sulfuric acid batteries are their large dimensions and high weight. The cells are charged with a voltage of 1.8-2 V while maintaining a current of 0.1-0.15 * C.

Lithium-ion batteries for screwdriver

This is the most common modern solution. Batteries of similar design are used in smartphones and laptops, other household and professional equipment. Pros:

- the best indicators, in comparison with the analogs discussed above, in terms of energy storage per unit volume (weight);

- wide working temperature range;

- long-term preservation of good performance parameters;

- no excessive disposal requirements.

One standard cell is charged with 3.6V to 4.2V. Exceeding the threshold set by the manufacturer will shorten the service life. A low level limits accumulation possibilities. The energy potential of the batteries is restored with careful temperature control.

The principle of operation of the memory

If the charger fails, it makes sense to first try to restore it. For repairs, it is advisable to have a charging device circuit and a multimeter. The circuitry of many charging devices is based on the HCF4060BE microcircuit. Its switching circuit forms the delay of the charging time interval. It includes a crystal oscillator circuit and a 14-bit binary counter, making it easy to implement a timer.

The principle of operation of the charger circuit is easier to disassemble with a real example. This is how it looks in the Interskol screwdriver:

This circuit is designed to charge 14.4 volt batteries. It has an LED indication showing the connection to the network, LED2 is on, and the charging process is on, LED1 is on. The U1 HCF4060BE microcircuit or its analogs: TC4060, CD4060 is used as a counter. The rectifier is assembled on VD1-VD4 power diodes of the 1N5408 type. The Q1 PNP transistor operates in a key mode, the control contacts of the S3-12A relay are connected to its terminals. The key operation is controlled by the U1 controller.

When the charger is turned on, an alternating voltage of 220 volts is fed through a fuse to a step-down transformer, at the output of which its value is 18 volts. Further, passing through the diode bridge, it is straightened and goes to the smoothing capacitor C1 with a capacity of 330 μF. The voltage across it is 24 volts. When the battery is connected, the contact block of the relay is in the open position. Microcircuit U1 is powered through a Zener diode VD6 with a constant signal equal to 12 volts.

The used SK1 button works non-latching. When it is released, all power is supplied through the VD7, VD6 chain and the limiting resistance R6. And also power is supplied to LED1 through resistor R1. The LED lights up, signaling that the charging process has started. The operating time of the U1 microcircuit is set for one hour of operation, after which the power is removed from the transistor Q1 and, accordingly, from the relay. Its contact group breaks and the charge current disappears. LED1 goes out.

This charger is equipped with an overheating protection circuit. Such protection is realized using a temperature sensor - thermocouple SA1. If during the process the temperature reaches more than 45 degrees Celsius, then the thermocouple will work, the microcircuit will receive a signal and the charge circuit will break. After the end of the process, the voltage at the battery terminals reaches 16.8 volts.

This charging method is not considered intelligent, the charger cannot determine the state of the battery.Because of this, the battery life of the screwdriver will decrease due to the development of the memory effect. That is, the capacity of the battery decreases every time it is charged.

Checking the battery status with a multimeter

Not always, when the battery runs out quickly or does not function at all, it is necessary to buy a new one or carry the unit to the specialists of the service center. In many cases, even an inexperienced electrician can independently find the cause of the malfunction, having familiarized himself with the search algorithm. To do this, you will need to use a multimeter or devices similar to it in terms of measuring capabilities. In addition to this device, you will also need the following tools:

- screwdriver;

- soldering iron with soldering kit;

- knife;

- pliers.

In order to accurately determine the cause of battery malfunctions, it is necessary to find out the operability of each individual supply element. But it is recommended to check the charger first. With the help of a multimeter, this is done in this way:

- turn on the device;

- set the switch of the measured values of the multimeter to constant voltage;

- install the probes in the corresponding sockets of the multimeter and touch them to the contacts ("+" and "-") of the charger;

- compare the value displayed on the device display with the output voltage of the charger indicated in the operating instructions or on the case;

- if the values do not match, then they repair the adapter or buy a new one.

To check the battery of a screwdriver with a multimeter, do the following:

- fully charge the battery pack;

- check the output voltage of the battery with a multimeter by setting the switch of the device to its constant value, and touching the plus and minus with the probes;

- if a discrepancy between the measured parameter and the value specified in the operating instructions is found, then disassemble the battery pack and take out all the batteries;

- when there are no damaged cans (leaked or swollen), then check the voltage at the terminals of each battery with a multimeter, having previously unsoldered the circuit using a soldering iron;

- a load is connected to the batteries in turn for the same time (for example, a light bulb of the corresponding voltage);

- on which battery the greatest drawdown occurred, that one is damaged.

For testing, nickel-metal hydride and nickel-cadmium energy storage devices are fully discharged - this is done to avoid the "memory effect".

Once you find a defective battery, you can replace it with a new one, or try to temporarily restore it by adding distilled water or exposure to high voltage. You can also measure the current strength with a multimeter: if it grows and exceeds 1 A in the first hour, then the battery is considered to be operational.

If there is no voltage at the output of the battery, then there is a high probability of breaking the continuity of the circuit inside the unit. At the same time, they also disassemble the block and look first visually, and then with the help of a multimeter, the place of the break.

Before using a new cordless screwdriver, carefully read the instructions for use of this product supplied by the manufacturer. The type of batteries installed on the power tool should be taken into account in order to properly charge them and store them for a long time. Compliance with simple recommendations will allow you to extend the battery life until the resource is completely depleted. When there is no proprietary charger, then the following alternative methods of recharging will temporarily help.

If the capacity of the batteries drops, the operating time on a single charge decreases, you can repair them with your own hands. To do this, it is enough to set the output current or voltage values with a multimeter and compare their compliance with the standard values of these parameters.

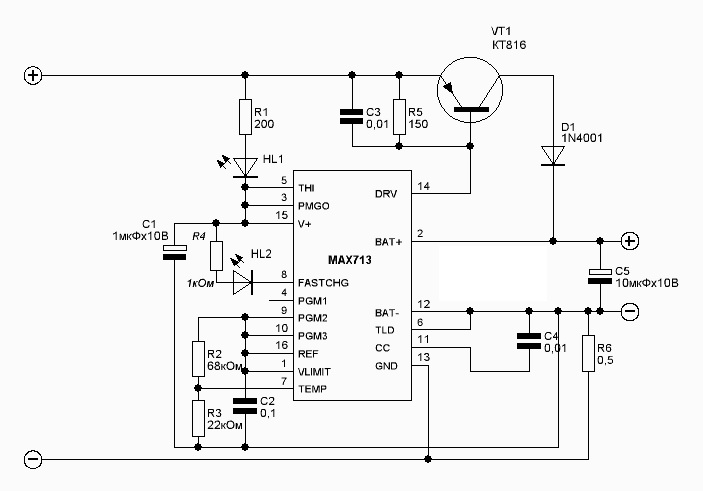

Charger circuit for a screwdriver.Electronic circuit of the screwdriver charger

A huge number of modern screwdrivers operate on a rechargeable battery. Their average capacity is 12 mAh. For the possibility of the device always remained in good working order, you need a charger. But in terms of voltage, they are quite different.

Now models are produced for 12, 14 and 18 V. It is also important to note that the Russian car industry uses different components for chargers. To be able to understand this matter, you should look at the standard charger circuit.

Types and types

There are also universal chargers for all types of batteries, but still, in most cases, the best solution will be a charger that is optimal for the needs of a particular battery. Interestingly, numerous reviews indicate the imperfect correspondence of the "native" chargers supplied with the screwdriver itself. Say, manufacturers often save on this part, which is why even a new tool can break down rather quickly. For this reason, many consumers prefer to assemble chargers on their own, but in this case it is worth strictly adhering to the scheme and the correspondence of all parts.

With built-in power supply

The built-in charger makes the cordless screwdriver similar to the mains one - it simply plugs into the socket, and when charging is complete, the cable is either disconnected or hidden in a special compartment. Such an analog mechanism mainly functions as a voltage stabilizer, it allows charging the battery without removing it from the device case. A significant disadvantage of this solution is that during charging, the tool cannot be used with a spare battery, since the only place for the battery is already taken. On the other hand, the likelihood of losing or forgetting the power supply is minimized, since it is not a separate mechanism and will always be at hand - in the same place as the screwdriver itself.

Considering that replacing such a built-in power supply is a significant problem, manufacturers usually try to make the mechanism conscientiously, therefore there should be no problems with updating the charger - it will turn out to be quite durable. The need to carry out the highest quality charger leads to the fact that it becomes the best solution for a lithium screwdriver - it can be charged at any time, and because of its integration into a large case, there are no problems with equipping the unit with microcontrollers to turn off the current supply.

With external power supply

A remote power supply for an analog charger is an alternative solution to what was described above. It works in a fundamentally different way: here, for charging, the battery is removed from the screwdriver body and installed in the socket of the charger itself, which is a completely separate mechanism. This solution seems to be good for the reason that it allows you to charge one battery while the screwdriver itself works, powered by the second. This fact even largely neutralizes the characteristic drawback - the very low charging speed of such devices, which often throws them into the category of household devices that are not designed for long-term autonomous operation.

It is chargers of this type that often turn out to be universal, aimed at working with different types of batteries from the three described above. This is because manufacturers, in an effort to provide the consumer with the maximum choice of positive qualities of the battery, offer both a lithium-ion and a nickel-cadmium battery in the delivery set. The presence of a separate case allows you to build into it a more complex circuit that allows you to set the necessary power parameters for each case, however, such a solution, of course, will take up a little more space.

Impulse

These chargers, in contrast to the two analogue ones described above, turn out to be both the most expensive and the most "smart", and therefore professional screwdrivers should be considered their main field of application. As befits an expensive unit, it is almost always designed for batteries of different types, and most importantly, it has the ability to charge extremely quickly, literally within an hour, in order to minimize possible downtime. For efficient work with nickel-cadmium batteries suffering from the "memory effect", such a charger also has a fast discharge function.

At the same time, one of the important advantages of a pulse charger is its small size with fast power supply. Theoretically, it is possible to assemble an analog solution similar in characteristics, which will be cheaper, however, in this case, the dimensions of the charger will be approximately comparable to the dimensions of the entire screwdriver.

DIY power supply for a screwdriver

The standard charger uses a three-channel IC. On it, depending on the voltage, a different number of transistors is placed, for example, 4 transistors are installed in a 12-volt charger.

To reduce the negative effects of clock frequency, capacitors are installed in the units. They are of the impulse or transient type. To minimize the consequences of overloading the electrical network, thyristors are used in chargers.

Standard screwdriver charging circuit

This is important: in different models, not only a different number of transistors are installed - they differ significantly in their capacity.

Power supply for a screwdriver from an energy-saving lamp

In order to make a UPS from an energy-saving lamp, it is necessary to slightly change the electronic choke contained in each lamp by putting a jumper, and then connect it to a pulse transformer and a rectifier.

For power supplies of small power (from 3.7 V to 20 watts), you can do without a transformer. To do this, you just need to add a few turns of the semiconductor to the magnetic circuit of the choke located in the ballast of the lamp, if there is a place for this. The winding can be done directly over the factory one. For this, it is better to use a wire with PTFE insulation.

Power supply for the screwdriver from the charger

One of the cheapest ways to make a power bank is to use a regular smartphone charger. In every house now there are two or more of them, and if you don’t have too much, you can buy it for 50–100 rubles.

This is how the insides of charging from a smartphone look like

Changing the charging is done in the following sequence:

• With a small diameter enamelled conductor, add one turn of winding. After that, turn on the charging and connect the screwdriver to the battery. Using an oscilloscope, we measure the amplitude of the pulses and determine the voltage created by one turn of the additional winding.

• We solder the USB connector, remove the test coil and tighten the required number of turns until the required voltage is obtained. The new winding is soldered to the factory one in series.

• We change the standard capacitor and zener diode for new ones corresponding to the required voltage.

DIY switching power supply for a screwdriver

A suitable microcircuit is selected for the pulse unit, and the assembly is carried out in the following sequence:

• Diode bridges and a thermistor are placed at the input.

• Two capacitors are installed.

• Drivers are used to synchronize the operation of the gates of field-effect transistors.

• When installing transistors, the flanges are not short-circuited. They are attached to the radiator using insulating washers and gaskets.

• Diodes are installed at the output.

Power supply for a screwdriver from an electronic transformer

To adapt the transformer to the charger of your instrument, it needs to be modified. To do this, you need to connect a capacitor at the output of the rectifier bridge. The capacitance is determined as follows - 1 μF per 1 W. The capacitor voltage must be at least 400 V. In the break of one mains cable, a thermistor must be installed to limit the inrush current.

The diode bridge is installed to rectify the voltage with a frequency of 30 kHz. For the normal operation of the device, it is required to ensure a smooth start. The L1 throttle does an excellent job with this.