Features of a homemade all-terrain vehicle from a walk-behind tractor

An ATV in the classical sense is a vehicle designed for off-road and road travel, regardless of their coverage. The all-terrain vehicle from the walk-behind tractor is small in size and lightweight.

Before you start making a mini all-terrain vehicle with your own hands, you should follow these steps:

- Prepare a running gasoline or diesel engine with a traction potential sufficient to move the unit and transport the driver;

- Determine the undercarriage - tracked or wheel type. Mini all-terrain vehicles on wheels are less passable, but making them with your own hands is much easier than tracked models.

You need to purchase or make your own hands the key structural units:

- Frame for fixing all parts;

- Rear axle for rear wheels;

- A driver's seat, which must be protected from water and dirt flying from under the wheels;

- Lighting for the possibility of movement at night.

Technical characteristics of the finished off-road vehicle:

- Carrying capacity - 200 kilograms;

- Engine with power from 10 hp. with.;

- The average speed is 10 km / h.

How to re-equip equipment?

An all-terrain vehicle in the traditional sense is a vehicle designed to move along muddy roads and highways, regardless of their surface. The all-terrain vehicle from the walk-behind tractor is characterized by small dimensions and light weight.

Before embarking on the conversion process, you need to navigate the individual aspects. You can create a crawler or pneumatic unit. At the same time, the caterpillar structure is more ingenious, and it is necessary to know and understand how to operate it.

The next thing that needs to be clarified is where and how the unit will be used, how much capacity, and also what load it can move on itself. Having dealt with these questions, you can start creating a drawing of the future unit.

The motor should not be taken either. It must certainly be with forced cooling. Choose motoblocks that have an air or water cooling system. The engine must be powerful enough to be able to move around any terrain without problems.

How to make low pressure wheels with your own hands?

Regardless of the type of equipment manufactured, driving on wet and unstable grounds requires lugs that provide high grip. Low pressure wheels are most suitable. A walk-behind tractor on pneumatic wheels has a minimum impact on the soil.

On the rear axle, self-made special wheels are used, which can be installed on a swamp vehicle, snowmobile (snowmobile), snowmobile or motorized towing vehicle from a walk-behind tractor. You can buy ready-made items or buy parts separately (tires, tubes, wheels).

Wheel collection scheme:

- Conventional discs and mounting plates are welded with metal tubes. This creates large cameras with improved fixation;

- The camera is put on the finished expanded disk. It can be purchased or used from trucks;

- An air valve is introduced into the opening of the disc;

- Inflate the wheel with air;

- Install the finished tires on the pneumatic drive from the walk-behind tractor.

The permeability of a conventional wheel is increased by an additional protector. Chains, a conveyor belt, and homemade tracks are used to secure the cameras.

To make all-terrain vehicles / karakats on a pneumatic drive, you need to prepare the necessary materials and tools in advance. The described schemes and video instructions will help to understand the process.

Step-by-step instruction

Many people ask the question - how to make caterpillars on a walk-behind tractor with their own hands? To answer this question, consider several effective methods of self-manufacturing tracks, tested in practice.

From the transport belt to increase the cross-country ability of the all-terrain vehicle

One of the simplest methods is considered to be the manufacture of a caterpillar from a conveyor belt, using a sleeve-roller chain. The ease lies in the fact that for their manufacture it is not necessary to use a large number of tools and aids.

Conveyor tape

To extend the service life of our conveyor belt in the tracked walk-behind tractor, you can sew it along the edges with a fishing line, observing a step of 10 mm. To connect the tape into the ring we need, you can sew it along the ends, or use the hinge.

Particular attention should be paid to the thickness of the conveyor belt, because it directly depends on the degree of load on the unit. The optimal choice will be a tape with a thickness of at least 7 mm. In addition, we need to take care of an additional wheel on each side.

You can take it from an old car, but remember that the diameter must be identical to the wheel on the walk-behind tractor.

Track module from a tire

Caterpillars from car tires for a walk-behind tractor are also a fairly common home-made product, characterized by a high reliability of the design. However, in order for the resulting tracked walk-behind tractor to be practical, you need to take care of finding the right car tires.

In particular, they must have the required tread pattern, preferably from tractors or large machines. The tread pattern is very important because it acts as a lug and also increases the grip of the track.

Car tires

Let's divide the manufacturing process into several steps:

- Having found suitable tires, we need to cut out a track for caterpillars from them. This is a rather laborious work, which will take a lot of time.

- For cutting, you can use a well-sharpened boot knife, which from time to time needs to be moistened in soapy water - this will help to cut the rubber better.

- You also need to cut both sidewalls off the tires. To simplify the process, the sidewall can be cut with a fine-toothed electric jigsaw.

- If necessary, remove excess parts from the inside of the tire. This manipulation must be performed if the track is too hard from the inside.

The advantage of this method is the absence of the need to connect it into a ring, since the tire already has a closed structure

This increases the reliability of such tracks, which is quite important in conditions of heavy loads.

However, such tracks are of a rather limited length - exactly along the length of the car tire.

How to make a homemade track from belts and chains

ATVs on tracks from a walk-behind tractor can be made using the most common belts with a wedge-shaped profile. The belts are connected to each other by means of a lug, attached to the belts with rivets or screws.

Another method is to make the tracks from chains of the same size. Many summer residents have such material in bulk in the garage, which simplifies the search issue. The whole manufacturing process boils down to the following points:

- Two chains of the same size are taken.

- The last links of these chains must be unclenched, and then connected into a closed ring.

- Next, we clamp the links and weld them.

The chains are fastened to each other using lugs, which can be made from ordinary steel plates of the required thickness. They are connected to the chain with bolts.

Scheme

Motoblock on Buran tracks

If you have no desire to make your own caterpillars, then you can borrow it from old technology.For example, a walk-behind tractor on tracks from Buran shows pretty good work.

It is advisable to use just the old part, because the new Buranovskaya caterpillar will be quite expensive, and the purpose of such alterations is the maximum cost savings.

Cultivator-based Karakat: Features and Build

A caracat from a walk-behind tractor in its intended purpose is similar to the above-considered device.The differences are:

- increased wheelbase with belt clutch;

- bulkiness;

- extended operating conditions - the karakat is capable of generating speeds up to 70 km / h on rough terrain.

In view of the fact that the main emphasis in this alteration concerns precisely the tires, we will dwell on them in more detail.

Among the existing methods of self-replicating powerful and large stingrays on a karakat, several main ones can be distinguished:

- considered the lightest. Two metal discs are taken and aggregated onto a bushing. Cameras are put on them, fixed with a conveyor belt. The tiller on cameras has good stability and endurance;

- only one of the discs is attached to the hub. Jumpers are installed on it. The rings are adapted to the last welding machine;

- resembles the previous method, however, an additional spoke is needed for the central disc, which can be made from a metal blank or pipe;

- will give new life to discs from an old scooter, which are standardly attached to the hub.

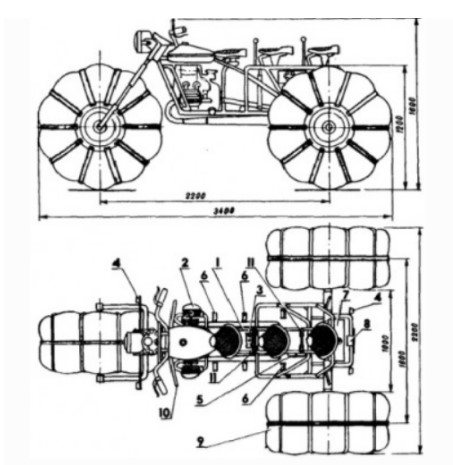

As a reference outline for the further assembly of the karakat, you can use the proposed drawings.

Home-made carakat based on an engine from a tillage machine such as "Neva" or "MTZ" is collected as follows:

- we cook a frame from a metal profile or pipes;

- install front and rear wheel drive. It is allowed if they are without differential and solid;

- the front axle can be borrowed from the vehicle chassis. The steering rack is taken from it;

- the engine is borrowed from the tillage machine. You can leave the original gearbox or replace it with a multi-stage gearbox. In this case, it will be easier to control the speeds in the karakata. With a gearbox, you will have to stop before changing the speed of movement;

- put the slopes and proceed to testing the karakart.

What type of diesel or gasoline engine to choose for an all-terrain vehicle?

It is impossible to answer this question concretely. Both

the motor has its advantages and disadvantages.

The chassis is recommended to be made with independent suspension.

wheels. It will take some effort to do this, but comfort

those inside will be provided. Excellent results are achieved when

the suspensions are paired with low-pressure pneumatic wheels.

If we are talking about a tracked all-terrain vehicle, the frame for it is

one-piece construction. In the case of wheeled vehicles, an articulated

option. Although an articulated frame can be selected for a tracked all-terrain vehicle.

Step by step instructions

Karakat from a walk-behind tractor is a rational investment of efforts and finances. An all-terrain vehicle from a walk-behind tractor is created according to the scheme. Construct the base. It will be possible to take ready-made frames. For example, remove from used cars Ural or Izh. They are durable and flexible. The rear axle includes both suspensions, which are made of: rack, mow, bushings. For all-terrain vehicle wheelbase. It is allowed to use a used spare tire from a truck. Transport on SND is easy to ride, with maneuverability. A prefabricated engine structure is mounted so that the all-terrain vehicle performs the necessary functionality. If the installation of the motor is over, put:

- transmission;

- exhaust parts;

- brake structure.

Parts from old vehicles will do. The ATV is characterized by good cross-country ability, maneuverability and safety. It looks like a 4-wheeled motorcycle vehicle. Usually an ATV is designed on a walk-behind tractor from a Neva car. The step-by-step instructions are as follows:

- Alteration of wheels.The wheels are set apart at an equal distance from the car body with adapters.

- The frame is being modernized and reinforced. It is correct to use a ready-made base from a motorcycle, it is reliable, it will not provoke problems.

- Install autodisks. Low profile can be applied. To reduce friction between the tires, the rim can be made of fabric pads.

- Mount tires. Truck wheels fit. You can take tires with low pressure. There is no need to install shock-absorbing elements.

After simple manipulations, the created ATV from the walk-behind tractor is used off-road. In addition to transport, you can make SND.

Note: Regardless of the type of vehicle you create for riding on marshy terrain, it is important to have a high grip. ShND will do.

A walk-behind tractor with pneumatic wheels creates minimal impact on the road. On the rear axle, homemade tires are used, which can be put on:

- Swamp vehicle.

- Motor sleds (aerosleds).

- Snowmobile.

- The towing vehicle is a motor-block.

You can buy in-store items or buy parts separately (tires, cameras, wheels). The assembly diagram is as follows:

- Standard discs and fasteners are welded with metal tubes.

- Large chambers are made with more reliable fastening.

- Tires are attached to the finished expanded disc. It can be bought or used from a truck. An air valve is inserted into the hole in the disc.

- The wheel is filled with a pump. The created tires are mounted on an all-terrain vehicle from a walk-behind tractor.

To increase the power of the standard wheels, they are equipped with a protector. Chains and tracks made in a workshop are suitable for fixing cameras.

More popular home-made models with a motor from a walk-behind tractor have been described. However, this is not the end of the ingenuity of the masters from the people in relation to such a unit. Residents of the north have long appreciated the advantages of aerosleds, snowmobiles, and snowmobiles. And a mini-tractor or a towing vehicle on a walk-behind tractor is actively used by farmers.

How to make tracks for a walk-behind tractor with your own hands

Consider how to make tracks for a walk-behind tractor with your own hands. To assemble the caterpillar on your own, you can use a variety of materials that are easy to find. List of materials and tools that are needed to make a caterpillar:

- Bulgarian;

- drill;

- jigsaw;

- welding machine;

- bolts;

- nuts;

- keys;

- knives;

- screwdrivers;

- pliers;

- sanding belts;

- chains.

The crawler drive for the walk-behind tractor must evenly distribute the load on the ground during operation. Therefore, it must be strong and light at the same time.

Consider how to make tracks on a walk-behind tractor with your own hands. There are several ideas to choose from to build homemade caterpillars.

The most affordable way is to use a roller chain with a conveyor belt. To obtain a track from the specified materials, the edges of the chain and tape must be stitched.

To do this, you can use a machine, or you can sew by hand. But this method is unreliable. A hinge similar to a piano tape is also suitable for connection.

Consider how to make homemade tracks for a walk-behind tractor from tires. There is another method of making homemade tracks for a machine that uses a tractor or car tire tread.

These caterpillars are easier to prepare and much more practical. This method has another advantage - there is no need to prepare the lugs separately.

Manufacturing method: first you need to pick up a tire and carefully cut a tread track out of it. If you do this by hand, you will need a well-sharpened knife. But, as practice has shown, it is better to use a jigsaw and a file with fine teeth.

To reduce friction, while working with the jigsaw, you need to wet it from time to time with water or a special soap solution.

After the cut, you need to pay attention to the seamy side. If extra layers are noticeable, then they must be cut off.

As for the lugs, if there are not enough lugs, new ones can be cut.

The advantage of a tire track is that it is initially round and has a closed circle. The downside may be the limited width of the tire.

Specifications:

- Engine and gearbox VAZ 2106.

- Transfer case with VAZ 2121.

- Front-wheel drive.

- The body is a sealed boat.

- Weight 600 kg.

- Driver + passenger capacity.

- Carrying capacity of about 100 kg of cargo.

- The maximum speed is up to 40 km / h.

The next photo shows a step-by-step process of assembling a tracked all-terrain vehicle with your own hands.

The author used the engine and the VAZ 2106 gearbox.

Transfer case from Niva.

Hubs and calipers prepared.

The tracks will be made of 10 mm conveyor belt.

Blanks for track links are cut from a 40 x 20 x 2 mm profile tube.

The author made a homemade device for stamping tracks, before stamping the workpiece, you need to lubricate it with engine oil.

Drilled holes for fasteners.

The tracks will be attached to the tape with these plates.

We fasten with bolts.

Finalization of the bridge.

Caliper installation.

Suspension arms prepared.

Preliminary fitting.

All-terrain vehicle drive axle.

Support wheels on R13.

Disc brakes on the drive axle.

The shock absorbers are mounted on the suspension arms.

Track tensioning mechanism.

Trying on the tape.

Trying on a transfer case.

The process of installing a 4-speed gearbox.

We connect the boxes with such an adapter.

We turn to the manufacture of leading sprockets, each sprocket will have 8 teeth.

The author made the teeth from low-pressure polyethylene.

The author made the teeth from low-pressure polyethylene.

The workpieces were sawn off at the sawmill.

We weld the nuts to the hub, to which the sprocket teeth will be attached.

Fastening the tooth to the hub (hubs are wrapped with a conveyor belt).

Leading star assembly.

Canine teeth are bent to restrict track links 10 cm long.

We install the box and the engine.

The engine mounts are welded to the frame.

Future cab, dashboard with sixth model Lada.

We weld lugs to the tracks.

Assembling the track, each track has 44 tracks.

According to the author's idea, the hull of the tracked all-terrain vehicle will be a boat, so the frame was scalded with 1.5 mm sheet metal.

The bottom of the boat.

All-terrain vehicle control levers.

The cooling radiator is borrowed from the VAZ 2108.

The exhaust system has been prepared.

Test drive homemade equipment.

The author lined the body with sheet aluminum.

The author decided to make arcs and stretch the awning.

Tests.

An air intake is made for the radiator.

The all-terrain vehicle also easily overcomes water obstacles, we watch the video of homemade tests.

Another video with a tracked all-terrain vehicle.

The author of the all-terrain vehicle, Evgeny from Vitebsk, decided to name his home-made tracked all-terrain vehicle - "Mars-3".

Tracked mini all-terrain vehicle

Before starting work, orient yourself with the toolkit. We can state with absolute certainty that you will need:

- a variety of screwdrivers;

- hammer;

- electric welding;

- a device for bending pipes (if there is no prepared frame).

Before creating drawing materials, familiarize yourself with the typical structure.

Frame. Any tracked snowmobile has a frame: the more sophisticated the structure, the stronger and more reliable the frame must be. The ideal option is to borrow from a scooter, ATV or motorcycle. If there is no such element, you can weld it yourself from steel pipes with a diameter of at least 40 millimeters.

Sitting. The ATV seat needs to be sturdy as the structure itself is rather low. An indispensable condition: it must be made of a moisture-proof material.

Motor

When choosing a motor, focus on its resource. If you want the all-terrain vehicle to be powerful, then the motor must be the same.

Fuel tank

A tank with a capacity of 10-15 liters, made of iron, is ideal for a fuel tank.

Skis. If you do not have ready-made skis that can be adapted for an all-terrain vehicle, you can create them yourself from wood.It is desirable that it be 9-ply plywood, no less.

Steering wheel. When choosing a steering wheel, think about your comfort. It is desirable that it be borrowed from two-wheeled vehicles.

Caterpillars. Making caterpillars is probably a particularly difficult task.

Actuator. In order for the tracks to spin, you need a power drive - preferably a motorcycle chain for this option.

Frame

If a completely finished frame is not available, then it is simply welded from a profiled pipe, and the configuration is given by means of a pipe bending device.

When the frame is finished, treat it with an anti-corrosive solution and paint it with a high quality paint that can withstand both moisture and winter frost.

Caterpillars

Everyone who once created a tracked all-terrain vehicle on their own declares: the creation of tracks is the most difficult procedure.

The easiest way to make them is from car tires. This method is very profitable - durable and low-cost. The component is made in a closed circle, for this reason, a tire rupture cannot happen.

Let's take a look at the tutorial on how to create tracks, they can be done in two ways.

From car tire:

- take the tire and cut the sides (use a sharp knife);

- it is necessary to cut it so that the bendable part with the protector remains.

From the conveyor belt:

- cut off the desired piece of tape;

- we sew the edges with a thread from a fishing line;

- we fold into a ring, we sew the ends;

- we fix the lugs on the made canvas, in their role we use plastic pipes with a diameter of at least 40 millimeters (cut along);

- we fix the pipes to the canvas with screws.

Perhaps the above information will be useful if you have decided to create an all-terrain vehicle based on a walk-behind tractor.

How to make an all-terrain vehicle from a walk-behind tractor with your own hands, see the next video.

How to make a homemade wheeled all-terrain vehicle

An example of a drawing of an all-terrain vehicle on low-pressure tires

It makes sense to equip the base unit with a reduction gear. The reason is that gasoline and diesel engines have the best torque ratings at a crankshaft speed of about 75-85% of the maximum.

ATV frame

An example of a drawing of a fracture frame

A frame is created between the front and rear axles. It is better to use rectangular or square shaped pipes as a basis. They provide greater rigidity than rolled corners, channels and I-beams of the same mass.

The joining of the frame elements of a wheeled all-terrain vehicle can be rigid, then it will be formed in a one-volume format. When using heavy motoblocks "Neva" or MTZ, this option will be preferable.

As an option, a breaking frame (fracture) is made, the option is used for areas with a complex profile. Here, the articulation is performed through the king pin. Front and rear axles have independent suspension from each other. Such all-terrain vehicles masters create on the basis of the "Neva" and "Ugra" motoblocks.

Rear axle and suspension of a homemade all-terrain vehicle

Some DIYers use a ready-made rear axle from a car to simplify the design. For example, from the car "Moskvich-412": its low weight allows installation on a light all-terrain vehicle. Suspension is made on shock absorbers for a smooth ride and reduced vibration.

Other craftsmen make independent suspension for each rear wheel. This approach is implemented on the "Ant" scooter. When driving, a slight swaying is felt, at the same time, the wheels experience less resistance on bumps, and fuel consumption is noticeably reduced.

Connect the rear axle to the frame with long hardened bolts. For elastic joints, rubber inserts are used, for example, silent blocks. This improves the operational characteristics of the all-terrain vehicle based on the walk-behind tractor.

Wheels (low pressure chambers)

You can use lugs to move on wet and wobbly ground.They provide high grip. Large diameter low pressure chambers behave even better. Pneumatics have minimal ground pressure, and the presence of air trapped in the chambers of the all-terrain vehicle will make it possible to create a floating all-terrain vehicle.

For installation on the rear axle, home-made or special wheels for all-terrain vehicles, swamp vehicles and snowmobiles are used. They are purchased as an assembly or as separate elements: a tire, a camera, a disk. Assembling the wheel is simple.

- Homemade pneumatic discs are made by welding conventional discs and mounting plates using metal tubes. This expansion is necessary in order to fit the small diameter of the car rim for large cameras and better fix them.

- A large camera is put on a specially expanded disk - either a proprietary one or from other units (GAZ 53, Ural, Kamaz or another truck, aircraft camera, etc.).

- An air valve is discharged into the opening of the disc.

- The wheel is inflated with air.

- The resulting tires are installed on a homemade all-terrain vehicle.

It is possible to increase the permeability of conventional wheels on low-pressure chambers by creating an additional protector. For example, you can additionally secure the cameras with chains, conveyor belts, homemade tracks or in another way.

Another option is to cut an overhead lug out of the tire. The depth of the hook of the structure reaches more than 20-25 mm. The rolling resistance is increased, while the slip coefficient is sharply reduced.

Assembling a homemade all-terrain vehicle from a walk-behind tractor

When all the tools, spare parts and accessories are prepared, you can start assembling. This is a rough plan for how to assemble a homemade all-terrain vehicle, it all depends on the chosen design.

- A walk-behind tractor is installed on a welded or finished frame.

- The rear axle and, if necessary, the front axle are mounted.

- The seat is placed on the frame.

- If provided by the drawing and diagram, the steering is installed.

- Protection is attached to the frame; it is made of plastic or metal sheet.

- The prospective driver should test the comfort of landing, if necessary, provide auxiliary devices for adjusting the fit.

- The performance of the brakes is checked.

- Electrical circuits and lighting fixtures are being installed.

After the completion of the bench tests, the field tests are started. You need to know how the car behaves in difficult conditions.

How to make an all-terrain vehicle with your own hands from a walk-behind tractor

Light homemade ATVs are called "pneumatics" or

"Carakats". The best passability is provided by large cameras.

Stages of creating an all-terrain vehicle:

- Choice

the basics of the machine.

The frame of the URAL or IZH motorcycle can serve as the basis. Car on

base IL, more maneuverable. And many people opt for this very thing.

option. Such a car moves well off-road.

- Manufacturing

suspension and rear axle.

For independent rear and front suspension

the spars are connected by a brace, a steering sleeve and a special rack. Such

the suspension ensures smooth running, and any type of all-terrain vehicle should have it.

- Fastening

wheels.

Any light all-terrain vehicle should have a truck camera.

It is attached to the suspension using a metal hub. Cameras applied

low pressure from KamAZ trucks, their trailers, as well as URAL vehicles. it

provides ease of steering and increased safety when

movement.

- Mounting

systems and engine.

When the suspension with wheels is installed, the motor is produced

walk-behind tractor. At the same time, the clutch, brake,

gas emission systems.

Upon completion of the assembly, the all-terrain vehicle is tested. If everything is okay

you can start operating it.

Homemade all-terrain vehicle and its use

All-terrain vehicles pneumatics showed excellent cross-country ability

swampy terrain, riverbeds and mud. They have good buoyancy, therefore

a small water obstacle can be overcome without difficulty on such an all-terrain vehicle.

As a rule, a pneumatic can accelerate to 75 km / h.