Device

The roller design is a frame curved in the shape of a seven. The top is called a tube and serves as the base for a rotating cylinder called a "bobbin".

An absorbent coat is attached to the top of the bobbin, which can be either glued to it or fixed with plugs. The bobbin itself can be attached to the frame using a frame or clasp method. The first one is distinguished by the presence of a bearing, a lock, plastic plugs and fixing the fur coat using stoppers. The second is typical for more expensive reusable designs and, if necessary, involves a complete replacement of the cylinder and fur coat.

General rules for choosing a roller

Before considering which roller is best suited for water-based paint, you have to familiarize yourself with a number of rules for selecting the appropriate device for normal work:

In order to choose the right tool, it is necessary to clarify with which dye to work.

The scale of the work to be done is assessed without fail, as well as the presence of hard-to-reach places.

If a paint roller is selected, it is recommended to pay attention to products that can be used repeatedly.

If you plan to do the job efficiently and without streaks, you should pay appropriate attention to the material of the cylinder.

It is necessary to determine for yourself the optimal distance at which it will be convenient to apply paint to the surface.

The material of the surface, which is to be encountered during subsequent processing, must be taken into account.

The desired consumption of the dye, the thickness of each layer and the drying time of the component are taken into account.

If you take into account all these points, it is possible to choose the right device, both for water-based paint and for any other paint that is planned to treat walls or other structures.

Bracket attachment

In this case, you will not have to choose for a long time, since there are only a few basic varieties that can be subdivided into collapsible and one-piece structures. In practice, if you plan to use the roller more than once, and also apply several shades of color, it is better to use devices that can be disassembled, and then make the appropriate replacement. As for the one-piece accessories, they are suitable only when an open surface treatment is required without the presence of hard-to-reach places. In a separate situation, you can consider a bracket with a double fastening for the cylinder, since this is the most robust and resistant structure to mechanical stress.

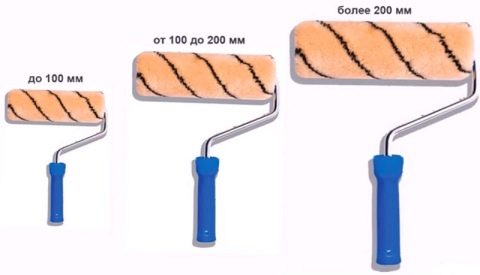

Width and size of the cylinder

Currently, finding the appropriate dimensions should not be difficult, since in almost every hardware store you can find ready-made cylinders with a width of 50 to 600 millimeters. Here everything rests on the surface area, which will subsequently be processed. For hard-to-reach places, you should choose the smallest in the width of the product, as they provide the best staining of these areas.

Separately, when searching, it is recommended to pay attention to the groove diameter. Here the value varies within 6-12 millimeters.

The thickness of the bracket on the roller, which has already been purchased for painting structural elements, will help to determine the choice.

Foam rubber or pile

If we consider which roller to paint the surface with water-based paint, then tools with a foam or pile version of a fur coat immediately come to mind. It all depends on what kind of effect you want to achieve from the finished layer. If we consider the pile, then subsequently on the surface irregularities, streaks and the corresponding roughness will necessarily remain on the surface, which in some situations is necessary. As for the foam rubber coat, it provides an absolutely even coating, however, due to the specifics of the material, there is a significant increase in the consumption of the paint used. In addition, some areas after processing may require additional staining, which is not always convenient, especially when a wide cylinder is used.

Velor and polyamide

There are two more types of cylinder fur coats, which are very often used when working with water-based paint. Of course, it is not so easy to determine exactly what is right for you, since each type has its own advantages and disadvantages. As for the velor, it has a relatively small service life, and in addition, a fairly high cost. Moreover, velor coats contribute to smudges and irregularities during paint application, but at the same time allow the dye to ideally penetrate into the most difficult-to-reach areas and gaps present, due to which the final coating will not have pronounced defects. If we consider polyamide cylinders, then there is the smallest consumption of dye for surface treatment. Of course, the tool will not allow paint to penetrate into the most difficult-to-reach places, however, it is difficult to find a better option for working with a large and even surface.

The technology of painting the ceiling with a roller

At first glance, the task may seem elementary - you just need to dip the roller into a bucket and roll it across the ceiling. However, the technology for the correct coloring of horizontal surfaces provides for a number of nuances. Start by diluting the colorant according to the instructions on the label or in the appendix. You should not experiment with proportions, dilute the paint, regardless of its type, strictly according to the instructions. Some coloring compositions do not need to be diluted at all, this must be indicated in the instructions.

Ceiling painting scheme

Before touching the working surface with a roller soaked in paint, it must be rolled out on a special tray. This is necessary to evenly distribute the composition over the instrument. The tray is a small, angled, grooved stand. Instead of a tray, you can use a piece of linoleum spread on the floor.

Paint tray and roller

If the roller is not first rolled out, this will lead to the formation of holes on the painted surface - unpainted. Even if you cover them right away, the coating in this area will differ in shade from the main one. Evenly distributing the coloring composition over the roller, you can roll it out already on the ceiling. The paint is applied in parallel stripes up to 1 m wide so that their borders intersect at least 10 cm.

It is better to start painting from the window. During the application of the first layer, follow the direction of the roller - the last one should go in a straight line, without coming off the surface. The easiest way for beginners to master the so-called. square-nested staining method. It provides for dividing the ceiling into squares with a side width of 0.7-1 m. They are painted over gradually, horizontally or vertically - as it is more convenient to work. Do not worry that after the paint dries, the borders of the squares will be visible - the subsequent layers will overlap them.It is recommended to paint over one square "in one go", without smoke breaks - otherwise the edges of the areas that have already dried up will stand out.

How to paint the ceiling with your own hands

Advice! It is impossible to objectively assess the quality of painting while being under the ceiling all the time. It is necessary to periodically go down and consider the result of the work from different corners of the room. If you look at the coating from a right angle, you may not notice many of its shortcomings.

If, after the first layer dries, unpainted "holes" remain, it will not be possible to cover them up imperceptibly. Therefore, it is most convenient to work with four hands - one paints, the second dilutes the paint, rolls out the roller and monitors the quality of the coating.

How to paint the ceiling with a roller

The saturation of the coating and its texture depend on the number of layers. Water-based and acrylic paints are applied in at least 3-4 layers, with an interval of 12 hours. Experienced painters recommend starting painting the ceiling at lunchtime, then in the morning you can start applying the next layer. You cannot apply the second layer before the first has dried, since the structure will be broken and ugly stains will remain on the ceiling.

How to paint the ceiling in the apartment?

Possible options, as well as detailed painting technology, you can find in this article. We also recommend reading about how to properly whitewash the ceiling.

One of the most common mistakes beginners make when painting ceilings is sagging. They remain if the roller is not pressed firmly against the surface or if you hold it obliquely. Paint build-up can be eliminated only before the layer dries with a foam sponge. If the paint has already dried up, only polishing of this area will help to remove the build-ups.

Paint the wall with a roller

Wallpaper for painting does not lose its relevance, so a special version of the tool should be selected for them. It is necessary to decide which roller to paint the wallpaper with for painting, depending on the type of base and the type of paint used. The process consists of the main stages:

- Preliminary preparation of the tool and surface.

- Painting works.

- Completion of work.

- Tool processing.

Each of the steps is important to get the desired result.

Preparation for work

Before painting, it is important to prepare the surface. It is necessary to eliminate all defects on it: chips, cracks, irregularities

This can be done with sand-cement mortar and putty. If it is not possible to level the walls, they can be sheathed with plasterboard. It solves the problem of unevenness and insulates the structure of the building. Masking tape is needed to protect the skirting boards and platbands.

Before starting painting work, you should prepare everything you need for effective work. In addition to the main elements (paint and roller), you will need:

- handle extension;

- container for paint;

- protective clothing, respirator and goggles.

All surfaces of furniture and other items located in the room should be covered with a protective film. Where possible, ventilation should be provided. It will remove toxic fumes resulting from the evaporation of chemicals.

Painting works

Work should begin by pouring the dye into the container. Dilute the paint in accordance with the manufacturer's instructions. Any experimentation can nullify all the efforts made: the paint can become too liquid or thick.

Then the roller is lowered into the working composition for impregnation. The tool is then rolled out on a grooved tray to remove excess.

Visually, the entire surface should be divided into several zones. When processing large areas, it is advisable to drive the roller diagonally. This technology allows you to evenly distribute the composition by overlapping the first layer with the second layer. You need to roll it out so that the layer is thin. Professionals believe that it is better to make three thin layers than one thick one.

Do not linger in one place to avoid swelling of the paint and changing the surface texture from smooth to rough. If the area is skipped, it is better to wait until the surface dries. Only then can you start re-staining.

Application technology

Roller painting technology differs from paint application with brushes. Coloring should start from the top, moving downward. Painting starts from the window for a more even application.

The square-nested staining technique is considered optimal for beginners. It's kind of a trick to make a large canvas piece by piece. It assumes a breakdown of the entire surface by 1 meter (0.7 m if necessary). The squares are filled in gradually. You can perform work horizontally or vertically.

After the first coat, the stripes (border of the squares) may be visible, but they will quickly disappear after a second coat of paint.

The saturation of the coating depends on the number of layers. Paints of different composition require individual application: acrylic and water-based paints should be applied in 3-4 layers with an interval of 12 hours, oil paints can be applied in 2-3 layers.

Therefore, before painting, you should study the instructions for using this or that composition.

End of work

The paint remaining after work is isolated from direct contact with air. The water emulsion can dry out after 2-3 days. Oil paints also do not tolerate such contacts and lose their properties, so they must be placed in a jar with a tight-fitting lid. Do not add paint to a can of untouched paint. Such mixing will negatively affect its quality.

Masking tape must be removed from platbands and baseboards. This must be done before the painted layer is completely dry, so that a strip does not remain. After the paint has completely dried, you can remove the film from the furniture and throw away the used cape.

Lamps, sockets and switches can be installed on the painted surface.

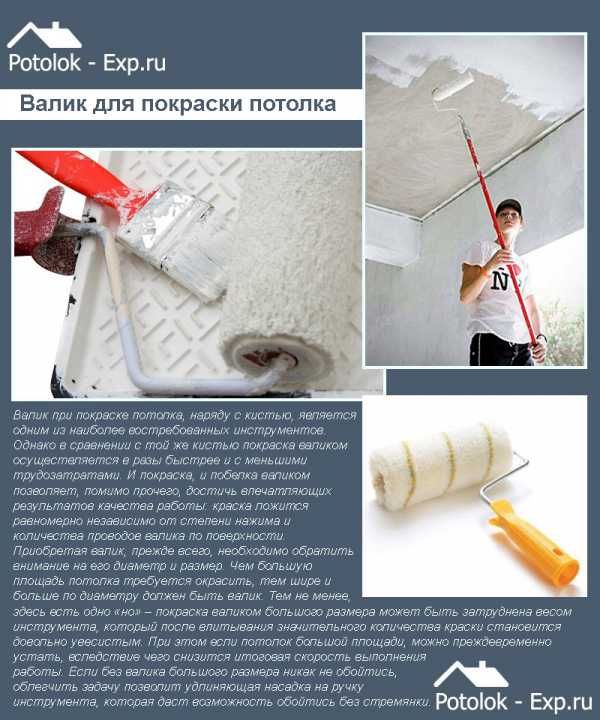

What roller to paint the ceiling

The long-handled roller is very comfortable

Choosing a tool for the job

When working from the floor, an extension cord is indispensable

Ceiling painting can be tedious, especially for the unusually tense muscles in the arms and neck. You need to do everything as quickly as possible, without stopping until the layer is completely applied. Therefore, the painting tool should be comfortable. And give a high-quality imprint on the surface. In fact, compliance with these requirements is the basis for choosing which roller to paint the ceiling with.

Sheep fur coat is ideal for ceiling, but man-made fibers can do quite well

With regard to convenience, a lot depends on the available device for working at height. If it is a stepladder or construction trestles, you can purchase a regular roller with a handle length of up to 30-40 cm. It is more difficult for those who are forced to work from a chair or from the floor. In this case, you will have to take care of the presence of a long handle-holder for the tool. Or use an extension attachment. For example, telescopic. The length of such extensions varies in the range of 0.7-2 m (sometimes up to 4 m). But, not always this device can be used (sometimes it does not fit the handle).

Convenient to use roller extensions

At the roller, a cylindrical nozzle is put on a curved clasp-rod. A cover is glued or stretched onto it, which protrudes directly with the working part of the tool. Convenient when the core diameter is large. This means that it will rotate more slowly, and will produce less spray. For finishing the ceiling, it is better to choose a large product with a core of medium (10-15 cm) or large (18-25 cm) length. Choose one with a clasp with a diameter of 6-8 mm and a connecting sleeve built into the nozzle. It is recommended to paint large surfaces with tools with a thick wide working part to reduce paint consumption.

Fur roller head with curved handle

Let us also clarify which roller to paint the ceiling with acrylic paint or other water-based emulsion. The fur coat should have a soft and sufficiently long pile (6-18 mm). The short one won't pick up enough paint. Natural sheepskin is preferred for the ceiling. It will work even better than llama or goat fur. Although, you can also choose a pile from polyamide (nylon), polyacrylic, polyester. The main thing is that it should be moderately long and not cake. This will provide the greatest coverage. Velor works well for finishing.

Velor is the best option for a topcoat

Fur coats made of dense high-quality foam rubber (they are usually dark blue) are good in their own way. But they absorb too much, and when processing the ceiling, they can drip more strongly. The hard and coarse-celled yellow foam rubber leaves traces or bubbles after rolling, just like on the material itself.

Tool Basics

Good hiding power will be provided by a pile of sufficient length that does not cake

It is useful to know which roller to paint the ceiling with water-based paint. But this is not enough - you still need to learn how to use the tool correctly. Otherwise, after the rental, there will be gaps or vice versa, the paint will fall in influxes. Its excess will drip from the pile and be wasted.

Hard-to-reach areas will have to be brushed beforehand

The roller is thoroughly moistened with dye poured into the paint tray. And then it rolls out in the same place. If there is no special pallet, you can remove excess paint on a sheet of cardboard, linoleum or other unnecessary surface. The course of the coating should be carried out so that the direction of the last layer coincides with the lines of propagation of the main light (usually from the window). This is how they achieve visual masking of possible irregularities in the structure. In general, the paint is applied in parallel stripes, which should overlap at the edges by 2-3 cm. Each subsequent layer lies perpendicular to the previous one. For maximum uniformity, the paint material should not be too thick. The tool does not always work to reach the joints and corners. They are carefully painted over with a brush before starting work with the main canvas.

What rollers are

Trying to sort all the rollers on sale on the shelves is still a gamble. The fact is that a variety of criteria can act as a starting point for classification. Starting from the type of fur coat used and ending with the size of the drum. All this ultimately affects not only the speed of the work, but also the immediate convenience in this case. Let's try, nevertheless, to systematize the accumulated experience and consistently go through each of them.

Handle size

As a rule, in domestically produced rollers, this indicator fluctuates within 30-50 centimeters... Experts note that it is these dimensions that allow you to confidently hold the roller in your hands and carry out uniform painting. If the task is to paint individual elements, and not the ceiling as a whole, then you can choose a roller with a smaller handle - 15 centimeters... As a rule, foreign companies are the manufacturer of such products.

An excellent option is a tool with replaceable handles, one of which is short, and the other, on the contrary, is long. Such a roller can be used successfully for a number of very different tasks.

Drum size

The standard drum size in modern rollers is from 20 to 40 centimeters... Of course, you can always find options both less and more, but such tools cannot be called universal, since they are not very convenient for general painting and are more suitable for use in solving a local problem related to painting visible decorative elements of the ceiling surface ...

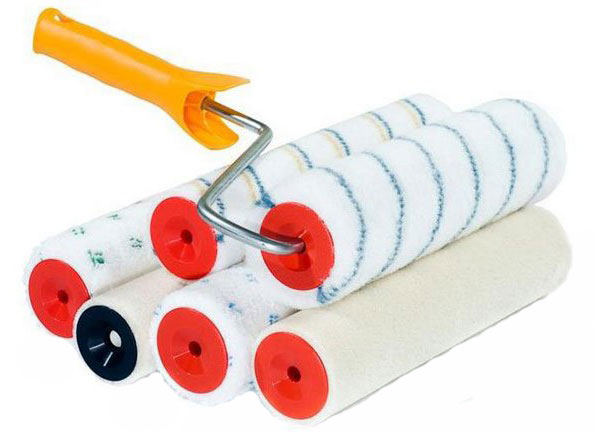

Drum design

The drum can be mounted on the roller body both on one side and on the other.By all accounts, the first option is preferable, since it allows you to change the drum coat over time, making the tool suitable for solving other tasks.

The double-sided design, alas, significantly limits your "user interface" and you cannot change the fur coat.

Coat type

- fur;

- foam rubber;

- polyacrylic;

- polyamide.

The advantage of a fur coat is that it saves paint and distributes it evenly over the entire surface. The natural fibers used to make such coats have a reference absorbency, but are easily squeezed out during the dyeing process. Of course, the final usability is correlated with the length of the pile.

Longer bristles allow more paint to be absorbed and a much thicker, more consistent coat. It uses a strong and thick thread. In rollers with short or medium pile, the thread is much thinner, and the surface of the ceiling after being treated with a roller will be covered with a thin and even layer of paint.

Now correlate the information received with how you want to see the ceiling surface in the end - and make the right decision.

Foam rollers are best used when you pursue the goal of creating a certain texture, relief on the ceiling. They are excellent "friends" with oil paint, which has the most dense high-quality structure.

As for polyacrylic and polyamide paint rollers, the main area of their use is decorative work. To emphasize some curious detail on the ceiling, refresh the color mood, diversify the fragment - this is the kind of roller that should be used to paint the ceiling if your goal lies in this plane.

Types of rollers for painting the ceiling

When deciding which roller is best for painting the ceiling, you need to understand the features of the tool. All rollers differ not only in the dimensions and design of the drum, but also in the length of the handle, as well as in the type of coat (drum cover).

Answering the question of which roller is better to paint the ceiling, it is worth noting that it is more convenient to work with a tool with a long handle. In this case, you do not even need a stepladder or a scaffold, because the product will reach the ceiling anyway. Usually the handle length is 150-500mm. There are devices with an adjustable handle or a set of interchangeable nozzles. For ceiling painting, lengths from 300 to 500 mm are suitable.

It is the drum coating (fur coat) that is responsible for the quality of the application of the coloring composition and its uniform distribution. The fur coat is made of synthetic and natural materials. On sale you can find drums with fur, foam, polyacrylic, polyamide, polyester, thread and polymer coatings. The latter products are used to apply a certain pattern to the surface (more often to wallpaper).

Roller with fur drum

If you do not know which roller to paint the ceiling with water-based paint, then products with a sheepskin fur coat ideal for these goals. Such coatings are divided into several subspecies, depending on the length of the pile. They are short- and long-haired, with medium pile and velor.

The advantages of this variety are as follows:

- suitable for painting various surfaces;

- the coating absorbs the optimal amount of the coloring composition;

- surfaces of any complexity can be painted;

- has an impressive service life (provided that after use the tool is placed in a container with solvent or water);

- uses paint sparingly;

- holds well any types of coloring compositions;

- a high quality coating is obtained.

Choose a tool only from a trusted manufacturer, for example, high-quality Anza rollers. Otherwise, pile may fall out of the fur coat, which will remain on the painted surface and spoil the whole impression.

Foam cover

If you are looking for a ceiling whitewash roller, which is better, you will find out if you understand the features of the foam drum cover. The foam coat absorbs liquid solutions well, but is not suitable for use with acrylic and water-based paints, because when you press the tool, the paint flows down the handle. In addition, when used with the listed compositions, small bubbles remain on the surface.

But for working with thick chalky or lime whitewash, the foam drum is ideal, because it absorbs a mixture of creamy consistency well and holds it well. Also, a tool with foam rubber sheathing is used to paint gypsum stucco moldings.

Polyester rollers

If you need to use a water-based emulsion or acrylic paint to paint the ceiling, then a drum with a polyester finish is suitable for these purposes, because its main advantages are as follows:

- has high absorbency;

- reliably holds the coloring composition;

- liquid does not flow down the handle;

- the painted surface is monochromatic, without stripes and streaks.

Polyacrylic and polyamide coating

Outwardly and to the touch, these fur coats very much resemble natural fur. They are suitable for the application of liquid water-based colorants to a variety of surfaces. The difference between polyacrylic and polyamide upholstery is in price - a polyacrylic fur coat is cheaper (from $ 0.3), but wears out faster.

The advantages of polyamide and polyacrylic coatings include the following:

- absorbs and retains the dye mixture well;

- the solution does not drip or run down the instrument;

- a uniformly colored coating is obtained;

- suitable for water-based and acrylic paints.

Types of paints

Suitable for painting the ceiling surface are paints such as:

You can choose the paint for every taste

Water-based ceiling paint

This type of paint is most commonly used for painting ceilings and other surfaces. Sometimes people wonder if water-based paint is harmful for living quarters? We can assure you that it is absolutely safe, because the dyes in it are diluted on a water basis, this makes them completely non-toxic (there are no other solvents).

This paint has a high fire safety. It is not for nothing that water-based paint is used almost everywhere (see Paint for the ceiling: selection criteria). They paint rooms in kindergartens, schools, hospitals and other institutions. I think the choice in favor of water-based paint is obvious.

What is the best paint to paint the ceiling

Acrylic paint

One of the most popular ceiling paints is acrylic paint.

- It has exceptional moisture and wear resistance properties. This allows you to regularly clean it from contamination with detergents.

- Resistant to direct sunlight, acrylic paint will not fade. Easily pulls together small cracks in the ceiling putty.

- It dries quite quickly and does not have an unpleasant odor.

- In hardware stores, you will find a variety of acrylic paints in a wide variety of colors (see Paint for ceilings and walls). Each manufacturer presents on the market at least several items of this direction, with different characteristics of the paint.

When choosing, paint for painting the ceiling, keep in mind that, giving preference to white, it will often have to be washed.

Silicate paint

It is used for painting mineral surfaces, as it itself consists of liquid glass. It is not suitable for application on polymer coatings, which makes its use for painting the surface of the ceiling almost impracticable. Significantly less elastic than acrylic paints

Silicate paint

Silicone paint

We can say that the most suitable paint for the ceiling is silicone, if not for its high cost.

Combines the best of mineral and organic coatings. Good elasticity allows you to tighten cracks with a thickness of 2 mm. Excellent vapor permeability, and at the same time, water-repellent properties allows the overlap to "breathe" and the surface does not get dirty. Fresh paint has practically no smell. Silicone resin prolongs the durability of the paint and prevents the development of any fungi ...

Silicone paint

Latex paint

It is the most expensive of all of the above.

- You can wash it as often as you like - it won't rub off.

- Has the best water-repellent and vapor-permeable properties.

- Ideal for application in a thin layer without losing its functions.