Varieties by purpose

Now some historical facts. Mankind has invented axes since ancient times. However, the first tools were awkward, extremely heavy and short-lived. People could not do without them, since they had to build housing, cut down tools and hunt wild animals. And wild animals had to be driven away from prey manually.

The main part of such a device was an iron chopper, which was mounted on a well-hewn club. Over time, the axes were divided according to their functional purpose. The heaviest models were transformed into powerful military weapons, and due to their high cutting power and low cost, they became the main weapon of the militia. Lighter models began to be used for economic purposes, and we will dwell on them in more detail.

Before talking about what types of axes exist, it is necessary to note the main parameters that distinguish them from each other, namely:

- mass of the tool;

- blade type;

- the shape and quality of the hatchet;

- nozzle method.

Let's start with the main thing - weight. The smallest tool threshold corresponds to 900 g. Of course, there are axes that weigh less, but their functionality is not clear - in most cases these are not axes, but simply tourist hatchets, which can be used to cut thin branches and sharpen stakes under a tent. As a rule, they are optimal for day trips, but not suitable for long hikes.

The weight of a reliable ax should vary from 900 to 1600 g. In this case, it is possible to chop off medium-sized branches, and it is much easier to wield a tool of this mass, since the lumberjack feels how it is "fixed" in his hand. Similar axes are used in low-rise residential construction and decoration.

Let's dwell on the most popular types of axes.

Economic

A utility ax weighs less than a kilogram. It is distinguished by a straight, sharp cutting edge - this tool is used for finishing various wooden blanks and trimming wood. He does not need to cut solid trunks, therefore he does not need a massive butt. These axes are quite sharp, they sharpen almost like a razor.

Plotnitsky

This ax is considered a versatile woodworking tool. It is distinguished by a thin, well-sharpened blade and low weight, thanks to which, with the help of such a tool, you can perform the widest range of tasks, including cutting grooves and adjusting the parameters of the deck to the required dimensions. Such an ax has the shape of a straight, slightly elongated skirt, the mass is 1200-1300 grams, and the blade sharpening angle is 20-30 degrees.

Angles of 30 degrees are considered more versatile, as they allow you to chop non-solid wood and trim wood parts. A sharper angle of 20 degrees brings it closer to an economic one, and a more obtuse one - to a cleaver.

Cleavers are heavy, massive tools with a fairly wide blade, they are needed for splitting logs. The metal part of this gun is distinguished by a rather blunt sharpening, the angle of descents is about 30 degrees. The weight varies from 2 to 3 kg, less often there are instruments weighing 5 kg. The handle is long - from 80 cm and more.

All axes produced by modern domestic industry are classified into two large groups:

-

with a straight blade;

-

with rounded.

In the old days, the manufacture of such an instrument in Russia was mainly carried out by blacksmiths. Today, products of this type are, of course, produced mainly by the industrial flow method.However, even nowadays, you can find hand-made axes on sale, which are distinguished by an attractive design and, at the same time, are quite convenient to use.

Axes are used everywhere in Russia as a quality household tool. Their varieties are as follows:

-

cleavers;

-

carpentry axes;

-

intended for felling forests;

-

hunting;

-

tourist;

-

kitchen.

All these types of axes are on sale today. And their purpose can be easily determined by the size, as well as by the shape of the hatchet.

Making an ax with your own hands

If you are interested in the question of how to make an ax, then remember that you will not be able to make a blade yourself from scratch. You can only give a regular blade the desired shape by processing with a grinder or emery wheel.

But the hatchet is quite capable of making. For this you need:

- pick up a workpiece with a diameter of more than 120 mm and a length of 200 mm more than the planned handle;

- dry for several months at a temperature of 22-24 degrees and a humidity of 15%;

- using an ax or a large knife, remove the excess part of the wood in accordance with the outlined contour;

- carry out processing with a chisel and a hammer.

Now it is important to learn how to plant the ax correctly. Do this with gauze and epoxy resin.

The wedge provides the best strength. After that, polishing is performed, the handle is varnished. Sharpening is done on a machine or manually.

The ax is a useful helper in the country, and in the hike and when working in the forest. It is only necessary to choose the right model, focusing on the required characteristics and quality of manufacture of a particular specimen.

1 GARDENA 2800S

The best choice

Country: Germany

Average price: 4,060 rubles.

Rating (2019): 4.9

It would seem, as usual, in fact, an ax can cost 4 thousand rubles. For which the manufacturer takes that kind of money. But look at it more closely, and you will even visually determine all the advantages of this tool. First, the most comfortable and ergonomic handle. It is made of durable plastic with steel reinforcement. Secondly, high-alloy steel, which practically does not dull and easily withstands blows from a sledgehammer. And thirdly, the fastening of the elements. The steel headboard is poured into the handle, and it will not be easy to separate them even with a strong desire.

These and many other parameters, such as balanced weight, fully justify the seemingly high cost of the tool. Buying such a cleaver, you get a durable and durable product that will not fall apart after several uses. Well, in the end, visual appeal. Yes, the ax can hardly be called a beautiful tool. But take another look at the photo of the GARDENA 2800S. How is it? Have you changed your mind?

Attention! The above information is not a buying guide. For any advice, you should contact the specialists!

About methods of work

When a log is trimmed to the right, the worker's right / working hand should be in front of the left hand on the ax, and if the log is amused on the left, then the left hand should be in front of the right hand. If trimming the logs on the right is more or less a familiar occupation, then the processing of the log on the left will already require much more practice, because in this case you will have to master the skills of working with the left hand.

So, in order for the edging of the log, which is being processed, to turn out to be a plane without "waves", the craftsmen do the following. The log is fixed on the chopping blocks with staples. And when the process of lacing is completed at the end of the log, a vertical line is drawn with the help of a plumb line, along which embossing begins. Periodically, the coincidence of the edge at the end with the rest of the edge zones is checked as we move in the direction along the log. There is another technique - for beginners, periodically control the verticality of the edge with a plumb line.

There is one more good tip for those who like to work with an ax.A person who works with an ax must work alone, that is, not change him.

And factories - manufacturers of axes, it would be desirable, would release their products sharpened, taking into account certain requirements of practice.

Preparatory stage

Each work, even the simplest one, consists of several stages. Ax assembly is no exception. In order to get a ready-to-use tool, you must:

- pick up an ax;

- fit it correctly under the eyelet;

- make the required number of cuts;

- prepare wedges, wood or metal;

- plant an ax;

- wedge the ax in one of the ways.

So, before planting an ax on a hatchet, the latter must be picked up and purchased. In terms of material, professional carpenters and lumberjacks recommend well-dried birch.

This material is quite common, and also has properties that create convenience when working with the tool. Harder woods work well for decorative options, but not for workers. The most convenient form of the ax, which gives the least return to the hands, has long been determined. Ideally, the CD axis (fig. 1) intersects with the gripping center P or there is a slight backward and upward offset. In the other two cases, the impact has to make unnatural movements to compensate for the recoil.

Fitting the ax to the eyelet means cutting it to the required shape. For this, some kind of woodworking tool will come in handy, for example, another ax, a sharp knife, and the like. And here there is one point that must be taken into account.

The axis of the ax blade and the longitudinal axis of the ax must be in the same plane. Simply put, the blade needs to be aligned with the ax.

A few words about the eyelet. It can be either straight or conical in a certain part of the ax. The conical shape of the lug is considered more suitable for good attachment. Before cutting the hatchet, you need to carefully adjust the shape.

It was the turn of the cuts on the upper end of the ax. Their number is determined by the selected wedging method, of which there are many. It can be only one longitudinal groove, it can be two or three lateral, one longitudinal.

Many professionals consider one longitudinal and four lateral. This can be seen in photo 1, but these are not all options. You can select both a slight offset of the cuts and a split rip cut. Many people decide this question based on their own ideas about the mechanical properties of such compounds.

Figure 2. Diagram of an ax attachment on a hatchet.

Pay particular attention to the depth and width of the cuts. The depth should be such that the resulting groove is completely hidden in the eyelet

Otherwise, the handle may split when wedging or working. The kerf must correspond to the thickness of the wedges. The wedge should not enter the cut too easily, then it will not make any sense, but it should not enter too tightly, then it will not be possible to drive it inside.

Wooden or metal wedges (fig. 2) you can buy or make yourself. Both methods work equally well. They are inexpensive, but if there is nowhere to buy, you can simply cut them out of well-dried birch. The shape and dimensions must correspond to the parameters of the cuts. A metal wedge can be made from a fairly hard sheet, for example, from an unnecessary shovel. (fig. 2)

If the preparatory stage is passed correctly, then no special problems should arise.

- The main types of axes

- Optimal material for an ax

- Basic methods of ruling

- Ax Care: Practical Tips

For chopping firewood, building a log house, finishing boards - the versatility of the ax is amazing. It is quite understandable that every craftsman wants to have a good ax so that it does not break and dull.If you know how to put an ax on a hatchet, in what conditions to store it, it is possible to extend the service life of this tool.

Axes characteristics

Before we start talking about the varieties of axes, it should be noted those characteristics that all of them are distinguished from each other.

So, when choosing an ax, you should pay attention to the following characteristics: - the shape of the ax blade;

- the shape of the ax blade;

- quality, as well as the shape of the handle;

- the quality, as well as the method of packing.

So, let's start with the simplest - weight

The minimum weight threshold that you should pay attention to when choosing an ax is 900 g. That is, axes that have a weight less than this mark are necessary for completely incomprehensible purposes

As a rule, such light weight is inherent in tourist axes, so to speak, hatchets. But, in fact, even in a tourist vacation, such a light tool will not be enough. With the help of such a hatchet, it will be possible only to sharpen the stakes under the tent. Chopping wood for them will certainly not work.

Therefore, the optimal weight of an ax is in the range from 900 to 1700 g. With an ax of this weight it will be very comfortable to chop wood of medium thickness, working with such a weight is much more comfortable, as it feels like the tool is in the hand. In addition, such an ax is perfect for work in construction, when processing wood materials. If you need an ax to chop large wood with it, use the Weighted Splitting Ax. The weight of such an ax, as a rule, is in the order of 2200-2500 g, and such a tool has an elongated ax to increase the impact force.

Next, regarding the shape of the blade. The ax is a ubiquitous tool - it was used and is used both in Canada or the United States, and in Russia or African countries. But, depending on this fact, the axes received a different shape of the blade and hatchet. Actually, let's talk about the blade. The most common type of ax blade is a carpenter's ax - a standard, issued in accordance with GOST, an ax produced since Soviet times. It is convenient to work with such an ax in the construction industry, in carpentry, and so on. The shape of the blade is made in such a way that it will be convenient to work with boards, small logs and other wooden blanks with this ax.

But, to put it mildly, a carpenter's ax does not fit in a "forest". That is, it will be difficult to cut down a branch or a tree trunk with it, especially if it is a matter of dense wood species. Therefore, for such cases, there are several more varieties of ax blades. For example, the "Finnish" shaped blade is very popular. This type of ax is distinguished by a rounded blade, as well as a cut on the bottom. The rounded shape of the blade will allow the lumberjack not only to chop wood, but also to chop it. Moreover, this blade has an interesting sharpening, as a result of which it is convenient to perform various types of work with such an ax.

The taiga ax is another type of ax blade, which differs from other types, first of all, in that it is convenient to cut dense wood with such an ax. The fact is that the blade of this ax, in relation to the ax handle, is located at a sharper angle than the Finnish or even more so, the carpenter's ax. This makes ax blows more effective, since the top corner of the blade is the first to hit the wood. Also, the ax called "Deer" is very similar. It has practically the same shape, but it has a lower mass, about 1 kg, versus 1.5 kg of the Taezhny ax.

Universal axes

Cold Steel Trail Boss Ax

Cold Steel Trail Boss Ax

Cold Steel Trail Boss Ax

Trail Boss is a true American tomahawk. By the way, he managed to gain an impeccable reputation in states such as Vermont, Mississippi, New Hampshire and other wooded areas. And not only in the USA: Canada and Russia welcome this brand with a bang.

On the Rockwell scale, the Cold Steel Trail Boss Ax has a very good hardness of 54-56 HRC.Other Boss parameters are as follows:

- Length - 660 mm

- Weight - 1.115 kg

The ax is made from a single piece of walnut. The handle is very comfortable to hold due to its ergonomic design. According to field testing of the renowned YouTube channel Preparedmind101, the blade of the tool is as sharp as a new razor. In addition, you need to chop more than one hundred logs before it gets a little dull.

Since the Trail Boss is versatile, it is suitable for chopping wood, chopping wood, butchering meat, building / gardening, and even camping. The butt is quite durable, so if necessary, the Boss is not forbidden to use it as an impromptu hammer.

PROS:

- Solid forged steel blade

- Ergonomic handle

- Natural walnut

- Doesn't dull for a long time

- Can be used as a hammer

- Famous brand

MINUSES:

- Price: 3 460 rubles

- Now produced not in the USA, but in the PRC

The Cold Steel Trail Boss (Review)

Ax for all occasions | TOP 10 Best: Rating + Reviews

Fiskars X10-S

Fiskars X10-S

Fiskars X10-S

The Finns, like the Swedes, know their business well: the Fiskars company has been forging axes and other truly male tools since 1649!

The dimensions of the X10 are 44.3 cm and 980 grams. Which is not too bad: at this length, the physics of levers comes into play - with a longer length, less effort is needed. And if we add almost a kilogram weight, then we get a universal "soldier": prepare a woodpile, chop a stump, carpentry / joiner - Fiskars can do everything. Except, perhaps, meat carcasses and bones.

The blade is manufactured from double hardened high carbon steel. It is additionally protected by an anti-friction coating: the ax enters the log clearly, but softly - as if it were laying. At the same time, the bad habit of getting stuck in a tree was not noticed behind him.

Also, the tool is not afraid of water due to anti-corrosion: this is insurance in case it is forgotten in the open air during the rainy / snowy season.

The handle is made of fiberglass reinforced polyamide. And again it combines FiberComp and SoftGrip - technologies that are responsible for shock absorption and comfortable use. At the end of the handle there is a kind of hilt that will not allow the ax to slip out and fly away in an unknown direction.

A trifle, but nice: the X10 comes with a fixed holster-cover.

PROS:

- Convenient to hold

- Low energy consumption

- Hardened steel blade

- Rust immunity

- Hanging hole

- The handle holds the tractor wheel

- Finnish quality

MINUSES:

- Price from 2 190 RUR

- You can only work with wood

AXES: FISKARS X10 / TOURING y8 / LARGE # 2 y7 / COMPARISON / TEST

Ax for all occasions | TOP 10 Best: Rating + Reviews

7.9

Total Score

10 best axes for all occasions

Matrix 21816

7

Fiskars X11-S

8.5

Bahco 494-600

8

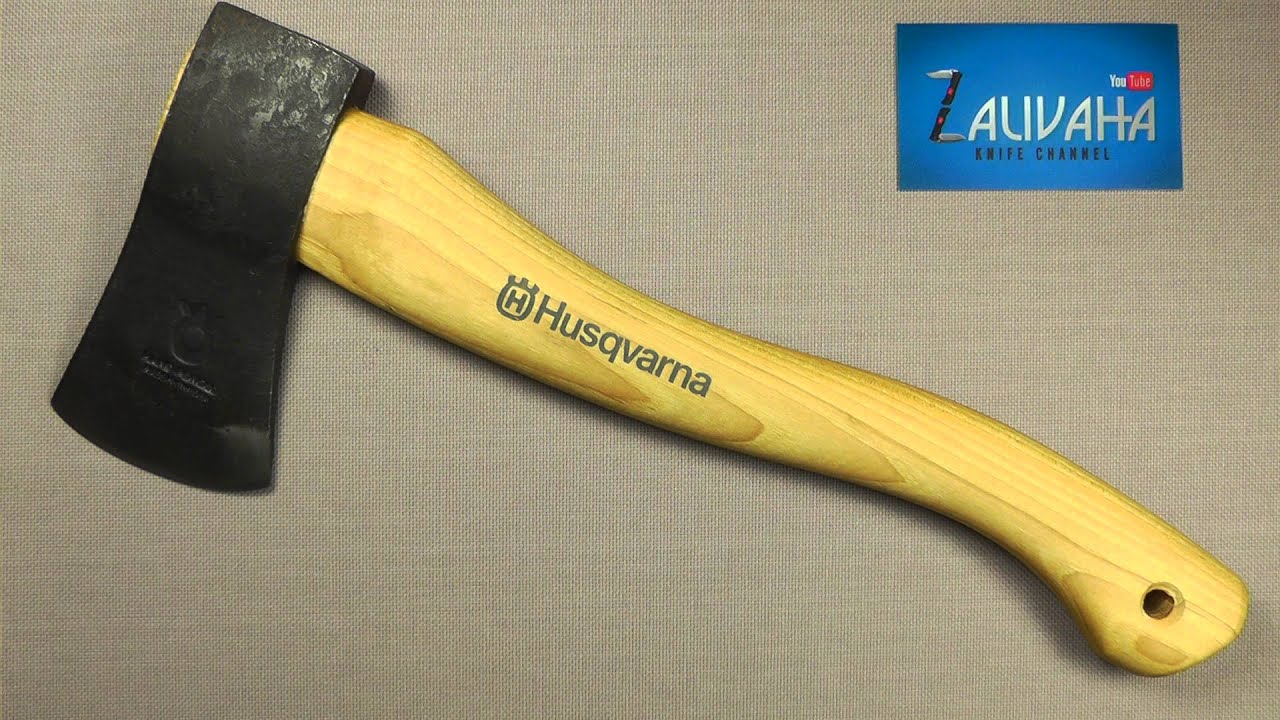

Husqvarna sledge ax

9

Zubr 20643-06

7

Gardena 900B

8

Izhstal 030904-120

7

Husqvarna 5769264-01

8.5

Cold Steel Trail Boss Ax

8

Fiskars X10-S

8

The best hilt for a touring ax

Several types of steel are used for the production of axes, but the 9XC brand is considered the best. Before making a tool from it, the steel is subjected to high-temperature treatment twice, which reduces the level of deformation during broaching.

During the forging process, the workpiece is stretched and the cross-section is reduced - this is how the metal gets the necessary ductility and strength. In simpler terms, the ax becomes capable of withstanding a blow against a tree, while maintaining its integrity.

The 9XC grade contains 0.9% carbon, chromium - 1.5% and the same amount of silicon. Carbon is responsible for strength, chromium adds hardness to the alloy. The latter also protects against corrosion. Silicon is responsible for rust resistance.

Carpentry axes have a very comfortable and comfortable handle, while the thickness of the blade is of an average size. However, many skilled carpenters will only sharpen the blade at their own discretion.

In this case, the weight of the ax is of no small importance, this should also be taken into account, since carpentry work has its own specifics and features. Therefore, carpentry axes are an indispensable tool for various carpentry jobs.

Pros:

- has a high degree of balance.

- has a comfortable handle.

- it is allowed to independently sharpen the blade at your discretion.

- has a special coating on the blade that prevents rubbing with wood.

This ax model is made by forging, and this work is usually done by a skilled craftsman by hand. For the manufacture of a forged ax, only very high quality steel is used, since it depends on how high-quality the product will be.

Pros:

- such products are manufactured individually.

- have a comfortable and long handle.

- made of high quality materials, its blade is made of hardened steel; it is universal, such an ax can be used to chop wood, cut wood, or cut carcasses.

- has a long service life.

- has little weight.

Minus: since this is handmade, the cost of such a product will be very high.

Therefore, if you have any questions or doubts about choosing an ax, you can familiarize yourself with a photo of a good ax.

Of course, we can say that there is nothing complicated and incomprehensible in choosing an ax. However, this is not at all the case. The fact is that when choosing an ax, you need to decide what you need an ax for, and for what purposes?

Next, you need to turn your attention to the steel grade and the sharpening of the blade. After that, you can choose a handle for yourself

Which should be comfortable and comfortable and pleasant to hold.

There is often debate about which ax is better to take into the forest: a hunting one or a tourist one? Many people do not know that there is no clear division of axes into such categories. An ax that can be used to build a hunting shed or ambush is not suitable for skinning. If you sharpen it to a razor sharpness, chopping logs with it means immediately ruining the sharpening.

The ideal ax handle is made from birch. The tree must be dry (preferably the lower part of the trunk). The birch handle is lightweight and durable. With proper operation, it will last at least five years.

The shape of the handle should be straight, at the end a bend or thickening is desirable, for better fixation of the ax in the hand. Many people choose beautiful lacquered hatchets, which is highly undesirable. Such a handle will easily slip out of your hands and fly in an unknown direction.

The best mass-produced axes, which have perfectly proven themselves in work, are produced by Fiskars. Its axes are quite expensive, but their range is wide enough and everyone can choose a suitable ax by weight.

Quite good axes are made by MORA. True, this manufacturer does not differ in the variety of models.

Today, the industry produces many different types of axes. You can choose a good copy at specialized exhibitions, where you can also order a handmade ax from blacksmiths. Choose an ax in accordance with your tasks, and it will not let you down in any situation.

Special models

To solve some problems, separate variants of axes have been created. Let's consider them.

For felling wood

The axes used for felling are usually the longest - the minimum length of the ax is 90 cm, and the weight of the tool reaches 3-3.5 kg. Such a long stick allows for the required swing and impact force parameters, which makes wood harvesting work faster. It should be noted that it is quite difficult to work with such an ax, therefore this occupation is associated with great physical efforts of lumberjacks.

For chopping meat

Axes with a fairly wide and perfectly straight blade are most suitable for chopping meat. Usually, it is sharpened at an angle that prevents the cutting edge from breaking quickly with constant contact with hard, hard bones. The handle of this ax is usually short and extends down to the cutting edge, which is why the device allows very precise cutting blows.

Bilateral

Double-sided axes have found their use in chopping wood blanks, preparing firewood and performing a variety of installation work. The working part of such tools has two blades, in most cases they are made of forged steel using the double heat treatment method. The handle is made of hardwood, most often from hazel.

Fireman

Axes are widely used in the work of rescue services, in particular, firefighters use two types of axes - belt and assault. There is a rather sharp peg on the butt of the belt tool, which is necessary for knocking down locks and knocking out double-glazed windows. In addition, this hook can be driven into various surfaces to keep it in the wall or on the roof. Usually, fire axes are painted black and red, although yellow inserts are often seen. The handle is covered with rubberized pads that protect the hands from burns. Unlike belt models, assault models are much larger in size, but their shape is very similar.

The butt often has a hook, or it can be flat, like a sledgehammer. This type of weapon is a mandatory component of any fire shield, which, according to safety regulations, must be located in all public places.

Marching

The tourist ax is called a multitool and has a wide variety of models. Their distinctive feature is their low weight, which is not surprising, given that the instrument has to be dragged on the back for many hours. The handle of such an ax usually becomes a pretty convenient storage for various small things that are needed on any hike. With the help of a tourist ax, different branches are cut, small trees are dumped and even stones are split to create a hearth. They are usually equipped with covers that protect a person from injury while carrying the instrument.

They are fairly compact and lightweight devices that are necessary for cutting into the ice, if there is an ascent to the snow-capped peaks. This climbing equipment is made double-sided, while one part resembles a well-sharpened hook, and instead of a butt, a sharp blade is made, placed perpendicular to the handle - this structure is optimal for forming a depression in the ice. An army ax can also come in handy on a hike. It is widely used for preparing logs for a hearth, digging trenches, hammering tent pegs, and also as a defense weapon.

For information on how to choose the right ax, see the video below.

Peculiarities

The taiga ax is used for various tasks.

- Felling of trees - this includes logging, sanitary felling, and felling at the sawmill. The taiga ax successfully copes with all these functions.

- Working with large logs - this refers to rough work, such as delimbing, removing dense bark, making grooves and some other types of work.

- For survival - such a tool can be used by hunters to quickly create kulemoks, as well as traps for wild animals.

- Erection of huts, various flooring or “quick cooking” huts - it is obvious that it is impossible to build a hut without an ax. At the same time, the use of the taiga version allows you to carry out all the necessary work 3-4 times faster than using the carpentry.