Purpose and types of structures

Pipes are bent in cases where the use of factory fittings and bends when working with utility networks is not possible. With the help of a pipe bender you can:

- set a custom angle of rotation;

- set a custom bend radius;

- avoid the use of welding, threaded connections.

The main criterion by which the devices differ from each other is the method of action on the deformable pipe. These include running-in, winding, rod pressure, and rolling. The machines are produced on the basis of a manual, hydraulic, electric, electro-hydraulic drive. They can be stationary, mobile (wheeled), portable.

The rolling is performed using a stationary template around which the pressure roller is rotated. The profile of the elements is selected according to the shape of the section of the pipe, which is fixed between the template and the roller using additional fasteners. The winding template rotates around its axis together with the deformable tube, which is fixed by the friction and pressure rollers.

The stem pressure principle is used in crossbow type pipe benders. The pipe is supported on rollers set at the required distance from each other. A jack is used as an active element, a shoe (punch) is fixed on it, pressing on the bent element in the middle. Since pressure is applied to a limited area of the product, there is a risk of pipe wall thinning at the point of contact with the shoe.

Tube bending machines for rolling (rolling) consist of three rollers: two support and one central. The central roller exerts pressure, sets the radius of curvature of the product. Rolling machines do not require special templates, they can be used for pipes of different profiles, materials (including stainless steel) and different thicknesses. The smallest possible bending radii are shown in the table.

If the required bend radius is less than the minimum allowable, a mandrel pipe bender is used. It allows bending in zones of plastic deformation with all-round uneven compression. A rod with a fixed mandrel is introduced into the pipe - a mandrel made of steel with pivotally connected rings at the end. It is quite difficult to create such a device at home; the design is often simplified to the detriment of the quality of the finished product.

Option number 8. DIY electric jack

Our selection is completed by a rather complex lift, which not every home craftsman can handle. The electric jack consists of:

- electric drive;

- lever mechanisms.

Power window from VAZ 2110

Step 1. A drive with cables is not required, so everything needs to be unscrewed, leaving only the motor with the gearbox. In addition, you will need a 7 mm square head.

Square head

Step 2. The author also used a standard Lancer jack, but you can use any screw rhombus jack instead. For fasteners, you can use strips of metal or, as in our example, furniture corners.

The example uses furniture corners.

Step 3. The corners are trimmed, they are given the desired configuration. Then they are attached to the gearbox.

The corner is clamped in a vice Bending the corner Another photo of the process

Step 4. Then the mount and the head are welded to the jack, which is put on the gearbox.

The angle is attached to the gearbox The same, but from a different angle Head and mount are welded

Step 5. To control the structure, a button from the same power window will be used.

The design is controlled by a button from the same ESP

Which jack to choose

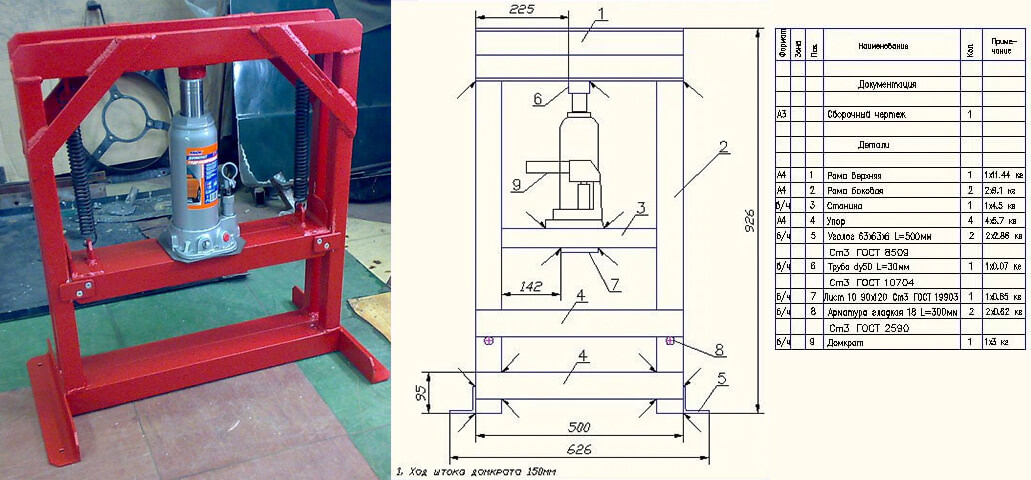

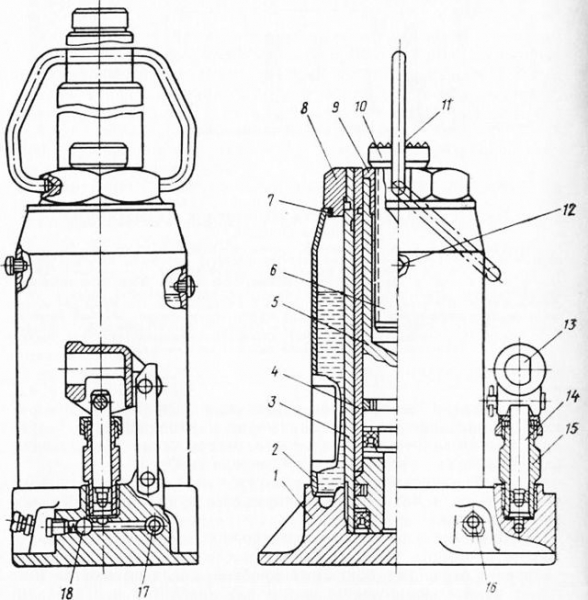

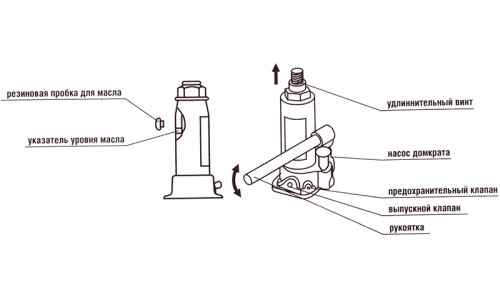

For production, devices of the single-stem bottle type are optimally suited, which are distinguished by a simple design scheme and high reliability. Presses made on the basis of such a jack have a higher power when compared with equipment, the main working body of which is lever, crank, screw or eccentric mechanisms.

Hydraulic jack press

Various models of hydraulic jacks are capable of producing a force, the value of which ranges from two to one hundred tons, which makes it possible to use them as a very effective lifting mechanism.

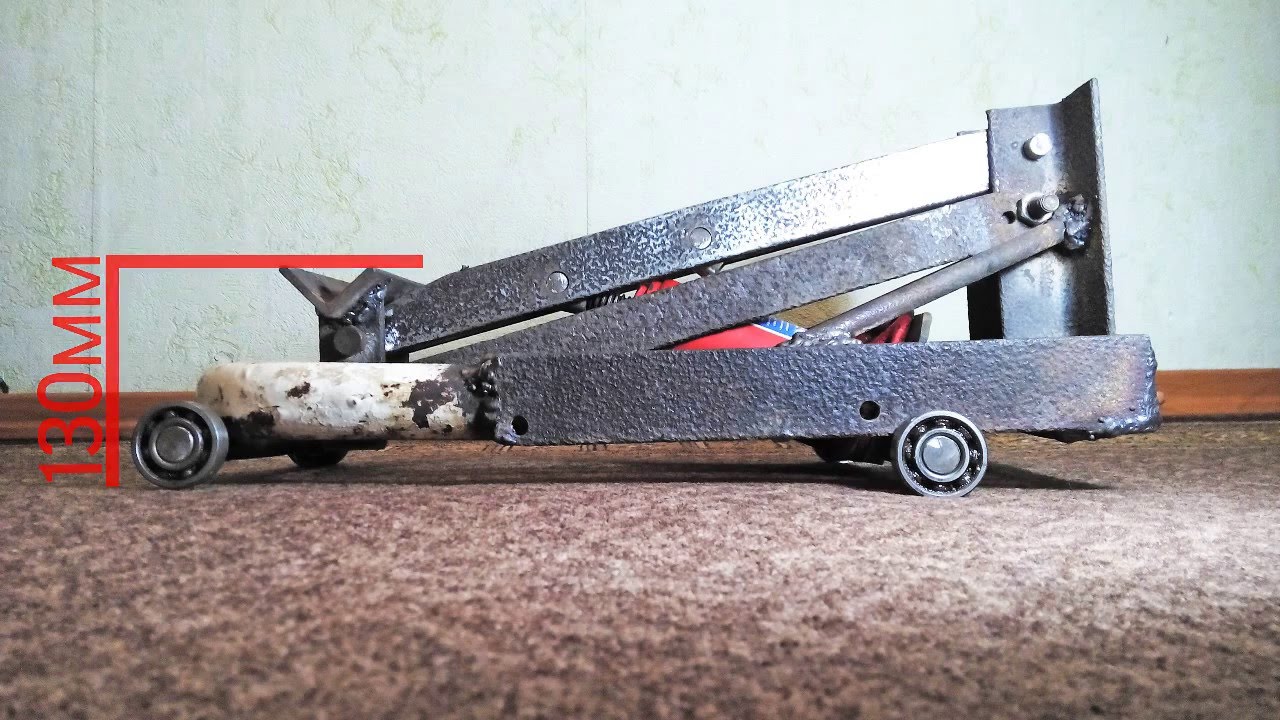

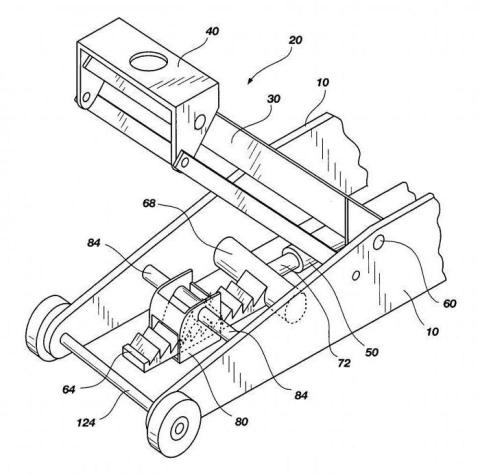

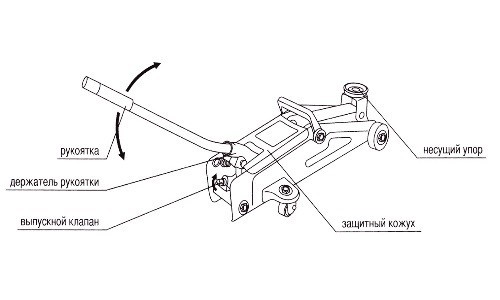

Option number 2. Homemade rolling jack

Homemade rolling jack

Hydraulic type construction for repair / maintenance of passenger cars. For manufacturing you will need:

- a bottle jack with a pickup height of 23 cm;

- channel 12 mm (for a rack and a jack swing);

- channel 10 mm (for base and lifting arm).

The structure is made from a bottle jack

In the front part there are rollers taken from an old washing machine. A cup was taken from the car bump stop.

Washing machine rollers installed in front

For the manufacture of braces, a 20 mm bar was used.

The braces are made of steel bar

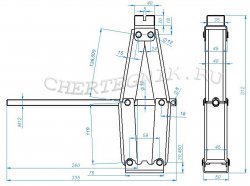

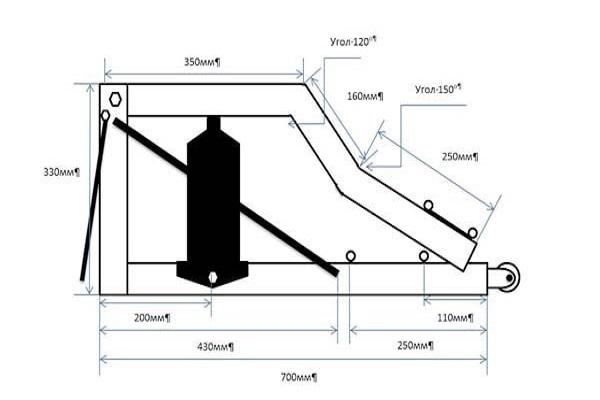

And this is a drawing of a homemade rolling jack with dimensions.

DIY trolley jack drawing

Below you can see the rolling jack in action.

It is quite convenient to work with the jack

You can learn more about the work of such a homemade device from the video below.

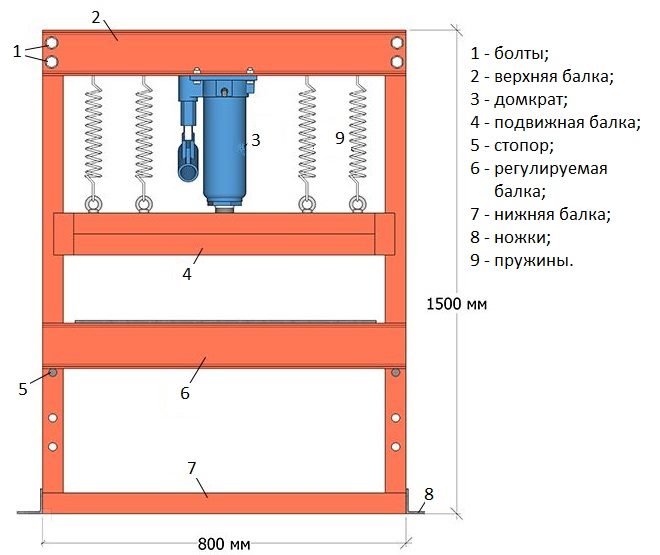

What you need to make a press

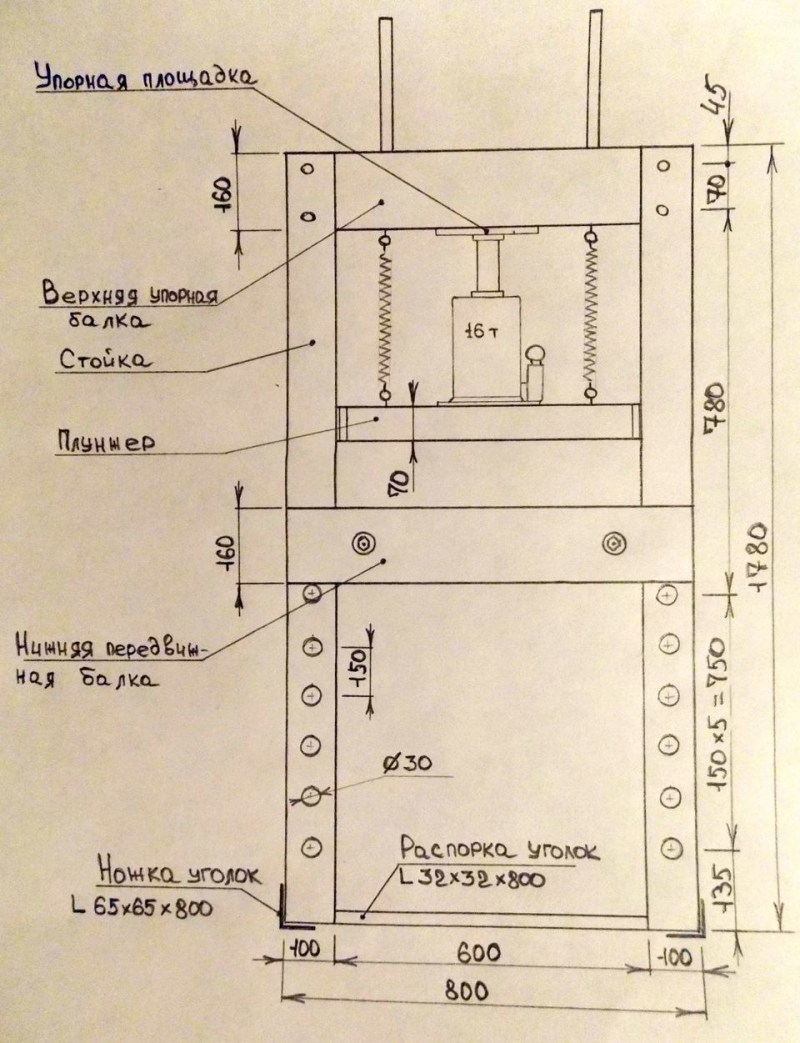

Drawings of such a device allow making a press from a jack with your own hands. They are easy to find on the Internet in the public domain.

Drawing of a homemade press from a hydraulic jack

For the manufacture of a hydraulic press from a jack, you should also prepare:

- the hydraulic jack itself is of a single-stem bottle type (for a press that will be used at home, a jack that develops an effort of up to 10 tons is also suitable);

- inverter with a set of electrodes;

- hacksaw for metal;

- grinder with a set of discs designed for cutting metal;

- a section of a channel of size 8 and higher with a length of 4 m;

- square or rectangular shaped tube with thick walls;

- equal metal corner No. 50;

- steel strip with a thickness of more than 10 mm;

- a piece of pipe 10–15 mm long, the diameter of which must match the size of the jack rod;

- metal plate 25x10 cm in size and 9-10 mm thick;

- two springs, which are needed to return the stop to its original position (springs from car seats, doors, etc. will do).

Channel blanks

How to make a do-it-yourself garage jack

Among the large number of homemade homemade device schemes, screw and hydraulic mechanisms are popular. And if in the first case excellent skills in threading are required (a complex shape is made), then the hydraulic option is easier to make.

Building the circuit

The hydraulic homemade jack is great for do-it-yourself use. And there is no reason to doubt its ability to ensure safety, because the oil cannot suddenly lose its properties and break out of the retained level.

Therefore, when working, it is important to pay attention, perhaps, only to the strength of the levers and their reliability.

Popular scheme of a homemade hydraulic jack

Selection of material and preparation of tools

In a homemade design, it is important to take care of strength. Therefore, metal is chosen as a building material.

For the frame, use:

- channel 10 mm;

- channel 12;

- rods 12 millimeters;

- wheels for moving;

- rubber part for the cup device;

- fastening material.

To fit the material you will need:

- welding machine;

- grinder with circles for metal cutting and grinding;

- drills for metal;

- wrenches and screwdrivers;

- measuring instrument: tape measure, ruler, marker.

The supporting part is fixed by welding to create a solid and strong structure. Upper pivot pieces are bolted or rod-mounted.

Construction collection

First, an L-shaped base is created from a 12 mm channel. A hydraulic bottle jack is attached to it. Then, with the help of bolts, the upper lip is attached to the base, on which the jack rod will act. The stem is secured with a swivel rod.

Wheels are additional equipment in the manufacture (suitable from old household appliances). They will help you move the overall structure around the garage.

An example of a homemade hydraulic jack

Selection of screw lifts

A device is selected taking into account the planned scope of work and after carrying out the necessary calculations. When choosing a jack, decide first whether you have enough strength to use a mechanical device or you need an electric drive.

If the load is supposed to be lifted manually, the calculations are not carried out, but when more serious tasks are to be performed, the screw device is calculated. The calculations are reduced to determining the required power. For this purpose, calculators are used, offered by a number of sites.

Even when choosing a jack, you need to pay attention to its main characteristics - working stroke and lifting height

For hydraulic devices, the gear ratio is important, on which the force transmitted to the handle and the power of the electric motor depend

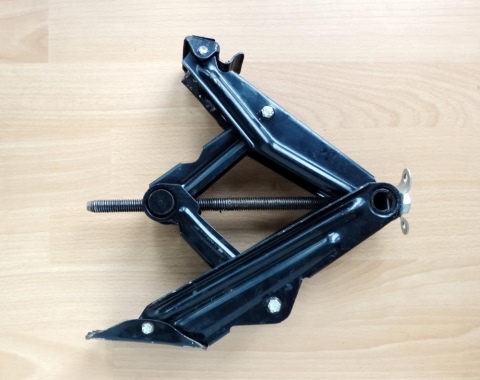

The most common jacks among motorists are mechanical devices. They have a simple design, inexpensive, undemanding storage and transportation conditions, and are easy to repair.

Nevertheless, the most popular are rhombic jacks, because the overwhelming majority of Russian-made cars are equipped with them. If you need to buy a new device, find out the weight of your car and select a jack of the appropriate capacity. Buy a device with a small margin and do not forget that more powerful mechanisms have a greater mass and dimensions, therefore, they need more space in the garage and trunk.

It is better to buy domestic jacks, since in comparison with foreign counterparts, the difference in functionality is small, and the cost is much lower. In addition, not every major city has service centers that repair imported devices.

If there is a fairly flat platform under the bottom of the car, any jack is suitable, in principle, but when recesses for a specific device are provided, you will have to look for it. For lifting a car in the garage, almost any model with a hydraulic, mechanical or electric drive will fit. In the field, a hand-operated mechanical jack is recommended.

What is a jack for? Types of jacks

The main function of the jack is to lift the car wheel in order to replace it or the tire. The jack is used for self-replacement of car wheels in the absence of repair services. Also, sometimes you have to crawl under the bottom of the car in order to carry out repair work. The jack will come in handy in this case too.

Outside of the automotive industry, jacks are often used to install structures at the required level during construction and repair work, when lifting goods in warehouses and spare parts in workshops.

You can read about how the drive shaft crosspiece is replaced on the VAZ-2107 in the detailed material of our author.

You may also be interested in information on how to choose and securely fix the caps on the wheels with your own hands.

The important characteristics of the jack are listed below.

- Carrying capacity. Each of the jacks has restrictions on this parameter. When manufacturing the device, the weight of the vehicle must be taken into account. It is also necessary to take into account the weight of the cargo in the luggage compartment.

- Lifting height. This parameter is especially important for vehicles with a low floor. In this case, the lifting height must be acceptable for the ability to climb under the car and carry out repair work.

- Pickup height. This is the height of the instrument. This parameter should be compatible with the vehicle's ground clearance (distance from the surface to the bottom point). This parameter is different for each individual model. It is necessary to choose the height of the pickup so that it is comfortable to work.

Jacks are of various types according to the type of drive.

- Mechanical type, in which lifting occurs by pressing the handle. These jacks are designed for infrequent use. Such devices are compact, but require physical effort.

- Hydraulic type. Similar to the previous one, but requires less effort. The wheel rises due to the pressure created by the working fluid. Great for frequent use.

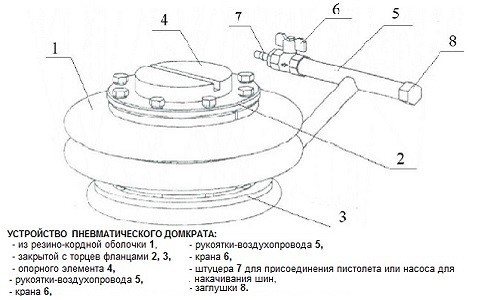

- Pneumatic type. The device is powered by compressed gases. Gas cylinders are required for use. The gas builds up pressure, the chamber increases in size, and the car begins to rise. No physical effort is required.

According to the principle of operation, jacks are subdivided into screw, rack and pinion, pneumatic and hydraulic jacks. Jacks are stationary, mobile and portable. Homemade devices are most often portable, since they are small in size. Stationary jacks are designed for large loads and are rarely of interest to car owners.

Rating of the best models

Among the described tool, it is worth noting the top of the most popular models.

"Stankoimport" HM5903

This model is equipped with a manual type drive. The driveline mechanism ensures a smooth and gentle descent. There is a safety valve to prevent overloading the hydraulic system. This device is used for vehicles weighing less than 2 tons. The unit has good performance, which show itself well both in a large car service and in a garage.

"Zubr 2T Professional" 43053-2-K

This product is designed for lifting a variety of loads, the total weight of which should not exceed 2 tons. The tool is considered quite compact when compared with other models. The weight of the entire device is 7 kg. The device has a swivel cup, which makes it much easier to operate the mechanism. The design is considered durable. In addition, there is a comfortable handle.

Ombra

This model can be a good assistant for a garage master. Low carrying capacity allows this product to serve only passenger cars. The large weight does not affect mobility, the swivel wheels allow transporting and installing the lifting mechanism very quickly and easily. The handle of this jack consists of 2 parts, which allows it to work from a distance.

AUTOPROFI DP-17K

The design of this product is very simple and robust, allowing this small jack to handle weights up to 2 tons. The structure is equipped with high-quality wheels, which makes it easy to transport. This model can be installed only on level and hard surface. The hydraulic drive can lift various loads no higher than 30 cm. The product is supplied in a plastic case, in which carrying and transportation is much easier. The total weight of the product in the suitcase is 7.7 kg.

Jack requirements

When choosing the described tool, you must be guided by certain principles and requirements:

- Efficiency. It must be at least 25 percent.Ideally, this figure should be close to 90 percent.

- High accuracy. The upper support of the mechanism, which is in contact with the body element (threshold), must exactly follow its contours. Usually there is a special groove on the threshold. A jack is inserted into it. If it does not follow the shape of the groove, it can provoke a rollover of the car. As a result, damage to the body and the jack itself. By the way, in order not to scratch the metal part of the car, this support has a rubber or polyurethane pad. If it is, this is a big plus. Indeed, if the paint is damaged, such metal begins to rot quickly, especially if the roads are sprinkled with salt.

- Carrying capacity. The higher the indicator, the more versatile the mechanism will be. It can be used not only for cars, but also for trucks.

- Good lubrication. The areas where the nut contacts the screw must be well lubricated. If not, such a mechanism will not last long. If water gets in, rust forms on the threads. As a result, such a car can no longer be lifted with ordinary hands. This grease must withstand temperatures from minus 45 to +95 degrees Celsius.

- Lifting height. The higher it is, the better.

Hydraulic jack

These jacks are capable of lifting large loads, which is an important aspect when working with heavy vehicles. They are used mainly in service stations. Since this model is the most common, we will start with it today.

Before all work, in order to make a jack with your own hands, you need to familiarize yourself with the drawings. After studying the theoretical material, prepare everything you need for further work. Namely welding, hacksaw for metal, grinder, steel.

Jacks, which work with the help of a liquid, are of several types.

Standard, bottle-shaped, rolling (purchased in a specialized store, or made by hand, most often used among professional locksmiths at service stations) hook-type, diamond-shaped, hybrid.

On the Internet, there are many photos of do-it-yourself jacks. You can familiarize yourself with them.

The first step is to create a support area, or in other words, a jack platform. A metal profile with dimensions of 5 by 5 cm is suitable.

Next, we cut off 4 parts 30 cm long from the metal pipe. We lay them with their sides one to one and weld the bottom and top.

The next step is to make racks and stops. Cut off 2 pieces from the metal pipe. Their length is easy to calculate, and based on the possible stroke of the stem.

The jack support is also made of metal. Its length must match the width of the platform for the mechanism stop. We weld the stop with the racks.

It is necessary to weld a structure in the form of the letter P to the bottom of the jack. The stop of the jack, which is removed, must move along the guides, and also transfer pressure to the part that is being processed.

All this can be done from steel strips. Everything is connected using a welding machine. When you install the block on the press frame from a jack with your own hands, you need to pick up 2 bolts, washers and nuts for them.

Stages of work

A homemade car jack is usually small and simple in design. This allows even beginners to make it. Usually materials for manufacturing are inexpensive, and you need very few of them. They can be found at home, in a garage or shed, or purchased from a store.

To work, you need to prepare a steel tube, a square plate, a nut, a washer and a long bolt, as well as a drawing. The latter is the hardest part of the job. Drawings can be found or drawn by yourself. When working on a drawing, you need to indicate the correct sizes of parts, and not do everything "by eye".

The creation itself is not difficult. It is based on a steel tube.The diameter is determined independently, there are no requirements for it. The pipe length must be up to 25 cm.

The first step is to attach the tube to the square plate. It needs to be welded on and the surface cleaned with a grinding disc.

A prepared washer should be placed on the pipe, a long bolt should be inserted into it, onto which a nut must be screwed in advance.

Once the mechanical screw jack is ready, it can be used to change the wheels of the machine. Lifting is due to the nut, and the retention is due to the plate, which is the supporting part.

DIY screw jack

Do-it-yourself assembly of a screw jack is cost-effective if you save a budget or have specific operating conditions. Self-production will cost less than the finished version if you have basic locksmith experience, guided by certain schemes.

For manufacturing, you will need several rack pipes, a sheet of metal 4-6 mm thick, a mechanical bar. The pipes are welded in parallel, the base and the top are held together with a piece of metal. Then the nut is welded, connected to the rod at the bottom of the future jack. Next, you need to complete the structure by attaching the fastening mechanisms and a handle.

When self-manufacturing lifting devices, it is important to be guided by the purpose of the mechanism. For an elementary wheel change, a compact screw-type device is suitable, which can easily fit in the trunk of a car

Correct installation accompanies safe work and must be monitored to avoid injury or property damage. When working, it is possible to use a static stand as the main support, for example, a large stump.

Varieties of screw mechanical jacks

There are many types of car lifting devices, the most popular is the screw rhombic jack. The screw jack, the price of which is at an average level, is the most stable and compact.

Car jack

The main advantages are:

- The car is lifted in a vertical plane without pushing it in different directions.

- Subject to the maximum permissible loads, it is durable and does not break.

- Differs in increased stability.

- Repairable, compact folds.

Repair of this type of mechanisms occurs without difficulty, the screw part often fails, which can be replaced with a screw-type construction hairpin. With the necessary locksmith skills, it is enough to cut off the stud in accordance with the size of the jack, weld the nut from the mounting side. The device can be made by hand, but the time spent is not worth the savings, because the price of a mechanical screw jack starts at 400 rubles.

Mechanical jack

The jack mechanical lever-screw type is distinguished by reliability during operation, due to the least number of moving elements. The price of such a device on the market is not high, but there are a number of disadvantages. The stability of the device is not at a high level, when it is lifted it pushes the car body away from itself. Increased effort is required to lift equipment with such a device, which is not very convenient for women, as well as for long-term work.

In the domestic auto industry, vertical screw jacks have been used for a long time. The design features long travel and smooth force applied to the handle. The lifting height sufficient for any type of work made the unit attractive for motorists.

Vertical screw jacks

Rack screw mechanisms are used less and less due to the high cost, specific purpose of work. Require the raised object to have special holes for the guides. If installed incorrectly, it is easy to damage the paintwork of the car.

Bottle devices differ from competitors in higher carrying capacity.There are varieties that can lift up to 5 tons, this solution will help owners of SUVs or minibuses. The design consists of a thrust thread with impressive internals, so you don't have to worry about durability. The price of the device is high, which poses a choice between a conventional design, such jacks will help for construction purposes and other households.

Bottle jacks

In the household, special screw construction jacks are used, which allow you to hold the load at a certain height. Under conditions of frequent use and a greater mass of objects, an electric jack is used, also of a screw configuration.