Features of the manufacture of clamping tools of different types

The clamp has different types, they differ from each other in design, material, size. Consider the types of clamping tools and the nuances of their manufacture.

Keyless

Pistol-type clamp. When the trigger is pulled, the sponges are parted. By loosening the locking screw, the gap between the jaws can be changed. The clamping force is low. You can make it yourself, but it is economically unprofitable. There is a lot of work, but it is inexpensive.

Quick-clamping clamp

But such a clamp with a cam clamp is very easy to do. And she holds tight.

PHOTO: pimg.mycdn.me Cam Clamp

G-shaped

G-shaped clamps differ from C-shaped clamps only by the presence of a molded stationary jaw. This allows for a clearer and more secure clamping of parts.

End

The end clamp can be made using the C-shaped technology. The only difference is that it has three clamping screws. Its dimensions are selected based on the dimensions of the future object of work.

End clamp

T-shaped

In the manufacture of such a clamp, it is necessary to accurately maintain the size of the holes of the sliding parts.

T-clamp

F-shaped

To make such a clamp, milling work is required to make a serrated notch on the rod.

F-shaped clamp

Tape

Tape clamps are used for gluing frames, boxes, boxes. The tight band wraps around the product and prevents it from falling apart prematurely. Manufacturing requires good drawing and accurate adherence to all dimensions.

Tape clamp

Pipe

"Pipe" clamps are basically a thick pipe. They are used when gluing shields. The thickness and length of the pipe are determined by the size of the shield: its width, plus 10 cm for the length and diameter of the pipe (from half-inch to three-quarter).

PHOTO: youtube.com for gluing panels

Spring loaded

Such a clamp creates a clamping force due to the spring. The size of the gap between the "heel" of the bracket and the "heel" of the clamping screw is created precisely by the rotation of this very screw. First, you need to set the solution, then pull back the movable part of the clamp, compress the spring, insert the part into place and release the spring.

Homemade spring clamp

F-shaped

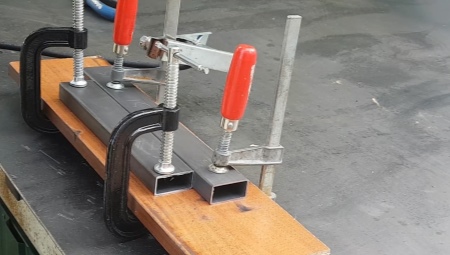

In order to facilitate the work, you will need to prepare a few simple clamps. In advance, you need to prepare small cuts of any profile, a nut with a screw and mounting bolts. Corner welding clamps are made in 2 steps.

Base

It will take three trimming of the profile pipe. You can use any profile that is at hand, but it is better to take it with different sizes of shelves. For example, a 25/60 pipe can be an excellent base blank.

Parts are cut off with a length of 300, 200, 100 mm. Distribute a smaller segment in the middle of a long one and grab them. The base is 180 mm wide.

From the larger edge, the corners are marked and cut at 450. A section of the profile with a length of about 150 mm is welded in the middle of the long part of the base. A nut with a clamping screw will be attached to this part.

Cut off a corner or profile along the length of the bevel on the base and grab the segments to the end of the base. These parts of the structure serve as workpiece guides and as stops for fixing.

Boil all the joints and clean them well with a grinder with a cleaning stone. The base of the angle clamp for welding is ready, you can proceed to the final part of the assembly.

Clamp

It remains to make a clamp.To do this, at the end of the straight trim extending from the base, a nut with a screwed-in screw is welded at a sufficient distance. To prevent damage to the threads during welding, the screw must be well lubricated with grease or other thick grease.

Now two pieces of 100 mm are cut off, the ends are cut under 450, the piece is joined and welded. This will be the retaining bar. It can be made from a corner or profile. You can bend it in a semicircle

In any case, it is important that it reliably fixes parts of the structure.

At a short distance from the inner corner of the clamp, a steel plate with a thickness of 4-5 mm is welded. Then a hole is burned to pass the end of the screw.

The joints are cleaned with a grinder. Insert the end of the screw into the hole in the plate, and a retainer is welded to its edge. A handle for rotation is welded to the other end.

The design of the angle welding clamp is ready. This is the simplest version of the clamp, which is easy to do with your own hands. You can make a fixture with several fixing screws or with a variable angle of joining of workpieces.

It is quite easy to make a corner vise for a welder. Now it remains to attach the clamp rigidly using electric welding to a table or workbench. You can drill holes in the welding table and clamp the welding clamp with a bolt connection.

The most common clamp will allow you to connect parts at right angles for inserting mullions or for assembling a wicket or gate.

DIY process

There are several options for making these devices with your own hands.

Corner for furniture assembly

Those who had a chance to assemble furniture on their own often quarreled during assembly because of the inconvenience when connecting large parts to each other. It is especially difficult to do this if there is no assistant. Such an assistant can be a simple furniture vice, more precisely, several simple clamping devices and a solid rectangular table or carpenter's workbench, the manufacture of which can be found in this article.

Those who had a chance to assemble furniture on their own often quarreled during assembly because of the inconvenience when connecting large parts to each other. It is especially difficult to do this if there is no assistant. Such an assistant can be a simple furniture vice, more precisely, several simple clamping devices and a solid rectangular table or carpenter's workbench, the manufacture of which can be found in this article.

Grooves are installed on the table to fix the parts of the assembled furniture, and the carpentry clamps serve as clamps. There are so many different options for how to make such devices.

Joiner's clamp

The simplest screw clamp is made according to the principle of a caliper. This will require a few sturdy wood blocks and a small sheet of plywood. To fix such a device in a certain position, a screw device with a fixing bar on the rail of this simple tool is used.

Self-clamping clamps are often used to press the workpiece to the table. Their principle of operation is very simple. On the workbench, such a device is fixed with a screw pin, and the clamp is made with a special lever with a rounding at the clamping end.

Such tools are very convenient to use for processing a large number of parts of the same shape. For example, when milling or grinding, as well as when drilling and sawing.

For welding

Today, a welding machine in the garage is no longer a rarity, and sometimes a necessity. For welding work, clamping parts at a certain angle is sometimes necessary, like air. Purchased tools often fail due to the dishonesty of their manufacturers, so it is better to make an angle clamp for welding yourself.

Having found a boring drawing or making it yourself, we prepare the necessary material and tools. After that, we start manufacturing according to a simple scheme:

Making the base. We weld steel plates and a corner of the same thickness according to the drawings of the selected option. The main task is to carefully measure the angle at 90 degrees to secure the parts to be welded. The angle may be different if you are making the instrument for a narrow target.

Clamping device manufacturing. For this, large diameter nuts can be used.We fix them with a bolt so that they can be changed in the event of a thread break. You can find screw devices with broken vices or workbenches

Again, it is important to make sure that the clamping feet are at right angles, or whatever angle our device is designed for.

Product assembly and fastening. When the base and clamp are ready, they are connected, depending on the design of the product: by welding or using bolts and nuts

Here you can think over the option of fixing the device to a fixed surface. To do this, you can drill several holes in the base for such an attachment.

Making any option requires a lot of effort and effort. All this will pay off handsomely when the next welding or joining of two rails at right angles goes quickly and smoothly. After all, you will have a reliable assistant who is always there and ready to serve the person who made it with his own hands.

Model overview

Belt (tape) clamps are used to align complex, multi-level, oversized surfaces, for example: for gluing frames, fastening wooden chairs and tabletops. Coopers cannot do without a tape clamp when tightening barrels, boat craftsmen are in dire need of them when adjusting the stem and side boards, they are also needed in many other areas.

The length of the belt is enough to tighten the multi-level parts, while it does not harm the tightened surface, and the metal parts do not touch it. Sometimes you need special parts to press the corners of the frame or box, box. Manufacturers produce wooden, metal, nylon corners. Scope of application - furniture, cooperage and repair work, construction, etc.

Tape clamp Matrix Baguette 4000 mm is a universal device. It is used for gluing boxes, furniture parts, facades. It fixes and holds in the desired position the corners of the picture frames. Moreover, if you choose corners of different degrees, it works on polygonal structures - it holds hexagonal, octagonal and others.

The Bailey Stanley strap clamp is also worth considering. Purpose - fixing frames and products with complex shapes. Durability of operation is ensured by the metal body and nylon parts, the ergonomic comfortable handle rests firmly in the palm of your hand, does not slip during pulling, which increases the torque during operation. Made of two types of material, it has a comfortable section that holds the handle in the palm of your hand. Includes four 90 ° nylon corners. The length of the tape is 4 m.

Manufacturers

For a full acquaintance with the corner clamps, it remains only to get acquainted with the most interesting offers that are present on the Russian market.

- The Top Tools model with a maximum jaw extension of 75 mm has an aluminum body and a pair of clamping screws. Light weight, compact size, convenient adjustment of the clamping force and affordable cost - these features attract users. The tool can be fixed to the workbench. The disadvantages include the shallow depth of the jaws, which makes it impossible to work with large workpieces.

- The Wolfcraft Spring Angle Clamp is a more serious tool that features a movable jaw. This feature makes it possible to fix workpieces with different thicknesses. Compact dimensions, well thought-out design and convenient operation are the main advantages of this model.

- The Bailey Stanley Power Corner Clamp features a die-cast aluminum construction that can withstand heavy loads. The upper jaw is equipped with a hinge mechanism, which makes it possible to clamp parts of the same and different thickness. This tool can be used to fix parallel parts.

What is a tool for, its device and types of tool

The clamp belongs to the additional joiner's and locksmith's tools. The main purpose of the clamps is to fix the workpiece on the support surface or several workpieces for gluing them together, therefore, the tool design must include at least two elements: the support surface and a movable jaw equipped with a locking mechanism. The movement of the movable jaw is carried out, as a rule, using a screw or a lever, which allows increasing the compression and preventing backward movement during operation. Depending on the specialization and design features, the following types of clamps are distinguished:

-

Screw G-shaped - the most common, are simple in design and relatively low cost. They are represented by a metal bracket, on one side of which there is a supporting surface, and on the other - a threaded eyelet with an adjusting screw screwed into it. The inner part of the screw is equipped with a working jaw, the outer part is equipped with a handle. The tool is effective when working with heavy, large workpieces with a simple shape.

-

Quick-clamping F-shaped - more versatile, their supporting surface is fixedly fixed on a long rod, along which the working block with a sponge slides. The movement and fixation of the block is provided by an auxiliary screw or a stepping push mechanism.

-

Pipe - allow you to fix large-sized workpieces by varying the length of the pipe. They consist of two separate elements - a base plate with screw clamping and a jaw sliding along the pipe.

-

Corner - designed to simplify the joining of workpieces at a right angle, for which they have two supporting and working surfaces. They are divided into two subspecies. The first assumes the presence of two clamping screws located perpendicular to each other; the second is equipped with one screw with a double-sided corner block at the end. It is very rare to find specialized clamps that allow you to position workpieces at an acute or obtuse angle.

-

Belt - equipped with a flexible element and several sponges floating on it. By fixing the jaws in certain places of the belt and adjusting its tension, it is possible to process workpieces of complex shapes.

-

Pliers - consist of two hinged parts and a spacer spring. In practice, they are rarely used due to the relatively low reliability of the joint, however, they provide the maximum speed of installation and removal of the workpiece.

At home, clamps of the first three types are most often made, since they are not too demanding on materials and production technologies, and also allow you to solve most household tasks that require the use of an auxiliary tool.

Where are homemade clamps used?

In the garage, the carpentry room, the master collects a set of tools that will be needed for various crafts. It is often necessary to firmly attach the workpieces to a table or workbench in order to finish the material.

A clamp will be needed to maintain the stable position of the parts in the following cases:

- during furniture assembly, when boards, boards are glued together, parts of the elements must be held;

- during the installation of echo sounders at the ends of boats, anglers use to fix the bait;

- a table lamp is easier to hang on the wall, various household items that need to be held with one hand;

- installation of the saw blade on the grinder occurs with an additional holder;

- wood floor screed is made with a holding device;

- repair the wings of the machine using the device;

- clerks use self-made clamps to bind large accounting journals;

- closing the covers on the repairman's watch with miniature, supporting installations;

- shoemakers use homemade clamping devices in their workshops.

Welders, too, often need a sturdy, secure grip with a metal body to work freely with both hands.