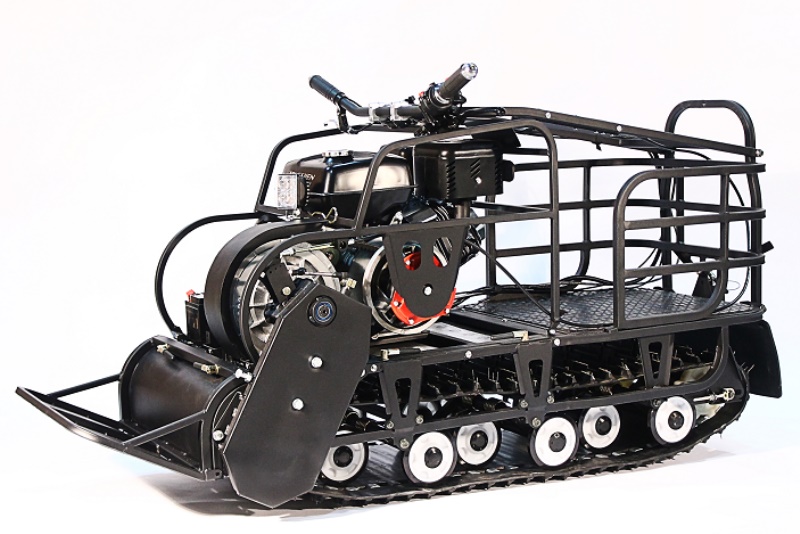

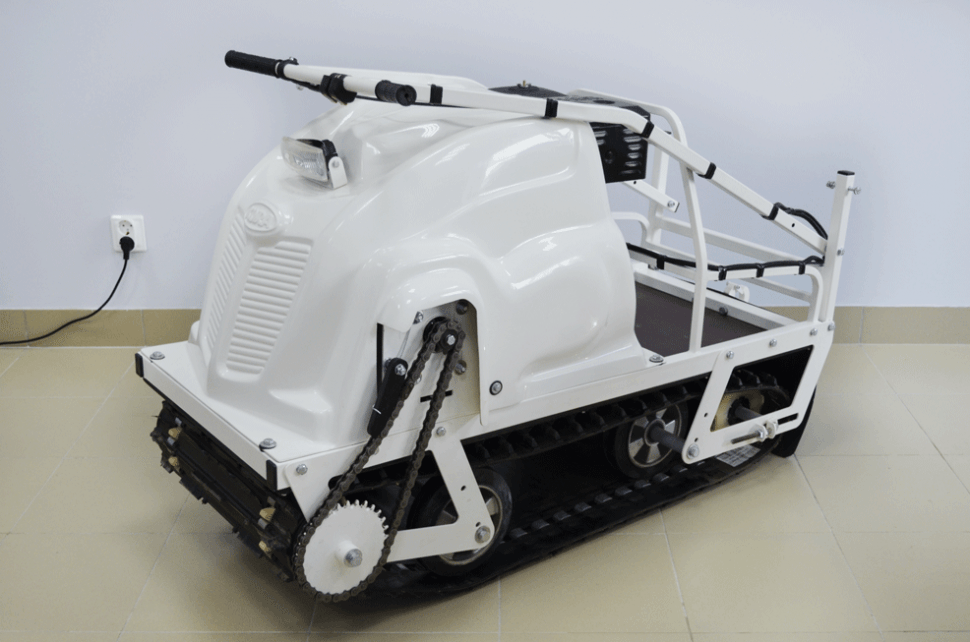

Popular brands

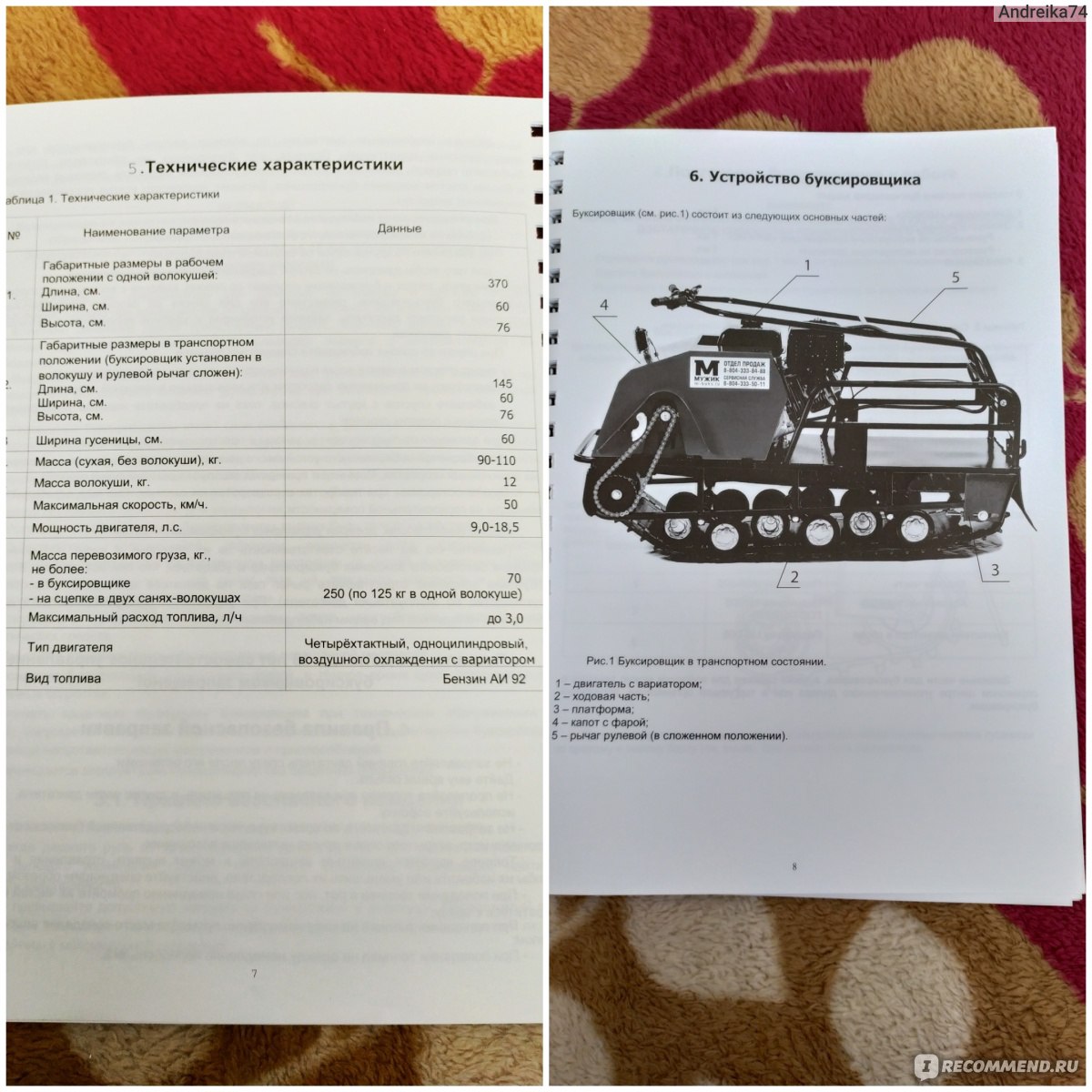

A set of mechanisms and equipment for motorized towing vehicles and snowmobiles is sold under different brands. The "Safari" variator is popular, it changes the gear ratio and subsequently smoothly adjusts the speed of movement of the equipment. This mechanism is also used for installation on a utility snowmobile, for example, "Buran" or "Taiga". This type of variator has a reinforced crosspiece, as well as a high-quality pressing mechanism. These two components contribute to the overall reliability of the product.

The Safari is lightweight, has a simple design, and is characterized by good reliability. With a mass of 3800 grams, the diameter of the movement is 21 centimeters, and the length is 16.7 centimeters. The variator for the snowmobile and the Forward towing vehicle is also in demand among consumers. This mechanism is characterized by high quality construction, durability and reliability.

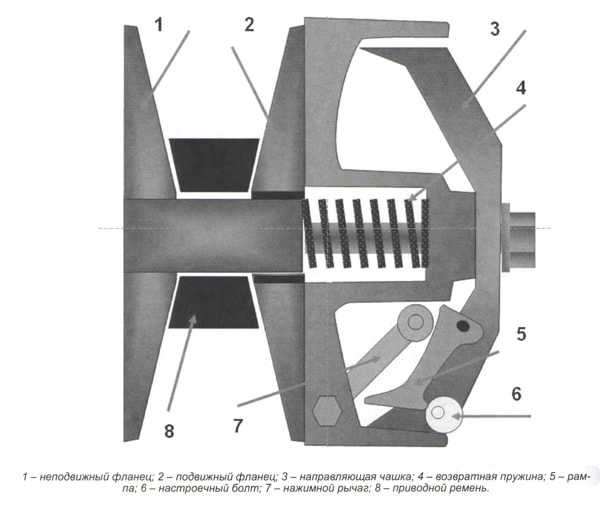

Regulator design and operation

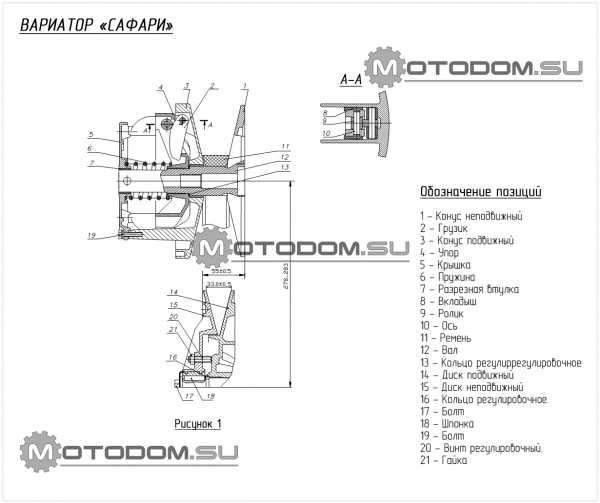

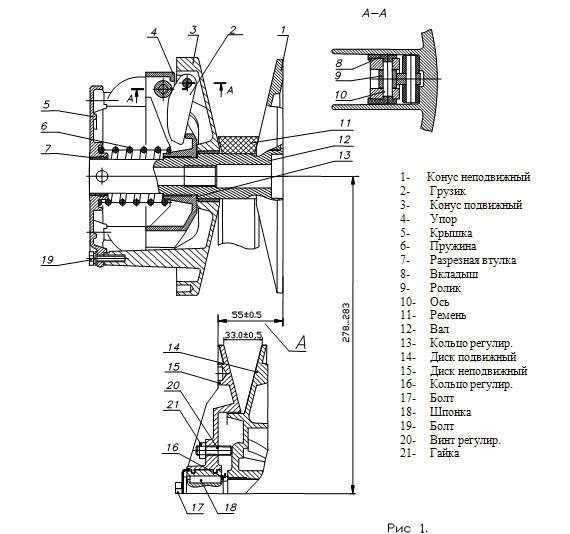

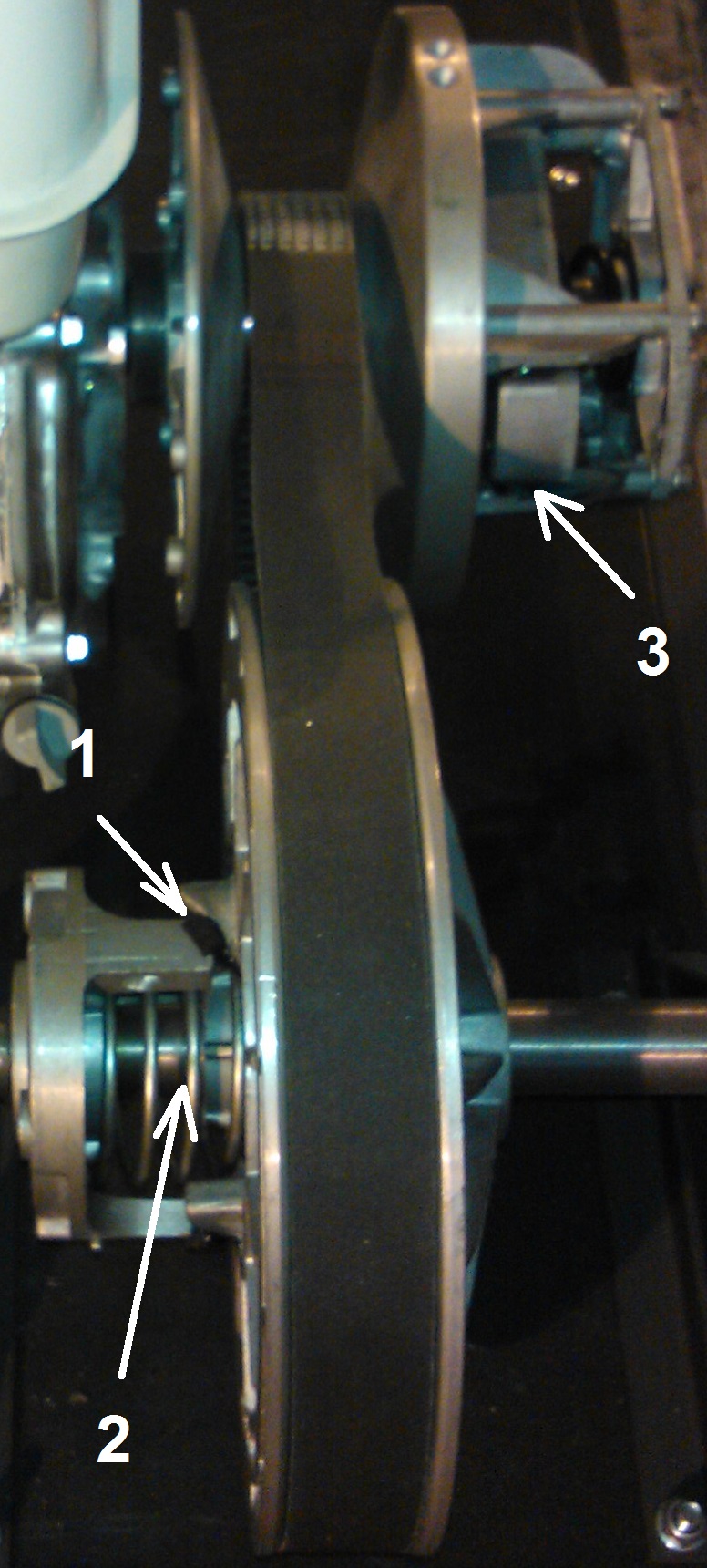

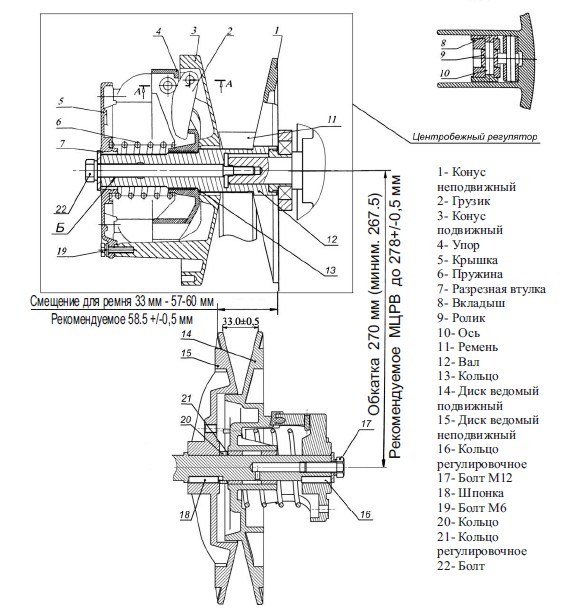

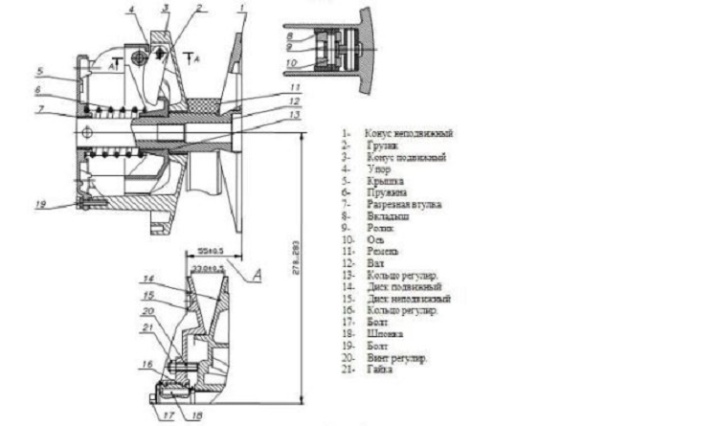

The centrifugal regulator includes a fixed cone 1 mounted on a shaft 12, a movable cone 3 with weights 2 that rotate on axes, a stop 4 with rollers 9 designed to move the weights, a spring 6, which is installed between the stop and the cover 5. The cone the fixed and the stop are seated on the shaft using a metric thread. The installation of these elements is carried out with a screwdriver with a tightening torque of 8-10 kgm. The spring spreads the cone of the drive pulley when lowering shaft revolutions engine, thereby providing idle speed. At idle speed, the gap between the V-belt and the surface of the movable cone is 1-3 mm.

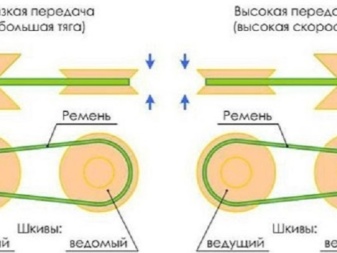

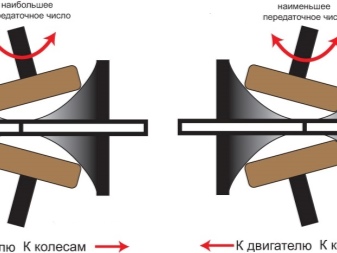

The regulator works as follows: when the shaft rotates, centrifugal forces, acting on the weights, tend to turn them and move the movable cone away from the stop, thereby clamping the belt in the pulley groove. The return spring resists centrifugal forces up to 1600 rpm. With an increase in the engine speed, the cones grip the belt, increasing its tension and compression from zero to the nominal values required to transmit torque and overcome the forces of resistance to the movement of the vehicle.

How to lubricate the Safari variator

For lubrication of the leading and driven structural elements, the manufacturer provides several compositions:

- CIATIM is a viscous lubricating substance that does not allow moisture to pass through and allows you to keep the pulleys intact under the influence of an aggressive environment, it is sold in a standard container with a spray;

- Lithol is a similar substance that, moreover, prevents the spread of corrosion and completely envelops the workpiece.

Also, the owner can use silicone lubricants from other manufacturers, but their effectiveness should not be inferior to the above drugs, otherwise there is a great risk of damage.

How to install the Safari variator

For the correct and correct installation of the variator in both snowmobiles and towing vehicles, it is necessary to follow the manufacturer's instructions and follow the safety rules. The devices must be de-energized, all their systems must be in good working order, otherwise there is a high probability of incorrect operation of the variator.

If a malfunction is found during the installation process, it must be eliminated before complete installation. Also, for the installation of the transmission of the safari variator, no special repair skills are required, only the keys for adjusting the clearances must have different heads.

Installing the Safari variator on a motorized towing vehicle

In terms of installing the device on a motorized towing vehicle, the manufacturer does not expect any special differences. Most towing vehicles provide a regular place for mounting the variator, which is suitable for these mountings in terms of its dimensions.The installation sequence is the same for snowmobiles, but there are some nuances when adjusting idle speed and torque gain. For a towing vehicle, a high speed set is unnecessary - the emphasis is on traction characteristics. Therefore, when adjusting, it is necessary to set the clearances and downforce of the pulleys taking into account the characteristics of the increased thrust of the device.

Installation of a safari variator on "Buran" and "Taiga"

To install this unit in a snowmobile body, certain rules specified by the manufacturer must be followed:

- before installing the installation, it is necessary to dismantle the old device and check the operability of the other systems of the towing vehicle or snowmobile, as well as clear the grooves for installation;

- the cone of the device must be connected to the crankshaft of the snowmobile engine in one part, the other is threaded to the stop;

- the pulleys are installed with fasteners in the standard seats, a belt must be fixed between them (in the future, the idle speed must be adjusted and installed);

- after installing the housing, it is necessary to adjust the operation of the system with this engine; in addition to idle speed, the gaps between the pulleys and the clamping force of the spring are subject to it.

Important! When installing this unit in its original location, the owner must follow the manufacturer's strict recommendations. In case of incorrect installation of individual elements, incorrect operation of the variator is guaranteed.

Safari CVT malfunctions

The most common malfunctions that sometimes manifest themselves with improper operation include:

- Incorrect installation of the device, which can lead to mechanical damage, work with the wrong gear ratio of the Safari variator, as well as failure of the engine itself due to overloads.

- Jamming of pulleys at high overloads or lack of permanent preventive lubrication. Such a malfunction leads to a complete replacement of the entire apparatus.

- Abrasion of liners due to lack of lubrication, or due to loss of their properties due to overload or old age.

Such problems are most common and require timely prevention of the condition of the liners and their replacement.

Service

Like any other component in the design of a motorized towing vehicle, the variator requires maintenance. It should be carried out every 3000 kilometers of vehicle run. The owner of the car should not forget about the variator lubrication. It is worth lubricating the parts with a special universal agent. After the equipment has passed 6,000 kilometers, it will be necessary to check the condition of the liners on the weight axles. It is necessary to warm up the engine in neutral position, this helps to prevent rubber winding on the shaft. Rubber deposits on the shaft can be removed with a piece of cloth soaked in gasoline.

CVT "Safari" for motorized towing vehicles: rules of maintenance and operation

The transmission on motorized towing vehicles can be implemented in two options:

- a simplified and cheap way is to install a reduction gear and an automatic centrifugal clutch on a motorized dog;

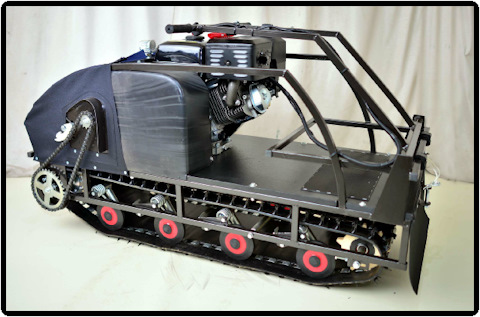

- a more expensive and optimal method from the point of view of design is the use of a V-belt variator. The variator allows you to smoothly change the torque, which contributes to an increase in traction when overcoming difficult sections of the track. From the variator, the moment is transmitted by means of a chain drive to the drive sprocket of the track. Safari variators have gained particular popularity among modern designs of motorized towing vehicles.

What is a Safari variator

The Safari variator for the Taiga snowmobile is a continuously variable V-belt type gearbox. This device acts as a standard transmission for Buran and Taiga snowmobiles, and can also be installed as a replacement for standard motorized towing vehicles.

The continuously variable transmission appeared over 50 years ago in the automotive market. Over time, having entered the everyday life of motorists, such a unit began to be installed on more compact equipment.

The principle of operation of the system remained the same, as in the car versions, but the dimensions have changed downward. Snowmobile engines have less displacement, torque and size, and therefore do not require large transmissions to transfer torque and power to their tracks. A similar situation is with motorized towing vehicles, where the "locomotive" traction without reference to the acceleration speed and power indicators plays a decisive role. Therefore, a Safari CVT assembly for a snowmobile must have specific characteristics:

- Ease of maintenance is one of the determining factors when choosing a technique. Taking into account the small dimensions of the product and the simplicity of the design of this variator, maintenance work, minor repairs and replacement of individual parts that have failed, the consumer can perform independently with minimal technical knowledge and tools.

- The cheapness of the unit and spare parts. This system is designed for snowmobiles and its final cost in a complete set rarely exceeds 6,000 rubles. In comparison with competitors, this indicator is 15-20% less on average.

- Ease of installation is also an important parameter in operation. Replacement is carried out using a special tool and with subsequent adjustment. Also, in comparison with competitors, this type does not require special repair skills (with the exception of the adjustment process, which is quite laborious).

- The traction properties of this variator are high by the standards of a snowmobile. Among similar devices, this device is among the leaders, providing the ability to tow several adult passengers or cargo weighing up to 150 kg when used on a towing vehicle.

High reliability has been repeatedly confirmed in practice by snowmobile owners. The system is designed to operate in low temperatures and is excellent for this kind of terrain. Even when the maximum thrust mass was exceeded, the unit coped with the load more than once and did not show design flaws.

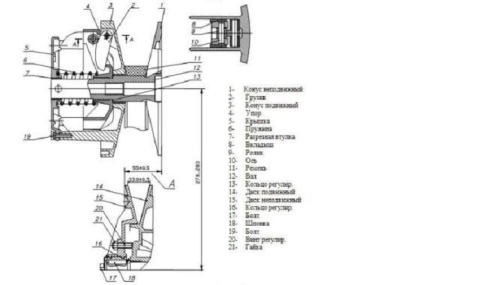

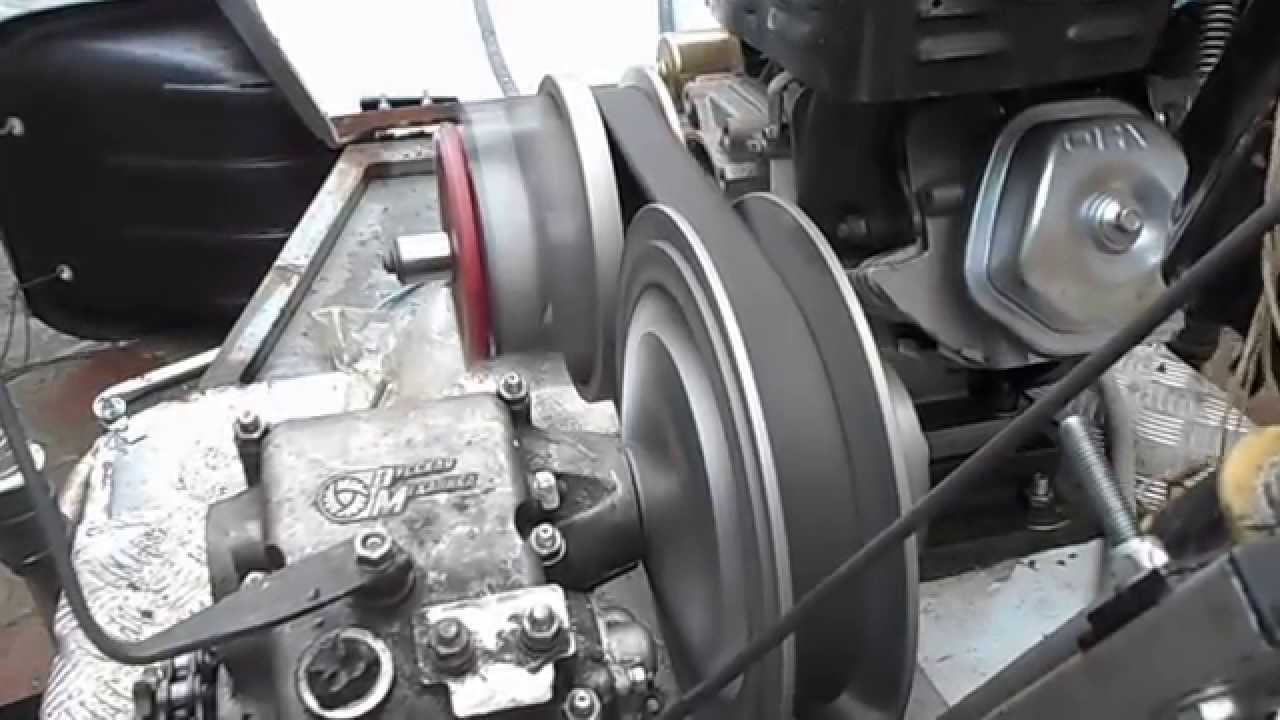

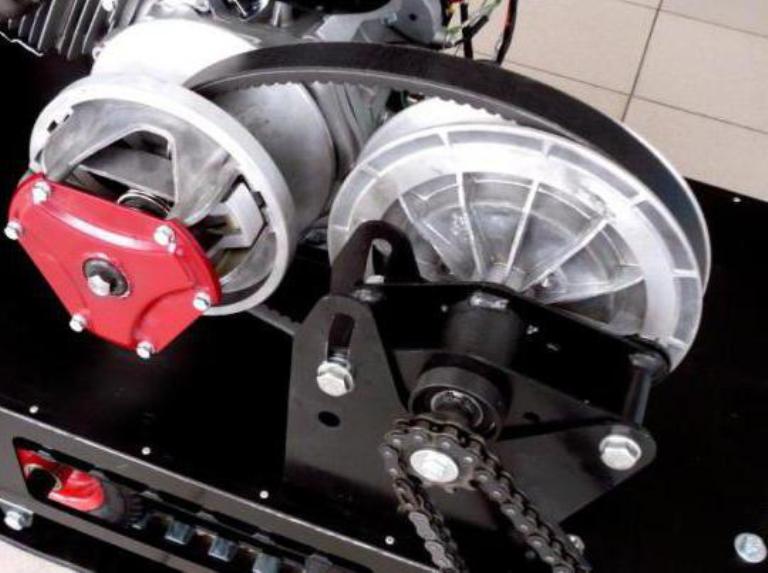

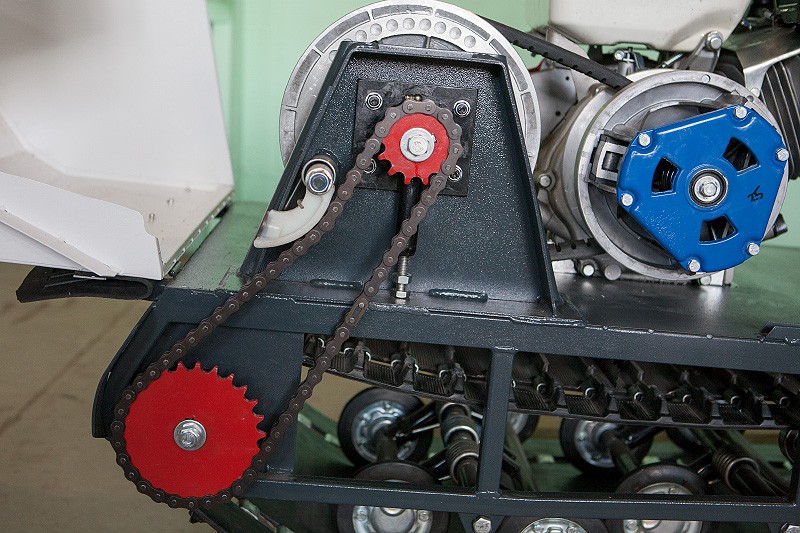

The assembled device is shown in the photo.

Possible malfunctions

Any equipment and its elements fail, the variator is no exception. When using this device, you may notice the following problems.

- Uneven movement of the motorized towing vehicle, the presence of extraneous sounds during operation. The reason for this situation may be a worn-out CVT belt or wear of its plastic inserts. To eliminate the problem, you will need to replace the belt or inserts.

- A spread of metallic hum may indicate bearing damage. To correct the problem, the bearings will need to be replaced.

- With the development of engine speed, no movement of the motorized towing vehicle is observed. In this case, it is worth checking whether the belt is torn, whether the track roller has turned over from mechanical damage. Correcting the problem involves replacing the belt and returning the roller to its original position.

- Jamming of the variator during overheating. Worn bushings or belt slippage can cause this trouble. In order for the variator not to jam the bushing, you need to check the belt, clean the discs.

In order for it to function without problems, you will need to follow the maintenance recommendations.

How to set up the variator on a motorized towing vehicle, see below.

Maintenance

The Safari variator requires periodic maintenance. This procedure is performed every 3 thousand km of run. The shaft will need to be lubricated. It is located under the split bushing. The lubricant should be of a universal type of lithol. This will prevent premature destruction of metal parts.

On the axles of the weighting materials, as well as the condition of the material of the liners, it is necessary to check every 6 thousand km of run. The amount of wear can be determined by measuring the backlash distance. It should not be more than 1 mm. Also, the size of the gap of the guides and liners of the movable cone is determined. A gap of no more than 1.5 mm should be determined here.

To prevent rubber from getting wrapped around the shaft, the engine must be warmed up exclusively in neutral position. If a rubber deposit appears on this structural element, it must be removed with a rag. The material is wetted before cleaning in gasoline.

DRIVEN PULLEY Snowmobile Taiga

Withdrawal

Remove the clutch cover and clutch belt from the snowmobile.

Unscrew the bolt 15, remove the lock washer 14, bushing 13, then remove the driven pulley from the variator shaft.

Disassembly

To disassemble the driven variator pulley, use a spring compression tool (puller for the driven variator pulley coupling half).

Align the pin with the keyway

Examination

7.9 Sleeve

Check for cracks, scratches and free movement when reassembling with a stationary disc.

Using a bore gauge, measure the diameter of sleeves 7 and 9.

The measuring point must be at least 5 mm from the edge of the sleeve.

If the wear of the bushing 7 is more than the specified one, it is necessary to replace the movable disk with bushings, if in the bushing 9 - replace the bushing.

8 Earbuds

Check liners for wear. Replace when the side edge is 3.5mm or less.

Measure the thickness of the base here

Disc adjacent surface

Assembly

8 Earbuds

Reassemble the pulley parts in the reverse order of the disassembly procedure.

15 Pulley fixing screw

Tightening from 21.57 to 27.45 N · m (2.157 ... 2.745 kgf · m).

ADJUSTMENT

See section 05-05 for pulley adjustments.

Adjust the height of the clutch belt in the driven pulley to obtain the specified belt tension section 05-02.

10 Spring

General

There is usually no definitive recommendation for adjusting the preload of a new spring during its running-in. The factory preset spring preload is slightly overestimated to compensate for its setting. After running-in (300 km of operation), set the spring load in accordance with the technical data in section 10-02.

Spring preload

To check the spring preload adjustment, use a balance wheel and spring balance bracket.

Remove the drive belt. Place the bracket on the moving disc. Secure the stationary disk 2 from turning, pull the movable disk with a balance bar (spring scales) perpendicular to the pulley axis.

Take the first measurement of the twisting force when the movable disk begins to turn. Rotate the movable disk 10 mm in the outer diameter. Keep the balance in this position. Slowly release the force from the balance and take a second spinning force measurement when the plunge disk begins to return. Spring preload is the arithmetic average between these two measurements.

1 measurement 2 measurement (when opening) + (when closing) = Spring preload

2

Example:

Usually

Stage 1.1st measurement

Stage 2.Dimension 2

To adjust the spring preload, change the position of the spring end in the coupling half by sliding it clockwise to increase the preload and counterclockwise to decrease it. See technical data section 10-02.

If there is not enough preload adjustment margin, try to move the other end of the spring in the movable disc (holes 1, 2, 3).

The numbers in the illustration are true, embossed on the details.

NOTE: Always recheck the preload after adjustment.

.

Device and principle of operation

After purchasing a variator for a motorized towing vehicle, it is recommended that you carefully read the instructions. Having studied the correct operation, you can extend the service life of your motor vehicles. The mechanism includes a centrifugal-type regulator, in which there are cones with moving and stationary weights. In order for the weights to move, stops with rollers are used during their production. Also in the design of the mechanism there are a cover and a spring.

The fixed cone, which has a stop, is threaded to the shaft. The crankshaft is mounted to a fixed cone. The spring is needed to create idle speed.When properly installed, the location of the variator belt should be fixed 1-3 millimeters from the surface of the cone. This option helps to adjust the idle speed. To change the gap, rings are used, which are located on the border of the shaft stop and the protrusion. In the operation of the variator, a certain algorithm is traced:

- the regulator rotates;

- centrifugal forces arise;

- centrifugal forces affect the weights.

The above actions contribute to the belt compression of the pulley groove in the variator. The return spring counteracts the centrifugal force. For this reason, weights can easily overcome opposition. The number of revolutions per minute must be at least 2200. When this threshold is exceeded, the force that acts on the belt increases to the working reading. With these factors, torque arises, and resistance is overpowered.

Disassembly of the mechanism

The Safari variator may require disassembly. In this case, the regulator will need to be removed from the vehicle. In this case, the fixed cone will need to be fixed in the lathe (another convenient method can be used).

You will need to insert a duralumin rod between the parts of the movable cone. You can use wooden blocks in this case. The cone must be unscrewed together with the cover and stop. If you knock a little in the area of the ribs of the cone, the dismantling process will be much easier.

Next, unscrew the 6 bolts holding the cover on the movable cone. When there are only 2 bolts left, it must be held. Otherwise, the spring can “shoot” strongly. When the turn comes to the stop, it is necessary to remove only the liners. The shafts and rollers must be thoroughly rinsed. For this, kerosene or gasoline is used. By inserting new liners, you can assemble the stop in the reverse order. Grease should not get on the surface of the disc cones.

Which variator is better - Alpina or Safari

In the segment of motorized towing vehicles and snowmobiles, in terms of gearboxes, there is a vigilant competition between two proven units - Safari and Alpina. Both products are standardly installed on Taiga and Buran snowmobiles. Also, both have similar characteristics - the differences are only in the details - the maximum work of revolutions and the total mass. However, with a detailed comparison, it is quite possible to identify the nuances that make it possible to give preference to Safari, namely:

- the maximum traction mass of the towed weight for Safari, though not much, is still higher - 150 kg (as opposed to 140 kg);

- the maximum number of revolutions is also higher for Safari, which allows for greater speed;

- in terms of maintainability, both products have deservedly acquired a good reputation among owners as reliable devices and quite affordable for self-repair;

- at a cost, both competitors are also approximately equal - the Safari variator assembly or Alpina can be purchased within 4-6 thousand rubles.

With a small advantage, Safari bypasses its competitor Alpina in terms of consumer characteristics and properties. The rest of the models of domestic and Chinese production in terms of their characteristics in total are already significantly inferior to these models.

More about the purpose of the variator

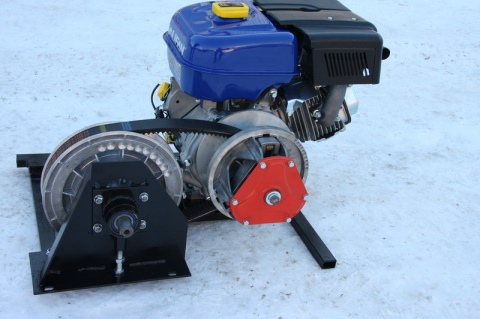

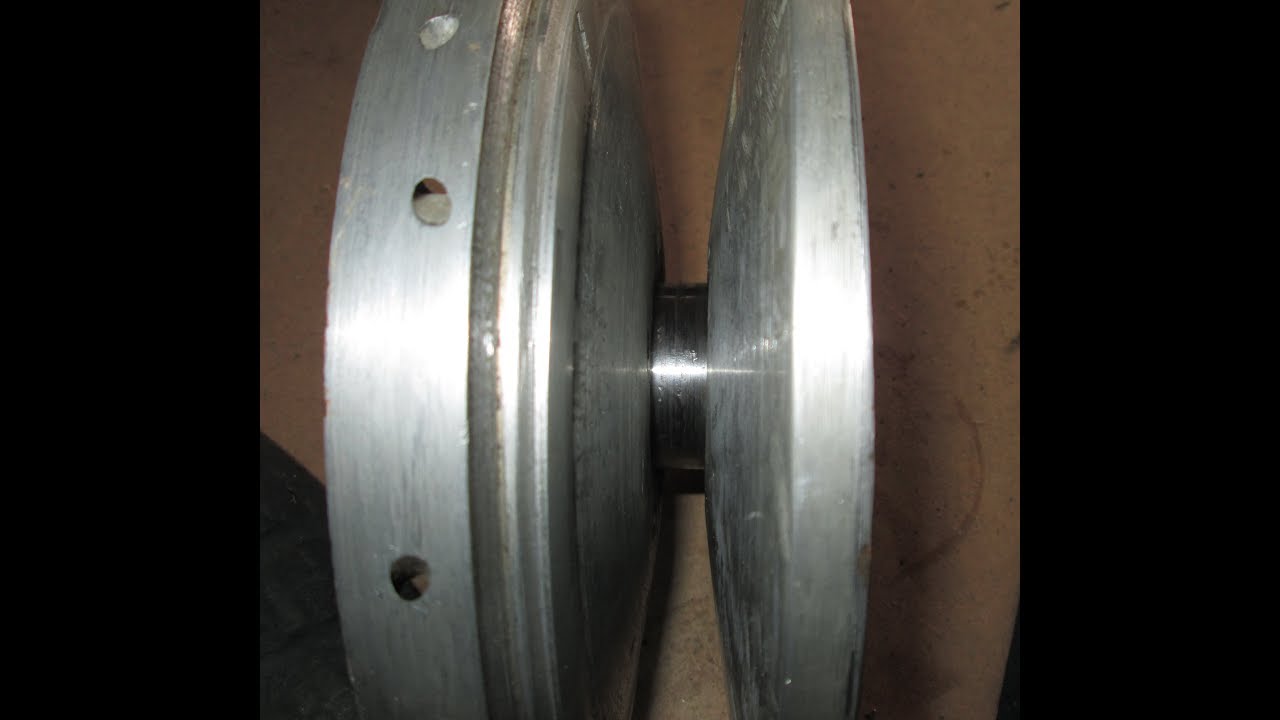

The Safari variator used on modern motor vehicles and vehicles (snowmobiles, towing vehicles, ATVs) is a stepless V-belt transmission. The CVT design shown in the photo below consists of two pulleys.

The variator automatically adjusts the gear ratio according to the following parameters:

- resistance to the movement of the "dog";

- the speed of the crankshaft of the motorized towing engine.

Depending on the combination at a particular moment of movement of the above parameters, a certain gear ratio of the variator is automatically adjusted.In addition, the drive pulley of the V-belt transmission performs the functions of a clutch, and when the engine speed drops below 1500 rpm, the engine shaft is automatically disconnected from the intermediate shaft of the transmission.

CVT technical data

Safari variators used on motorized towing vehicles have the following dimensions:

- the diameter of the drive pulley - 210 mm;

- length - 167 mm;

- weight - 3.9 kg.