Reducer for motoblock Neva

Land cultivation for modern gardeners is no longer as big of a problem as it was in the recent past. Such versatile equipment as walk-behind tractors appeared on sale, which greatly facilitate the life of agronomists and gardeners.

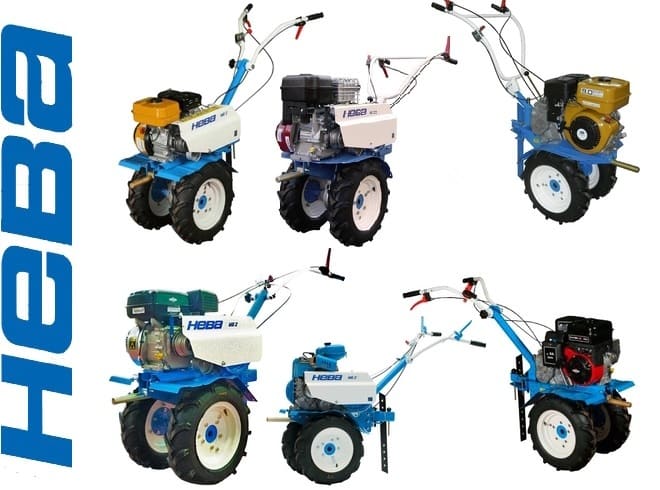

Motoblocks Neva are one of the best units in their line. They are reliable, durable and versatile. You will be able to cultivate the land, and take care of plants, and collect and transport crops and garbage.

Here we will tell you about the gearbox for motoblock Neva, about its device, repair. This is one of the most significant elements in any car, so if you want it to serve for a long time and without breakdowns, you should know all the subtleties of its device, as well as the causes of malfunctions and methods of their elimination.

Gearbox device on the Neva walk-behind tractor

The Neva walk-behind tractor gearbox is responsible for the transmission of rotation coming from the motor to the wheels and attachments. It controls rotational number, speed, and direction - forward or backward. In principle, the gearbox for the MB 2 and MB 1 models is not much different, so here we will consider the second option. The device of the gearbox is made in such a way that the components necessary for changing gears are located on its outer part of the housing.

The gearshift lever has 5 positions. When you push it down, the fork disengages the clutch. When you drop the lever, the fork resumes its original position. The tiller will pause when the drive is connected to the right axle shaft. Torque comes from the sprocket. When the handle is recessed by engaging the left sprocket, the gear is down. If you need top gear, the handle must be fully extended.

Gearbox malfunctions and repairs

Like any other technique, walk-behind tractors can also fail. If the problem lies in the gearbox, you need to disassemble and repair it. Often the breakdown turns out to be insignificant and you can easily cope with it yourself.

First, you need to thoroughly clean this part from dirt and oil residues, which will also need to be drained. All parts must be inspected and checked for damage. If something is out of order, it needs to be replaced. Use only new elements that are suitable specifically for your Neva walk-behind tractor model. Also, do not forget to add oil after assembly.

Some common gearbox failures:

- broken spring or clips. They need to be replaced with new ones and then adjusted;

- the settings in the switching system are out of order. You need to loosen the screws, turn on the first gear, tighten the screws back;

- oil oozes through the shaft. Most likely the reason is the cuff, which is worn out. It needs to be replaced with a new one. How to replace oil seals? It is enough to remove the old ones by prying them with a screwdriver or other object and install new ones;

- jamming appeared. Perhaps this is due to an open circuit. It needs to be replaced with a new one;

- cannot fix the transmission. The reason is the worn out fork brush, so it needs to be replaced.

These are the main and most common gearbox failures.

It is very important - if you cannot fix the breakdown yourself, then you should seek professional help

Oil change in the gearbox of the Neva walk-behind tractor

It is also worth talking separately about changing the oil in the gearbox of the Neva walk-behind tractor. This should be done every fifty hours of work.

It is also important to check the oil level. An even wire is suitable for this.

You put it in a container of oil and it should be 25-30 centimeters wet. What kind of oil to fill in the gearbox of the Neva walk-behind tractor, you will learn from the operating instructions.Most often these are transmission TAD-17I, TAP-15V and others in accordance with GOST 23652-79.

.

What kind of oil to pour into the engine of the walk-behind tractor

In order for the walk-behind tractor to work flawlessly for a long time, it must be properly maintained and operated. Oil is a key factor in engine performance. We will try to figure out what kind of oil to pour into the engine of the walk-behind tractor on this page of the site.

The most correct recommendation for the selection of oil will be the recommendation of the engine manufacturer for the walk-behind tractor. Therefore, we will familiarize ourselves with the operating instructions of the main engine manufacturers for walk-behind tractors and cite excerpts from the instructions.

The choice of engine oil, like any other type of oil, depends on two main parameters - the operating category and the viscosity class.

OIL GRADE CLASSIFICATION API classification by service category (American Petroleum Institute). For more details see here

VISCOSITY CLASSIFICATION SAE (Society of Automotive and Transportation Engineers) classification. See more here

Winter - with the letter W (Winter). Oils meeting these categories are low-viscosity and are used in winter - SAE 0W, 5W, 10W, 15W, 20W, 25W

Summer - no letter designation. Oils satisfying these categories are high viscosity and are used in summer - SAE 20, 30, 40, 50, 60.

All-season - at the moment, the most widespread are universal oils that are used both in winter and summer.

Such oils are designated by a combination of winter and summer series: 5W-30, 10W-40

Use an oil with a lower SAE number (less viscous) in winter, and an oil with a higher value (more viscous) in summer.

Multi-grade oil is highly stable under seasonal and temperature changes. For example, an SAE 10W-30 oil is suitable for multigrade use. At low temperatures, it is equivalent in viscosity to SAE 10W oil, and during operation it has the same lubricating properties as SAE 30.

Engine oil for motoblocks recommended by manufacturers.

| Motoblock engine make | Manufacturer's Recommended Engine Oil | ||

| summer | winter | service class | |

| Robin Subaru (Subaru) | SAE 10W-30 - in temperate climates | SAE 5W-30 - in cold regions | Automotive engine oil; class SE or higher (SG, SH or SJ recommended) |

| Honda (honda) | SAE 10W-30 is recommended for use at all temperatures. If you wish to use seasonal oil, select the appropriate viscosity grade based on the average temperature in your area. | SG, SF. | |

| Lifan | SAE-30 | SAE-10W-30 - all-season | |

| Briggs & Stratton (brigs) | Briggs & Stratton recommends the use of synthetic oil when operating in temperatures below 0 ° C. If you do not have synthetic oil, you can use Briggs & Stratton 10W-30 non-synthetic oil, part number 998208 Note: Synthetic oil that meets the ILSAC GF-2 certification mark, API and API service symbol labeled “SJ / CF ENERGY CONSERVING” and above, can be used at any temperature. Change the synthetic oil according to the normal schedule. Air-cooled engines heat up faster than car engines. Using a non-synthetic thickened oil (5W-30, 10W-30, etc.) at temperatures above 4 ° C will result in high oil consumption. If such oil is used, the oil level should be checked more often. | SF, SG, SH, SJ or above | |

| DM-1-01 (JSC Kaluga Engine) | М63 / 12Г1 or М53 / 10Г1 GOST 10541-78, oil corresponding to API requirements: SF; SG; SH and SAE: 10W30; 15W30 | ||

| DM-1K Instruction from OJSC "Red October" | M10GI, M12GI TU 38.10148-85 M63 / 12G1 or M53 / 10G1 GOST 10541-78, | ||

| Cascade MB-6 | Motor oil M-5z / 10G1, M-6z / 12G1 GOST 10541-78 (It is allowed to use motor oils for carburetor engines according to SAE classification in accordance with recommendations for use at various ambient temperatures. Mixing of mineral and synthetic oils is not allowed.) |

How to replace

Periodic maintenance of the gearbox and engine provides for a timely oil change.

Oil is poured into the cultivator through a special hole; a watering can is required to simplify the procedure.

In the gearbox

In most cases, any gear oil can be used to lubricate the gearbox.The replacement procedure is carried out as follows:

- The device is located on a horizontal plane, it is tilted slightly. This simplifies the pouring procedure.

- A dipstick is inserted into the hole on the gearbox. It is required to determine the level of the old substance.

To replenish the oil level in the gearbox, a new one is topped up. A completely dry container is filled with about two liters. Some models are equipped with a special hole to remove old material, which may contain a large amount of impurities.

In the engine

Changing the oil in the engine is carried out depending on the manufacturer's instructions. Engine oil changes taking into account the following points:

- The first replacement is carried out after the engine has been run-in. It is carried out exclusively at idle, because overloading can cause wear and tear on major structural components.

- Some manufacturers recommend replacement at 40 hour intervals. The lubricant must be replaced after a period of winter operation.

- Before direct replacement, it is recommended to warm up the walk-behind tractor. This is required to increase the fluidity of the substance. At the same time, the walk-behind tractor is installed in a horizontal plane. There should be a drain tube at the bottom of the structure, after unscrewing the plug, the old substance is removed.

- After draining the old substance, the plug is screwed back. There is a filler neck in the upper part of the structure; level control is carried out using a dipstick.

After checking the lubricant level, you can tighten the plug and start the engine. The first few minutes you need to do a run-in at idle, because it takes time to lubricate all structural elements.

Do I need to add oil to gasoline

You can determine whether you need to add oil to the gasoline of the cultivator by studying the basic parameters of the device. In most cases, thinning is carried out for a two-stroke engine, recommendations regarding proportions are taken into account. The operation of the four-stroke engine is ensured when refueling with pure gasoline.

Do not mix gasoline with four-stroke engine oil. Such a mixture will cause malfunctions within a few hours of operation.