What is riveting

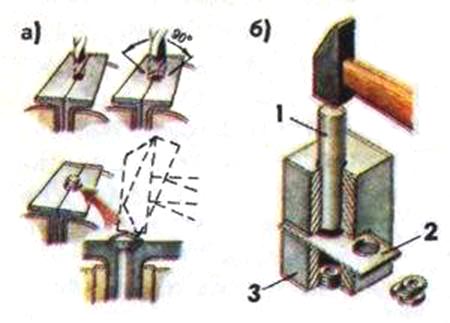

The mechanical connection of parts using a series of rivets is called a riveting, and the connection itself is a riveted seam. It is used where it is inconvenient to weld parts or where non-weldable materials are connected. Not only metals are riveted, thus they connect parts in clothes, accessories, etc. But there it is more of a finish than a loaded connection. So further we will talk about riveting in construction or home improvement. In principle, instead of riveting, you can use a screw connection, but bolts and nuts are more expensive, and their installation takes more time.

This is what a riveted joint looks like

If we talk about installing fences made of profiled sheet, rivets are more reliable, since they can only be removed by reaming the fasteners. When installing screws or self-tapping screws, they can be unscrewed and carried away both metal and hardware. In some cases, riveting is more convenient when installing a roof from corrugated board or metal. On the roof, the installation of screw connections is problematic and time-consuming. And with rivets, and with a good tool, you can do it in an hour or even less.

The most common use in the personal household

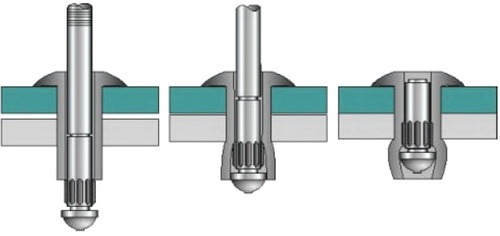

How are parts connected with rivets? The rivet is inserted into the prepared through hole. It has a head that rests against the material and the rod. During the riveting process, the end of the rod is flattened, changing shape under the influence of force. Therefore, plastic metals are used for these hardware.

How to install accessories on clothes

Clothing accessories are an additional, sometimes even the main decoration of clothes and accessories.

Leather products are especially adorned with various blocks, buttons, eyelets. However, it is not always possible to correctly and reliably install the accessories with your own hands. It is often necessary to spoil more than one block or button before installing it. To make this work easier for you, use our tips designed specifically for installing blocks, various buttons, denim buttons at home.

It should be noted right away that if you have the opportunity, then do not "save" on installing the blocks manually. Entrust this work to a master who has not only experience, but also a special press, various devices and a set of tools. Well, if you do not have such an opportunity, then let's figure out how to independently install clothing accessories using simple devices.

Rivet strength

When repairing structural elements of an aircraft or boat, the strength of the installed rivets is of paramount importance. If during the repair rivets are used that have a lower strength than the original, "native" rivets, then they must have a larger diameter to compensate for this "shortage" of strength

For example, rivets from alloy 2024-T4 can be replaced with rivets from alloys 2117-T4 or 2017-T4 only if rivets are used one size larger.

Rivets made of alloy 2117-T4 are used in general aircraft repair work, since they do not require preliminary heat treatment, are very plastic and at the same time sufficiently strong. In addition, these rivets are highly corrosion resistant for most types of aluminum alloys.

What material should the rivet be of

Rivets are usually taken from the same material as the parts to be joined - this avoids electrochemical corrosion

Pay attention to the strength characteristics. But, as a rule, when connecting aluminum parts, the strength of aluminum hardware is sufficient

In general, rivets are made from the following metals:

steel:

- ordinary - grades St2, St3, St10;

- corrosion-resistant Х18Н9Т;

- galvanized;

Read also: Wrench for loosening wheel nuts

When connecting copper parts, the installation of brass and copper is permissible. Aluminum is bonded with aluminum alloys. Steel sheets - the corresponding grades of steel rivets. There are also mixed hardware - from two different metals (chemically non-conflicting). The most common are aluminum-steel.

For the installation of facade elements, slopes, ebbs, metal tiles and profiled sheets, blind rivets made of galvanized painted steel are usually used. Coloring - in tone with the details.

Blind rivet steel

with standard collar ST / ST - steel / steel. Sizes of steel blind rivets from 3.0 x 6 to 6.4 x 45 mm. They are used to create permanent joints of thin sheet materials. Using a riveter, riveting is possible when only one side of the material is accessed.Characteristics and dimensions of steel blind rivets with standard shoulder ST / ST

| Rivet size | d | dk | K | R max | d1 | L1 | Breaking force N | Shear force N |

| 3.0 | 3.0 +0.08 -0.10 | 6.5 -0.7 | 0.8 ±0.2 | 0.2 | 1.90 | 27 | 1125 | 915 |

| 3.2 | 3.2 +0.08 -0.10 | 6.5 -0.7 | 0.8 ±0.2 | 0.2 | 2.00 | 27 | 1285 | 1060 |

| 4.0 | 4.0 +0.08 -0.15 | 8.0 -1.0 | 1.0 ±0.3 | 0.3 | 2.50 | 27 | 1990 | 1550 |

| 4.8 | 4.8 +0.08 -0.15 | 9.5 -1.0 | 1.1 ±0.3 | 0.3 | 2.90 | 27 | 2920 | 2300 |

| 5.0 | 5.0 +0.08 -0.15 | 9.5 -1.0 | 1.1 ±0.3 | 0.3 | 2.90 | 27 | 3255 | 2575 |

| 6.0 | 6.0 +0.08 -0.15 | 12.0 -1.5 | 1.5 ±0.4 | 0.4 | 3.40 | 27 | 5000 | 4000 |

| 6.4 | 6.4 +0.08 -0.15 | 13 -1.5 | 1.8 ±0.4 | 0.5 | 3.85 | 27 | 5400 | 4350 |

The thickness of the materials to be joined and the size of the rivet hole in mm

| Rivet size | Thickness of materials to be joined | Side diameter | Hole diameter |

| 3.0 x 6 | 1.5 — 3.5 | 6.5 | 3.1 — 3.2 |

| 3.0 x 8 | 3.5 — 5.5 | ||

| 3.0 x 10 | 5.5 — 7.0 | ||

| 3.0 x 12 | 7.0 — 9.0 | ||

| 3.0 x 14 | 9.0 — 11.0 | ||

| 3.0 x 16 | 11.0 — 13.0 | ||

| 3.0 x 18 | 13.0 — 15.0 | ||

| 3.0 x 20 | 15.0 — 17.0 | ||

| 3.2 x 6 | 1.5 — 3.5 | 6.5 | 3.3 — 3.4 |

| 3.2 x 8 | 3.5 — 5.0 | ||

| 3.2 x 10 | 5.0 — 7.0 | ||

| 3.2 x 12 | 7.0 — 9.0 | ||

| 3.2 x 14 | 9.0 — 11.0 | ||

| 3.2 x 16 | 11.0 — 13.0 | ||

| 3.2 x 18 | 13.0 — 15.0 | ||

| 3.2 x 20 | 15.0 — 17.0 | ||

| 3.2 x 25 | 20.0 — 22.0 | ||

| 4.0 x 6 | 1.5 — 3.0 | 8.0 | 4.1 — 4.2 |

| 4.0 x 8 | 3.0 — 5.0 | ||

| 4.0 x 10 | 5.0 — 6.5 | ||

| 4.0 x 12 | 6.5 — 8.5 | ||

| 4.0 x 14 | 8.5 — 10.5 | ||

| 4.0 x 16 | 10.5 — 12.5 | ||

| 4.0 x 18 | 12.5 — 14.5 | ||

| 4.0 x 20 | 14.5 — 16.5 | ||

| 4.0 x 22 | 16.5 — 18.0 | ||

| 4.0 x 25 | 18.0 — 21.5 | ||

| 4.0 x 26 | 18.5 — 22.5 | ||

| 4.0 x 28 | 21.5 — 24.0 | ||

| 4.0 x 30 | 21.5 — 26.0 | ||

| 4.8 x 6 | 1.0 — 3.0 | 9.5 | 4.9 — 5.0 |

| 4.8 x 8 | 3.0 — 4.5 | ||

| 4.8 x 10 | 4.5 — 6.0 | ||

| 4.8 x 12 | 6.0 — 8.0 | ||

| 4.8 x 14 | 8.0 — 10.0 | ||

| 4.8 x 16 | 10.0 — 12.0 | ||

| 4.8 x 18 | 12.0 — 14.0 | ||

| 4.8 x 20 | 14.0 — 16.0 | ||

| 4.8 x 22 | 16.0 — 18.0 | ||

| 4.8 x 23 | 16.5 — 19.0 | ||

| 4.8 x 24 | 17.0 — 20.0 | ||

| 4.8 x 25 | 18.0 — 21.0 | ||

| 4.8 x 28 | 21.0 — 23.5 | ||

| 4.8 x 30 | 23.0 — 25.0 | ||

| 4.8 x 32 | 25.0 — 27.0 | ||

| 4.8 x 35 | 25.0 — 30.0 | ||

| 4.8 x 40 | 30,0 — 35.0 | ||

| 4.8 x 50 | 40,0 — 45.0 | ||

| 5.0 x 6 | 0.5 — 2.5 | 9.5 | 5.1 — 5.2 |

| 5.0 x 8 | 2.5 — 4.5 | ||

| 5.0 x 10 | 4.5 — 6.0 | ||

| 5.0 x 12 | 6.0 — 8.0 | ||

| 5.0 x 14 | 8.0 — 10.0 | ||

| 5.0 x 16 | 10.0 — 12.0 | ||

| 5.0 x 18 | 12.0 — 14.0 | ||

| 5.0 x 21 | 14.0 — 17.0 | ||

| 5.0 x 25 | 17.0 — 20.0 | ||

| 5.0 x 27 | 20.0 — 23.0 | ||

| 5.0 x 30 | 23.0 — 25.0 | ||

| 6.0 x 8 | 2.0 — 4.0 | 12.0 | 6.1 — 6.2 |

| 6.0 x 10 | 4.0 — 6.0 | ||

| 6.0 x 12 | 6.0 — 8.0 | ||

| 6.0 x 14 | 7.0 — 9.0 | ||

| 6.0 x 16 | 9.0 — 11.0 | ||

| 6.0 x 18 | 11.0 — 13.0 | ||

| 6.0 x 22 | 13.0 — 17.0 | ||

| 6.0 x 26 | 17.0 — 20.0 | ||

| 6.0 x 30 | 20.0 — 24.0 | ||

| 6.4 x 8 | 2.0 — 4.0 | 13.0 | 6.5 — 6.6 |

| 6.4 x 10 | 2.0 — 5.0 | ||

| 6.4 x 12 | 4.0 — 6.0 | ||

| 6.4 x 14 | 6.0 — 8.0 | ||

| 6.4 x 16 | 8.0 — 11.0 | ||

| 6.4 x 18 | 9.0 — 13.0 | ||

| 6.4 x 20 | 11.0 — 15.0 | ||

| 6.4 x 22 | 13.0 — 16.0 | ||

| 6.4 x 25 | 15.0 — 19.0 | ||

| 6.4 x 26 | 16.0 — 20.0 | ||

| 6.4 x 28 | 17.0 — 22.0 | ||

| 6.4 x 30 | 18.0 — 24.0 | ||

| 6.4 x 32 | 22.0 — 26.0 | ||

| 6.4 x 35 | 24.0 — 30.0 | ||

| 6.4 x 40 | 30.0 — 35.0 | ||

| 6.4 x 45 | 35.0 — 40.0 |

You can order and buy steel blind rivets of any size at wholesale prices.

192007, St. Petersburg, st. Kurskaya, 27

Trading House Neva sells wholesale DIN and GOST fasteners, galvanized hardware and high-strength fasteners. Construction fasteners are supplied to all regions of Russia.

In industry, one of the main operations is the connection of structural elements and parts.

One way is to join with rivets. It is used when it is not possible to weld structural elements, and has many advantages over it. To perform this technology, there is a special riveting tool.

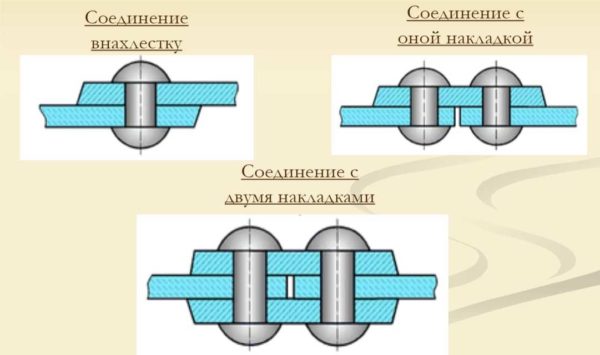

Types of riveted seams

If we talk about the method of joining sheets, then riveted seams are overlapped (one sheet is superimposed on another) and end-to-end. Docking seams can be with one or two overlays. More reliable with linings, used in critical and loaded places.

Types of riveted seams: overlap and butt with overlays

By location of rivets:

They can be located opposite each other or in a checkerboard pattern. Seams can be strong, tight (sealed) or strong-tight. Dense ones are performed using elastic gaskets laid between the parts to be joined. Strong-tight are mainly used in boilers. Now they are more often replaced by welding.

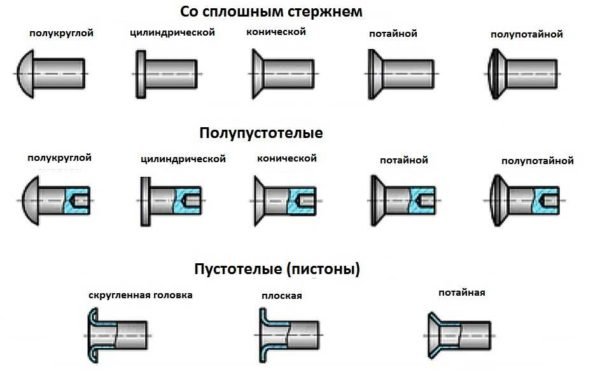

Dimensions (edit)

Various factors affect size, head type and even strength. Among them, one can note the type of loads acting directly on the rivet, the thickness of the material with which the work is carried out, and its type. The location of the product also plays a role. For example, when it comes to countersunk rivets, it is advisable to use them in cases where it is necessary to ensure the aerodynamic smoothness of the surface. Universal ones can be used in various situations.

You can not use too thick products, riveting thin sheets. This can cause the surface around the head to bulge. If, on the contrary, you take a rivet that is too small, the fastening will not be strong enough, due to which it may not withstand the imposed loads.

When choosing the size of the rivet, it is recommended to follow a general rule of thumb.It states that the diameter of the product should be at least 2.5 - 3 times the thickness of the most voluminous of the sheets with which the work is carried out. For example, in the aviation industry, rivets are most often used in the size of 2.5 - 9.5 millimeters. If the diameter is smaller, such products must not be used for load-bearing structures.

However, this is not the only option for sizing. Another way looks like this.

For example, when sheathing 1 millimeter, the unit is multiplied by 3, the result is 3.0. That is, the rivet further in diameter has a size of 3.2 millimeters.

Regarding standard sizes, they will depend on the type of rivet. Hammer products have a diameter of 1 - 10 millimeters and a length of 5 to 20 millimeters. Exhaust hoods with a diameter of 2.4 - 8 can be much longer, 6 - 45 millimeters. Threaded rivets have indicators of 3 - 10 and 8.8 - 22 millimeters, respectively. They can have both countersunk and universal heads.

The video below shows several methods of fastening using aluminum rivets.

The essence of the rivet as a fastener

Before installation, the rivet consists of a smooth cylindrical shank with a factory head on one end. To join two or more sheets of metal together, the rivet is placed in a hole slightly larger than the diameter of the rivet itself. Once the rivet is installed in this pre-drilled hole, its rear end is upset or deformed in one of several ways, from hand hammer riveting to pneumatic riveting tools. As a result of these actions, the rivet shank expands to a diameter of approximately one and a half times the original. This forms a second rivet head that holds the materials to be joined together securely.

It's simple - How to set rivets yourself ||

I hope it helps you understand how and what to do.

What riveters are:

Regular low-cost model

Take, for example, the cheapest option from Stayer - the very first photo.

Its cost is 300 rubles.

It supports all rivet diameters (2.4mm, 3.2mm, 4mm and 4.8mm), so you can choose the most suitable rivet diameter for the materials to be fastened.

For example, thin rivets with a diameter of 2.4 mm are intended for fastening sheet material with a total thickness of up to 5 mm. Of course, there is also such a parameter of blind rivets as length. The longer the rivet, the thicker the material can be fastened.

I bring to your attention a table of the ratio of the size of the rivets and the thickness of the material.

Riveters with swivel head

It differs from the usual one in that the “head” of the riveter can be rotated 360 degrees. This helps a lot when working in hard-to-reach places, where ordinary people cannot crawl. True, it costs more, about 350 rubles. We also consider the model of the Styer firm.

It differs from the usual one in that the “head” of the riveter can be rotated 360 degrees. This helps a lot when working in hard-to-reach places, where ordinary people cannot crawl. True, it costs more, about 350 rubles. We also consider the model of the Styer firm.

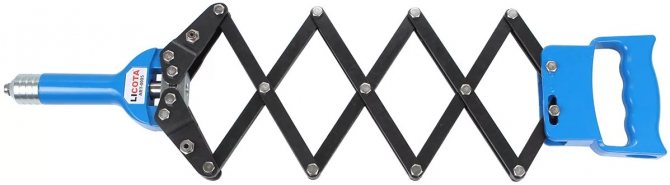

Reinforced models (two-handed)

For people who work as a riveter constantly, power options are released.

They differ from the usual ones in that they squeeze it with both hands, respectively, forces are significantly saved. Imagine you need to rivet 500 rivets. It will be difficult to perform such a volume of work with an ordinary riveter, but with a reinforced riveter, you can rivet everything much faster and without tension. How reinforced looks like - in the photo below.

Professional models with extended service life

In addition to household models, for household work, there are also professional ones on sale. They differ from household ones in better quality performance and increased service life. For example, a model from kraftool. The usual, non-rotating model, however, costs a lot more. In the photo below, the riveter Kraftul - the price is 400 rubles.

All riveters come with 4 interchangeable nozzles for different rivet diameters. They are changed using a special key, which is also included in the kit.

Rivets are usually sold in small packs of 50.Rivets differ in diameter and length, the thicker and longer the rivet, the more expensive the packaging is. For example:

- 3.2 * 6 mm - price 26 rubles

- 4 * 12 - cost 35 rubles

- 4.8 * 16 - 50 rubles

When buying consumables, do not forget that rivets are needed for the riveter, pull-out. Ordinary ones are also sold in stores, which are riveted with a hammer.

What is riveting

The mechanical connection of parts using a series of rivets is called a riveting, and the connection itself is a riveted seam. It is used where it is inconvenient to weld parts or where non-weldable materials are connected. Not only metals are riveted, thus they connect parts in clothes, accessories, etc. But there it is more of a finish than a loaded connection. So further we will talk about riveting in construction or home improvement. In principle, instead of riveting, you can use a screw connection, but bolts and nuts are more expensive, and their installation takes more time.

This is what a riveted joint looks like

If we talk about installing fences made of profiled sheet, rivets are more reliable, since they can only be removed by reaming the fasteners. When installing screws or self-tapping screws, they can be unscrewed and carried away both metal and hardware. In some cases, riveting is more convenient when installing a roof from corrugated board or metal. On the roof, the installation of screw connections is problematic and time-consuming. And with rivets, and with a good tool, you can do it in an hour or even less.

The most common use in the personal household

How are parts connected with rivets? The rivet is inserted into the prepared through hole. It has a head that rests against the material and the rod. During the riveting process, the end of the rod is flattened, changing its shape under the influence of force. Therefore, plastic metals are used for these hardware.

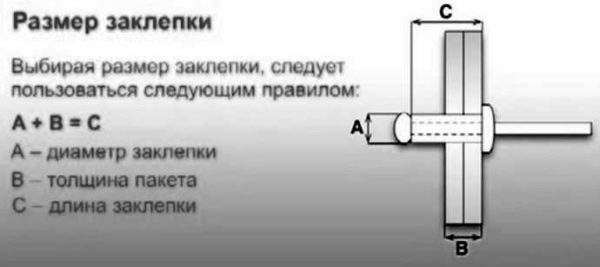

Sizing rivets

The rivets are selected based on the thickness of the metals to be joined. In this case, the following are important: the parameters of the insert head, the diameter of the rod. The diameter of the bar determines the diameter of the drill, which is used to prepare a hole in the parts to be joined. You can roughly determine the diameter of the rivet by doubling the thickness of the parts to be joined. The length of the rod is at least 2 diameters of the rivet, and the protruding part must be at least 1.25-1.5 of the diameter.

| Rivet diameter | 2.0 mm | 2.3 mm | 2.6 mm | 3.0 mm | 3.5mm | 4.0 mm | 5.0 mm | 6.0 mm | 7,0 mm | 8.0 mm |

|---|---|---|---|---|---|---|---|---|---|---|

| Hole diameter for precision assembly | 2.1 mm | 2.4 mm | 2.7 mm | 3.1 mm | 3.6 mm | 4.1 mm | 5.2 mm | 6.2 mm | 7.2 mm | 8.2 mm |

| Hole diameter for rough assembly | 2.3 mm | 2.6 mm | 3.1 mm | 3.5mm | 4.0 mm | 4.5 mm | 5.7 mm | 6,7 mm | 7.7 mm | 8,7 mm |

In general, the diameter of the rivet shank can be from 1mm to 36mm, and its length can be from 2mm to 180mm. Moreover, a larger diameter is not equivalent to a greater bond strength. Here both the material from which it is made and its type (hollow or solid) play a role. How do you choose? According to the characteristics of rivets. After all, you choose them for the connection of certain materials of a certain thickness. You know about the load that will be applied to the connection.

Therefore, when selecting, pay attention to what the manufacturer recommends

How to choose a rivet according to the thickness of the material to be fastened? According to the manufacturer's instructions, but in general, the diameter of the rod should be at least twice the thickness of the materials

Recommended connection diameter. You just have to pick up the drill and make a smooth hole without burrs.

Minimum and maximum thickness of the bundle to be joined

It is important that your connection is in the specified range.

Shear force. This is the load applied perpendicularly to the joint that the rivet can withstand without breaking.

Breaking force

At what load along the rivet will it collapse?

It is the tensile and shear forces that determine the strength of the future seam. The higher these values are, the more loads it will withstand.

Aluminum hammer rivets

Solid shank rivets - hammer rivets - are a common type of rivet used in aircraft structures. These rivets are the oldest and most reliable of all fasteners. They are also widely used in the construction and repair of small river and sea vessels, such as motorized aluminum boats and cutters.

The advantages of rivets are relatively low cost, as well as less labor intensity compared to screws and nuts. In addition, automatic high-performance tools and equipment can be used to set rivets.

Rivets are designed to be shear, so they are not used for joining thick materials or if the materials to be fastened are subject to tensile loads. This is because the tensile strength of rivets is usually quite low compared to their shear strength. The greater the overall thickness of the sheets to be joined, the more difficult it is to connect them well with rivets.

Riveted joints are in principle not airtight unless special sealants or gaskets are used for riveting. Since the rivets are set "permanently", in order to remove them, they are drilled out, which is a rather difficult task.

How can you make steel rivets yourself?

But first, let's figure out how to put on the simplest denim button. Poke a hole in the waist of your jeans with an awl and insert the leg into it. Place the button on the anvil (preferably on a metal surface) and hammer the leg. It is the leg, not the button. When buying a denim button, choose a set that has a leg cut, as shown in this photo. This foot will be securely held inside the button. A smooth leg can "jump out" over time or under load.

Now let's try to install a button for jeans of a more reliable design, the leg of which moves freely. This is where you need a dowel cut down on emery. The fact is that the leg of such a button needs to be expanded inside the button itself. You will not be able to "get close" to it without a special tool. But with the help of a sawn dowel, this is easy to do. And since the dowel does not bend, it can reliably expand the leg with it. But first, pass the leg into the belt, put a button on top of it and see how far the leg comes out of it. Perhaps the edge of it will need to "bite off" with pliers. Otherwise, your leg will simply bend and then not be flared.

The antennae button (No. 1) is installed approximately the same way, only this operation needs to be performed only for the upper part of the button. The lower part is much easier to install. To install the second part, in the store you can buy a special tool with a recess inside. But if you do not have one, then you can use a metal plate with a hole exactly the size of the "pimples". Insert this pimple into the hole of the metal plate, and “slam down” the leg with a hammer on the back of the garment. The antennae button is very difficult to install without special tools, so buy more of these buttons than you need.

The latter type of button, which is sometimes used in knitted garments, is not difficult to install. However, some advice can be given too. First, make sure the petals on the bottom of the button fit exactly where they should be. Sometimes they are bent, so you have to bend or align them with pliers so that during installation all the petals "go" into the upper part. If for some reason the button is not installed correctly, remove it and put another, new one. It is better not to use the damaged button anymore, since it will no longer be securely held. They are inexpensive, so buy them with a margin.

How to open a mini-studio At home, a press for installing buttons is not required, but in an atelier, such a tool is definitely needed, especially if your atelier is engaged in the repair of leather clothes, bags and other accessories, where various accessories are often used.

Technology of sewing and cutting natural fur Sewing of fur or leather can only be performed with high quality by a professional who has special equipment, tools and experience, including tools for installing clothing accessories. However, in some cases it is possible to install buttons or blocks without special tools and fixtures.

Recommendations for working with leather Almost any leather clothing, accessories use various accessories. To "punch" a neat hole in the skin to install a button or a block, you must use a special punch.

How to sew curtains yourself - small tips For curtains, special accessories are often used - eyelets. The eyelets outwardly resemble blocks, however, it is impossible to install the metal eyelets on your own, since without a special press you will not be able to accurately flare their edges. Use plastic eyelets. Their halves are snapped to each other and therefore installation will not cause any difficulties.

Interlining and adhesives When installing accessories on loose, knitted fabrics, be sure to use adhesive fabrics. The glued sections of the garment will be securely held between the parts of the block.

2 Application Methods - How to connect 2 plates?

Before using rivets, you need to know how to rivet certain parts correctly. There are many connection methods, but they are usually divided into 3 types. Strong fasteners are used exclusively where certain loads are present. Sealed, as the name implies, are needed in order to ensure tightness at the joints of sheets or any parts. Finally, the permanently sealed ones perform both functions. It should be noted that for the second type, that is, for sealed rivets, the insert heads are made reinforced.

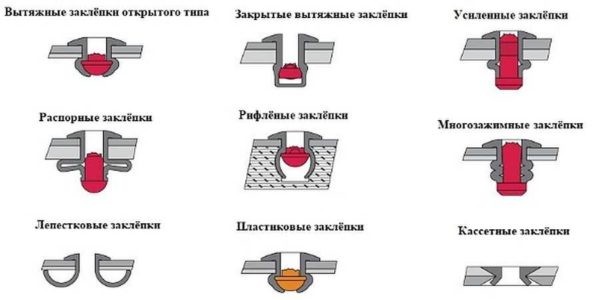

Blind rivets

The most common method of connection is overlap, while it is applied not only to sheet metal, but also to parts of complex shapes. This option is also called single cut. Under the influence of multidirectional loads, for example, when stretching, such a seam can easily deform. A butt joint is more durable, using one or two (on both sides of the seam) overlays, but this option, also called multi-cut, greatly heavier the structure and leads to greater material consumption. Installation of rivets for fasteners can be chain or staggered, the second is more reliable, but very laborious.

A wide range of hammer rivets in our company

A special place in the assortment of our company is occupied by rivets of various types and modifications. We have hollow rivets, copper rivets, brass rivets, aluminum rivets, steel rivets and hammer rivets at the most affordable price. The latter type is widely used in mechanical engineering. Experts and practitioners also call it "shock", since the formation of fasteners during its use occurs from impact.

The best domestic and foreign manufacturers today provide us with products of any modifications. Hammer rivets are made not only from pure metals, but also from alloys. The combination of different materials improves the performance of the product.

Various types of such products are widely represented in the OPM company. They differ in the way they are installed and used. A product such as a hammer rivet is widely used in the automotive industry, and exhaust models are mounted using rivets, and most often they are used to fasten sheet metals and products from them.

A wide variety of hammer rivets are used in construction for fastening facing materials to frames and bearing joints, in mechanical engineering - in various units and elements of machines, in aircraft construction, in the production of various household appliances and electronics - from washing machines to computer cases.

They are used for one-piece joints, and a product such as a hammer rivet is used in joints that must be characterized by increased resistance to mechanical stress. Non-ferrous metal products are resistant to corrosion, therefore they are used in the joints of structures, structures, devices and mechanisms that can be used in various aggressive environments.

Hammer rivets are produced in different strength classes, types of heads, and their model series also differ in diameter and length. There are various types of fasteners on sale, only a very small part of them are listed here.

The OPM company works with the best domestic and foreign manufacturers of fasteners, and in the company's catalog you can find products of any modifications. And the hammer rivet is represented by one of the widest model ranges. We offer an individual approach to each client. Also at your service - prompt delivery of the ordered goods not only in St. Petersburg, but also in other regions of the Russian Federation. The highest quality of fasteners from leading manufacturers is guaranteed. For more information, use the contact numbers: 8 (812) 335-00-52, 8 (812) 600-40-71 or 8 (812) 320-28-84.

Peculiarities

Rivets are fasteners in the form of a sleeve or a rod with a embedded head at one end and a head that closes in the process of riveting at the other. Threaded rivets differ from blind rivets by the presence of a thread. That is, they are hexagonal or cylindrical bushings with a support flange in the upper part and a thread in the lower one. The upper part is made in the form of a thin-walled tube without threads and often has a longitudinal outer notch. During the installation process, it is deformed. The vertical notch on the top ensures uniform deformation and prevents material tearing.

The advantages of threaded rivets include:

- ease of use;

- strong fastening of elements made of fragile and thin materials such as sheet metal without deformation;

- the possibility of one-sided fixation in the event that the total thickness of the parts to be joined exceeds the length of the fastening element without loss of strength;

- maintaining the strength of the connection over time;

- mechanical and chemical non-aggressiveness;

- maintaining the integrity of the surface and paintwork;

- the ability to connect elements from different materials;

- lack of mechanical stress in the structure;

- possibility of dismantling and re-installation.

Despite the fact that at present, in most cases, instead of rivets, welded or glued joints are used, the fasteners under consideration have a number of advantages in comparison with them, which determine their indispensability in some nodes. First, threaded rivets are thermally stable. Secondly, they do not cause structural changes in elements during installation, unlike welding, which is especially important when joining parts made of different materials, the behavior of which can be unpredictable. Thirdly, threaded rivets ensure movement retention.

However, these fasteners have several disadvantages:

- installation is complicated by the need for pre-making holes;

- most threaded rivets do not seal the seams;

- installation is associated with high noise levels.