Best inexpensive miter saws

On average, the cost of such products is 6000-10,000 rubles, usually their power is 1000-1500 watts. These options are suitable for home applications where speed and performance are not the most important parameters. There are not very many inexpensive devices on the market, and 4 models were selected from the analyzed proposals.

Hammer STL1400 / 210

The powerful Hammer STL1400 / 210 saw is designed for long cuts in wood and machining aluminum profiles. With its help, the cut is made exactly in any direction - straight, obliquely, at an angle. This is facilitated by a special base for holding the material. The model is equipped with a work table with optimal dimensions and a rotating surface, which makes its use more efficient and comfortable. For the manufacture of the base, durable aluminum was taken.

Dignity

- Rotation speed - 5000 rpm;

- Power - 1400 W;

- Can be connected to a vacuum cleaner;

- Good equipment;

- Deep disc entrance;

- Considerable dust collector.

disadvantages

Weight 6.3 kg.

The inexpensive Hammer STL1400 / 210 miter saw has several cutting depths, which depend on the angle of inclination of the blade: at 45 ° it is 3 cm, at 90 ° - 5.5 cm, and the cutting width is 12 cm.

Bison ZPT-210 - 1400 l

It is a compact miter saw that makes it easy to work with both large and small workpieces. The set includes a table for fixing the device, if necessary, its position can be easily changed by 47 degrees to the left and right. The disc of the model is sharp and cuts accurately, but it is not able to cope with a thickness of more than 60 mm. For high-quality performance of work, the manufacturer has provided laser illumination of the cutting line stroke. The device operates at a power of 1300 W and with such parameters it separates well not only wood, while the disc diameter is 21 cm, which reduces the time.

Dignity

- Low noise level;

- Ease of installation;

- Ease of transportation;

- Does not chip at the disc exit;

- Saws excellently, even at different angles.

disadvantages

- Weight 6 kg;

- Not instant dust removal.

The reviews indicate that when working with blanks, the canvas does not go to the side, but it still takes time to get used to the laser marker.

Caliber PTE-1750/255-Am

Saw "Caliber PTE-1750/255-Am" is designed for cutting plastic, not thick aluminum, wooden blanks. The device does its job perfectly both at oblique angles and in the straight position of the cutting blade. It is protected from overheating by built-in ventilation, which prevents premature failure. It is convenient to use it due to the possibility of changing the position of the table, which is carried out using a convenient handle and a clear scale. The model is suitable for both hobbyists and professionals who need a worthy alternative to a sawing machine.

Dignity

- Cutting depth - 70 mm;

- Power 1750 W;

- Disk rotation speed - 6000 rpm;

- Effective dust removal system;

- Ease of controls;

- High build quality.

disadvantages

- Weight 13.6 kg;

- Cutting width - 13.6 cm.

Metabo KS 216 M Lasercut

A compact, affordable miter saw that is easy to carry in one hand. If necessary, the device can easily change the cutting disc, there is a preliminary spindle lock. All controls are visible and easy to use. The saw head tilts to the left for more accurate and efficient back cuts. The work is carried out safely due to the high supports that move to the side. The support extends for machining long workpieces. The model operates from the mains, the accuracy of the results is guaranteed by laser marking of the cut line.

Dignity

- Long dust suction channel, which improves the efficiency of its collection;

- Fast and easy setup;

- Ease of transportation;

- Cast construction;

- Cable length 2 m;

- The number of revolutions is up to 5000 per minute.

disadvantages

- Weight 9.4 kg;

- Noisiness.

The dimensions of the support surface of the device are 155 x 725 mm, so long workpieces can also be freely placed on it. The width of the cut varies on average from 80 to 120 mm, depending on the angle of the disc.

Which company miter saw is better to choose

The rating includes products from 7 popular manufacturers with good characteristics, numerous reviews from experts and buyers. These companies include German, Russian and some other firms. Here's who are on the leaderboard:

- Hammer is a brand of power tools for professionals, distinguished by their compact size, high speed (about 5000 rotations per minute), low noise level and reliable protection against overheating. The devices can withstand heavy loads without problems and are successfully used for various types of sawing. They are effective in working not only with wood, but also with thin aluminum surfaces.

- Bison is a budget manufacturer of power tools, including saws. They are used for both simple and complex cutting of blades at different angles of inclination of the disc. The large depth of the entry of the working elements and their decent diameter guarantee the acceleration of the process. The products have a powerful motor that can handle even high loads.

- Caliber - brand devices are suitable for processing workpieces not only made of wood, but also plastic and aluminum materials. They cope with a wide range of thicknesses with a large cutting disc and keep waste at an acceptable level. The company's products are distinguished by a compact table, reliable stops and clamps, which guarantees a safer and more efficient use of miter saws for wood and other materials.

- Metabo is a manufacturer of professional electrical equipment, which is distinguished by high build quality, good motor power, sharp discs. The company's products are functional and reliably protected from premature failure. The diameter of the cutting elements ranges from 216 to 315 mm, depending on the specific model.

- Makita - the company's range is replete with miter saws, the average power of which is 1600 watts. The instruments have discs with a diameter of about 20 cm, rotating at a speed of 3000-6000 revolutions per minute. Many of them are equipped with a comfortable table and a broaching mechanism that improves the quality of work.

- Bosch is a German manufacturer of mostly premium products. Its saws have a compact size and adequate weight, equipped with a comfortable handle and durable stops. The company's structures are distinguished by high-quality assembly and are made from durable materials. They have easy-to-replace cutting elements and intuitive operation.

- DeWALT - brand saws are appreciated for their good quality and high level of safety for the user. They keep the work surface clean when equipped with a dust collector. Most of the assortment is represented by network models powered by an outlet. The average power of the product is 1300 W, the cutting depth is about 3 cm, however, the tools weigh about 15 kg.

The best circular saws according to user reviews

What it is?

The wood and metal miter saw is a highly specialized static cut-off tool that is used to cut materials at a specific angle. This ability is provided by a rotating platform and a movable working unit with a disc above the base. The Miter Saw is capable of processing narrow wood slats, bars and planks. In addition, it can be used for sawing laminates, oriented strand boards and fibreboards. This fixture is perfect for cutting plastics, aluminum profiles and polyurethane moldings.

Due to its high speed, accuracy and ease of operation, trimming has a wide range of applications.It is practiced for joinery, construction, and cladding work involving wood products. This device is indispensable in furniture manufacturing workshops, where accurate and high-quality sawing of products is especially important. There are universal devices that perform metal trimming. By means of a specialized disc, metal products and molded profiles are cut. Such side saws for metals are widely used in industries that are engaged in the creation of metal-plastic windows.

How to choose a miter saw?

When planning to make a purchase, you should understand the parameters that you need to rely on. The main properties of the tool are the depth and width of the cut. This determines the processing capabilities. Disc diameter, bed and slewing block are also important.

The following points are taken into account when choosing a tool:

- work that is planned to be carried out with a miter saw;

- the presence of a protective disk that ensures safety;

- convenience for the work of dimensions and the tool as a whole;

- a sufficient diameter of the dusty disc (at least 20 cm).

Home miter saw

Household tools are likely not to be used often. Therefore, for these purposes, it is enough to buy a unit with a standard set of functions.

Professional miter saw for work

The type is characterized by the presence of a special traction function. As a rule, the working unit is installed on two rods along which the functional module moves during cutting. There is also an extension of the table to the basic set. However, if the work is carried out with large parts, other supports will be required.

What kind of work is the miter saw used for?

Most often, the unit is purchased for sawing wooden blanks at an angle. Also, sometimes laminate, aluminum and plastic are subjected to processing. The miter saw does its job well. In some industries, for example, furniture, it is impossible to do without it.

Miter saw for wood

Most of the work with the tool is for cutting wood. Therefore, almost all models are suitable for these purposes.

Miter saw for metal

In this case, you need a truly reliable tool. A professional grade miter saw can handle metal work.

Sliding miter saw

The broaching mechanism increases the functionality. The machine with a broach is capable of sawing wider boards. The function is necessary for professionals who regularly use the tool in their work.

Combi miter saw

The crosscutting capabilities are combined here with the functions of a circular saw. It is clear that such a saw is not used for professional purposes. The tool is good for hobbyists who use it from time to time.

Miter saw manufacturers

The most technologically advanced and safe tools include: Hitachi, Makita, Metabo, Devolt, Bosch. The most robust units have a frame made of aluminum or magnesium alloy. These tools are lightweight and highly reliable. An example is Bosch GSM 10. Its weight is 15 kg.

Some Devolt models have a built-in XPS system that allows you to generate additional lighting, and therefore guarantee high accuracy in work. Metabo units are distinguished by a mechanism that regulates the tilt and rotation of the disc. Basically, the fasteners are provided above the work table.

How much does a miter saw cost

The cost of the unit depends on the manufacturer, as well as on the household or professional class. So, an inexpensive model JET JMS-10 will cost 3,680 rubles, and the price of a Festool tool with a KAPEX KS 120 EB broach reaches 120,780 rubles.

Miter Saw Rating

Having dealt with the design features and functionality of the model, as well as having studied the most popular manufacturers of miter tools, it remains to choose the appropriate unit. The rating of saws, which includes the most popular models, can help in this.

The best among the inexpensive tools are:

| Bosch PCM 7 | JET JMS-10 |

Best value for money is recognized.

Accuracy is important in construction. It is rather difficult to provide it without a target instrument. One of the specialized machines that can handle the task is the feed-through miter saw.

How to choose?

Today the construction market is represented by a huge assortment of miter saws, which differ not only in design, but also in technical performance. Therefore, it is difficult to make the right choice in favor of a particular model. Experts recommend to study its capabilities before purchasing a tool, as well as to determine the scope of planned work. If the equipment will be used only for domestic purposes or rarely, then the simplest modification, equipped with the usual type of functions, will do. For frequent and high-quality cutting of parts from various materials, you will need a professional saw, a versatile option that has a wide range of possibilities.

In addition, when choosing such a device, it is important to pay attention to several important parameters. Security. It is better to give preference to a tool in the design of which there is an option of blocking against accidental starting and a protective cover

Such products are much more expensive, but they completely eliminate injury when cutting.

It is better to give preference to a tool in the design of which there is an option of blocking against accidental starting and a protective cover. Such products are much more expensive, but they completely eliminate injury when cutting.

Security. It is better to give preference to a tool in the design of which there is an option of blocking against accidental starting and a protective cover. Such products are much more expensive, but they completely eliminate injury when cutting.

- Dimensions and weight. The saw must be ergonomic and mobile. This will ensure a comfortable working experience. Small and lightweight saws are well suited for cutting workpieces at height. Despite their size, they have high productivity and are in no way inferior to large end machines. Professional modifications are always available in size, since they have more power.

- Depth and width of the cut. For high-quality processing of workpieces, you should choose devices with a disc diameter of at least 20 cm. Moreover, the larger it is, the more convenient it will be to work with the equipment.

- Manufacturing material of the bed and the working unit. The service life of the saw depends on this. The right decision is considered to be the purchase of devices, the main parts of which are made of durable metal.

- The number of revolutions and power. Powerful saws are suitable for fast work, as they have a higher number of revolutions of the blade. For simple modifications, the power is equal to 1.6 kW, it is enough to carry out various works. Professional saws have a capacity of over 1.8 kW, but they require good electrical wiring.

- Duration of operation. Household tools are inferior in terms of use to professional ones.

- Manufacturer. Despite the fact that the equipment of different brands may have the same technical characteristics, they differ significantly from each other. This is due to the fact that manufacturers use various materials and assembly technologies in the manufacture of tools.

- Price. Low-cost options for products are usually designed for processing soft wood species. The more expensive models are equipped with universal blades that allow you to cut hard wood, metal or plastic.Therefore, it is recommended to buy inexpensive saws as training equipment and for simple work when installing fences or building houses.

It is also important to choose the right saw blades. These elements can differ in the bore, outer diameter and shape of the teeth.

The inner diameter and seat are usually 3 cm, while the outer diameter can vary from 21 to 30 mm. In addition, the discs are matched to the power of the motor. Large discs are not recommended for powerful models, since during processing, an inaccurate cut may result.

The larger the outer diameter, the more teeth it has, which reduces the load on them. Such diameters last longer. Discs with few teeth are typically used for rip cuts

When choosing discs for a saw, you need to pay attention to their markings, which are written on the surface. It indicates the direction of rotation of the cutting element, maximum rotation speed and compatibility with a particular model of the device.

Sliding miter saw: design features of the tool

The miter saw for wood has a fairly simple design, which includes a saw blade, a motor with a gearbox, a base and a handle with a start button. The saw motor can be collector or asynchronous. The first option carries out a greater number of revolutions, does not require regular maintenance, but only requires a periodic change of brushes. And the second is much quieter and more durable. In the classic design of the device, the motor is located to the right of the disc. However, there are improved models where it is placed on the back, which increases the viewing angle during cutting, thereby making it more convenient to work.

The rotation of the saw blade is carried out by the operation of the motor, which transfers the gear or belt drive through the gearbox. During operation in the first gear, the possibility of slipping of the product is excluded even at high engine loads. The second gear provides less noise and reduces disc vibration. And this has a positive effect on the quality of work and on the service life of the tool. However, in such devices, the belt quickly wears out, which can also come off during a sharp change in speed. There are more reliable and durable models that differ in direct transmission. However, their torque is significantly lower than its counterparts.

Crosscut saw device with broach

To expand the capabilities of a conventional miter saw, a broaching mechanism can be built into it. In this case, a regular saw turns into a wood miter saw. In such models, the functional module is installed on two rails that are parallel to each other. This design allows the saw blade to move freely during cutting, which allows you to cut wider workpieces.

The functional module is fixed to the base. This base is a movable round part that can be moved when the angle and stop are set. The miter saw frame is usually made of magnesium or aluminum alloys. The design of the saw includes a protective cover, which is put on the circle when the device is idle to avoid injury.

Stand, saw table and additional stops

One of the main and complex elements of a wood angle cutter is a saw table. On one side, a stand is attached to it, on the other side, a disc moves above the neck. On saws with a broach, the neck is much longer. At the end of the device there is a clamping handle, which serves to fix the table relative to the base, and a push lock used to quickly adjust the most common angles.

A miter saw table can be purchased from a specialist retailer or you can make your own.

There are angular scales on the table and stand, on which the angles of rotation and tilt are indicated. The table can be rotated in both directions from 0 to 45 degrees. And securely fixed in the selected direction using a special groove with a latch.

The stand can be immovable or tilted to the left by 45 degrees. A tool with a tilt of the rack to the right is extremely rare, which is explained by the need to significantly complicate the design of the saw. In addition to the basic graduations, several special ones can be provided, which make it possible to choose the optimal angle for cutting skirting boards and moldings.

For reliable fixation of workpieces of any size, built-in clamps and various stops are used. When working with long products, using folding or pull-out stands that are located on both sides of the bed, you can expand the dimensions of the base. These additional stops are usually included with the miter saw. They are represented by U-shaped steel rods bent up to the level of the table.

Clamps and stops are used to securely hold the material while the saw is running

There are more complex base designs with cast stands, which are fixed relative to the support with thumbscrews. Many manufacturers complete miter saws, the price of which will not be much higher than classic tools, with separate stands or special tables. They can be located at some distance from the tool, depending on the length of the products.

Advantages and disadvantages

The high appraisal of professionals and the growing consumer demand for combination miter saws are due to a number of important advantages of these devices.

- The device incorporates the best performance characteristics of both tools: from the miter saw, it inherited the high accuracy of measuring workpieces, and from the circular saw - an absolutely smooth and even cutting surface.

- The ability to create slices of arbitrary configuration contributes to the implementation of any, even very complex technical tasks.

- The combination of two tools in one device at once eliminates the need to purchase each of them separately. This allows for significant budget savings and more efficient use of space in the workshop or garage.

- The versatility of the devices allows you to install saw blades of various purposes in them, which makes it possible to work with almost any material.

- The ability to perform not only transverse, but also longitudinal cuts allows you to trim the edge of lumber and engage in the production of narrow blanks.

- Despite its versatility, the tool is quite mobile and can be easily moved to the desired location.

Like any complex electromechanical device, combination saws have a number of disadvantages. These include the rather high price of the device, which, however, is still less than the cost of two separate saws. Also, many professionals note the small, unlike traditional miter saws, the cutting depth, which does not allow them to be used for cutting thick material.

The device and functionality of the miter saw

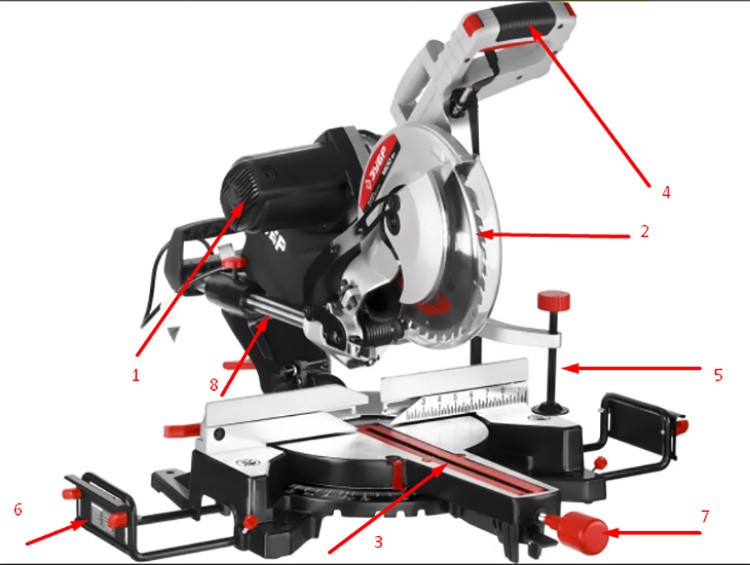

The trimming device is easy to understand from the figure, which shows the main components of the tool. Everything else is just add-ons that do not change the principle of operation, but only improve functionality and usability.

1. Handle with power button. 2. Saw blade 3. Protective cover. 4. Clamp for fixing the workpiece.

5. Stops for the workpiece. 6. Mechanism for fixing the table at a given angle. 7. Horizontal angle adjustment scale 8. Table.

9. Vertical angle adjustment mechanism. 10. Dust collector. 11. Engine 12. Carrying handle.

The main elements of the miter saw are an electric motor and a saw blade made of high quality, ultra-strong steel.The motor, the saw blade and the gearbox connecting them make up a functional block, and a handle with a toggle switch is also located here.

The entire block is attached to the base - the bed, on which the workpiece to be sawn is placed. On the base are fixed the turntable, which moves when the cutting angle is set, and the stop. The beds of relatively expensive devices are made of durable and lightweight aluminum or magnesium alloys, which provides not only the reliability of the base, but also the mobility of the entire tool due to weight reduction.

The functional unit is connected to the bed via a pivot arm using a spring-loaded hinge. The swing arm is called a pendulum, and the miter saws of this type are called pendulum saws.

The pendulum provides movement of the working module. To perform a cut, the lever must be lowered down, "drowning" the saw blade in a stationary workpiece (for unobstructed sawing, there is a slot in the swing circle of the bed). This is the simplest version of a miter saw. As a rule, all modern models are equipped with a mechanism that ensures the rotation of the desktop, along with all mechanisms, in a horizontal plane.

Thus, the guides and table elements remain stationary, and the tool itself changes its position in the horizontal plane. The use of such a tool gives more possibilities for facing.

The saws of the combined type have another hinge that allows the lever to rotate about the vertical axis (that is, with such saws, the cutting angle can be changed in two planes). Often, rotation around the horizontal axis is allowed only in one direction - opposite to the electric drive.

But there are models that allow you to tilt in both directions.

Such technical solutions greatly expand the list of functionality of the tool. Cutting inclined in relation to the vertical allows you to face workpieces whose height is greater than the active radius of the disc.

The cutting width of a miter saw is relatively small, especially when working at an angle or tilt. For example, an average pendulum saw with a 10-inch disc at a right angle will cut a 95 × 95 mm bar or a 69 × 135 mm board (setting any other angles reduces the allowable workpiece size). In other words, the miter saw is not suitable not only for ripping, but also for cross-cutting wide workpieces.

To increase the cutting width, the saw is equipped with a traction function. The working block at the trimming with this function moves not only around the hinge axis, but also along the cutting line along the guide rods, due to which the maximum kerf width at an angle of 90 ° increases from 80-180 mm to 280-340 mm. Such tools are called broaching miter saws or horizontal motion saws.

At the same time, the mechanisms that implement the movement of the saw along the workpiece differ depending on the manufacturer and model of the device.

Rating of miter saws without broach

It is far from always that carpentry workshops process such large parts that it will be necessary to broach the head of a miter saw, and this mechanism significantly increases the overall cost of the device. The difference in price can be from one hundred to two hundred percent, and there are no differences in working with small details. An important advantage when choosing may be the compactness of the device - it simply requires less space for installation, plus it weighs ten to one and a half kilograms less than analogs with a broach.

If these considerations are important, then the rating of models without a feed mechanism will help to determine which miter saw is better.

| Dewalt DW 713 | Makita LS 1040 F | Metabo KS 216 M Lasercut | |

| Rim diameter, mm | 30 | 30 | 30 |

| Disc diameter, mm | 250 | 260 | 216 |

| Power, W | 1600 | 1650 | 1100 |

| Saw ability to tilt left / right | 48 / 3 | 45 / — | 47 / 2 |

| Table adjustment to the left / right, degrees | 50 / 50 | 45 / 45 | 47 / 47 |

| Max depth of cut at an angle of 45 °, mm | 89 | 67 | 45 |

| Max depth of cut at an angle of 90 °, mm | 89 | 93 | 60 |

| Max width of a cut at an angle of 90 °, mm | 162 | 95 | 120 |

| Max width of a cut at an angle of 45 °, mm | 114 | 93 | 80 |

| Speed control | |||

| Number of revolutions, rpm | 5000 | 4600 | 5000 |

| Cutting depth adjustment | |||

| Backlight | |||

| Laser | |||

| Smooth start | |||

| System for maintaining constant speed under load | |||

| Weight, kg | 13.6 | 11 | 9.4 |

Dewalt DW 713

+ Pros Dewalt DW 713

- high-quality components and assembly;

- fine tuning out of the box;

- high ergonomics and overall reliability of the device;

- Convenient design of clamps, which set the angles of the cuts;

- the angle scale is made by stamping on an adjustable plate - if it is necessary to readjust, then this is done by unscrewing one mounting bolt;

- a small amount of dust, provided that a good vacuum cleaner is connected;

- large work surface;

- ready-made grooves for frequently used corners.

- engine power allows you to work with various materials: wood, plastic, aluminum, polyurethane.

- Cons Dewalt DW 713

- there is no smooth start - when starting, the handle pulls up a little;

- the complexity of the search for components;

- the disadvantage not of this particular model, but of all Dewalt products, is the small number of service centers.

Makita LS 1040 F

+ Pros of Makita LS 1040 F

- Rigid construction to ensure accurate cuts

- well-matched components;

- due to the presence of a soft start, the saw remains stable when starting and braking;

- the weight of the device is well chosen - it is enough for the saw to be stable, but does not cause discomfort when moving to another place;

- if it is necessary to replace the brushes, a quick access system is provided;

- low noise level.

- Cons of Makita LS 1040 F

- the starting and braking mechanisms do not always work out correctly - for treatment it is necessary to sort out all the electrical equipment;

- frequent complaints about the blown fuse of the backlight lamp, and in rare cases the lamps themselves;

Metabo KS 216 M Lasercut

+ Pros of Metabo KS 216 M Lasercut

- the saw is designed for maximum ease of use - all settings are visible, easily clamped and released;

- one-piece body for increased strength;

- laser illumination is located in the least dusty place, which allows it to "hold out" longer without cleaning;

- light weight makes it easy to carry the saw from place to place;

- well-calculated ergonomics of the device.

- Cons of Metabo KS 216 M Lasercut

- frequent complaints about the rapid failure of the laser and backlight;

- light weight is good for transportation, but because of this, the rigidity of fastening the workpiece suffers;

- during transportation, there is a high probability of "flying off" settings - it is advisable to recheck them after transportation;

- for good operation of the device, it is advisable to sort it out and lubricate it after purchase (of course, without breaking the seals).