Angle grinders

Angle grinders, or "grinders", are called so because they are easy to handle not only straight surfaces, but also corners. This is achieved due to the design of this machine, due to the fact that the movable shaft on which the plate with grinding discs is attached is at an angle of 90 degrees relative to the engine.

To grind the part, a special plate with a fleecy surface is screwed to the machine, on which the emery wheel is fixed. LBMs of Japanese and European manufacturers fail noticeably less often than their Chinese counterparts. The "Bulgarian" is a versatile tool, it can not only grind, but also cut off hard materials. We do not recommend buying angle grinders only for grinding, in this it loses to conventional grinders. Of course, it will process the surface, make it smooth. But during work, you will experience discomfort. The "grinder" does not have a dust collection system, therefore, even after polishing a small part, the entire room will be filled with small dust particles that will enter the human respiratory tract and settle on interior items and clothing. And on the street it is recommended to work in a protective suit and a respirator, and it is better to place the workpiece on the leeward side. Otherwise, you run the risk of looking like a miller from a fairy tale - your clothes, head and hands will turn white.

Also, the angle grinder has a strong vibration, which makes it difficult to work with this tool for a long time. The downside for grinding is the high speed of the motor shaft, which is not adjustable. If you hold the sanding pad in one place for a few seconds, you risk leaving a dark stain of burnt wood on the surface. It is recommended to use the angle grinder as a grinder only in some cases, in order to process hard-to-reach places where other tools will not crawl, for work in the fresh air or for processing small parts when the purchase of a conventional grinder is not planned as it is unnecessary.

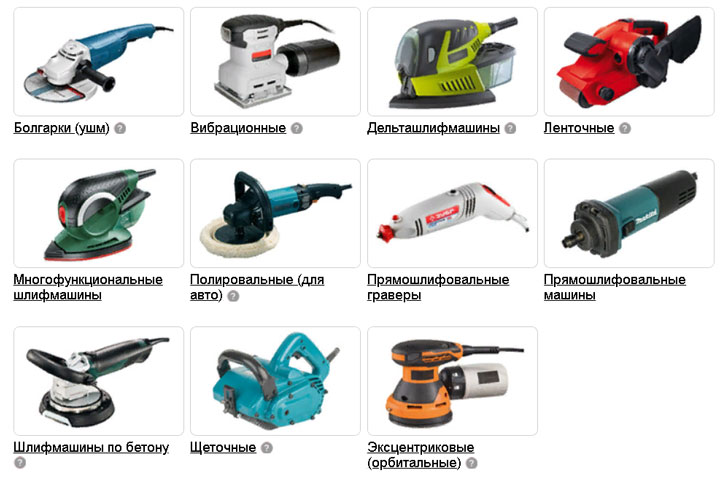

Types of grinders

The power tool produces different results when performing the same task. So, they distinguish:

- Machines for rough finishing.

- For medium sanding.

- For finishing preparation.

Manufacturers also offer to purchase devices for surface polishing. Then it becomes smooth with a slight gloss.

Angle grinder (angle grinder)

Angle grinder

For wood processing, a flap disc or circles in the form of a plate with sandpaper are used. The latter is easier and faster to change if you use the Velcro attachment.

Thanks to the rotary motion, the cleaning and leveling process takes less time than when using a tool with a different nature of work.

Wood dust from the sandpaper can be easily removed with a brush or a medium bristle brush. Another option also involves removing the wax. It is enough to grind the metal surface within a minute (or less).

Belt sander (LSHM)

Belt sander

Closed sandpaper (endless) is used as a nozzle. It is set in motion by a mechanism equipped with rollers. The tape is put on them.

The advantage of draw frames is the working surface area. Compared to angle grinders, it is larger. Accordingly, it takes less time to process wood.

Difficulty grinding corners, grooves and gaps between parts.Due to the weight of the device, vertical structures and tops are more difficult to handle. In addition, LSHM make a lot of noise, and sanding occurs only in the central part of the sole.

Orbital or eccentric sander (OSHM, ESHM)

Orbital or eccentric sander

Most of the models are equipped with garbage collectors with filter plates or have an outlet for connection to a separate construction vacuum cleaner.

The orbital machine is equipped with a mechanism for circular motion only. Eccentric additionally produces reciprocating. Due to the latter, ESM is considered more effective.

Machines are used for any kind of grinding. They work without noise, weigh a little, and hard-to-reach places can be processed (unlike LSHM). The radius of rotation is 3-8 mm. Disadvantages: inability to grind corners and the fact that the edges are grinded less efficiently than the central part.

Vibration sander (VShM)

Vibration sander

The outsole can be shaped with three or four corners. The work platform handles surface treatment in virtually all hard-to-reach places.

Hard elements under the sandpaper dig into the wood, which leads to the formation of grooves and scratches. This can be eliminated if you first clean the surface, connect a vacuum cleaner, periodically sweep the debris and change the cloth with a finer abrasive.

Oscillating sander (MFI)

Oscillating sander

A multifunctional tool is also called a renovator, multitool and multi-cutter. It is intended, among other things, for sanding all hard-to-reach places. For this, a flat triangular platform is installed.

The MFI is intended for the restoration and processing of small-area material. This is due to the small amplitude of the oscillations. The grinding result is precise and high quality.

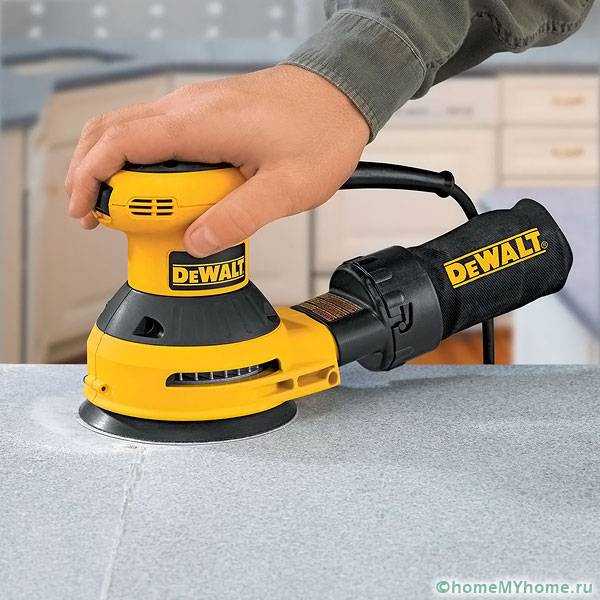

DeWALT DWE6423

5 049

The model of the DeWALT company ends our rating of the best eccentric sanders. No, this does not mean that the DWE6423 is inconvenient or unreliable: it is just that it is already a tool in the amateur segment, and by its standards it could have reached the top.

The engine power here is 280 W, the vibration amplitude is 2.4 mm. The machine is compact and lightweight, which will allow it to be successfully used in delicate finishing work. Adjustment of revolutions is provided (although the wheel was installed in a place somewhat strange from the point of view of ergonomics) and their electronic stabilization. The only pity is that you have to hold it by the "head" - there is no side handle.

Standard dust removal works well, although, of course, you should still connect a vacuum cleaner. However, do not forget that this machine is not very suitable for professional practice: the brushes wear out quickly, and the platform drive itself is worn out. In the home workshop, it will last a long time and will only deliver positive impressions.

Main pluses:

- Low vibrations

- Rubberized grip points

- Stabilization of revolutions

Minuses:

No side handle

8.9 / 10 Rating

Reviews: I think the purchase was successful. I have a hobby - making furniture, this machine gives you no problems to work for your pleasure on the weekend.

Comparison with other models

It is worth considering how a vibratory surface grinder differs from eccentric and belt models. It is considered a more versatile option, allowing you to vary the level of surface finish. The belt sander is convenient for handling objects with a uniform texture, suitable for rough finishing. The surface grinding option allows you to achieve results regardless of the initial smoothness of the coating.

Eccentric models have their own characteristics. They are designed primarily for work on large surface areas and allow successful finishing. The eccentric sander is suitable for working on parquet floors.But it will not help in working with other, harder materials. Whereas the surface grinding unit will ensure successful processing even on the surface of fragile plastic or metal heavily corroded.

In fact, in terms of functionality, the vibratory PSHM is somewhere between the belt and eccentric models. With them, you can successfully complete the final processing of surfaces of various areas. Mini-versions successfully cope with narrow areas of material, difficult and hard-to-reach places. The adjustable rotational speed makes the PSHM as convenient as possible for working with surfaces with an inhomogeneous texture.

2 How to choose?

Now let's figure out how exactly to select a specific model.

First of all, it is necessary to decide on the purpose of the tool: whether it will be used for body repair of cars, or for woodwork, or the machine will be used for various works in the garage.

If the product is taken to the workshop, where there is already a pneumatic compressor, the pneumatic "orbital" will be relevant. In other cases, it is better to opt for models with an electric drive.

Now let's consider what parameters you should pay attention to:

Mini sander

-

Weight and dimensions. Most of the eccentric models weigh from 1 to 2.5 kg. There are both lighter and heavier devices, but their choice is small. They are intended mainly for a specific type of work (either for too thin grinding, or vice versa - for cleaning a large area).

-

Grinding disc diameter. It can be from 100 to 225 mm. In some models, you can use discs of different diameters (for example - 125/150). You need to choose depending on the area of the processed products.

-

Eccentric stroke and adjustment. Indicates how many millimeters the disc is offset from the axis. It can be from 2 to 7 mm. The smaller the stroke, the more accurate the grinding. The larger the stroke, the easier and faster it is to process a large area. Ideally, choose models with adjustable travel (they are more expensive, but they allow you to customize the product for a specific task).

-

The presence of a stopper for the start button. It is relevant if you plan to use the machine for long-term operation (it is inconvenient to keep the start-up constantly pressed on your own, so the stopper will be very useful).

-

Handle type ("pistol" or classic). For finer work with small areas, it is recommended to choose the first option.

-

Number of handles. For long-term work with a large area, it is more convenient if the model will have 2 handles.

-

Disk rotation frequency. On average, it is from 6 to 12 thousand revolutions (such models are suitable for "garage" workshops, and for car services, and for furniture workshops, often working with wood. In general, the range varies from 2600 to 24 thousand.

-

Power consumption. The main selection of models has a wattage from 250 to 600 watts, the total range is from 135 to 1500 watts. The more powerful the machine, the more revolutions it can make (and the more it costs, and the greater its size and weight). If you do not plan to regularly process products with a large area, you can limit yourself to a model with a power of 400-500 W.

-

The presence of a dust removal system (own dust collector, or the ability to connect a vacuum cleaner). This option is optional, but very useful.

-

Wire length (for electric models). Most often it can be from 2 to 4 meters.

As for the cost - an eccentric machine with average characteristics (dust collector, power of about 400 W, revolutions from 6 to 12 thousand with the possibility of adjustment, disc diameter 150 mm) will cost about 4000-5000 rubles.

2.2 Briefly about manufacturers

There are no less than fifty models of "orbital" machines on the modern market. The most popular brands are:

-

Metabo. Among such products are compact and inexpensive eccentric machines.

-

Bosch.A wide range of high quality models, mainly - medium and high (over 600 W) power, medium size. Most of the models are equipped with useful options (braking system from idle, adjusting speed and eccentric travel). The price segment is above average.

-

Makita. A wide range of models that are suitable for both garage work and specialized workshops. Equipped with a good dust extraction system, have adjustable disc speed and eccentric stroke. Some models have an additional removable handle.

Hyundai BS 900

Main characteristics:

- Power - 900 W;

- Belt speed - 400 m / min;

- Tape - 533 × 75 mm;

- Weight - 3.6 kg;

Body and ergonomics. All elements of the body of this grinder are made of high quality plastic. Comfortable grips fit snugly in your hands thanks to rubber pads. The tool weight of 3.6 kg does not require additional pressure when processing horizontal surfaces and allows you to work without undue stress on the weight.

Design features. The grinding mechanism is filled with an abrasive belt 75x533 mm using a lever device for optimal tension. Its position is manually adjusted without the use of additional keys using a screw with a wide handle built into the design. A container for collecting sawdust is attached to the side, instead of which you can connect a hose from the vacuum cleaner.

Container for collecting sawdust.

Functionality and capabilities. The machine is equipped with a powerful 900 W electric motor. Electronic control of the shaft rotation speed allows, depending on the properties of the processed material, to change the belt speed in the range from 240 to 400 m / min. It is possible to attach to the table in an inverted position for the convenience of grinding small parts.

Equipment. The standard set of the tool includes a sanding belt, a dust collector, a sleeve for connecting a vacuum cleaner, two screw clamps and an instruction manual.

Pros of Hyundai BS 900

- High power.

- Speed regulation.

- Convenient design.

- Effective dust extraction system.

- Low vibration.

- Not heated.

- Inverted fixation.

- Adequate cost.

Cons of Hyundai BS 900

- Lack of automatic centering of the belt.

- The presence of plastic parts in the drive.

- High noise level.

BLACK + DECKER KA88

4 559

The budget sander in our rating has become the weakest in terms of performance: a 720-watt motor provides a belt speed of no more than 250 m / min. But in the design, one cannot fail to note several very good points. First of all, it is a small diameter protruding roller - by lifting the protective casing, you can get into hard-to-reach places, which the other participants in the rating cannot do. The rear drive roller, on the other hand, is enlarged in diameter to avoid slippage. The front handle can be adjusted to suit you. And, finally, dust extraction is well thought out.

However, such a "tractor" layout with the main mass shifted back will take some time to get used to the peculiarities of the machine - the rear part of the working section of the belt is pressed against the processed plane more strongly. We also note that the possibility of mounting in an inverted position is not provided, and in fact it is one of the most convenient "chips" in belt sanders.

Main pluses:

- Convenience of work in "narrow" places

- Comfortable noise and vibration level

- Good dust extraction

Minuses:

- Short and stiff standard cord

- No speed regulator

8.8 / 10 Rating

Reviews: It is very convenient to get into such cracks, where previously you had to work by hand. Because of this, and bought, in fact.