Cone Log Splitter Requirements

The tool that is considered optimal for harvesting wood fuel must meet certain requirements. This applies to any of the existing types, hydraulic, mechanical and cone. The kone log splitter must have the following parameters for successful work:

- working length (this is the name of the distance between the wedge and the piston, 50 cm is considered optimal);

- good splitting power (5-7 tons is considered standard), necessary for trouble-free splitting of the workpiece;

- a sufficient rotation speed (not less than 400 rpm, but not more than 600) to apply a directed force to the wood fibers;

- the second indicator of speed is the movement of the piston, which is usually done 4 cm / sec forward and 7.5 cm / sec - in the opposite direction;

- the presence of a travel stop, which simultaneously increases productivity and reduces the consumption of energy consumed;

- sufficiently powerful engine (about 3-4 kW);

- the shape and functionality of the screw, where the minimum operating speed determines the performance of both an industrial and a home-made device, in which the screw plays one of the defining roles.

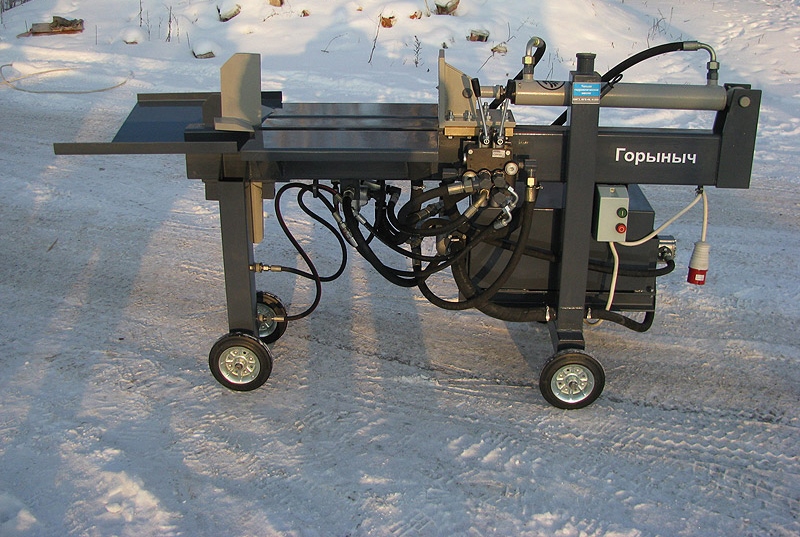

Size, power and maximum performance are three factors in the cost of purchasing a device made in an industrial environment.

Fact! A small mechanical model can be purchased for 6 thousand rubles. The more powerful the engine, the splitting force and the performance, the more expensive the device. The price of a wood splitter-screw can reach from 20 thousand rubles *. up to 125 thousand rubles *. The last installation pierces a 40 cm workpiece in 2 seconds.

Screw wood splitter diagram

How to choose?

The choice of instrument is dictated by the following criteria:

- the weight;

- material;

- the size of the hatchet;

- sharpening form.

Finding a tool that matches the physical characteristics of an employee is not an easy task. If the cleaver is too light, it will be difficult to split massive fragments, and when working with a heavy tool, more physical effort will be spent, but at the same time it will be much easier to split heavy ingots.

It is also important that the handle is made of solid wood that has "knitting" properties. The handle experiences a significant load, so it must have the above qualities

The short handle also does not fit - it is difficult to work with. Handles that are made of PVC or steel are not the best choice. Such axes are expensive, but it is inconvenient to work with such a tool. Such a tool will not be able to trim the trunks saturated with moisture, the diameter of which is more than 25 cm. The ax gets stuck in such material quite often.

Zealous owners, as a rule, use one of two types of ax: classic or wedge-shaped. The first type is convenient to handle freshly cut wood, in which there is a lot of moisture. The second type is convenient to chop dry scraps of logs.

Cone axes are easy to use and quite effective (especially when working with solid wood). The ingot is installed perpendicularly, a screw is driven into it, then it splits. The work is just mechanical.

The hydraulic drive helps in solving production problems - it makes it possible to separate the logs immediately.

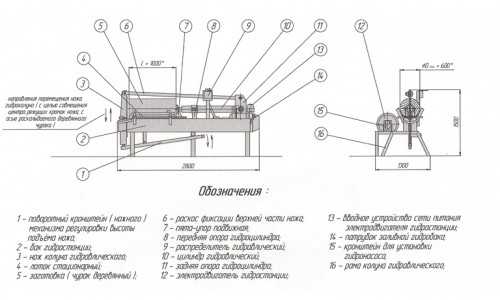

Assembling the structure

Of the two types disassembled above, the lightest in execution is the screw wood splitting unit. This is a common design with no complicated knots. It includes an electric motor, a screw cone, several bearings, a shaft and a gearbox.By the way, the latter can be in the form of a chain belt drive, it can be used as a factory unit with a gear drive.

Of the two types disassembled above, the lightest in execution is the screw wood splitting unit. This is a common design with no complicated knots. It includes an electric motor, a screw cone, several bearings, a shaft and a gearbox.By the way, the latter can be in the form of a chain belt drive, it can be used as a factory unit with a gear drive.

As for the motor, the best option is an electric one, although you can put a gasoline one if a huge wood splitter is going to be assembled. Remember that for a small machine, you can take a motor from an unnecessary washing machine, which operates on a voltage of two hundred and twenty volts. Although it has low power, by installing a high-quality gearbox, you can increase its power a couple of times

It is important here to choose all the elements correctly. For example, you can put a small pulley on the motor shaft, and install a huge pulley on the shaft on which the cone is placed.

And the more the difference between the diameters grows, the more powerful the device will be.

Do not forget! A very serious indicator is the speed of rotation of the working tool. It should not be higher than 500 rpm. Therefore, you need to choose the right gearbox for the electric motor.

Selection of bearings

Now about the selection of bearings. In principle, any can do, the main thing is that the shaft created under them is suitable for the loads acting on it.

Now about the selection of bearings. In principle, any can do, the main thing is that the shaft created under them is suitable for the loads acting on it.

For small wood splitters, a shaft with a diameter of 25 mm can be supplied. Accordingly, bearings with an inner diameter that fit the outer diameter of a certain shaft are bought for it.

The bearings themselves are mounted on a device in a special cast iron housing.

The housing can be separate for each bearing or one for two at once. You can buy a case from a master, but it is better to purchase old structures, which can always be found at any scrap yard.

The bearings are fixed to the bed with bolts. The frame itself at the installation site should be quite strong, therefore it is in the parts of the fastening under the bearing housings that a metal profile (angle, channel) is placed, which is welded to the frame of the wood splitter by electric welding. The very base of the machine is made of pipes or corners.

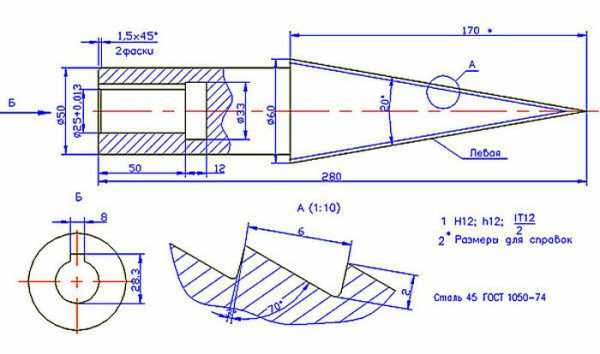

Cone

And the most important element of a screw device with a two hundred and twenty volt motor is the cone. To begin with, they create it from very strong tool steel. Therefore, it is very difficult to create it yourself - even for a master - at home. But this is not worth doing, because screw cones are now sold freely. Remember that you need to choose the right size for it, because what chocks can be cut depends on this. Here is the ratio of the dimensions of the cone to the dimensions of the materials to be cut with one tool length:

And the most important element of a screw device with a two hundred and twenty volt motor is the cone. To begin with, they create it from very strong tool steel. Therefore, it is very difficult to create it yourself - even for a master - at home. But this is not worth doing, because screw cones are now sold freely. Remember that you need to choose the right size for it, because what chocks can be cut depends on this. Here is the ratio of the dimensions of the cone to the dimensions of the materials to be cut with one tool length:

- diameter - seventy mm, bevel size - 1.1. With the specified characteristics, the split depth will be approximately 450 mm;

- diameter - eighty mm, bevel - 1.2, splitting depth - 550 mm;

- diameter - one hundred mm, bevel - 1.5, splitting depth - 750 mm.

Great attention should be paid to the direction of threading. She must be left

That is, during installation, the cone must rest against the log and still pull it towards itself. In fact, with the help of the thread, an auxiliary movement of the part is made - translational. It turns out that the working element itself will rotate.

This is quite important for household cone log splitters, because they will not have a special feed unit. Everything will be done manually

It is this option that will provide conditions under which it will not be necessary to apply tremendous pressure on the cut wood block.

The choice of the cone will depend on its design. There are only two types of them:

- with a shank;

- with an internal special hole.

In the first version, a hole is drilled from the end face into the shaft, on which the cone will be placed, for the dimensions and diameter of the shank. The final one is inserted into the hole in the shaft and fixed in it with a locking screw, which is installed on one side. In the second version, the shaft itself is inserted into the cone landing hole, where it is fixed with two locking screws.

Screw wood splitter

Log storage

When all the wood has been split, they must be put in a woodpile. A typical mistake of many summer residents and villagers is that they dump ready-made firewood in a heap. This cannot be done, because a wobbly structure can quickly collapse if at least one log is unsuccessful. But the most important thing is that the firewood piled in a pile does not dry well, which means that it can become infected with fungus and mold.

When all the wood has been split, they must be put in a woodpile. A typical mistake of many summer residents and villagers is that they dump ready-made firewood in a heap. This cannot be done, because a wobbly structure can quickly collapse if at least one log is unsuccessful. But the most important thing is that the firewood piled in a pile does not dry well, which means that it can become infected with fungus and mold.

You need to fold the firewood carefully, in much the same way as children, while playing, add blocks of the constructor. Logs, beautifully laid in a woodpile, look spectacular and make a pleasant impression on the neighbors in the country. It is also convenient to take them out when it becomes necessary to bring a few pieces of wood home. You need to store firewood only under a special canopy so that rain does not fall on them. If they are outdoors, cover the wood from rain with tarps or plastic wrap.

People who buy firewood from an ad often complain about the dampness of the delivered wood. In this case, the logs must be dried immediately and only then put into a neat pile.

If a woodworm beetle or other parasite has wound up in one of the logs, such a log should be immediately sent to the stove. Parasites are dangerous in that they gradually destroy the wood, and also make the wood more vulnerable to fungus and mold. Periodically, the logs need to be inspected and checked in what condition they are, and if they are folded nicely and neatly, it will not be difficult to do this.

Chopping firewood with a homemade cleaver is not as difficult as it seems. The main thing is that the ax is comfortable and sharp enough. There is a common misconception that a sharp ax can easily injure oneself. In fact, lumberjacks most often get injured precisely because the cleaver is not sharpened well enough. Having made an ax with their own hands and adapting it "for themselves", a summer resident or a villager will be able to significantly facilitate the annual work on the preparation of fuel for the Russian stove. It is much easier and cheaper than buying expensive equipment or purchasing someone's firewood of dubious quality.

The owners of country cottages, who heat the house with a solid fuel boiler or stove, annually harvest up to 12 cubic meters of firewood, depending on needs. It will take several days to prepare such a volume. To speed up the process, you can make a cleaver with your own hands - a special device for mechanized chopping of firewood.

We make a wood splitter screw ourselves

The simplicity of design and impressive performance are strong arguments for making such a machine with your own hands.

The most important part - a screw cone for a wood splitter can be purchased at a specialized tool store or ordered from a lathe. The cost of screws depends on the diameter (80-100 mm) and ranges from 1,500 to 5,000 rubles.

If you do not want to search for pulleys and make your own shaft, then buy a ready-made wood splitting unit. It consists of a screw cone (carrot), a shaft with bearing supports and a double-strand pulley with a diameter of 200 mm. The approximate price of such a kit is from 3200 to 5600 rubles.

This solution will make it much easier and faster to make a screw log splitter with your own hands. You will only have to draw a drawing of the machine, indicate the dimensions of the desktop, the structure of the frame, the attachment points of the engine and the wood splitting unit.

Of the exotic options for homemade wood splitters, one should mention the installation of a small screw cone with a diameter of 30 mm on the shaft of a hammer drill or a powerful low-speed drill (1.5 kW, at 500-600 rpm).

However, this simple homemade wood splitter cannot be called versatile and very effective in work. The maximum thickness of a split log for a wood splitter perforator does not exceed 10-12 cm.

When the screw is buried in the chock, it has a powerful torque, so it is quite difficult to keep it from turning with your hands. This problem can be eliminated by permanently fixing the hammer drill to a workbench.

Considering the possibility of self-manufacturing a screw screw for a wood splitter, it should be said that only experienced turners can do this work. There are stories on the net that it is powerful to grind a cone with the help of a grinder, but they cannot be classified as serious advice.

The accuracy of manufacturing the thrust thread must be high, so no grinder can replace a good lathe and a high-quality cutter.

When ordering a cone screw for a wood splitter, leave the turner not only a detailed sketch, but also the parameters tested by the masters in practice: taper 1: 2, two-start thread, pitch 5-6mm. The profile of the tooth of the carving should be the same as that of a self-tapping screw for wood.

Craftsmen who worked on homemade screw wood splitters write in their reviews that this process requires great care. You should only serve the logs with your bare hands.

The glove can easily be screwed onto the screw, which will seriously injure your fingers.

When splitting logs with large knots and chocks from the butt of the log, you need to be especially careful, since the screw is often stuck in them and it is difficult to remove it if the engine does not have a reverse.

Useful video on the topic:

Before the start of the heating season, the owners of wood stoves and solid fuel boilers stock up on firewood. It is not a big problem to buy or prepare logs in the forest, and then bring them to your own backyard. And cutting the round timber into chocks using a chainsaw or circular saw will not be difficult. Many hours of exhausting work creeps up in the form of a heavy cleaver, wedges and a hammer, with which the logs are split into logs.