Impact Rotary Screwdriver Details

Naturally, today the price of an impact screwdriver depends on many factors.

As a rule, it depends on the quality, manufacturer and completeness of the tool. In the overwhelming majority, together with an impact-rotary screwdriver, the kit comes with at least two nozzles - one for a Phillips screwdriver, the second for a flat slotted screwdriver.

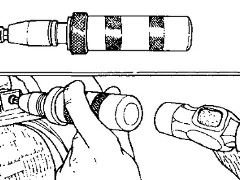

The connecting part of the tool and the nozzle have a hexagonal shape, therefore, when in contact with the screwdriver, the nozzle engages tightly.

The presence of these nozzles suggests that with the help of a screwdriver, you can tighten not only screws or self-tapping screws, but also work with nuts and bolts. This is convenient not only in construction or repair, but also in other areas of activity - for example, during the repair of cars or scooters.

A high-quality impact-rotary screwdriver is made of chrome vanadium alloy or high-quality tool steel. Such materials allow the screwdriver to be as strong and reliable as possible. It is worth noting that cheap models of impact-rotary screwdrivers have nozzles that are not always made of tool steel, and it is not clear from which alloys or metals they are made.

Therefore, as a result, a screwdriver of this quality will not last a long time and after several months of operation it may become unusable.

In addition to two attachments, a fairly large number of other attachments can be supplied with the tool, which will be useful in certain cases. By the way, a screwed-in fastener with a shock-rotary screwdriver can only be unscrewed with it or with a powerful screwdriver, but you cannot unscrew it with your bare hands.

Before you buy an impact-rotary screwdriver, also pay attention to the fact that the tool body itself is durable and of high quality, since it can withstand colossal loads during operation. The purchase of a low-quality tool will lead to the fact that you will be forced to change it to another

Therefore, pay attention to the manufacturer of the impact screwdriver. As a rule, those manufacturers who are engaged in the production of other tools and products make a really high-quality product. However, if you noticed a screwdriver model that has a controversial, "Chinese" name, most likely you need to refuse such an acquisition

The purchase of a low-quality tool will lead to the fact that you will be forced to change it to another

Therefore, pay attention to the manufacturer of impact screwdrivers. As a rule, those manufacturers who are engaged in the production of other tools and products make a really high-quality product.

However, if you paid attention to a screwdriver model that has a controversial, "Chinese" name, most likely you need to refuse such an acquisition.

A high-quality impact-rotary screwdriver costs about as much as 2-3 low-quality Chinese screwdrivers, but it will last much, much longer.

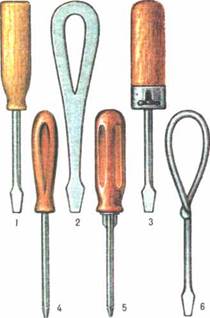

Everything about screwdrivers: types, materials and GOSTs

Precision Screwdriver (Precision)

An impact screwdriver is an indispensable tool in those frequent cases when the task is to unscrew a rusted or tightly tightened screw or self-tapping screw. For unscrewing rusted screws or self-tapping screws, an ordinary screwdriver will not work, since attempts will either lead to a break in the slot of the screw or damage the tip of the tool.A particular difficulty arises in situations where a steel screw is screwed into an aluminum part for a screwdriver. Under the influence of corrosion, a tight adhesion of the two materials occurs, as a result of which only an impact screwdriver can cope with the task.

How to choose the right one

Compare your needs and the money threshold for buying. Check out the types and technical characteristics of screwdrivers.

Varieties

Difference by type of food:

-

rechargeable. The advantage is freedom of movement. The disadvantage is depending on the capacity of the battery;

-

network. Can only be used where electricity is available;

-

hybrid. They are powered by mains and batteries.

Types of shape of cordless screwdrivers:

-

straight. Such a device is easy to put in your pocket. But it can be inconvenient when working in a narrow place, when the hole for the fastener is on the side surfaces;

-

L-shaped. This shape is similar to a pistol. Very easy to use. But you can't put such a screwdriver in every pocket;

-

T-shaped. It can be used to screw and unscrew the fasteners when the battery is completely discharged;

-

universal. This form is very convenient for transportation and operation. Because it can be changed from an L-shaped version to a straight line and vice versa. The only drawback is the wear of the swivel mechanism.

Cordless screwdrivers are classified into household and professional. The latter are distinguished by greater power due to their high torque and rpm.

Popular models

A number of the most popular models for home and domestic use stand out:

-

household screwdriver Makita 6723 DW. It is completed with a convenient case, 80 attachments. Charges in 5 hours;

-

household screwdriver Bosch PSR Select. 12 attachments. Thanks to the Bosh EasySelect system, nozzles will not be lost. Charger with indication and self-shutdown;

-

household screwdriver Sparky Professional GR 3,6Li. Cheap and lightweight. Weighs 300 grams. Has a charge indication;

-

professional screwdriver Bison Transformer-M ZO-7.2-Li KN. Works like a screwdriver. Speed 270 and 870. Spindle lock. 2 batteries included;

-

professional screwdriver Makita TD021DSE. Twists and drills. Has an impact twisting mode. Number of revolutions from 0 to 2300;

-

professional screwdriver Hitachi WH7DL. Has the highest torque of 25 Nm. Rotation speed 2400 rpm.

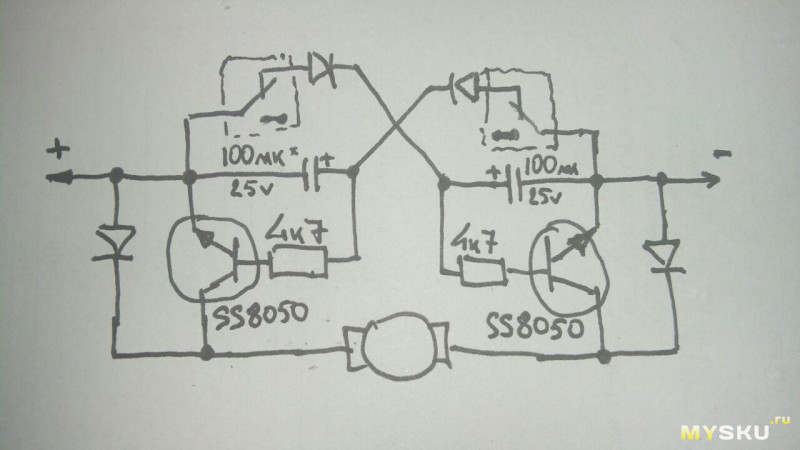

Impact homemade products

Many people wonder if it is possible to make an impact screwdriver with your own hands. You can, but before you do this, you should think carefully. The hammer or push screwdriver is made of special alloy steel. It should be impact-resistant, but not fragile. Mechanical processing of such steel at home is hardly possible; this requires a special tool. To transmit the shock impulse to the turning mechanism, the mating made must have a certain curvature. You can only grind them on a milling machine.

Many people wonder if it is possible to make an impact screwdriver with your own hands. You can, but before you do this, you should think carefully. The hammer or push screwdriver is made of special alloy steel. It should be impact-resistant, but not fragile. Mechanical processing of such steel at home is hardly possible; this requires a special tool. To transmit the shock impulse to the turning mechanism, the mating made must have a certain curvature. You can only grind them on a milling machine.

Some designs use bevel gears for the torque transmission function. Replaceable bits require a self-centering chuck or similar. Alas, all these details cannot be done at home "on the knee". You can make a kind of homemade impact screwdriver using softer materials. But in this case, there is a high probability that after several blows to such a device, it will become unusable and go to the scrap.

Without special materials and skills, you can, perhaps, make only a handle for a screwdriver with your own hands. Some models have a standard plastic handle. It often cracks, and craftsmen replace it with a wooden one of their own making.

This tool is an indispensable tool for the repairman. They can unscrew not only screws, screws and self-tapping screws.By fixing the hex adapter in the chuck, you can use heads of various sizes as a nozzle to unscrew the nuts.

Originally posted 2018-04-18 12:21:40.

Step by step manufacturing

Many craftsmen make a percussion unit with their own hands, while claiming that this work does not require any exceptional knowledge or additional skills. You just need to take into account the step-by-step instructions.

- First you need to take a rotor from any motor. Remove all elements present except the bushing and shaft.

- Place a piece of steel tube on the surface of the sleeve, which at the end will become a handle.

- A nut is inserted on the other side. It is she who helps to prevent damage to the handle in the process of physical impact.

- Next, the shank is sawn, to which the bits are mounted.

- The last stage of work is to connect all the elements to each other by welding.

- The device is now ready for use. It looks, of course, not as presentable as factory models, but in terms of service life it can be much stronger.

If you follow all the steps correctly, you get an artisanal impact screwdriver. As it turns out, making it is not as difficult as it might seem at the very beginning of work. There is no need to use special drawings and markings. But if you have any doubts, it is better to turn to a professional.

How to use an impact screwdriver

To make the unscrewing process as simple and high-quality as possible, it is enough to avoid irreparable mistakes and observe a number of individual rules:

-

The fasteners are preliminarily prepared for unscrewing, so they are cleaned of visible rust and wiped with a rag. After that, the compound is coated with a special chemical composition, for example, a highly effective cleaning agent WD-40. Brake fluid and kerosene perform well.

- Next, you need to fix the tip in the slot, observing a strictly perpendicular position relative to the screw head.

- Then you should strike with a hammer on the end of the handle with approximately medium forces.

- The blows are repeated until the screw head starts to move relative to the axis. Try to check the propeller stroke after each stroke.

- Unscrewing is completed with a conventional screwdriver.

If the tool is equipped with a reverse, many experts recommend setting the tightening mode after each head movement, repeating the blows several times, and then unscrewing the hardware again. This is due to the fact that this approach removes rust elements from the threads in a special way.

To avoid trouble, it is recommended to follow safety precautions:

It is important to put on good working gloves or gloves beforehand, which will prevent the handle from slipping inadvertently during processing.

Do not put too much effort into the punches. You can do with an ordinary hammer weighing up to 500 grams.

The blows should stay light

Do not tilt the hammer, as the firing pin can easily slide off the screwdriver, which will cause additional problems.

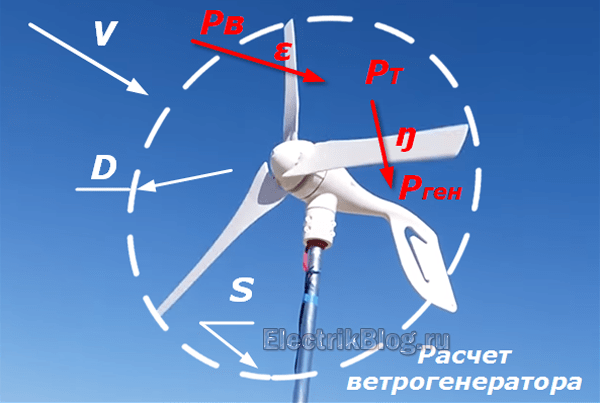

Features and working principle

The impact screwdriver has been popular since the days of the Soviet Union. At that time, it was performed in the simplest manner with the presence of a monolithic core. After a while, this device underwent a slight modification, and screwdrivers of this type began to be supplied with a hexagon near the tip, and in some models they installed it on the handle. That is why power screwdrivers have gained the ability to transmit rotational force from the wrench. To carry out successful work with the described device, it was necessary to use a double labor force.In simple terms, one master supported the sting and at the same moment created rotation with the pliers, and the second made superficial blows with a heavy object.

In the modern world, such a name as an impact screwdriver means a modified device capable of unscrewing any bolts. Classic models from the past have lost public interest and are no longer in demand. In current modifications, the shock-rotary unit is located in the handle, the sting is mounted on the gear. The movement of the device begins under the influence of a heavy object. The cage moves along the specified axis, due to which the fasteners are displaced by a couple of degrees. This distance is enough for the connection to loosen, after which the bolts are unscrewed. The return of the impact unit to its original position is due to a special spring located in the structure. Only one manpower is needed to operate this model of power screwdriver.

You should familiarize yourself with the technical data of the impact screwdrivers. It makes no sense to talk about the quality of the device and the reliability of the metal used in the production. Popular brands will never use low-quality materials for the manufacture of their products.

An important factor in the device of an impact screwdriver is the presence of a reverse. It is he who expands the capabilities of the impact device.

It is important to pay attention to the design of the handle. The presence of rubber or polyethylene interlayers in the body will allow you to hold the unit in your hand. In addition, it is a special safety condition.

In addition, this is a special safety condition.

Manufacturers take into account several factors when designing each model of impact screwdriver.

- The dimensions of the case do not change, but its use in difficult and crumpled conditions is strictly prohibited.

- Allows to increase the area of use and improve the level of convenience during operation. But then the reliability of the instrument itself may suffer.

When making a choice between one or another unit, it is necessary to understand the features of the upcoming work, with all possible difficulties and nuances, and only after that acquire a power screwdriver. It should be noted that the purchase of one screwdriver is extremely illogical. For this case, tool manufacturers have found solutions and began to release kits with several attachments of different sizes and tips on the world market.

Advantages and disadvantages of the tool

Like any tool, such a screwdriver has its advantages and disadvantages. Working with it, the masters note a number of key advantages:

- Effective distribution of impact energy.

- Much less need for physical effort. The classic version requires stronger and more intense strikes.

- Possibility of operation without the help of a partner.

As for the disadvantages, they are practically absent, however, if the basic rules are not observed during operation, such disadvantages often appear:

-

The probability of damage to the shock-slewing unit. The version of the simplest impact screwdriver is made of a monolithic structure, therefore, its service life exceeds the modernized solution. To prevent unexpected damage, it is enough to avoid too strong impacts on the shock-slewing mechanism.

- Propensity to wear quickly. Gear teeth and races are subject to extreme friction, coupled with shock loads. With prolonged operation, their resource significantly deteriorates.

What materials are impact screwdriver handles made of?

The handle of the impact screwdriver serves both as a handle and as a housing for the mechanism. In addition to structural strength (retention of the mechanical part is necessary), the handle also serves as a protection for the hands of the master.

Steel body-handles.

This tool is classified as professional.The robust steel case also serves as a clip for the swing mechanism. The absence of extra layers on the handle allows you to place the screwdriver in hard-to-reach places. One-piece design provides precise force metering and excellent process control.

These tools are usually supplied in kits with various attachments. All the same, the design is not monolithic, and therefore it can be supplemented with a universal chuck for standard bits.

Only when buying additional attachments should you remember about increased loads, and do not skimp on quality.

Component Sticks

The body of the screwdriver mechanism is covered with a rubberized shell. The material can be different - polyurethane, rigid polyethylene. The main thing is to provide shock damping and a firm hold in the hand. In the heel of the handle, a fungal tide is usually made. As with a bolt, it provides additional protection for the hand in the event of an inaccurate hit with a hammer.

The soft handle cannot be a part of the mechanism, the load is too great. Therefore, the question of the size of the power unit (and, therefore, the safety factor) arises sharply. If the mechanical part is left powerful and dimensional, as in products with a steel handle, the overall dimensions of the screwdriver will not allow working in cramped conditions.

The reduction in size reduces the strength of the tool, but makes it more convenient.

You can always choose the option that meets your needs.

Distinctive feature

This model differs from an ordinary hand-held device only in its reinforced body, which is made of metal with an admixture of chrome vanadium alloy and its thickness. It is several times larger than a traditional instrument. Thanks to the switching of the torque, the product is called reversible.

The package includes a screwdriver from 2 to 4 bits. They have a cross and a flat tip. The bits are installed according to the same principle that is used when working with simple screwdrivers.

The most important feature is the sting:

- it completely passes the length, starting from the slots and up to the end of the handle;

- made from a single piece of metal;

- made of high quality steel.

When manufacturing a tip, the use of joints and welding joints is unacceptable. This part of the screwdriver is in the shape of a hexagon, and on the heel of the handle of the device there can be a square or a hexagonal wrench shape.

When choosing attachments, first of all, you need to pay attention to what kind of metal they are made of. The most durable alloys are considered: The manufacturer applies the Russian-language instructions to the hand tool

The manufacturer applies the Russian-language instructions to the hand tool.

How to use?

For many people, especially those who have taken an impact screwdriver in their hands for the first time, many questions arise as to how it works. That is why, before you start using the tool, you need to familiarize yourself with its detailed instructions and understand how to use it correctly.

- Before starting work, you should carry out some manipulations with the fastener. It must be cleaned of possible contamination. To do this, just use a sponge, a brush.

- Several drops of brake fluid drip onto the surface of the fastener. If it is not available, you can use other means, for example, WD40 grease, which is used in the automotive industry, antifreeze, kerosene or any machine oil. Wait a couple of minutes after applying the lubricant. This time will be quite enough for the liquid to get inside the fastener.

- Next, you need to pick up the nozzle. Impact screwdriver kits generally have several types of bits, and you can try to find the perfect bit size.

- After that, it is necessary to install the nozzle into the shank and fix it in the base of the fastener.

- Then, a few hammer blows must be applied over the screwdriver. It is worth noting that when exposed to force, the screwdriver should be held in such a way that its axis coincides with the axis of the fastener being screwed, that is, it is located along the slots.

During prolonged use, the impact screwdriver may fail. But this does not mean that you need to buy a new model. First you need to disassemble the tool and determine the cause of the breakdown. In most cases like this, you just need to replace the rotor.

After repair manipulations, it is important to correctly assemble the unit and check the operation in action.

If the unscrewed element succumbed to dismantling, then the screwdriver system can be switched to reverse and again made several strong blows. As soon as you feel that the fastener is unscrewed from the base, you can remove the impact screwdriver, then use the usual model with a simple tip.

Although the impact screwdriver is the most common tool in manufacturing and construction, it is not always able to help the craftsman. Especially when old-fashioned corrosion has stuck between the fasteners and the base. To solve this problem, you will have to drill.

How to use the shock-rotary response, see the video below.

Let’s block ads! (Why?)

Impact screwdriver how to use video

Greetings, in this video I will tell and show you in practice how to use an impact screwdriver. That is, its application in practice, in order to carefully unscrew the sour bolts and at the same time maintain their condition. As a rule, we need such a tool to unscrew the bolts with a head: for a cross (plus), for a flat screwdriver (minus), for sprockets and hexagons

Due to the fact that such bolts should be unscrewed carefully so as not to damage (lick off) the edges, otherwise otherwise. You will have to suffer enough to unscrew such a bolt.

And for these purposes, an impact screwdriver is ideal. Since, she loyally unscrews and breaks the bolts in motion. But about all this - you will take away in the video itself!

Link to this video:

You don’t know how to use the impact screwdriver correctly, and for what purpose you need it? With the help of our article, you can find answers to all your questions.

There are times when it is impossible to unscrew a bolt or an old self-tapping screw with a traditional tool. At the moment, only an impact-rotary screwdriver will help you.

This model is suitable in order to loosen the tight tightening of the bolt or tighten the self-tapping screw harder. Most often, it is customary to use the tool to fasten the car door. If you screw it with a simple screwdriver, then soon the screws will loosen and turn out.

Using the tool at work

Before starting work, you need to clean the screw head as much as possible and especially the slot into which the working nozzle is inserted. To do this, you can use a metal bristle brush. Then apply a drop of brake fluid to the head to wet the rust. You can also use:

- universal aerosol lubricant WD-40 or any of its analogs;

- antifreeze;

- kerosene;

- any machine oil.

screw the chuck with the nozzle into the slot as tightly as possible

If the screw has moved out of place, switch the device to reverse rotation and again make a few light blows. You can repeat this operation several times, periodically adding a little lubricant to loosen new layers of rust. Then you can use a screwdriver or hand tool to unscrew the hardware completely.

Unfortunately, even this kind of impact screwdriver does not always help. Mating parts are sometimes so affected by corrosion that when you try to unscrew the screw or screw, it simply bursts. In this case, the only way to remove it is to drill.

Purpose and areas of application of cordless screwdrivers

The cordless screwdriver is used for screwing and unscrewing various fasteners into non-solid materials, for example, made of wood. The screwdriver battery is built into the handle, so the tool is small. The device can be used where there is no need to drill and tighten the fasteners too much, to work in narrow places and openings in which a screwdriver cannot fit.

The rechargeable screwdriver is used in the assembly of furniture, installation of windows, repair of household and computer equipment, maintenance of cars, when performing small household work.

The screwdriver can be used to assemble furniture

What is an impact screwdriver and how should it be used?

Welcome! Impact screwdriver - this is how it is called among the people, and its full name sounds like this: "Impact rotary screwdriver". Recently, we have already very often begun to ask questions about this unit, someone asks: How should it be used? For someone, its purpose is interesting, but for someone you just need to find out how much it costs and what types of it there are. Let's get down to parsing these questions.

What is the impact screwdriver for?

It is needed to loosen the tightening, as well as to tightly tighten the nuts that are required by design, for example, the screws that fasten the door lock on the car body must be tightened only with a shock screwdriver, otherwise, when tightening these screws with a conventional screwdriver, during operation the car (Over bumps, potholes, etc.) these screws will loosen and eventually they will completely turn out.

Note! The photo just above shows the lock and the same screws that need to be tightened with an impact screwdriver (Screws are indicated by arrows). The photo was taken using the example of a VAZ 2109 car!

How to use an impact screwdriver?

Everything is very simple! Take this screwdriver in your hands and take a hammer with it, or something else that you will use to hit the impact of the rotary screwdriver.

When you collect all the necessary substances, attach an impact screwdriver to the screw that you need to unscrew, and after you have applied it, make one blow of such a force that you think will be needed to unscrew this screw and not deform the surface.

After one or several blows have been made, put this screwdriver aside and then completely unscrew this screw that you unscrewed earlier with the help of a rotary screwdriver.

To tighten the screw you need, do the same operation but only in the reverse order, that is: First, tighten the screw until it starts spinning with a little effort, and then take the screwdriver in your hands and blow it with a hammer to tighten this screw until emphasis.

Note! Do not turn the screw in need of an impact, using a regular screwdriver to the very stop, because if the screw is screwed in to the very stop with a regular screwdriver, then when hit by an impact rotary screwdriver, the screw can damage the car body, thereby tightening more tightly!

How much does an impact screwdriver cost?

In fact, it is different everywhere. But this is understandable, because each owner of his store sets his own price for the product, and not the one that is written somewhere, let's return closer to the question. If you take a screwdriver only for yourself and for your car, then the most common impact screwdriver will do, which will cost you 200-500 rubles.

And if you are a service station worker and you need the screwdriver to be more convenient, and the screws can be removed faster with it, then your price range starts from 600 and ends at 3700 rubles.

Note! The entire price range is only approximate, and in most cases it happens that service station workers use an impact screwdriver purchased for 200 rubles, and the owners of their cars use a screwdriver whose price reaches 2100 rubles and more!

What types of impact screwdrivers are there?

The most basic type of screwdriver is produced in the form of an ordinary beard, how to use it was written a little above, and the greatest value of this screwdriver lies in its price, which is not much, not less than 300-900 rubles.

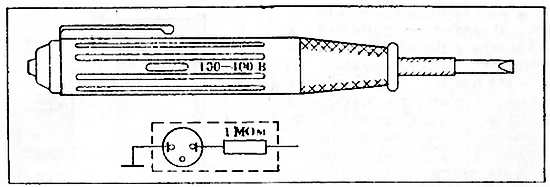

The next type is a screwdriver in the form of an ordinary screwdriver, that is, outwardly it is no different, but inside it has a special mechanism that helps in necessary situations to use it as an impact screwdriver, and in unnecessary situations just like a regular screwdriver. Its price range fluctuates slightly higher and sometimes even reaches 3000 thousand rubles, and starts from about 800 rubles apiece.

Additional video clip: You can study in more detail how to use a shock-rotating screwdriver in an interesting video clip, which is posted just below:

Features of the work

The principle of using an impact screwdriver.

In order to make the unscrewing process easier, the rusted fasteners should be wiped in advance with a rag, which should be moistened with brake fluid. After that, the screwdriver should be installed on the head of the hardware, if possible, this should be done strictly perpendicularly. Then the end of the tool should be hit with a hammer. How successfully the work will be carried out, in this case, depends on how firmly the tool is held in the hand. You can exclude the possibility of sliding the palm on the handle of the tool by wearing a glove, this, among other things, will protect the hand from possible injury.

After the fasteners rotate a little around the axis, it is necessary to make a few more blows with a hammer, and then switch the tool to the twisting mode, inflicting a few more blows. This will get rid of rust from the threads, which will facilitate further unscrewing work. After the fasteners have been displaced from their place, it is permissible to remove it using a conventional screwdriver.

Converting hammer impact energy into torque.

In some cases, even after carrying out all the above work, the hardware does not lend itself to influence, and it must be subjected to the treatment with brake fluid again, leaving it in this state for a period limited to 30 minutes. Such a "bath" should contribute to the faster dismantling of even the most firmly reinforced fasteners. If after that the removal was not successful, the fasteners will have to be broken off. For more efficient work, it is also necessary to choose the right hammer, such recommendations are given in the instructions from the manufacturer of the screwdriver.

Tools and materials for work:

- impact screwdriver;

- hammer;

- rags;

- brake fluid.

Some craftsmen make screwdrivers on their own, for this you will need a rotor from an electric motor, from which everything must be cut off so that the bushing and shaft remain. A piece of steel pipe should be put on the sleeve, which will become the handle. From the opposite end, a nut must be inserted into the cut, which will not allow the handle to break. After all the parts are welded.

How the impact screwdriver works

The simplest version of such a screwdriver is made in the form of a special tool with a monolithic core, which starts with a tip and ends with a massive heel in the area of the handle. A similar product has been in demand since the days of the Soviet Union.

Modern models are equipped with a hexagon near the tip or on the handle, so they are able to transmit rotational force from the key. To successfully complete the task, it is advisable to use a screwdriver together, since one worker will be able to hold the tip in the screw slot and create torque with a wrench, while the other will strike with a hammer on the back of the handle.

However, this solution has some drawbacks. Among them:

- The need for two partners to work together.

- No conversion of received energy into torque. Hammer blows only unscrew a self-tapping screw or screw, since they are capable of destroying rust and creating a certain vibration. The version of the impact-rotary screwdriver is more advanced, so it can transform the impact force into rotary motion of the blade, which is very convenient.

In the improved version, the shock-swivel unit is located in the handle, and the blade is fixed on the gear and has characteristic helical teeth. A holder with counter teeth is used as a handle. Under the influence of hammer blows on the heel of the handle, the clip begins to move along the axis, imparting a rotational motion to the tip by means of a gear transmission.

Thus, there is a rotation of several degrees, which is quite enough to weaken the protective connection and successfully unscrew the fastener using a conventional tool. As a result, the clip is returned to its original position by means of a spring.

It is not difficult to operate such a screwdriver. The pivot mechanism is capable of providing a combined translational and rotational force on the screw spline, which is very effective for successfully unscrewing stubborn threaded connections.