Features of different types of drills

Drill button connection diagram.

In the modern tool market, there is a large selection of drills for a wide variety of tasks.

The first type is a hammer drill. The main difference from an ordinary tool is that such a unit, in addition to rotational movements, makes translational movements. This increases productivity and makes it possible to work with higher strength materials such as concrete and brick. A conventional drill is best for working with wood and non-hard metals. The impact mechanism makes the tool more versatile. If necessary, the impact function can be turned off and the tool can be used like an ordinary drill.

An angle drill will help you make holes in the tightest places. The gearbox with the chuck is made in the shape of the letter "L" or an angle. Often used in garages when necessary, for example, to drill holes under the hood of a car.

Nozzles for construction mixers.

The drill mixer, in addition to its main purpose, allows you to stir a variety of solutions, coloring compounds, cement mixtures and many other materials. As a rule, such a drill has no impact function. For the convenience of stirring, the tool is equipped with an additional handle that can be fixed in different positions.

The drill-screwdriver will allow the home craftsman not only to make holes in different materials, but also to turn / unscrew screws, screws, screws if necessary. Typically, such tools are small in size and relatively low in power, i.e. you can't drill concrete with them.

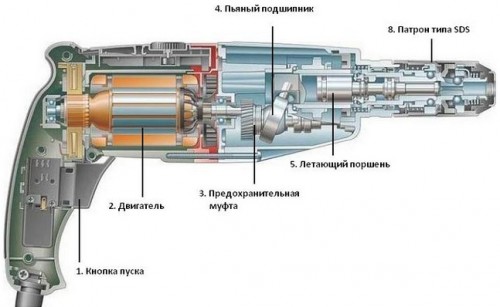

A separate category should include a tool such as a hammer drill. The main difference of this tool lies in the design of the gearbox. The main mode of the unit is blow, while in a conventional drill - drilling. The hammer drill is most often used by repairmen and builders. At home, the need for its use is extremely rare.

# 1. The purpose of the drill. Difference from a hammer drill and screwdriver

The main purpose of the drill is to drill holes in various materials. A conventional drill easily handles metal, wood, drywall and other not particularly dense surfaces. The hammer drill can easily drill through concrete, stone and brick. Special-purpose devices can replace a screwdriver and a construction mixer, and if you have special attachments, you can grind surfaces with a drill.

Drill

An impact drill can replace a hammer drill, since, in addition to rotation, it also has an impact force. That is why it can be used to easily make a hole in concrete. On the other hand, if you are going to work mainly with concrete and other dense materials, then it is better to take a hammer drill - it is designed for constant loads of this kind and will last longer. Otherwise, the path of the hammer drill and the hammer drill diverge. The designs of these devices are radically different, so the hammer drill can handle many processes that require high power. It is used for chipping walls, chipping tiles, chipping off bricks. The main function of a hammer drill is to hammer, while for a drill this function is to drill.

The difference between a drill and a screwdriver can easily be found by a person who generally does not know much about repair work. If the drill drills holes, then a screwdriver is needed to tighten and unscrew screws and bolts. The rotation speed of the screwdriver chuck is much lower, and this tool has fewer settings. There are drills with screwdriver function - this is a versatile tool at home.If you drill and screw in self-tapping screws at the same frequency, then it is better to take two separate tools so that the drill does not suddenly fail.

Instrument power supply system

Both screwdrivers and electric drills today are represented by models with a different type of power supply. Traditionally, both categories of tools operate from a conventional outlet - they are lightweight and compact instruments, but they depend on access to a power source. Moreover, for a hammerless power drill, compactness and lightness are fundamentally important, since the degree of pressure from the user's side is small.

The presence of a battery pack eliminates the need to connect the device to an outlet, but increases the weight and dimensions of the instrument. As a rule, rechargeable batteries with lithium-ion or nickel-cadmium cells are used as a source. Average cordless drills and screwdrivers can work autonomously for 45-60 minutes. For ease of use, many manufacturers provide a spare power supply in the kit that can be used while charging the main battery.

What is the difference between a drill and a hammer drill

An impact drill is perfect for the following type of work:

- Drill holes in different materials (including wood and plastic). In this case, it is possible, if necessary, to turn off the percussion function.

- Make (hammer) holes in some hard materials. With the impact function, a hole can be made quickly enough even in masonry.

- Screw in and out self-tapping screws, screws and screws. Only this should be done with the kick function disabled.

With the help of a puncher, in addition to the above work, you can:

- Punch holes in very hard materials (eg reinforced concrete).

- Use different types of chisels for chiselling. This feature can be used if you need to make a small break or gutter in a concrete or stone wall.

There are quite a few similarities between these tools (hammer drill and hammer drill), but there are still some differences. In order to better understand them, you must first understand the principle of the hammer drill. It consists in the following: there is a pair of toothed ratchets that interact with each other. In the impact mode, they act on the material. This principle has the following disadvantages:

- The harder the material, the more effort you have to make.

- Small amplitude with high recoil.

- Rapid wear of the ratchet teeth.

The hammer drill has no such disadvantages. Mainly because his device is very different from a drill. In some details, its mechanism is very similar to that of an automatic weapon. It is especially different when working on hard materials. It has less recoil and higher travel speed. However, the consumables for this tool are more expensive than for the drill.

But this does not give a reason to completely abandon the hammer drill. If there is no need to make holes in very hard materials, then it will be most appropriate to use it. In addition, it will cost less than a punch of the same level.

What else is the difference between an impact drill and a hammer drill? The difference is that the drill allows you to use conventional drills without unnecessary tools, and for this purpose, additional adapters are needed with a hammer drill. They make the tool inconvenient to use, i.e. increase its length.

Therefore, before you buy yourself a percussion drill or perforator, you need to know exactly the type of work that you have to perform, and what material you will work with. So, for wood and metal with brick walls, it is best to purchase an impact drill, and to work with concrete walls, you need a perforator.

How to choose a drill: tips and tricks + (Video)

What to look for when choosing a drill? Which drill should you buy? Consider the main technical parameters for choosing a tool. 1) Power

Initially, you should pay attention to the power of the product. An average power tool of no more than 600 watts is suitable for a home, but if you plan to carry out frequent repairs in the house, then you cannot do without a more powerful device. For drilling walls, screwing in screws and mixing liquid mixtures, you need to choose a household device with a capacity of 600-800 watts, but only if such work is not planned to be carried out often

1) Power

Initially, you should pay attention to the power of the product. An average power tool of no more than 600 watts is suitable for a home, but if you plan to carry out frequent repairs in the house, then you cannot do without a more powerful device.

For drilling walls, screwing in screws and mixing liquid mixtures, you need to choose a household device with a capacity of 600-800 watts, but only if such work is not planned to be carried out often.

2) Drilling diameter. It is indicated in the passport data for three materials: wood, concrete, metal. For the percussion instrument, stone and brick are added. Any drill can drill a hole with a minimum diameter of 0.6 cm, but the maximum diameter of 25 cm is subject exclusively to a professional unit.

3) Shaft speed. The efficiency of the unit depends on the speed. The higher the rotational speed of the drill, the better the holes are.

The frequency is indicated in the passport for the product, so it is important to pay special attention to this when choosing. The best units are those that are equipped with a speed change function, which is very important for a household appliance. For example, for screwdriving screws it is necessary to work at low speeds, for drilling holes - at high speeds, and for stirring liquids - at medium speeds.

For example, when screwing in screws, it is necessary to work at low speeds, for drilling holes at high speeds, and for stirring liquids, at medium speeds.

4) Cartridge. The type of chuck affects not only the ease of use of the tool, but also safety. There are two types of cartridges:

- key, that is, those that fix the nozzle with a special key;

- quick-clamping, the attachment is clamped manually.

Key chucks are often used in professional devices, where human safety depends on the quality of fastening. After clamping the bit with a wrench, you don't have to worry about it falling out during operation. With household tools, everything is much easier, since keyless chucks are used there. The nozzle is fixed manually, but there is a risk of it falling out during work. But since household devices are low-power, this feature does not cause any danger. Moreover, the keyless chuck is very convenient to use, although it is he who very often fails. If you buy a unit for yourself, choose the one that has a keyless chuck.

Key drill chuck

Keyless chuck

Additional points to which it is important to pay attention are presented in the form of a table.

| Name | Characteristic |

| Button retainer | A convenient function with which you can record its work when you start the drill. In this case, there is no need to constantly keep your hand on the launch, as a result of which it quickly gets tired. |

| Smooth start | An important point, since the appearance of jerks at the start of the device depends on this function. Almost all drills are equipped with this feature, as a result of which there is a smooth set of revolutions from low to high. |

| Speed shifter | With the help of an electronic speed switch, the rotation of the chuck is increased or decreased. The function is convenient, since the rotation frequency of the chuck changes from the force of pressing the start button. |

| Appearance | The view is also very important, so when choosing a drill, take it in your hand and check its ease of perception. The weight of the product is especially important, but it has a direct dependence on power. |

Overview of top models

Below is a table of the best electric drills that are leaders in certain categories.

|

Nomination |

Model |

Description |

Price, rub. (September 2015) |

Rating |

|

Best Impact Drill |

Bosch PSB 750 RCE |

|

4280 |

9.7 out of 10 |

|

Best Drill Mixer |

Interskol D-1050R |

|

2240 |

9.5 out of 10 |

|

Best Hammerless Drill |

Rebir IE-1206ER-A |

|

2400 |

9.3 out of 10 |

|

Best Angle Drill |

Hitachi D10YB |

|

8730 |

9.4 out of 10 |

|

Best Drill Driver |

Bosch GSB 19-2 RE |

|

5440 |

9.2 out of 10 |

|

Best Corded Drill |

Hitachi FDV16VB2 |

|

1756 |

9 out of 10 |

|

Best cordless drill |

Bosch GSR 1800-LI |

|

4890 |

9 out of 10 |

|

Best Diamond Drill |

Makita DBM130 |

|

26000 |

9.5 out of 10 |

|

Inexpensive Home Drill |

Interskol DU-580ER |

|

1240 |

9.8 out of 10 |

|

Best Impact Wrench |

DeWALT DWD024 |

|

2490 |

9.7 out of 10 |

Features of the drill screwdriver

For such a tool, some of the listed parameters are superfluous.

When creating it, developers have to pay attention to other characteristics:

- Availability of smooth adjustment of engine speed.

- Low weight of the device, which, in most cases, is held with one hand during operation.

- Possibility to quickly change the nozzles clamped in the chuck.

- Moderate electric motor power, which rarely exceeds 300 watts. Otherwise, the tool will simply be pulled out of the hands.

The existing differences determine the purpose of each of the discussed types of tools.

No. 2. Household and professional drills

Like many other power tools, drills are divided into two principal types:

- household, for home use;

- professional.

Sometimes a transitional type is also distinguished - semi-professional drills. The principle of operation for household, professional and semi-professional devices is the same - the difference lies in power, weight, price, set of functions and some other features.

A household drill for performing the vast majority of simple household repairs will be preferable. Its advantages, in addition to the lower price compared to a professional tool, include:

lightweight design, so it is easier to work with the tool;

versatility. Household drills are often supplied with additional functions, such as a screwdriver and a mixer, and there are a lot of components in the case with them.

Professional drills are focused on performing a specific task, therefore, in terms of versatility, they are inferior;

good protection and well-thought-out design makes working with a household drill more convenient and safe, which is very important for an inexperienced user;

Household drills are generally warranted higher than professional tools.

On the other hand, you cannot use a household tool for more than 4 hours a day, otherwise the drill will quickly break. The optimal time of continuous work is 15-20 minutes, after which the tool is allowed to rest and cool down for about the same amount of time, then you can return to work again. The thing is that less powerful engines and less sturdy materials are used to assemble household models. This does not mean that the drill will break quickly - it means that it is designed for light or irregular loads.

If you have to regularly work with a drill for 5 or more hours a day, then it is better to take a professional tool. It is distinguished by the presence of a powerful engine that easily withstands solid loads without overheating or breaking down. A professional drill can work continuously for more than an hour and about 7-8 hours a day, with small breaks. Such a tool is more expensive than a household one, less versatile, heavier, but better protected from dust and moisture, and a professional cannot do without it.

Semi-professional drills are a fairly limited class of devices. Transitional models can be represented by household drills with some properties from professional, or professional, but without any elements.

Which drill to choose depends on what kind of work and how often you are going to do it. If you need it in order to hang a shelf or a picture, if necessary, then you can safely stop at the household version. If repairs are your main or additional income, then it makes sense to consider professional drills.