How to choose a fire pump?

First, you need to decide for what purpose this technique is needed. For watering or irrigating the garden, it is not necessary to purchase a heavy-duty unit. You can take a closer look at models with a capacity of 130 liters per minute and a lift height of 7 meters.

If you want to create a water supply in the house using this technique, then you need a machine with a capacity of at least 500-800 liters per minute and with a lifting height of 35 meters.

If you will drain the site or pump out a septic tank, the mud pump should have the following parameters: productivity - 1000 liters per minute, lifting height - 20-25 meters.

Fire motor pumps differ in fuel type: gas, petrol and diesel. The first two are similar. In addition, a gasoline unit can be easily converted into a gas one by installing a special design for this.

It is also worth noting that gasoline motor pumps are best suited for summer residents. They have a four-stroke engine and low noise. However, the consumption of gasoline is quite large, besides, you will get a small motor resource. Another great option is gas units. Such fuel is cheap, its consumption is minimal.

Diesel engines are suitable for a large number of long-term works. Such a fire pump will cost more, but at the same time its motor resource is much higher.

For extinguishing forest fires

A small-sized mobile motor-pump "Mini-Stryker" is quite suitable for solving this problem. Despite its small size, it provides a high head. Such an attractive combination of properties allows the unit to be quickly transported to the scene of an accident and effectively suppress even strong flames.

Systems commonly used for fire extinguishing have an unjustified tilt to one side or the other. Due to the low consumption of fuel, it is possible to extinguish fires lasting more than 1 hour continuously.

The developers took care of preventing engine deformation due to a drop in the oil level in the crankcase. There is a special sensor that detects its excessive loss. This solution increases the pump usage time by 15% compared to analogues. The pump parts themselves are made of aluminum alloy, additionally anodized. The pump system can be used not only for fire protection, but also for purely domestic purposes.

What else to look for when choosing a motor pump

When choosing a fire pump, you must first outline the range of tasks for the solution of which such equipment will be used, which will determine the list of requirements for this technique. For the needs of a summer cottage or a private house, it makes no sense to purchase an expensive high-pressure fire pump, which will not be used to its full capacity, and the cost of maintenance (in particular, the purchase of spare parts for motor pumps of a professional category) will require a lot. For such purposes, you can purchase a budget model capable of operating with a capacity of 130 liters of clean water per minute and forming a flow of a liquid medium within 6-7 meters.

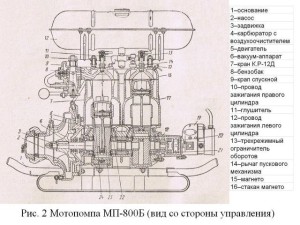

If a motor pump is purchased for the purpose of arranging an autonomous water supply system for a private house or summer cottage, then equipment will be required that works with a capacity of 1000 l / min, capable of creating a pressure with a water column height of 20-25 meters. Many models of pumps from Russian manufacturers, as well as products of foreign companies, correspond to such parameters.One of such devices, which has proven itself well among domestic users, is the MP 800 pump. Its prototype is the Soviet MP 600 motor pump, which is well known to many specialists and private users. The high-pressure motor pump of this model is characterized by high reliability, it is economical in terms of fuel consumption, and is easy maintenance and repair. Another advantage of choosing equipment from Russian manufacturers is that, as a rule, there are no problems with purchasing spare parts for motor pumps of domestic brands.

Soviet fire pump MP 800

To solve larger-scale tasks related to the drainage of large areas, as well as to extinguish fires, equipment with a higher productivity will be required. One of the successful options in this case is MP 1600 - high-pressure motor pumps transported to the place of use on a special wheeled cart. As in the case of the MP 800 model, there are no problems with the purchase of spare parts for the motor pump of this modification, as well as with its maintenance.

Features of operation

Before buying a motor pump, you need to imagine where it will be used, from which source the water will be taken. For high-pressure firefighters with a motorized motor, the suction height reaches 7-9 m. Suction hoses are completed with the corresponding length. The sleeves must be reinforced, which excludes breaking and stretching.

If the depth of the water source does not allow the hose to be completely immersed in it, then floating filters are used. They allow water intake from a depth of about 2 cm.

Each model is supplied with technical documentation that must be studied before launching. It describes what should be the operation of fire engine pumps, how to store, install, clean them. You should also figure out how to quickly stop the pump if an abnormal situation occurs.

Use lubricants recommended by the manufacturer. Do not pump seawater, chemicals, waste oil with a fire engine pump, unless otherwise specified in the documentation. All this can damage the pump and damage the unit.

To install a fire pump, choose a flat area with a hard or loose, non-sagging coating. There must be free access to the motor pump from all sides. The trailer is detached from the towing vehicle, support shoes are placed under the wheels.

Routine maintenance consists of cleaning from dirt and dust, adjusting the main components, refueling with oil and fuel. The oil level and the cleanliness of the filters must be checked. To prepare for winter storage, you must drain the fuel and change the oil. If you follow all the rules, then the motor pump will last 10-11 years without failures.

Model MP-600 "Virgo"

Despite such a romantic name, this product has a number of advantages:

-

high structural reliability;

-

low fuel consumption;

-

cooling the engine with air flows;

-

excellent resistance to pollution;

-

easy start;

-

high pumping capacity.

The attractive technical characteristics are due in large part to the quality manual piston pump. It is capable of pumping water from a depth of 7.5 meters.

The shaft is sealed axially and at the end in such a way as to minimize the need for maintenance. All pump connections are made in accordance with Russian GOST. The engine is started using non-contact transistor ignition; pressure lubrication is provided.

At the request of the customer, this motor pump can be equipped with:

-

electric starter;

-

mesh that prevents the absorption of dirt;

-

non-standard adapters;

-

spotlight.

A single-stage centrifugal pump with a suction height of 3 meters can deliver 10 liters of water in 1 second.

The dry weight of the device is 58 kg.After refueling, it grows to 66 kg.

The total power of the engine, which receives fuel from a tank with a capacity of 8.5 liters, reaches 18 liters. with.

Applications

Firefighting motor pumps are very popular both among representatives of public utilities, owners of agricultural and construction companies, and among owners of summer cottages and private houses. The most common tasks that can be effectively solved by a fire engine pump include:

- elimination of hotbeds of fire;

- elimination of the consequences of floods and flood situations;

- elimination of the consequences of accidents in water supply and sewerage systems;

- organization of watering of plants;

- pumping out water from flooded basements and cellars;

- drainage of construction pits and trenches;

- pumping water from natural and artificial reservoirs, underground and surface reservoirs;

- flushing of wells and shafts of wells before using them or after long-term operation.

Modern fire-fighting motor pumps are in no way inferior to civilian equipment in terms of equipment and often surpass it in terms of reliability.

If we talk about highly specialized areas of application of fire-fighting motor pumps, then this includes pumping water from the holds of ships, caves, grottoes, as well as reservoirs for any other purpose.

Technical characteristics of motor pumps

If you decide to purchase a fire engine pump for your site, then, first of all, you need to decide on the scope of its application. Motor pumps differ according to the following criteria:

- Suction depth. If you are going to be a unit to drain wells or pits, you need to determine the maximum depth, and then select the appropriate equipment. Also, this parameter is necessary when taking water from reservoirs;

- Performance. This characteristic is measured in liters pumped over one minute;

- Aggression. If you water a garden plot with a motor pump, then, based on its size, you can choose a machine with a suitable parameter for the horizontal water supply distance.

A motor pump for extinguishing a fire also has another important parameter - fuel consumption. Household units with low productivity do not consume more than 2 liters of fuel, but for high-performance models this figure can reach 5 liters per hour.

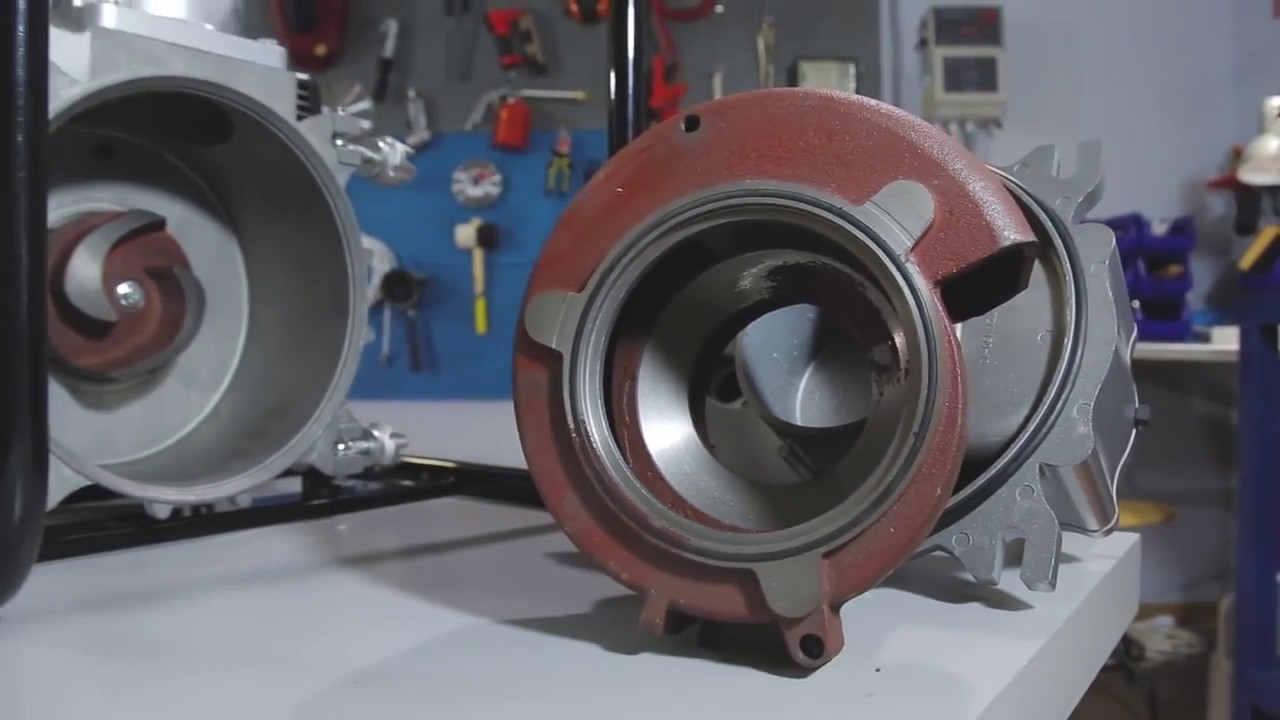

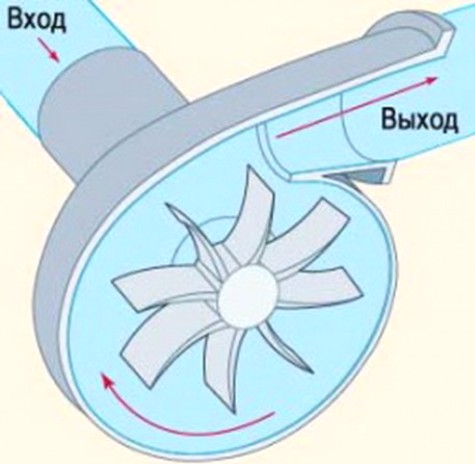

Motor pumps can have two types of pumps:

- centrifugal. It is used to work with clean or slightly contaminated water. The word "fire" is not an indicator that there is special equipment in front of you, but only that the equipment develops high pressure in the pressure head. It is used not only for extinguishing fires, but also for supplying water over long distances. Perfect for areas located at a great distance from the water source. Often, such pumps are equipped with a four-stroke gasoline or diesel engine, the capacity can reach up to 600 liters per minute with a lifting height of 60 meters;

- membrane is suitable for work with dirty and highly polluted water. Such units have great productivity, as well as the ability to pass solid debris up to 2.5 centimeters in size. The device is designed in such a way that you can easily reach the pump to remove particles larger than its capacity. The capacity is 2000 liters per minute with a lifting height of 35 meters.

Answer

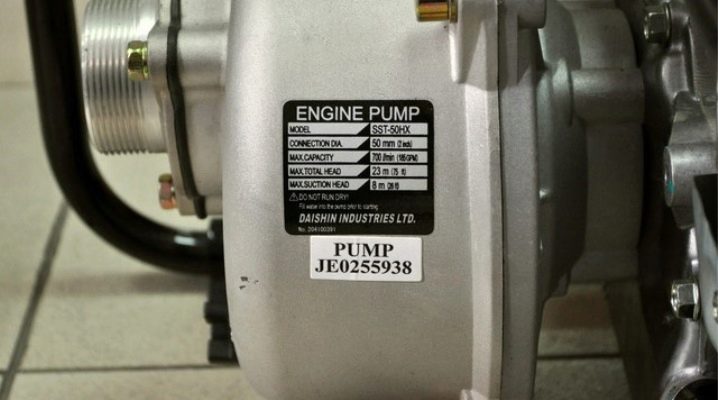

Today, many companies offer high-pressure motor pumps from various manufacturers (Koshin, Subaru, Honda, SDMO, etc.) for fire extinguishing. The fact that these units can be used for these purposes is indisputable, but how effective is it? With the onset of the summer season, we decided to consider this topic. For example, consider two motor pumps: a high-pressure model Koshin SERM-50V with a declared head characteristic of up to 90 m?/ h and fire Rabbit P555S with a head up to 100 m?/ hSo, let's turn to the technical characteristics: Motor pump Koshin SERM-50V:

Manufacturer: Koshin LTD., Japan Average retail price in Moscow: 28,700 rubles Maximum head: up to 90 meters Maximum flow: up to 500 l / min Engine: Mitsubishi GM182, Japan Dry weight: 34 kg Starting system: Hand starter Feature: Availability of 3 outputs on the pumping part: one 2 ”(50mm) main spigot and two 1” (25mm) auxiliary spigots. Motor pump Rabbit P555S:

Manufacturer: FUJIHEAVYINDUSTRIES Ltd., Japan Average retail price in Moscow: RUB 290,000 Maximum head: up to 100 meters Maximum flow: up to 1270 l / min Engine: Robin, Japan Dry weight: 88 kg Starting system: Auto starter (battery included) Feature: Vacuum pump As you can see, both models are Japanese-made with reliable gasoline engines, but the price difference is more than 10 times. For what? Let's imagine the worst situation - a fire. Your first reaction is to call the fire department. Further, an attempt to extinguish the source of fire on their own. For this, the motor pump must be assembled next to the water source, therefore, we do not consider the difference in the weight of these units by 3 times. Model Koshin SERM-50V with manual start and you start convulsively tugging on the starting cord. If the motor pump started up the first time, you're in luck! Otherwise precious seconds are wasted. The Rabbit motor pump has an auto-start and starts with the push of a button. Further, the Koshin motor pump requires, before starting, filling the pumping part with water for self-priming from the water source. It's good if it's warm outside and you can keep the pumping part flooded initially, but if it's winter? Again, the loss of such a precious time. The Rabbit P555S model has a vacuum pump, i.e. the motor pump will self-priming itself. Well, now the most important thing: with a pressure of 90 meters, the flow rate of the SERM-50V model will be 1 l / min !!! What can you put out with such a filing a big question? The fire pump P555S with a head of 100 meters has a flow rate of 870 l / min. There is a difference? Conclusions: If you need a real fire engine pump, which will allow you to cope with the source of fire on your own before the arrival of the fire brigade, this is the Rabbit P555S. Otherwise, it is only your choice!

How does it work?

The technique works according to a specific algorithm.

- The diaphragm or impeller is driven by a motor.

- In a rarefied environment, water fills the hose (self-priming system), then flows into the discharge pipe.

- The autonomous engine system makes it possible to work without a mains supply. Accordingly, the technique can be used for irrigation, water supply, extinguishing fires, etc.

Motor pumps are distinguished by their performance. Water supply can be carried out within a radius of hundreds of meters. Such pumps are indispensable in the household.

Water rises horizontally and vertically. The calculation is as follows: 1 meter of vertical water rise per 10 meters of its horizontal direction.

Areas of its application

In recent years, the technical characteristics and model range of such equipment have been constantly improving, and their performance has been increasing. These devices are used in various sectors of the national economy, where it is necessary to pump water using mobile devices. At one time, in the former USSR, at the Leningrad plant, trailed and portable fire-fighting motor pumps were produced. Their main difference from simple pumps is that they have a very high performance.

We watch the video, scope of application:

Therefore, pumping out flooded basements and wells, holds of ships, mines and caves, grottoes, as well as flushing wells, drilling - this is not a complete list of applications for a fire engine pump.

In agriculture, it helps to fight droughts and floods, in utilities and on construction sites, the equipment allows you to eliminate emergencies, and the most important purpose is to fight fire

Tohatsu VC72AS

This type of fire pump is equipped with a two-stroke engine with two cylinders. The total capacity of the plant reaches 40.8 liters. sec., which is not surprising, since the capacity of the combustion chamber is 617 cubic meters. see Such a powerful motor is water-cooled. To work for 1 hour, he needs 16 liters of AI-92 gasoline.

The energy generated by the engine is transferred to a single-stage turbine-type pump. Its head varies from 40 to 100 meters (from 4 to 10 kgf / cm2) with a step of 20 meters (2 kgf / cm2). Liquid flows in through a hole with a diameter of 10 cm. The outlet is noticeably narrower - only 6.6 cm. Self-priming of water is possible from a depth of up to 9 meters.

The pump body of this motor pump is made of a corrosion-resistant aluminum-based alloy. This solution made it possible to reduce weight, while at the same time extending the period of operation. Unlike steel counterparts, the unit can even pump seawater.

According to the manufacturer, the water used to cool the engine cools down, then returns, and therefore does not harm the environment. The engineers managed to solve the problem of starting the pump in all weather conditions.

If suddenly the power plant overheats for any reason (the temperature has reached 89 degrees or more), then at the command of a special sensor, it stops. The capacity of the fuel tank ensures maximum pump operation for 1 hour. The branch pipe through which the water is discharged outside can rotate at an angle of 90 degrees.

Choice in the market

The range of fire pumps on the market is quite wide. There are models of domestic production, European, Chinese. Japanese motor pumps are in great demand. Since fire extinguishing is a responsible event, the choice must be made based on performance, reliability and availability for repair.

A striking example of a fire-fighting motor pump on a trailer is the Geyser 1600 model. Geyser is a Russian trade mark widely known for its products.

Motor pumps from this manufacturer are purchased by public utilities not only for fire extinguishing, but also for pumping water from basements, pits, sewerage systems.

Geyser 1600 is a high-pressure fire engine pump with a gasoline engine and an electric starter. It gives a jet of water up to 190 m high, with a maximum flow rate of 1200 l / min. The engine uses a 4-stroke domestic VAZ 2108, which makes it easy to carry out repairs in the event of a breakdown. On one full tank, the capacity of which is 20 liters, a fire engine pump can work a little over two hours.

Due to its power, versatility and reliability, the MP-1600 motor pump of the Melitopol plant "Hydromash" is in demand. It is currently marketed under the brand name MM 27/100. The motor pump is installed on a two-wheeled frame. It uses a ZAZ-4121 engine and wheels from GAZ-24. The water consumption is at least 1600 l / min, the maximum jet height is 100 m.The pump can suck in water from a depth of 7 m.

In addition to working with water, a fire engine pump can pump a foam mixture to extinguish fires. Control over the operation of pumps, motor, foam generator is carried out using the control panel.

Among other brands, fire-fighting motor pumps of increased power Aquarius are popular. There is always a demand for Tohatsu, LZPM, Robin Subaru pumps. There are positive reviews about portable fire pumps Koshin, Champion.

Where is used

The main advantage of a fire pump is autonomy. It can be transported to almost any place, installed where there is no electricity or running water. The source of water can be artificial or natural reservoirs. Sometimes it is connected to hydrants if the burning object is too far away and the water pressure is not enough to extinguish the fire.

The purpose of a fire engine pump is much wider than one might imagine.It is used to pump out water in case of flooding of premises, basements, wells and pits. The motor pump is purchased by fire departments and enterprises, whose buildings are located separately from the main settlements. Often a motor pump is used in rural areas, cottage and summer cottages for irrigation. On sea and river vessels, construction sites, it is indispensable as a tool for pumping water.

Choosing a motor pump

For the needs of the suburban area and garden does not require "prohibitive" power and productivity. Watering the garden will be handled by a unit capable of pumping 130 liters of clean water in 1 minute and raising it to a height of 6-7 meters.

If we are talking about the water supply of a country house, then attention should be paid to models with a capacity of at least 500-800 l / min and a lifting height of 20-35 meters. To drain the flooded area or pump out the septic tank, you will need a mud pump capable of pumping out at least 1000 liters of liquid in 1 minute (lifting height 20-25 meters)

To drain the flooded area or pump out the septic tank, you will need a mud pump capable of pumping out at least 1000 liters of liquid in 1 minute (lifting height 20-25 meters).

Speaking about the selection of the unit by the type of fuel, it should be noted that gasoline pumps are characterized by a low price and low operating noise. Their weaknesses are high fuel consumption and relatively low service life. An important advantage of gasoline motor pumps is the 4-stroke engine. It is more durable than a 2-stroke one and does not require the preparation of an oil-gasoline mixture.

Another profitable option for a summer resident is a gas motor pump. It can operate from a conventional LPG cylinder or be powered by a main gas pipeline. Its fuel consumption is almost 2 times lower than that of gasoline.

If the pump has to work a lot and for a long time, then the best solution is a pump with a diesel engine. It is more expensive than a gasoline engine, but at the same time it has a service life several times higher than the capabilities of a carburetor engine (up to 5,000 hours).

General design features and principle of operation

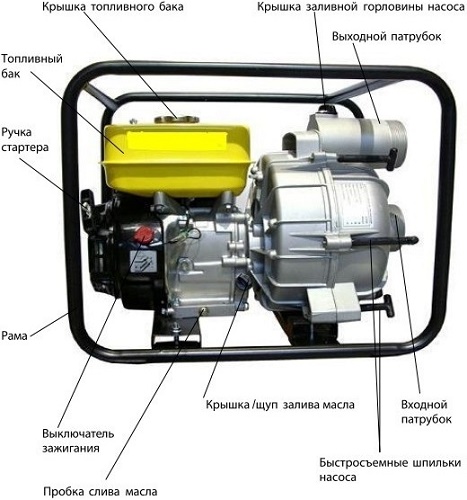

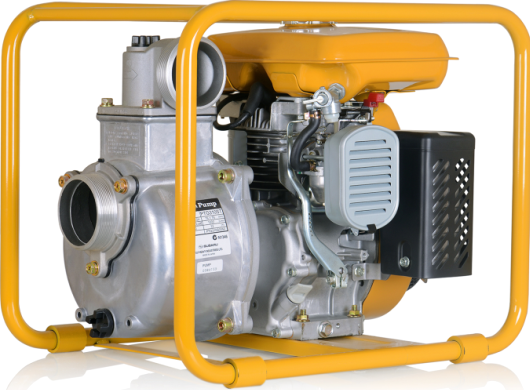

The general design features of motor pumps of both Russian and foreign production are the presence of the following elements in the equipment of such devices:

- drive motor;

- pump;

- a metal frame that performs a load-bearing function and protects all elements of the pump structure from vibration vibrations;

- a fuel tank, the capacity of which determines how much a fire engine pump can operate without interruption (models with a fuel tank capacity of at least 6 liters have rather good indicators of the duration of operation without refueling).

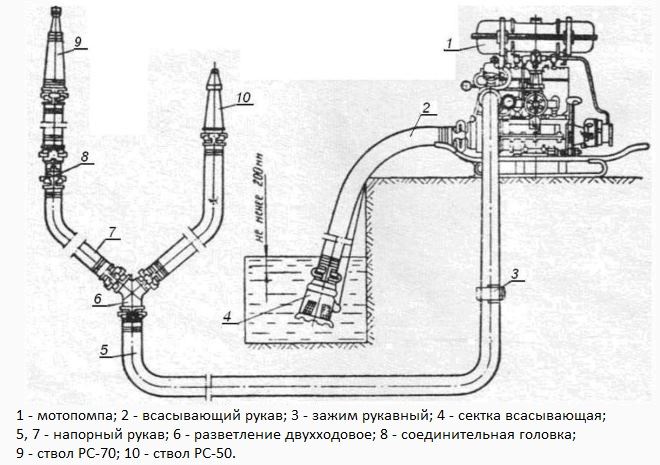

Portable fire pump device

Most modern models of motor pumps are equipped with mesh filters installed on the suction hose. The purpose of such a filter is not to let too large particles of solid inclusions contained in the pumped liquid medium into the pump working chamber. The size of the filter cells, depending on the technical characteristics of the pumping unit installed on the equipment, can vary within a fairly wide range.

An important parameter of autonomous fire pumps is the diameter of the outlet socket, to which the hose for the motor pump is connected. In many models, the inner diameter of the outlet socket is 10 cm, which allows you to create a good head of the liquid pumped by the device with an average productivity.

Installation diagram of a fire engine pump

Some models of fire-fighting motor pumps are equipped with closed-type housings, which allows for more reliable protection of structural elements from mechanical damage. Meanwhile, closed-type housings restrict access to the structural elements of the pump, which somewhat complicates its maintenance and repair.

A gasoline or diesel motor pump works in the same way as an electric pumping unit.The main difference between such devices is the type of motor driving the pump itself. Equipped with a gasoline or diesel drive engine makes the fire pump completely autonomous, capable of operating in places where there is no centralized power supply.

Design features and principle of operation

Scheme and device

Such devices differ in the type of drive (gasoline and diesel), in terms of water supply (outlet pressure up to 2 MPa and higher), in the way of movement (portable and trailed).

The fire engine pump pumps water from various sources (river, pond, well, tanks, pipelines) to extinguish fires or other household needs.

Autonomy in operation allows using the device in the most inaccessible and remote places, especially in villages and regional centers. Portable models are delivered by hand or by road, and trailed ones are mounted on a single-axle trailer.

How the motor pump works

At its core, a motor pump is a centrifugal pump powered by an internal combustion engine. The pump and motor are located on the same chassis, which makes the unit compact and mobile.

Gasoline or diesel engines can be used for the fire engine pump. Gasoline engines start better, give more revs. The gasoline engine is made with two or four strokes. Two-stroke models are less powerful, but more compact and mobile. They are used mainly in everyday life.

For production needs, models with a four-stroke engine are used. The gasoline motor pump creates less noise and is cheaper.

A diesel motor pump has a longer engine life than a gasoline one, fuel is cheaper, but a diesel model is more expensive.

Cooling of the motor pump is provided by an air or water system. Starting is done manually or with an electric starter. Some models have two options. The fuel supply is enough to work for at least 2 hours without refueling.

Modern models of motorized firefighters are equipped with a vacuum pump. Such a device simplifies operation. A vacuum is created at the pump inlet, therefore no preliminary filling of water into the pumping part is required.

MP-16/80 "Aquarius"

Such a device has increased power. The pump is capable of pumping 20 liters of water in 1 second. The nominal head is 80 meters (8 kgf / cm²), at maximum engine load it doubles. Liquid suction is possible from a depth of 8 meters. A motor from a VAZ 2103 engine with a total capacity of 71.4 liters is used as a drive. with.

Judging by the characteristics, there are few at least close analogs. "Aquarius" has been produced since 2004. Motor pumps of this model are subdivided according to the type of transportation into portable (equipped with skids) and transportable (with a cart) types.

Connection of pressure hoses of 0.2x7 cm format is allowed.

The suction shaft has a size of 0.1x10 cm. If we add adapters to the motor pump, it is possible to work with six shafts at once, located within 2 km from the water source. The device is equipped with a single-stage pump, which contains an impeller with a diameter of 25 cm.

It is recommended to use "Aquarius MP-16/80" at the following facilities:

-

on the territory of country holiday homes;

-

in suburban settlements;

-

at logging;

-

in other remote and inaccessible places for fire protection.