Repair

Different models of snow blowers may experience quite different breakdowns of some components and working units. This is due, mainly, in the individual features of the device of individual machines, as well as in some design points.

At the same time, the repair methods will be almost identical to those for other models of snow blowers. Consider a few specific examples of home repairs.

Craftsman

If Craftsman snow throwers are not working properly, the exhaust chute, i.e. does not throw out the snow mass outside, then you need to do a few manipulations. To begin with, we check if the safety bolts located to the left and right of the gearbox have not been cut off (see here).

If it's not about them, then the whole repair process will be reduced to the following:

- Disconnect the bucket from the frame structure of the snow blower.

- We take out the gearbox.

- Next, you need to open it and check the worm located on the shaft. Most often, the problem is in him - he is cut off the shaft.

- The repair will consist in the acquisition of a new worm pair, which must be installed on the shaft.

What to do if the Patriot device does not work well

Quite often, a situation arises when the engine of a snow blower simply does not start. To fix this breakdown you need:

- It is necessary to check the compression of the engine using a compression gauge. The optimal value is from 6 to 9 atmospheres. If it is normal, then go to the next step.

- The problem may be in the starter, the starter repair itself consists mainly in replacing the cord with a new one. The starter design provides a return mechanism, as well as a hole where the cord is threaded.

- First you need to cut off the old cord, and inside the starter, untie the cord knot that holds it.

- We rotate the mechanism counterclockwise, making 7 full turns. We insert a screwdriver between the ribs to block the return movement of the mechanism.

- Next, we stick a new cord into the corresponding hole; at its end it is necessary to tie a rather tight knot.

- Next, simply remove the screwdriver while holding the cord. The return mechanism will wind the cord around the spool itself.

Patriot

Analysis of Energoprom

If during operation, you notice that the Energoprom snow blower gives out abnormal vibration, then you need to check the engine mount. Most likely, the point is in it, and you just need to tighten these fasteners better.

Do-it-yourself Profi gearbox repair

Often, this snow blower has certain problems with the gearbox. Repair of the gearbox of the Profi snow blower consists mainly in replacing the gear, which is located inside. During operation, it tends to wear out, which leads to problems in operation.

All repairs are reduced to replacing it with a new part purchased from a specialized store.

Classification of belts in snowblowers

For the most part, snow blowers of well-known brands are equipped with elements of a predominantly gear type. In addition to their low weight, their main feature is their high strength. According to this parameter, they are almost in no way inferior to drive chains. The toothed parts are easy enough to install on the snow blower in-house. To do this, they have a high elasticity, which allows them to be placed in places with limited space.

All toothed belts used by manufacturers for snow plows are usually classified as follows:

flat-toothed - the high elasticity and resilience of these elements allows manufacturers to use them as auger drives.Plane-toothed parts differ from their market counterparts in increased resistance to deformation, which significantly increases their service life during intensive operation. Features of this type of elements include the ability to continuously provide synchronous interaction of two screws at once. This increases the stability of the utility snow blower when clearing heavy sticking masses;

2-sided - the advantage of these drive elements is the ability to stably transmit rotational force from the engine of the snow blower simultaneously in several directions. The reversible snow blower belt is most often used to complete the wheel drive of a utility vehicle. Provided that the unit is equipped with a transmission with a reverse function, the 2-sided element will allow it to move not only at any of the forward, but also at the reverse speed. Parts of this type are resistant to deformation and shock, therefore, with the correct operation of the machine, their service life can reach several years;

wedge - drive parts of this type are distinguished by a trapezoidal profile and a factory cross-section. They are less commonly used to complete snow blowers. This is due to the fact that the wedge element does not fit tightly enough to the surface of the shaft head, thereby not ensuring the stable operation of important units of the economic machine.

The drive elements of each of these types differ from each other in their factory section and profile. This must be borne in mind when choosing a part to replace a faulty standard belt for a utility snowplow.

Snow blower device

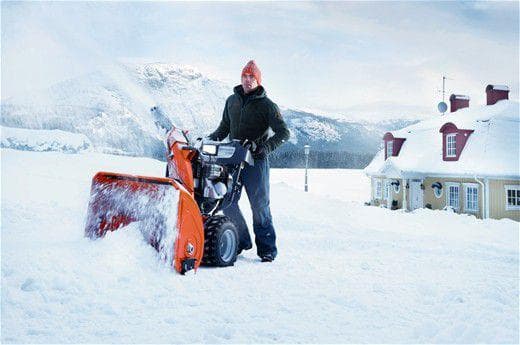

Snowblowers may differ in their technical characteristics, type of movement and engine, but the general structure will be similar. In principle, we can note the standard set of basic components that any snow blower includes:

Power unit. Depending on the configuration, the snow blowers can have a gasoline engine (see here) or an electric (see here) engine. The first is more powerful, and the second is more economical in operation.

Ladle

- Ladle. Inside the bucket there is the main mechanism that provides snow removal - auger shaft. The width of the bucket will determine the width of the lane that the snow blower can handle in one pass.

- Auger mechanism. This unit consists of a metal shaft on which there are screw elements located with screws towards the center of the shaft. They rake the snow mass towards the middle, where the blade pushes it further into the outlet chute.

- Discharge chute. It has the shape of a pipe, from which the snow mass is thrown out at the distance declared in the characteristics (up to 15 meters). There are plastic and metal versions.

- Chassis. Basically, there are wheeled units, but there are also machines operating on tracks.

- Controls and handle. In the immediate vicinity of the operator is the clutch, chute direction switch, and other levers and buttons for general control. By the way, some models have heated handles for greater comfort.

- Rotary mechanism. In some models, an impeller is provided - an additional mechanism located inside the device, providing additional crushing of the snow mass, before it is sent to the outlet chute.

For more information about the device of the snow blower, see the video:

The role of belts in a snowplow device

Drive parts are among those consumable parts of snow blowers that most often need to be replaced in a timely manner. At the same time, each snow blower is initially equipped with two belts, which guarantee the correct operation of the machine in all weather conditions.

The function of the first type of drive elements is to transfer the tractive effort from the motor to the factory snow blower auger.Parts of the second type play a similar role, but in their case, the tractive effort from the internal combustion engine is transmitted to the wheel drive of the utility vehicle.

Parts of the first and second types are susceptible to constant intense wear and tear, due to which they often fail. The standard controls of the snowplow will tell you about their deformation or breakage. If the snow blower does not move when the throttle lever is pressed, then the drive element connecting the engine and wheels is out of order. Likewise, the owner of the snow blower can determine if the auger drive belt is faulty. If the snow blower mechanism does not rotate when the corresponding lever is pressed, then its drive part will need to be replaced.

Parts of the first and second types are susceptible to constant intense wear and tear, due to which they often fail. The standard controls of the snowplow will tell you about their deformation or breakage. If the snow blower does not move when the throttle lever is pressed, then the drive element connecting the engine and wheels is out of order. Likewise, the owner of the snow blower can determine if the auger drive belt is faulty. If the snow blower mechanism does not rotate when the corresponding lever is pressed, then its drive part will need to be replaced.

Spare parts market

Spare parts for different manufacturers differ from each other, but if you want, you can always find cheaper counterparts. We leaf through the spare parts catalogs, estimate the approximate cost. We will identify the most expensive and most budgetary spare parts.

Huter

The Huter company (Germany) guarantees the excellent performance of its devices. We did not find original spare parts for the huter sgc 4100 model (hooter 4100).

Service center

Only the service center offered to write out spare parts to order: a gearbox and a wheel assembly, a drive pulley for the auger and wheels, a snow ejection impeller, a tension roller, a friction disc, a shear bolt.

Consumer reviews about this technique are as follows: “The weak link is the variator, or rather its friction ring. Unfortunately, such consumables are hard to find on the market. ” Why not order several CVTs in advance with a margin?

Snow blower spare parts from Champion

But cheap spare parts were found for Champion snowblowers (USA / China). For the Champion st 1170 e and Champion st656 models, the prices for the parts are as follows: belt pulley - 891 rubles, wheel assembly - 2 266 rubles. The most inexpensive element was the shear auger bolt. It costs only 38 rubles.

Self-propelled parts from MTD

Company MTD / MTD (Germany) positions itself as a manufacturer of simple functional machines. The main production is located in China. An excellent assistant in the household gasoline self-propelled snow blower MTD M56.

Chinese spare parts

However, due to neglect of the requirements regarding storage conditions and the principle of operation, equipment malfunctions occur. Chinese spare parts for MTD snow blowers are inexpensive, they are original, there is no point in faking them.

Remember that there are a lot of plastic parts in the body of the mtd 1170le snow blower, they are made of durable plastic, they rarely break and are easy to replace with new ones.

Spare parts for a snowblower from MasterYard (Master yard)

MasterYard (France) takes care of its customers, service is organized in the service center. You can also buy or order spare parts for masteryard snow blowers there. Fuel and air filters, spark plugs, gearboxes can be found in catalogs.

It is a pity that so far in Russia there are only 2 service centers of the company at the addresses Moscow, MKAD, 78 km, 14, Dexter shopping center and Moscow region, Khimki, Leningradskoe shosse, possession No. 29G. Come!

Although analogs are cheaper, you should not chase after cheapness, you risk reducing the service life of the unit.

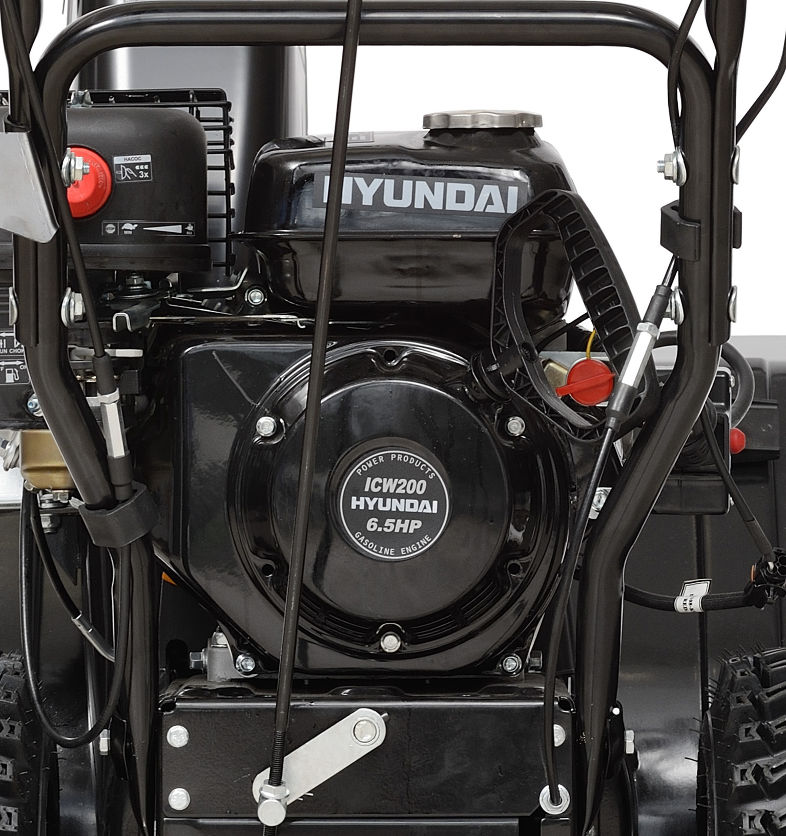

Hyundai

For hyundai s5555 Z and hyundai s5560 Z snowblowers, you will need the same parts. With an average price of 30,000 rubles for South Koreans, the prices for parts are not encouraging. The gearshift lever will cost 2,385 rubles, and the drive cable will generally cost 11,113.

If you order parts on the Internet resource, you will have to wait 25 days for delivery. There you look and winter will end. From the pleasant: there are Hyundai service centers in many large cities of Russia and you can look for spare parts for a Hyundai snow blower there.

Hyundai Service Center

DDE

But at the same cost of basic models of 30,000 rubles, the Chinese company DDE saves on repairs.Prices for spare parts for dde snow blowers are reasonable. For 500 rubles, buy a wheel drive control cable, and for 950 - a friction disc.

Alex67 shares his experience as a snow blower user. “Kraftsman is German, most of the equipment is produced under the MTD brand. Service for both Chinese and American is not cheap. But there is a great difference in the price of parts.

A shear bolt for a Chinese car costs 130 rubles, and for an American typewriter - 230. Some craftsmen do not strain, put simple bolts that are not cut off when pebbles or glass hit the augers, then they are surprised to learn the price of a crippled gearbox.

Here, the Chinese are very positive, they have a gearbox of 5,000-8,000, and almost 15,000 for mtd-kraftsman, I generally keep quiet about Husqvarna or a partner. For his Chinese snow blower, the pro p6560et bought a friction disc from spare parts for 3350 rubles and a set of 6 shear bolts for 450 rubles. Not bad in two years of work. "

We have conducted a serious research and can draw conclusions:

What are they?

Despite the variety of types of snow blowers and manufacturers, the main parts of the unit remain unchanged. So, let's list the main spare parts for snow blowers.

Engine

The engine on the snowblower drives all part of the snow. On devices manufactured and released by various manufacturers, one of two types of engines can be installed - electric (and it can be powered from the mains or from a battery) or gasoline.

Shroud (it can also be called a bucket)

Most often it is metal or plastic (sometimes there may be rubber inserts) - in one case or another, this spare part must be very durable and reliable. The main function of the element is to provide snow collection.

Discharge chute

This element, like the previous one, must be made of a fairly durable material. The outlet chute provides a snow throwing procedure (direction, distance).

Screw

The auger is the basic component of a snow blower that provides quality performance. This part crushes the snow and then throws the recycled sediment onto the chute. The auger device also includes a shaft.

Drive belt (or cable)

In the device of any snow blower, there are several belts at once. One of them transmits torque to the auger, and the other to the wheels. Most often, the material of manufacture is rubber.

The rotor is essentially a wheel with blades.

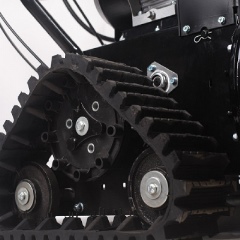

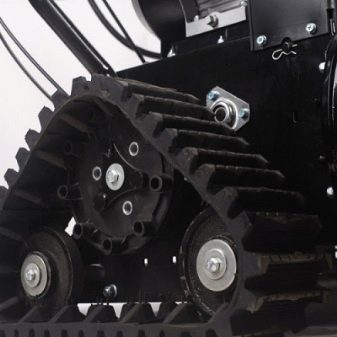

Caterpillars

These components are not present on all, but on many machines designed for clearing snow. Most often, tracks are installed on medium and high power models with an installed gasoline engine. Tracks provide more reliable traction of structures to the ground, as well as facilitate work in areas with uneven terrain.

Shear bolts (or fixing pins)

Shear bolts are fasteners that protect the snow thrower engine from various types of damage. Shear bolts can be fitted with a cotter pin.

Brush

Sweeping brushes greatly increase the productivity and efficiency of the device. They clean the area from all kinds of mechanical debris, thereby preventing damage to the unit.

Reducer

The gearbox without fail includes a gear. This element receives and increases the torque of the engine of the unit.

Handles and control panel

These functional elements of the snow blower allow the operator to control it. Modern models are also equipped with handle heating systems, which ensures a more comfortable operation of the unit.

Please note that this list of spare parts is not exhaustive. Many manufacturers can equip their devices with additional elements (especially for new modern models).

Causes of malfunctions and repairs

Many experts advise you to choose snowblowers that use a serviceable gearbox. Of course, it requires a certain amount of handling, but it will also last much longer than a maintenance-free gearbox.

However, this issue has a second side - such gearboxes tend to break down at the most inopportune moment. Let us consider, using the example of the Patriot, Celina, Champion and Profi snow blowers, what gearbox breakdowns can be, as well as methods for their elimination.

Repair

Possible problems:

- There is a sharp knocking noise in the gearbox of the Champion snow blower - the most likely cause of this problem is damage to the worm windings or bearings. The way out of the situation would be to adjust or replace bearings, as well as buy a new worm gear pair.

- If you observe that the Patriot snow blower gearbox heats up excessively, then several factors may be the reasons for this phenomenon. In particular, the case may be in the lack of lubrication, or in bearing wear.

- In the first case, you just need to add the required amount of grease, and in the second, you need to adjust the bearings, or replace them with new ones.

- If the gearbox of the Profi snow blower vibrates very much, the probable cause may be a misalignment of the shafts and the machine motor. Thus, do-it-yourself repair of the gearbox of the Profi snow blower is carried out by eliminating this misalignment.

Reducer Profi

- If grease is leaking from the Celina snow blower gearbox, the likely cause may be a clogged drain hole in the vent. To correct this situation, you need to rinse the vent plug in kerosene, and then wipe it dry.

- Another common cause is wear on the gear that is part of the gearbox design. This is understandable, because it is made mainly of bronze, therefore, during long-term use, its edges can simply be erased.

- The only way out of this situation is to completely replace the gear with a new one.

In most cases, snowblower gearboxes can be repaired without requiring replacement. Of course, it may be necessary to purchase separate gearbox components - oil seal, gears, etc. However, this is not such a big expense as in the case of buying the entire gearbox.

By the way, the cost of components may vary. For example, a gear wheel of a 24-tooth snow blower auger reducer will cost about 3 thousand rubles. By the way, gears of different types of gearboxes can have a different number of faces in their presence - basically, these are 20 teeth and 24 teeth, depending on the model of the snow blower.

For more information on repairing the gearbox, see the video:

Conclusion

The availability of spare shear bolts for owners of snow blowers is a prerequisite for the correct operation of this device.

Fortunately, specialized stores offer a fairly wide selection of this consumable for a wide variety of models of snow blowers. To save money on their purchase, in this case, will be an unforgivable stupidity, which can lead to breakdowns of more serious components of the device.

In addition, given that shear bolts can be made by yourself, just by reworking a regular bolt, the problem of constant replacement may not arise at all. (You can also make the auger yourself. Read about it here.)

If we consider that the average price for one bolt is about 250 rubles - the money for which you can purchase 1 kg of ordinary bolts, then making this consumable on your own becomes a rather expedient matter.

Read the article about another part of the snowblower - the belt.