The best saw blades with a diameter of 190 mm

Such equipment is used for cutting small wooden materials - boards and beams up to 75 mm high. The small size of the blade allows it to be used on compact hand-held circular saws. Here is a rating of saw blades for wood for a circular saw with such a diameter, which are distinguished by their speed of cut, cleanliness and a thin kerf, and are also suitable for chipboard and MDF.

Bosch 2.608.640.633 190x30 mm - fast cutting

When cutting speed is a priority, discs with a small number of teeth are chosen. This design has less resistance to rotation and facilitates faster cutting of the material. But due to the large distance between the cutting elements, the cut sides are rough and they will have to be ground for finishing.

This disc from the German brand has 12 soldered teeth and additional reinforcement on the back. Leaves a cut 2.6 mm wide.

+ Pros Bosch 2.608.640.633 190x30 mm

- Suitable not only for wood, but also for aerated concrete, cement-based fiber boards.

- Even cuts boards with nails.

- Very low price and proven brand.

- Interacts with a tool with an outstanding speed of up to 4900 per minute.

- Cons Bosch 2.608.640.633 190x30 mm

- Metal can lead if sawing for a very long time - the disc has no cutouts for thermal expansion.

- The cut is not clean and needs additional post-processing.

- It is more suitable for longitudinal cutting - on the cross cut it tears the fibers more, which spoils the quality.

- Over time, it starts to cut more slowly - an approximate service life of 4 years.

- Sharpening is seemingly dull (a feature of form and technology), therefore, it is not possible to determine the quality in a store - you just need to install it on a saw and try.

Output. This inexpensive blade comes in handy for quick cutting of wood when doing rough work.

CMT 272.190.42M (190x30 / 20 / 16x1.7 / 1.1 mm; Z42) - clean thin cut

For particularly thin cuts with a clean edge, thin blades with a large number of teeth are needed. Such tooling is used in the production of furniture, where accurate precise cuts and rational consumption of material are needed. But the payment for this is a thin section of the metal, which leads to biting or deformation.

This disc should be handled more carefully than others.

CMT 272.190.42M (190x30 / 20 / 16x1.7 / 1.1 mm; Z42) is an extra thin disc with a thickness of 1.1 mm. Has 42 teeth and leaves a cut 1.7 mm wide. Manufactured directly in Italy and designed for finishing.

+ Pluses CMT 272.190.42M (190x30 / 20 / 16x1.7 / 1.1 mm; Z42)

- Suitable for circular saws up to 8000 rpm.

- Very quiet operation.

- With it, it is easy to make longitudinal and transverse cuts in materials of various densities.

- Does not leave lumpy fibers at the edges.

- Cons CMT 272.190.42M (190x30 / 20 / 16x1.7 / 1.1 mm; Z42)

- The price is much higher than analogues.

- A complex sharpening that is not easy to restore at home.

- For installation on some circular saws, adapter rings are needed - those that are included in the kit are thicker than the blade itself, so the latter is not clamped to the end.

- You cannot rush to make a cut, otherwise it will be chipped.

Output. Ideal for a furniture workshop. It will allow you to cut through OSB and similar materials as cleanly and accurately as possible. The eight slots inside the disc provide good vibration damping and promote quiet operation.

Inforce 11-01-095 (190x30 / 20 mm; 48 teeth) - clean cut of plywood, chipboard, MDF, wood

MDF, chipboard and plywood are not very dense, but they can crumble strongly when roughly exposed to the equipment, so the disc should be as sharp as possible and cutting is required at an average speed. This blade has 48 teeth and a thickness of 2 mm, which provides strength and smoothness of the cut.

+ Pros of Inforce 11-01-095 (190x30 / 20 mm; 48 teeth)

- There are four heating expansion slots.

- There is an adapter included for mounting on saws with a seat of 20 mm in diameter.

- Leaves no chips on chipboard.

- Doesn't bite into the material.

- Resistant to bending and deformation.

- Cons Inforce 11-01-095 (190x30 / 20 mm; 48 teeth)

- An adapter for installing a disc on a shaft of a smaller diameter is glued to the back of the tooling - some users are at first afraid that it was not included in the kit.

- The soldering quality of the teeth is uneven.

Output. The model has tungsten carbine solders, so it keeps sharpening for a long time and ensures a clean cut of pressed materials. The disc is optimal in terms of value for money and is suitable for use in a personal carpentry workshop, but not for everyday use.

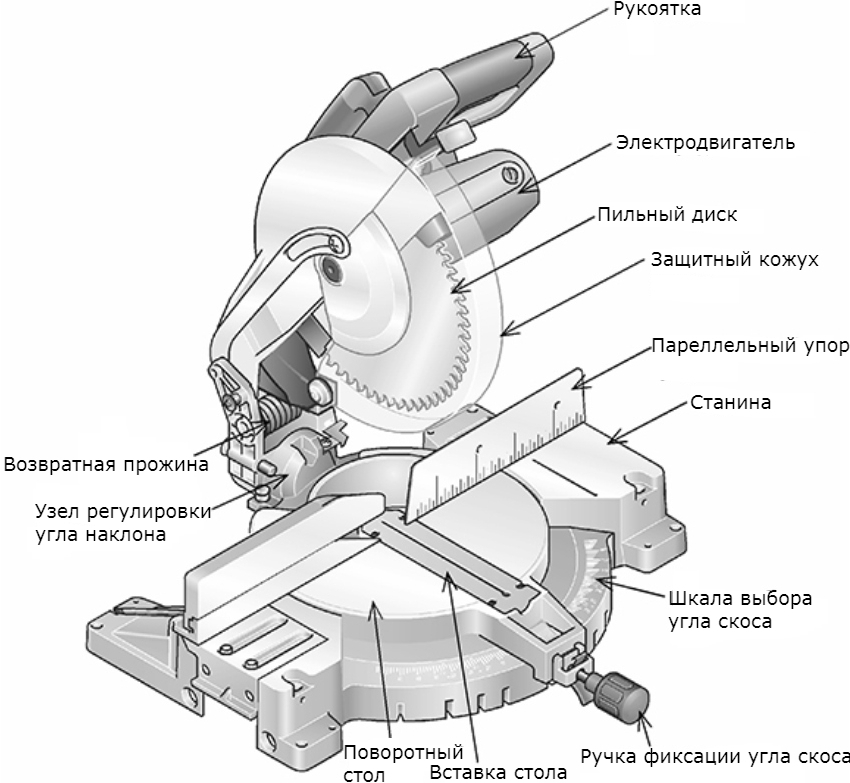

Device

The device of the miter saw is quite simple: its main elements are a gearbox, a cutting disc, a base, a handle with a start button, and a motor. Today it can be collector and asynchronous. The first option is good because it is easy to maintain, the second is durable and produces less noise during operation. As for the type of transmission, it can be belt or gear. It is the first one that is practically silent, in this case the disc does not vibrate.

The disadvantage of this type is slippage from the base if the unit is running for a long time. The serrated version does not have this drawback, but such a saw makes noise and vibrates during operation. The blade, which is the key element of the saw, is made of durable metal, as it must withstand an enormous load.

Another feature of the miter saws is the rotary table. It is due to this type of platform that the cutting at an angle is carried out. In order to achieve maximum accuracy, the saw is equipped with a fine graduated scale. The presence of a scale is convenient because the operator does not need to perform additional measurements with auxiliary devices. Some models are even equipped with a laser ruler.

In addition, the product can have an automatic broaching. This is convenient, since there is no need to independently advance the metal to the desired mark: this will be done by special grippers. Also, modifications can be equipped with special anthers, thanks to which you can not think about disposing of shavings and debris. This equipment is relevant for the maintenance of the workplace.

What is a wood miter saw. Purpose of the tool

A miter saw, a pendulum saw for wood and metal, or an angle cutter is a stationary cutting-off highly specialized tool that is used to cut materials at a certain angle. This possibility is provided by a turntable and a movable working part with a disc over the bed. The miter saw can cut narrow pieces of wood such as slats, bars and planks. It can also be used for sawing hardboard, laminate and OSB. The tool copes well with cutting plastic, aluminum profiles and polyurethane stucco decoration.

A miter saw for wood is used to cut material at a specific angle

Due to its high speed, precision and ease of operation, the miter saw has a wide range of applications. It is used for joinery, assembly and finishing work related to the use of wood products. The tool is indispensable in furniture manufacturing workshops, where it is necessary to perform accurate and high-quality sawing of products.

There are universal tools that perform metal trimming. Thanks to a special disc, a tool is used to cut metal products from steel, iron and cast profiles. Such side saws for metal are widely used in enterprises that manufacture window frames from metal-plastic profiles.

Important! A diamond or abrasive wheel must not be mounted on the tool instead of a saw blade. The technical documentation of each specific model indicates the limiting parameters of the product that the tool can handle.

Small miter saws cut products up to 60 mm thick. The medium-sized tool will handle workpieces with a thickness of 70-80 mm. Large-sized saws are used for processing products with a thickness of 100 mm and more.

The technical documentation of each specific model indicates the limiting parameters of the product that the tool can handle. Small miter saws cut products up to 60 mm thick. The medium-sized tool will handle workpieces with a thickness of 70-80 mm. Large-sized saws are used for processing products with a thickness of 100 mm or more.

In addition to the technical characteristics and class of the saw itself, the manufacturer directly affects its quality and cost.

It is the brand and its reputation that become a kind of dictators of pricing policy. True, there are trademarks that nevertheless managed to combine such a main combination as price and quality. These brands can be safely attributed to Stihl. If we talk about Stihl, then it is unrealistic not to mention the long and original history of the formation and development of this company.

Stihl tools are appreciated both by professionals and simply by those who only occasionally use them to accomplish their tasks.

It is worth noting here that only in real terms a high-quality tool can last for many years, and the Stihl quality has been tested by more than one generation.

Here is the Stihl assortment with the widest selection of products for every taste and for every need.

State-of-the-art drive miter saws meet high safety standards

Important! Miter saws cannot be used for processing stone, ceramics and ferrous metals.

Additional accessories

Almost all modern models of miter saws have some kind of additional devices and functions aimed at facilitating work and increasing safety. At the stage of selection, the future user of the tool will have to figure out which of them are really necessary to solve the typical tasks facing him, and which will be an unjustified waste of money.

1. The dust extraction system consists of a branch pipe and a dust bag or hose of an industrial vacuum cleaner connected to it. The second option is preferable, since it allows you to more effectively capture the fine dust of the material being processed, which is formed when performing an accurate cut when the saw operates at high speeds and / or with discs with an increased number of teeth.

The dust extraction system should not be considered as an additional, optional function, even if you are faced with the task of choosing a miter saw for your home, i.e. low-intensity episodic work on it is assumed. Working without a dust extraction system, you risk not only the safety of the equipment available in the workshop (and first of all the saw itself), but also your own health.

2. The blade guard completely covers the saw blade until it is immersed in the material to be cut, significantly reducing the risk of accidents when working with the miter saw.

3. Limiting the cutting depth is used to carry out work on the selection of grooves or trimming profiles.

4. The laser "draws" a leading line on the workpiece where the saw will cut. The presence of this option increases the accuracy of the cut (especially when sawing at angles other than 90 degrees), facilitates the work, and reduces the time for preparatory work.

5. Illumination of the working area is useful when working in workshops or workshops with insufficient general lighting.

6. Smooth start provides a gradual set of revolutions by the motor when turned on, which prevents the "jerk" of the tool at the start, reduces the risk of saw failure due to a sharp current surge and the likelihood of the equipment jamming at the beginning of work.

7.Automatic shut-off when the saw blade is jammed is another useful feature to improve safety when using the miter saw.

8. Adjusting the number of revolutions allows you to vary the cutting speed. Most miter saw models do not have this function. However, it allows you to better tailor the sawing process to the characteristics of the material being processed. Recommended for those who intend to work not only with wood, but with various materials based on it, plastic, plexiglass, etc.

9. Maintaining constant speed during increasing load. With this function, the engine speed does not drop with strong pressure, since the electronics make their own corrections to the speed. As a result, the cut is neat and clean.

Manufacturers you can trust

Below are recommendations for choosing a brand of miter saws. Data based on customer reviews and information from forums.

The optimal miter saw in relation to comfort, manufacturability and safety during work is considered to be the products of one of the following companies: "Corvette"; DeWalt; Metabo; Makita; Interskol. Hitachi; Bosch.

Most of these manufacturers provide an extension of a special table for the workpiece, however, in some cases, additional supports are required to cut dimensional parts. Such ones can be found, for example, at the manufacturer "Makita" in the LF 1000 trimming model. This addition greatly simplifies the user's work. In addition, the movable part of the metal saw is included in a stable bed, in which there is a place for assembling the cut angle.

The best trimmer, in terms of stability and reliability, is one whose frame is made of magnesium or aluminum alloy. They are stable, durable and, moreover, have a very reasonable weight. An example is the Bosch GCM 10 model - the most popular modification among professional models. With all other advantages, it weighs only 15 kg.

Hitachi is considered the leading manufacturer of hacksaws with a permitted inclination of the cutting edge to the workpiece. When Bosh, Metabo or Makita for the most part make it possible to measure the cutting angle only at 0, 90 or 45 degrees, then this Japanese concern provides the operator with the ability to measure at 30; 15; 22 and even 5 degrees. The option provided makes it necessary for the operator to add a rotary device to the device design. However, the weight of the installation for cutting sheets, pipes or profiles will still not exceed 30 kg. However, the cost will also increase from 15 to 25 percent.

Sawmaker DeWalt stands out for its XPS system, which projects a clear line. Before starting work, a shadow is projected from the saw blade, which allows you to make the cutting of metal more accurate. The models of the domestic manufacturer "Interskol" are, from the point of view of design, very simple, because they have:

- disk

- start button

- engine

- handle

- base

Additional advantages of the device are very affordable (you can pick up models from 5000 rubles), easy to hold on weight.

To cut a metal sheet, profile or pipe, you will need to turn either the disc or the table. The disc can rotate along its axis and against, which is very convenient for the work of the master.

Before making a purchase, we recommend that you turn your attention to the models of the above manufacturers, weigh all the advantages and disadvantages

Features of products with a broach

The options with the pull function are professional equipment, they differ in comparison with the household varieties. They are convenient for cutting long slabs and pipes. The design of such devices is equipped with two rails located parallel to each other. The cutting disc is mounted on the rails themselves, it moves freely along them and has especially fine teeth.This is no coincidence, since the smaller the teeth and the larger their number, the lower the level of stress on each of them.

The feed saw is characterized by a substantial kerf width on the part. Products of this type are heavier than other varieties. The rotation speed of some modifications can exceed 3000 rpm. Sometimes the model is equipped with an electronic control of the saw blade rotation speed. Such units allow you to get a smooth and fast cut.

Miter saw

This tool is also called a pendulum saw because of its characteristic design: the cutting disc swings along with the electric motor above the base like a pendulum.

All pendulum saws are mounted to work on a table, workbench or floor. For ease of operation and greater stability, it is even better to attach the bed to the table using clamps or screws.

An electric motor with a saw blade can turn over the bed in a special pendulum mechanism around three mutually perpendicular axes. The angle of rotation is measured using the available scales. This allows the saw to cut workpieces at exactly the right angle. For example, door trims are sawn at a 45 degree angle for a smooth and beautiful "mustache" connection.

It is equally important in the carpentry craft that the ends of the parts are strictly perpendicular. This operation is called trimming and is performed just with the help of a miter saw - "trimming"

To make the comparison of the two instruments more clear, we have made a table for you:

| A circular saw | Miter saw | |

| Appointment | Fast cutting of wood parts in any direction (straight line) | Finish cutting wood parts at a given angle |

| Workplace requirements | The operator holds the tool in his hands | The tool is installed on a table surface, etc. |

| Limiting the size of workpieces by length | No | No |

| Limiting the size of workpieces in width | No | Yes, depends on the diameter of the working disc and the design of the saw |

| Cutting depth limitation | Yes, the maximum depth is limited by the disc diameter | The maximum thickness of the workpieces is limited by the diameter of the disc |

| Sawing along the grain | Perhaps | Combined models |

| Sawing across the grain | Perhaps | Perhaps |

| Sawing at an angle to the plane of the part | Perhaps | Perhaps |

| Sawing at a given angle | No | Yes |

| Battery Powered Models | There is | No |

| Price on Yandex Market | from 2100 to 14100 rubles. | From 3200 to 40,000 rubles. |

How to cut?

Before turning on the unit, it is assembled and the reliability of the units is checked.

It is important to remove the wrench from the saw blade fixing screw. Before switching on, make sure that the disc is not obstructed and that it can rotate freely.

After that, you can start the device by pressing the start button, which is located on the handle. To turn off, release the switch button.

To perform bevel cuts at 90 and about 45 degrees, loosen the screw on the turntable mounting and rotate the table to the desired angle while holding the handle of the turntable mounting screw. Immediately you need to fix the given position. When working for a long time, it is necessary to check the accuracy of the trimming, since the screw that secures the turntable sometimes looses.

For sawing with a left tilt within 45-90 degrees, the correct tilt must be set. It is necessary to loosen the screw that secures the tilt angle and set the specified angle. When fixing the desired parameter, tighten the screw and clamp the workpiece with a vertical clamp. After that, the device is started and sawing is carried out. At the end of it, release the shutdown button, wait for the complete stop of the cutting blade, then return the handle to the upper position.

During this time, the cut-off element opposite the side surface of the cut-off wheel can catch on the teeth and fly off, which can injure the saw operator. During operation, the protective cover must remain on the device - it is strictly forbidden to remove it.When the blade is lowered for sawing, the guard will rise. Also, the cover will automatically lower when the handle is raised.

When turning on, you need to firmly hold the handle, since at this time the saw can move up or down

When cutting, it is important to hold the workpiece with a clamp against the front stop or the surface of the turntable. This will eliminate rotation or swaying.

It is important to ensure that no chips accumulate under the metal workpiece. You cannot cut several metal workpieces at the same time.

If it is necessary to use auxiliary surfaces, it is necessary to select supports that can hold the workpiece so that it does not slip during operation.

See the next video for adjusting and modifying the miter saw.