The principle of operation of installations

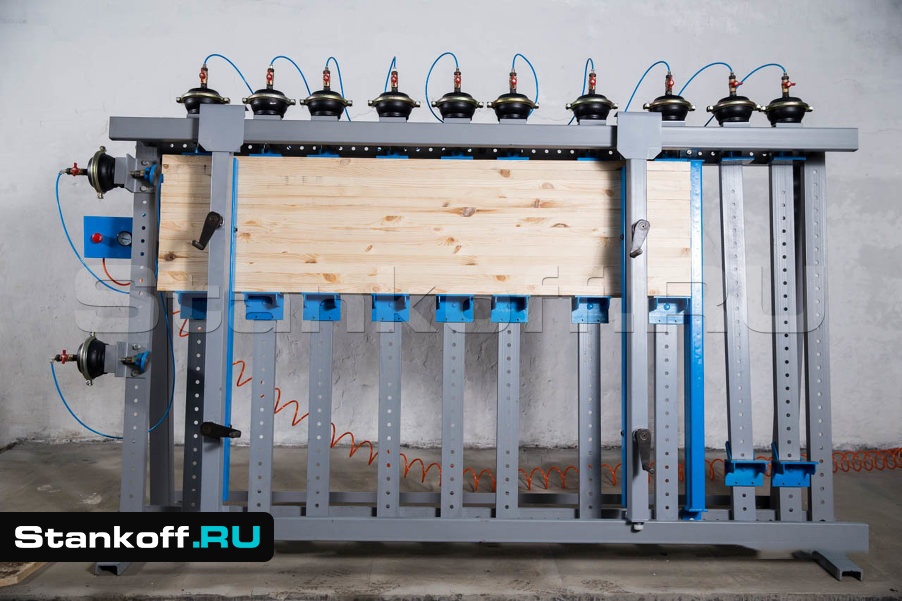

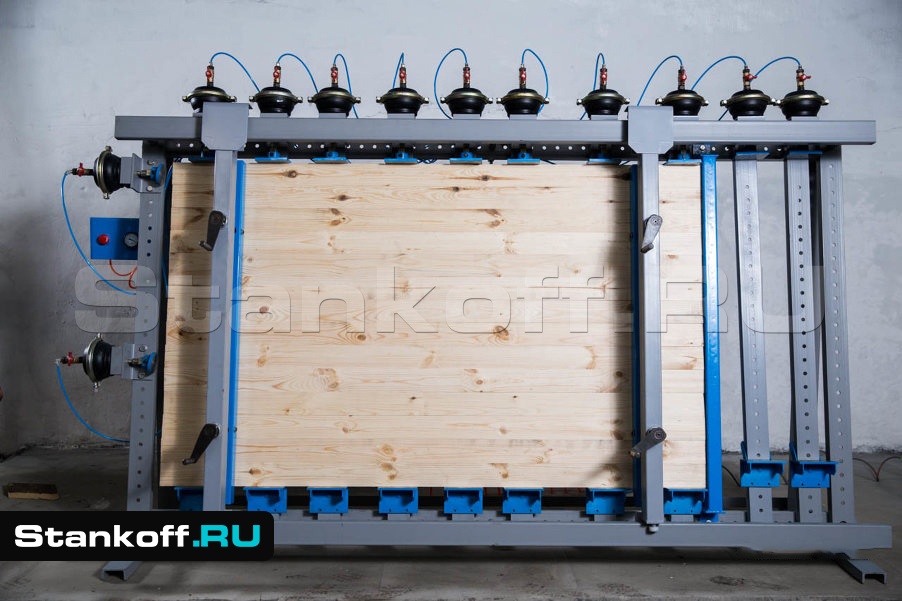

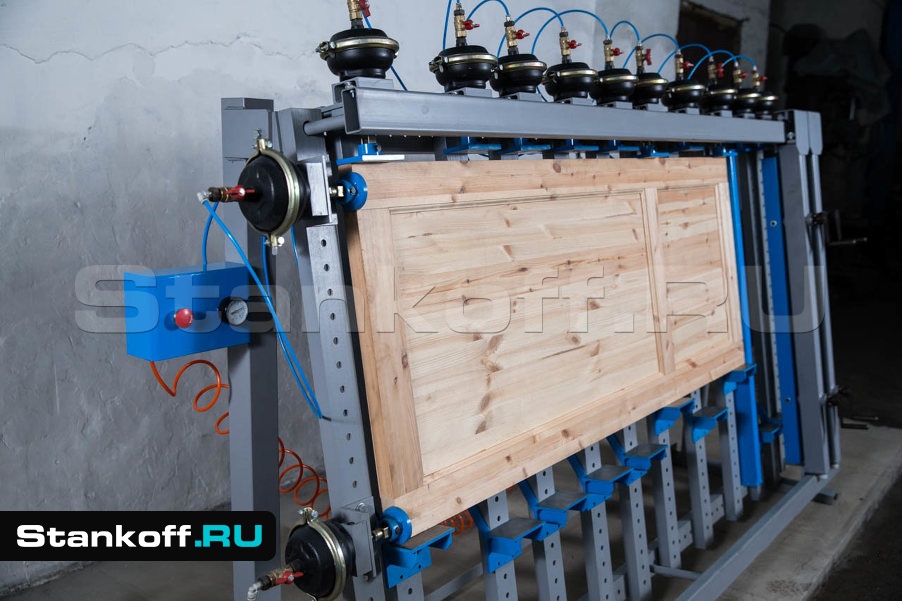

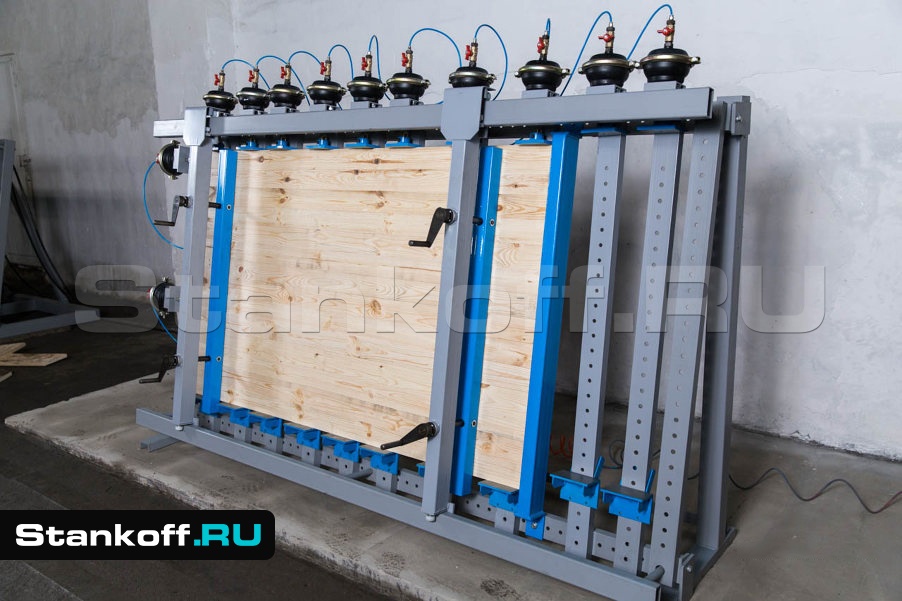

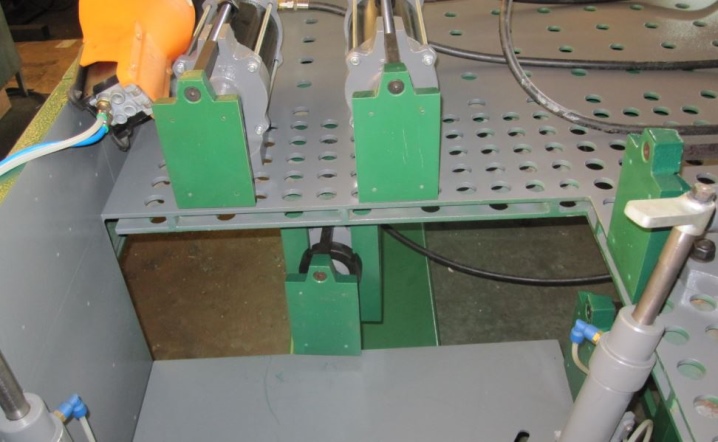

Clamps for furniture boards are distinguished by a fairly simple design, including nodes for locating, fixing and pressing a package of blanks. On a stable metal frame, stops are fixed, which serve to prevent distortions when stacking the package and are made in the form of stably fixed and movable rulers. The ability to quickly change the position of the locating elements provides a quick readjustment of operating parameters when working with workpieces of different sizes.

The force of the hydraulic or pneumatic equipment sets in motion the clamping elements, with the help of which the structure is assembled. The technological strength of the connection is achieved due to the force applied to the parts and the exact holding time of the package during pressing. In devices with heating elements, the processing time is reduced due to the thermal effect on the workpiece, which accelerates the curing of the adhesive. Changing the pressure parameters in the system is made from the control panel.

Where and how are they used?

The appearance and performance of any wooden product directly depends on the accuracy and reliability of the connections of all structural elements. Otherwise, the production technology will be violated, which, in turn, will negatively affect the corresponding characteristics of the structures. For the overwhelming majority of the types of joints used in the joinery, it is necessary to ensure the compression of parts with a certain pressure during a specific time interval.

It is the winders that allow you to create the required conditions. Thanks to the use of such installations, it is possible to minimize, and more often completely eliminate the risk of gaps at the joints. With the help of purchased and home-made presses, the following operations are performed:

- connection in various ways of structural elements of almost any shape;

- cladding of flat, as well as embossed and even volumetric surfaces;

- creation of frame structures of any configuration;

- production of stair steps;

- production of individual elements and assembly of furniture;

- gluing boards and timber.

For information on how to make a bond with your own hands and use it correctly, see the next video.

Stages of work

They start making a clamp with their own hands. It is necessary to prepare a rectangular profile pipe with dimensions of 60x30x3 mm. The pipe length should be 120 cm.

Such dimensions for the bearing beam were chosen due to the fact that it is often necessary to glue large sheets or make wooden doors. Therefore, the clamp must be of such dimensions that it is possible to fix workpieces of such large dimensions in it.

Too large workpieces are rarely performed. In most cases, small size furniture boards and intermediate staircases will be produced. It is necessary to provide in advance measures so that during the manufacture of the shield, the glue does not fall on the surface of the device.

In cases where the length of the clamp does not allow for a large workpiece, you need to glue such a shield in parts. First, workpieces of such a width are glued together, which can be clamped in a clamp. Then, a wide blank is assembled from narrow shields. For this, movable clamps are used.

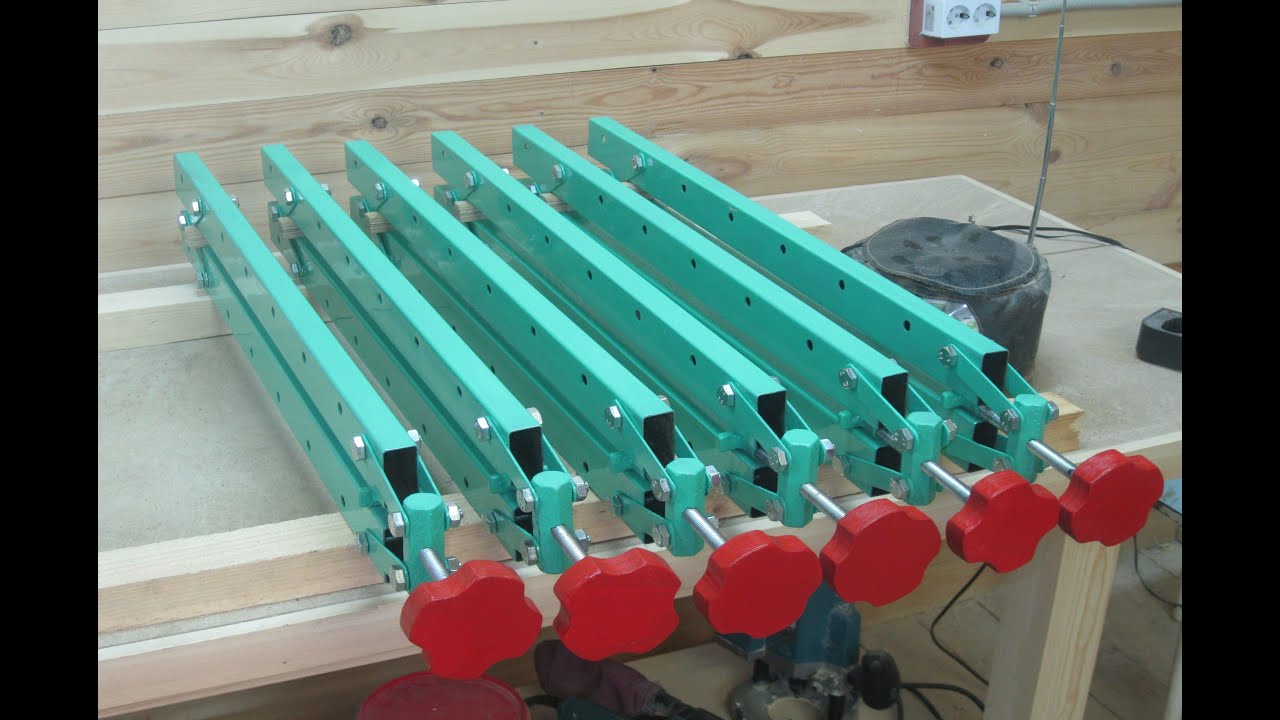

Then you need to make screws and nuts. The screw is made from a hexagon 300 mm long with a section of 28 mm. It must have a metric thread of 2 cm. The nut is made in the form of a 32 mm hexagon, 60 mm long.

Gaskets 1 cm thick are placed under the nuts. Then they are welded. After that, a clamp is made from a 5 cm metal rod.

It is undesirable to make a clamp having a smaller diameter. Otherwise, it will push through wooden spacers, which are placed between the workpiece and the clamp. If you do not use spacers, you can deform the workpiece.

You need to drill a 1 cm hole in the end of the screw on the clamp side. 2 ball bearings are installed in this hole in order to reduce friction.

Then the nuts are welded. Make sure that the screw is parallel to the profile. Otherwise, the workpiece will be pushed through.

It is necessary to completely tighten the screw and nut. Then a clamp is put on the groove. After that, gaskets are placed under it.

With the help of a level, they make sure that the parts are located strictly parallel. The parts are fixed and then welded.

Welding is performed with small seams in order to prevent deformation of the material when the metal is heated during welding.

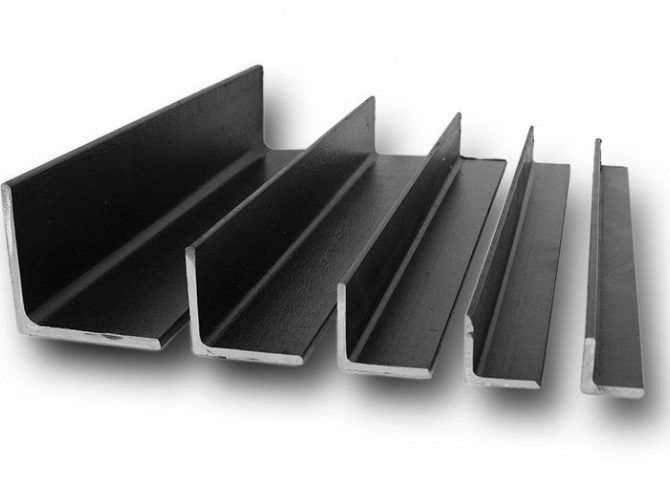

Then clamps are made from a corner with dimensions of 60x60 mm. The corner is welded to the profile. The profile is welded from two corners. They are adjusted so that there is a possibility of free movement and at the same time that there are no large gaps.

Fasten the clamps. For this, holes are drilled with a diameter of 12 mm. They put pins in them. Thanks to this, you can quickly change the position of furniture parts during manufacture.

If in the process of work during compression it turns the workpiece inside out, then the reason for this may be the non-perpendicular position of the stop in relation to the supporting beam. Therefore, you need to check the correct location of the parts using squares and a building level.

Then a hole is drilled, a thread is made and a screw is screwed on. The correct position of the workpiece can be adjusted with a screw.

When drilling holes, take into account that the screw with a movable stop moves 200 mm. When fixing the fixed stop, the distance between the holes must be 150 mm. Otherwise, such areas may appear in which the workpiece will not fit.

First, a through hole is made on the clamp. After that, put it in its place, press it with a clamp. Then the profile of the bearing beam is drilled through this hole. This allows precise joining of parts.

You can make a clamp in which you can press the shield to the bearing profile. This design is more reliable, but more difficult to manufacture.

This is where the work on making a homemade clamp ends.

The design of the clamp allows you to perform high-quality work on gluing furniture boards of various sizes and thicknesses.

On the site you can buy clamps for gluing furniture boards from leading manufacturers. In stock and on order more than 13 models of clamps for shields at the best prices. Only great deals with detailed descriptions and photos. Check the prices with the managers.

Work instructions

All the work on the production of clamps with your own hands involves several stages:

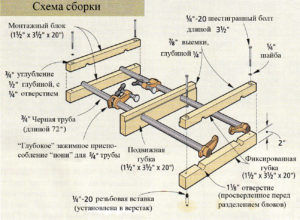

Clamp assembly diagram

Clamp assembly diagram

- Preparing the profile pipe. Its length is 1.2 m.

- Assembly of bolted structures. It will be convenient to weld the clamp elements together. For assembly on corners, the length of which is 250 cm, a channel is attached at the same distance.

- The edge of the channel 1 and the short corner should be perpendicular to each other, and located between the long fragments. It is necessary to put gaskets under the nuts, the thickness of which is 1 cm.

- Welding of joints. The inner joint of the short corner and the channel is not processed. If this condition is not met, the seam obtained as a result of welding will create problems when gluing wood blanks.

- Making clamps from a metal bar. Its diameter is 5 cm. A 1 cm hole is drilled at the end of the screw. 2 ball bearings are installed inside it, which reduce friction.

- Welding the nut.In this case, the screw must be parallel to the profile. If this rule is not observed, the clamping of the part will occur with punching.

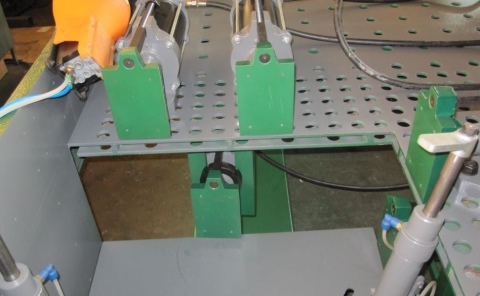

- Making clamps from a corner and securing them. For fixation, holes are drilled in the material, the diameter of which is 1.2 cm. Pins are inserted here, allowing you to change the position of the workpiece during the manufacture of a wooden product.

Stops are welded to the bottom of the resulting structure, thanks to which it will be stable. During the manufacture of the clamps with your own hands, you need to ensure that all the parts are located in parallel. For this, a building level is used. Weld seams should be small

In the process of fastening parts, it is important to ensure that the metal does not deform during heating.

Features of making a simple clamp from self-tapping screws and timber

Sometimes a craftsman needs a large clamp to make one piece. This does not require a permanent structure. You can make disposable clamps with your own hands. To make the tool you will need:

- wooden beam;

- durable long self-tapping screws;

- jigsaw or hacksaw;

- screwdriver;

- carpenter's ax.

To correctly build a structure, you first need to make a drawing of it. The technology for making a simple bond is as follows:

- wooden elements are laid horizontally on a flat surface;

- place the workpiece. The distance between the elements is 40 cm;

- on both sides of it, a long bar is placed strictly parallel, fixed to the crossbars with self-tapping screws;

- to compress the workpiece, the clutch is wedged with special wedges;

- as soon as the product is glued, the clamp should be disassembled. Its elements can be further used for different purposes.

Do-it-yourself carpentry clamps are an excellent tool for making doors, steps, window frames. Even if a person is not engaged in the production of furniture, then he can significantly reduce the cost of repairing his home.

In this article you will find detailed instructions for making vimes

do it yourself.

If you are engaged in the manufacture of furniture from, then you cannot do without carpentry clamps

... You don't have to buy it for this. A glue clamp can be made do it yourself

.

What it is?

Regardless of its type and characteristics, any clamp is a squeezing mechanism. Such devices are widely used for the production of:

- various pieces of furniture;

- frames made of wood;

- furniture boards;

- frames and much more.

Compression devices are responsible for the most reliable fixation of the fastened structural elements until the adhesives are completely dry. It should be noted that glued blanks of large sizes, in contrast to their analogs made of solid wood, are less susceptible to such a phenomenon as warping. Moreover, all characteristics and performance indicators directly depend on the quality of bonding. In this case, the following points will be the most important:

- the thickness of the future workpiece and all its elements;

- features of the glue used;

- orientation of layers;

- amount of elements.

Now in the furniture industry and other areas, various clamping structures are widely used. With their help, they quickly and efficiently connect not only timber into wooden shields

If we analyze the main operational qualities that modern press-clamps have, then it is worth focusing on the following clear advantages of their use

- Maximum uniform distribution of pressure over the entire surface, which ensures the appropriate quality of manufactured products from any type of wood, regardless of design features.

- Minimizing the risk of gaps between the parts to be joined after the adhesive has dried.

- Possibility of individual positioning of each element, depending on the characteristics of the future product.

- Many devices are relatively small in size, and are also as mobile as possible. Due to this, their operation does not provide for the allocation of a separate room.

- The overwhelming majority of models are characterized by the utmost simplicity of design and operation. This allows even novice craftsmen to use them successfully. The main thing is to take into account the manufacturer's recommendations.

What materials will be required

To build a homemade clamp, you first need to collect the necessary materials and tools. For work you will need:

- profile pipe, metal corner or channel;

- fasteners: nuts, screws, screws;

- stops;

- building level and squares;

- Bulgarian;

- metal welding machine;

- wooden spacers.

Do-it-yourself carpentry clamps must be strong and strong, otherwise, with great effort, you can bend or break the structure. To prevent this from happening, the stops must be resistant to heavy loads and be well fixed on the beam. It is necessary to make sure that they can easily move in the longitudinal direction. To be able to handle large-sized workpieces with your own hands, you need to fix the clamps on the clamps so that they can be moved.

Fasteners should also have high strength. Better to give preference to a reinforced structure and nuts. Due to the high load, store materials break down quickly. To get high quality and efficient carpentry clamps, you should order fasteners and stops from a lathe.

Better quality fasteners and stops can be made with a lathe or ordered from production

Better quality fasteners and stops can be made with a lathe or ordered from production

Making a clamp with your own hands

The basis of the construction of a homemade clutch is a strong load-bearing beam. It is made from a rectangular or square shaped pipe. Also, the beam can be made from a metal profile: a corner or a brand.

The load-bearing beam must be of high strength and withstand bending loads. This is necessary so that during operation the clutch structure does not bend or deform.

To compress the furniture board, you need to make a lot of effort. Therefore, if the supporting beams do not have sufficient strength, they will be bent along with the workpiece.

If the furniture board, which will be made on the clamp, must be large, then, accordingly, the material for the base must be selected the most durable. In the construction of the clamp, all stops and screws are located above the supporting beam. Therefore, the higher the stops and screws are, the stronger will be the bending loads acting on the entire structure. For this, the clamp must have a very solid base.

When the clamp is working, a lot of pressure will be exerted on all stops. Therefore, the stops must be designed for heavy loads. Otherwise, they may bend.

Characteristics of the clamp for gluing panels

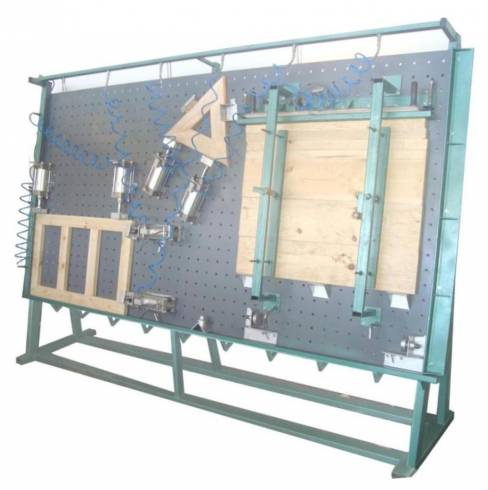

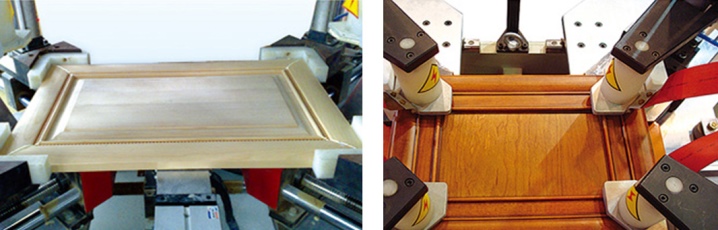

Modern devices for assembling wooden structures using the compression method are available in a wide range of varieties, the purpose of which is determined by the type of product being created. With the serial production of frame and panel products, there is an opportunity to buy clamps for panels, special devices for strong gluing of material using a side clamp.

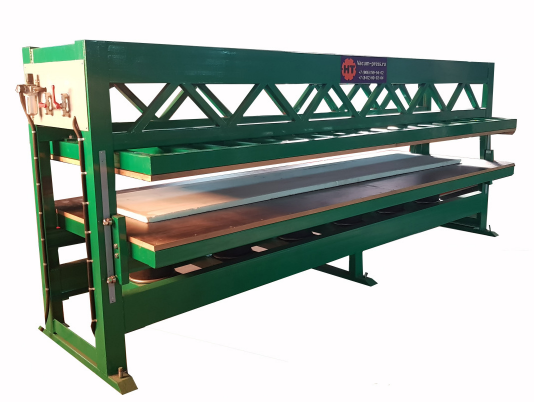

Machines for glue assembly of parts under pressure are a necessary type of equipment at factories for the manufacture of furniture facades, entrance and window groups. The uniform distribution of the clamp along the plane of the package makes it possible to produce products with high performance and decorative characteristics. The main purpose of the clamp for gluing panels is to create a clamping force with an optimal level of pressure, which provides:

- lack of a gap between abutting elements;

- extremely accurate position of the parts to be joined;

- clear geometric parameters of a given shape;

- tight and strong docking of elements.

Compact units do not require a special base, occupy a minimum area in production facilities, are economical to use and easy to maintain. Productive and reliable machines guarantee the manufacture of products in full compliance with the technical requirements for glued wood. The costs of purchasing press-clamps quickly return to the enterprise, and the improved product quality contributes to increased sales and real profit growth.