Helpful hints and tips

Please note that the handle should be made so that its section has a characteristic oval shape. Only by observing this condition, it will be possible to hold it successfully, without straining the hand too much. In this case, blows with an ax will be more accurate and light. It is recommended to make wood blanks for creating a hatchet in late autumn. It is during this period that the movement of juices is minimized (practically stops), which means that the tree becomes, as it were, dehydrated.

Many inexperienced craftsmen neglect to dry wood for the construction of an ax. As a result, this ends with the handle changing in size, and the metal part with the butt on it holds very poorly. It is permissible to refer to undried material only in special situations when the handle needs to be built urgently, and this spare part is done as a temporary one.

When making a new hatchet yourself, you need to draw up a detailed drawing / template of the future tool. If you have a very handy old ax in your arsenal, then you can remove all parameters from it. It will be much easier and more convenient. Take your time to turn the cutting edge of the tool. First you need to make sure that the metal is sufficiently hard. If it turns out to be too soft, then it will need to be additionally hardened under the influence of high temperatures.

It is very important to use a ready-made ax (both homemade and purchased in a store) correctly. Experienced craftsmen strongly do not recommend trying to cut various metal parts with such a device.

Even if you plan to chop wood, it is best to make sure there are no hard particles inside that could harm the tool.

It is strongly discouraged to throw the finished tool on hard surfaces, especially from a great height. It is not recommended to leave the ax outdoors. Precipitation or aggressive sunlight can negatively affect the quality of the wooden part. Keep such a tool in a dark and dry place. Only under this condition will the ax serve you for many years.

If the hatchet goes too easily into the eyelet, then this may indicate that during the work the master made a serious mistake somewhere (most likely in the calculations). An incorrectly prepared template often leads to such a problem. In such a situation, even another installed wedge will not change anything.

That is why it is so important to take the time to do all the calculations and make the template correctly

Do not forget to process the wood ax at the end of all work. Please note that the processing of this part must be carried out in several approaches. Each new protective layer should be applied only after the previous one has been completely absorbed. This is the only way to reliably protect the wood from rotting and destruction. Stock up on enough wood to craft a hatchet. You don’t need to make only one workpiece - it’s better to build several pieces. This is necessary because during the work, some of them may not work out and be rejected. There must always be at least one more piece in stock.

To make an ax, you cannot use a wooden block that has a large number of knots. Because of them, noticeable cracks can form on the material. Over time, the branches begin to crack, and all the material loses its strength. It is not difficult to make an ax on your own.If you doubt your abilities, are afraid to make mistakes and translate natural material, then it is better to refuse experiments. Buy a ready-made model or have an experienced craftsman make a good tool for you.

For information on how to make an ax with your own hands, see the next video.

Photos of the best cleavers

We also recommend viewing:

- How to choose a set of wrenches

- How to use the miter box

- Ratchet socket set

- How to make a pipe bender with your own hands

- Overview of modern pipe tongs

- Articulated knob

- How to make a sledgehammer with your own hands

- Types of dies for threading

- Nail gun

- How to choose a chisel

- How to choose a file

- Steel pipe cutter

- How to choose a hacksaw for metal

- How to choose a hacksaw for wood

- Hex keys

- How to choose good wire cutters

- Types of screwdrivers and their purpose

- Plumbing cable for sewer cleaning

- Types of hammers

- How to choose a good hand planer

- Differences between pliers and pliers

- Instructions on how to make an ax with your own hands

- Tapping taps

- Modern side cutters

- How to choose good round nose pliers

- Instructions on how to choose and use a dry powder fire extinguisher

- How to choose an adjustable wrench

Help the site, share on social networks

Classification of axes

In practice, many types of axes are used, which are designed to perform work with wood. They can be conditionally divided into three types:

- cleavers;

- for logging;

- construction or universal.

Accordingly, there are various versions designed to solve certain problems, for example, a firefighter is equipped with a pickaxe, with which you can pull beams and other structures out of the fire.

In addition to this classification, another one can be proposed - by the size of the blade, more precisely, by the size of the butt:

- wide;

- average;

- narrow.

The first ones are used for logging, the second ones solve many problems in construction and in everyday life, the third ones have found their application in carpentry. These tools are also distinguished by the length of the ax. That is, the larger it is, the stronger the swing and, accordingly, the blow. There is a difference between the width and shape of the blade. That is, if the tool has a straight sharpening, then it is designed to perform chopping blows. If the cutting part has a curved sharpening, then they can both chop and cut.

For the manufacture of hatchets, steel, wood, and polymer materials are used. But as experience shows, nothing better than a handle made of wood (birch) has not yet been invented. Other materials do not always cope with vibration damping.

The list of existing and widely used tools can be listed for quite a long time, we can mention such as:

- Tourist, it has small overall and weight characteristics, its weight is slightly more than half a kilogram, and its length is 350 mm. With its help, you can prepare dead wood, perform simple work, for example, put together a ladder or a raft.

- Hunting. It is used for cutting dead wood and butchering carcasses.

- Scandinavian. This tool is intended for professional woodcutters. It weighs 1.2 kg and is 640 mm long.

- Sledgehammer cleaver. Its use allows you to split any log.

GOST 18578-89 normalizes the main dimensions of the product, limit tolerances, parameters of the roughness of the cutting part. According to the requirements of this document, each product must be marked. This GOST defines the procedure for acceptance and shipment of finished products to the consumer.

Correct ax blade sharpening technology

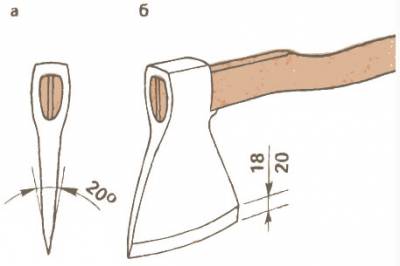

A hand-made ax blade will perform its function only if the angle of sharpening and the width of the chamfer are correctly maintained.

The sharpening angle affects the comfort of the ax and the degree of its functionality. If you plan to cut wet, freshly cut wood, the sharpening angle should be approximately 20 °. If dry trees, then 25-30 °.

The width of the chamfer is also very important, but in ready-made purchased blades, it is not possible for an ordinary home craftsman to change it. However, there is a way out: to grind off the ax blade with a double "descent". The first angle is milled at 15 °, the second at 25 ° (average value).

Sharpening of an ax: a - sharpening angle, b - chamfer width (should exceed the thickness of the blade by 2.5-3 times)

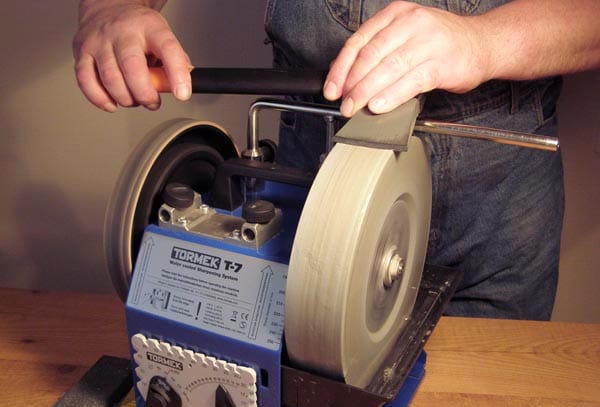

The ax is sharpened on an electric grinder. At the same time, make sure that the blade does not overheat too much - this leads to a deterioration in hardness near the cutting edge. Therefore, when starting the sharpening process, you should place a container with water next to the sharpener to cool the metal. It is advisable to immerse the blade in water after each pass along the circle.

It is necessary to minimize the beating of the grinding wheel by regularly straightening with special cutters. When sharpening, hold the ax so that the blade is directed towards the rotation of the electric sharpener. The butt is kept at 45 °. The blade is sharpened by smoothly moving the ax along the circle. The sharpening angle is carefully sharpened, the chamfer is ground.

Sharpening an ax on an electric grinder allows you to quickly get a sharp blade

The final sharpening of the ax (grinding) is carried out using a sharpening bar regularly moistened with water. Instead of a block, you can use a piece of plywood covered with sandpaper. Remember that working with a sharp ax is a pleasure, while a blunt tool will force you to exert more effort, leading to quick fatigue.

The significance of the handle

The optimal length of the ax can be selected based on the growth parameters of the master and the force of the blow. The strength, in turn, directly depends on the length, so when working with a large ax, it will be easier to chop logs of firewood.

Before making a choice, it is worth deciding on the desired result:

- heavy version of the tool (total weight 1kg-1.4kg., handle length from 55 to 65 cm.);

- lightweight version (weight 0.8kg-1kg., with a length of 40 to 60 cm.).

The quality of the wood from which the hatchet will be made is of great importance. Not every type of wood is suitable for manufacturing. Often, birch is used for this purpose (parts located near the roots or stem growths).

There are also handles made of oak, acacia, maple and other hardwoods. All selected workpieces require long-term drying.

After the piece of wood has dried well, the contours of the handle are drawn on it, according to a pre-made template. In order to avoid slipping of the hand during work and to increase the indicators of the convenience of the ax, a thickening must be provided at the end of the handle.

A knife, chisel, electric jigsaw will help to cut the contour.

After trying on the ax head and not finding any signs of a loose fit of the parts, you can safely continue improving the ax. The glass will help you loop the tool, and the sandpaper will be useful for sanding.

Sharpening the piercing part of the taiga ax

A properly sharpened blade gives excellent performance of the hatchet. The sharpening angle depends on the activity you will be doing with the ax.

The taiga ax is sharpened at an angle of 30-35 ̊. If they will be working with fresh wood, then sharpening is performed at an angle of 25 ̊.

If you use a grinding wheel for sharpening, then the handle of the ax must be held at an angle of 40-45 ̊. We reproduce the sharpening slowly, carefully.

If you have all the necessary tools in stock, a photo of the step-by-step manufacture of an ax, then its creation will not take a lot of time, effort and money, and in return you will receive a high-quality ax made with your own hands.

But do not forget that with a piercing part made of high-quality metal, the ax will last much longer and if the handle is treated with linseed oil, it will not rot and deteriorate.

Planting an ax on a hatchet

At first, this procedure seems straightforward.Such a false impression is due to the simple connection of elements - pushing and wedging. However, the procedure is quite laborious and has a number of subtleties that are by no means recommended to be ignored. In order to facilitate this work, a professional and experienced carpenter always follows strict step-by-step instructions.

Preparatory work with the tool

First of all, you need to acquire a hatchet. You can buy it at any specialty store, or you can make it yourself. Pre-dried birch is an ideal material. Experienced carpenters prefer this type of wood. It has the necessary set of properties and therefore is so popular.

When choosing a handle, it is recommended to pay attention to its density and shape. Grip comfort is an important criterion.

If you do not take this moment into account at the initial stage, while working with an ax, your hands will experience discomfort, which will quickly lead to severe fatigue.

Next, you need to purchase a handle of a suitable size, which will fit tightly into the metal hole. By means of a woodworking device or a sharp knife, it is necessary to cut the handle so that it acquires the required shape (straight or ellipsoidal). An ellipsoidal hole at the ax is considered more reliable due to its attachment. Then small cuts are made on the upper surface of the handle. Visually, they resemble longitudinal grooves.

The most important nuance at this stage is the depth of the grooves. The cut grooves should be hidden in the hole of the ax. Otherwise, during the wedging process or during use, the handle may simply crack. It is necessary to strive to ensure that the width and thickness of the wedges are the same.

Creating wedges

The reliability of the fasteners is largely due to high-quality wedging. This will help the use of wedges made of metal and wood. As with the hatchet, wedges can be purchased from a specialized department store or made at home. An important condition is compliance with the shape and size between the wedges and the material used in the manufacture of the hatchet. The best wooden wedge, according to professional carpenters, is made from dried birch, metal - from hard tin, the so-called shovel.

Hammering

Perhaps the main difficulty faced by everyone who decides to independently plant an ax on the handle is hammering in steel or wooden wedges. In fact, this process is not as complicated as it might seem at first glance. This stage can only be started after the handle and wedges are fully prepared. To begin with, the longitudinal wedges are hammered with light hammer blows. It is not worth carrying out strong blows due to the fact that the wood can deform. And this can subsequently lead to instability of the fasteners carried out further.

As soon as the wedges fit tightly into the grooves, using a hacksaw blade, you will need to delicately cut off the remains. You can verify the successful performance of the work by the strength of the clutch of the ax and the handle.

Wedging

There is an opinion that a wooden wedge must necessarily be made from the same type of wood as the handle. However, this is a delusion. The main condition for choosing a material is its strength. In turn, the direction of the wood fiber should also be taken into account, since it is recommended to keep the tapering of the wedges parallel. This will protect the tool from possible damage.

Successful wedging can be considered the complete filling of the space of the grooves with wedges, and it is considered impossible to remove the ax from the hatchet.

Sometimes it is still not possible to avoid gaps in the hole of the ax.Then an ordinary piece of gauze will come to the rescue, which was previously treated with epoxy resin. This composition allows the wood to be protected from moisture and impart a reinforcing property. To remove the gaps that have arisen before the procedure of inserting the ax, its upper part is wrapped several times with treated gauze. Thanks to epoxy resin, any gap, crack or gap is filled, forming a reliable and strong attachment of the ax to the handle.

Preparing the template

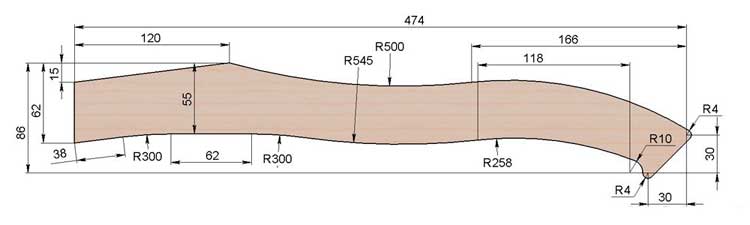

When ready-made material is available, you can start creating the hatchet itself. To do this, they think over and make a sketch of the handle, thanks to which the process of manufacturing the product in question is facilitated. The shape of the hatchet is determined by the type of tool. If a handle is required for a light ax weighing 0.8-1 kg, then its length is 0.4-0.6 m. The length of heavier ones can reach 0.6-0.9 m. Axes are classified by purpose:

- carpentry;

- lumberjacks;

- delimbing;

- cleavers;

- butcher's.

Based on the purpose of the tool, the length of the ax will also depend. When making it, you should adhere to the following rules:

- in order to prevent the hatchet from slipping while working with an ax, the tail should be somewhat wider than the handle itself;

- a cleaver's ax is made with a length of 0.75-0.95 m, while for a carpenter's ax it is 0.5 m;

- add 10 cm to the length of the handle for an allowance. This part is cut off after the butt attachment.

A future handle of the desired shape and size is drawn on cardboard, after which the image is transferred to a tree and cut out with carpentry tools.

How to choose the right wood for the handle

Curiously, not all tree species are suitable for making a hatchet. It is recommended to use only hardwood, previously dried in special chambers or cured in a dry place. Failure to comply with these requirements will lead to the fact that in the process of use the handle will dry out and it will be very problematic to securely fasten the blade to the handle.

Craftsmen use several types of wood to make wooden handles, each of which has its own advantages and disadvantages. Let's try to figure out which wood will make the best handle for an ax.

Birch

This is a come and take feedstock, but the availability of the material does not guarantee high quality. To make a high quality birch hatchet, the wood will have to dry for 10-12 months. Even then, the material remains sensitive to the humid environment.

Maple

Also available and common material with a limited area of application. In particular, maple sticks are not suitable for making quality tools for a carpenter or lumberjack. However, the wood has a beautiful texture, so it is ideal for decorative and souvenir wood products.

Hickory

This unusual name hides an American nut that grows in Canadian forests. For the manufacture of an ax handle, this is the best option, successfully combining indicators of strength, elasticity and durability. However, only American and Canadian loggers can truly appreciate these benefits.

Jatoba

It is a species of wood, unique in its properties, which is used for the manufacture of sports equipment and furniture. Jatoba is easy to process and has a presentable appearance. At the same time, in terms of strength, such an array is not inferior to oak, so the handles for an ax made of it are very reliable.

Ash

Among the listed options, ash is considered the optimal balance of availability and quality. At the same time, wood has an interesting texture, therefore, after appropriate processing, the wooden handle will have a presentable appearance without losing strength and elasticity.

The choice of blank and the manufacture of a hatchet

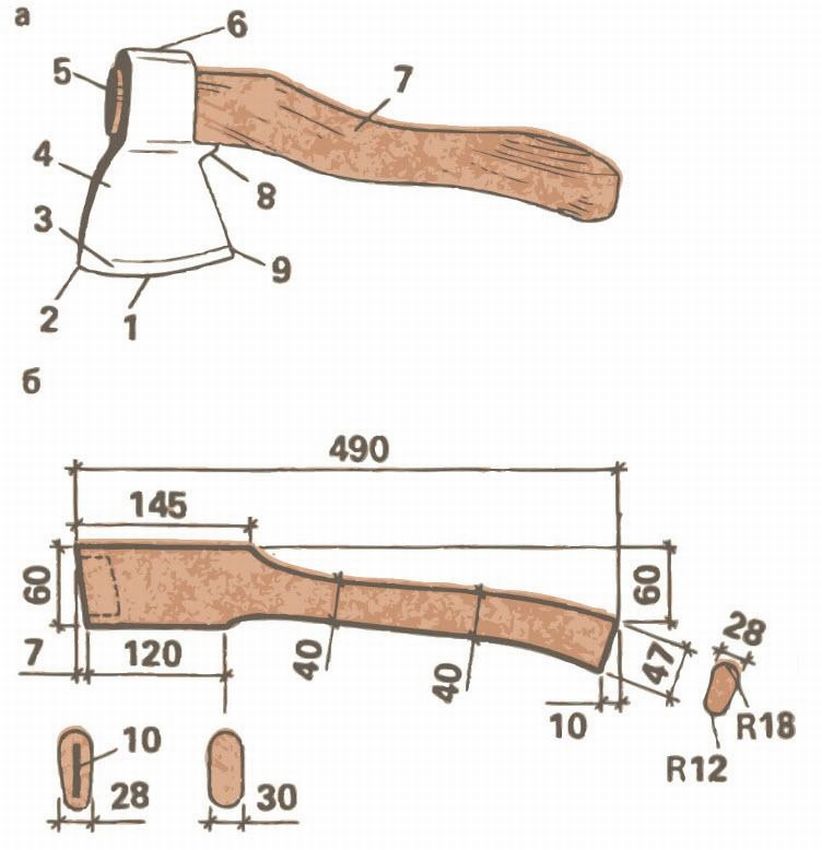

The length of the ax is chosen based on the height and strength of the master.The quality of the wood plays an important role in this. Lightweight axes, weighing about 800-1000 g, have handles ranging in length from 40 to 60 cm.In a heavy tool (1000-1400 g), the length of the ax varies from 55 to 65 cm.

Recent Entries

5 unusual zucchini dishes instead of pancakes and stews that have set the teeth on edge 8 folk remedies for fighting the Colorado potato beetle: for those who are against "chemistry" in the garden 5 ways to use garlic arrows that experienced gardeners know about

The force of the blow depends on the length of the ax. The longer the handle of the ax, the easier it is to chop wood. A person's strength and height also matters

Not every type of wood is suitable for making an ax handle. For this purpose, a true master goes through the entire forest before finding a suitable tree. Most often, the blank for the ax is made from the root part of a birch, or better from the growths on its trunk, which are distinguished by a special twisted and very dense wood. Maple, oak, acacia, ash, and other hardwoods can be used in place of birch. The workpieces must be well dried in natural conditions, which will take a lot of time.

On the prepared workpiece, the contours of the future hatchet are outlined according to the selected template. A bulge should be provided at the end of the ax handle, designed to "brake" the hand in the event of the tool slipping out. Then the excess wood outside the contour is removed with a knife, ax with a perfectly sharpened blade, chisel or jigsaw, which is much faster. Having completed the fitting of the ax on the hatchet with a mallet, and making sure that these parts fit snugly, you can continue further finishing the tool handle. Glass is used for scraping, and fine-grained sandpaper is used for grinding.

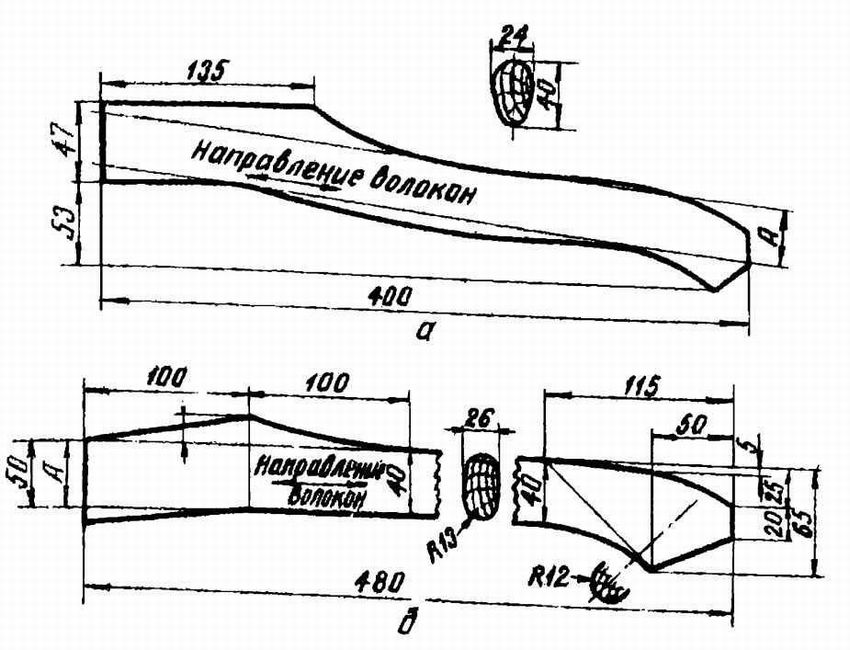

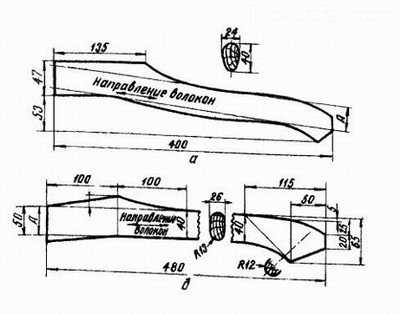

Above is a drawing of a hatchet (a) that meets the requirements of GOST 1400-73, and below is a handle of a camping ax (b) with an undisturbed fiber zone of 40 mm

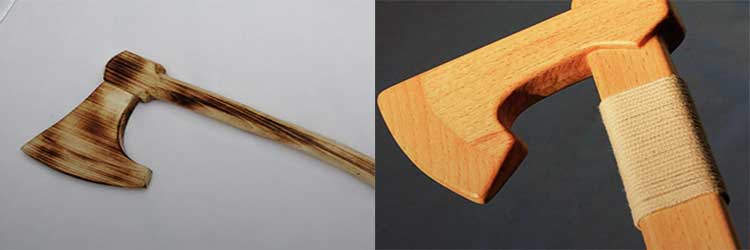

How to carve a toy ax

A homemade plywood ax can be an interesting toy for a child or a great addition to a New Year's costume. Often young children, adolescents and even adults want to make wooden axes, like in computer games like Minecraft. Such a product can be made in 1.5-2 hours with minimal financial costs.

It will take longer to make an ax from solid wood, since wood will be more difficult to process than plywood. The parts are cut with a special cutter or a sharp knife, removing the chips layer by layer, observing the observance of the dimensions and proportions.

With plywood, everything is easier. First you need to find a ready-made template or draw it yourself in full size. The drawing is transferred to a plywood sheet. Separately, the blade and the handle are cut out with a jigsaw.

To make the wooden toy look more natural, it is better to glue the blade from two halves, after cutting the groove for the handle.

> Then both halves of the plywood ax blade are placed on the handle, fixed with pins and glued with PVA wood glue. After drying, the wood blade is given a sharpening angle. You can perform this operation with an ordinary file. At the final stage, all surfaces are processed with sandpaper, the blade is covered with several layers of silver paint. You can custom-design or stick a sticker. The finished wooden toy looks very nice.

How to plant an ax on a hatchet

The ax assembly procedure may seem simple, but this is only at first glance. To do it correctly, you need to know some of the nuances that are not recommended to be overlooked. Therefore, certain instructions must be followed.

Preparing the ax

After buying or making an ax, it needs to be adjusted to the hole of the ax. The handle under the eyelet is cut with a sharp knife, achieving a straight or ellipsoidal shape.After that, cuts are made in the form of longitudinal grooves on the upper part of the handle.

The depth of the grooves should be such that they are hidden in the eye of the ax. Otherwise, the handle may crack.

Making wedges

The reliability of the tool tip is largely determined by the quality of wedging. The material for the wedges is wood or metal. These items can be bought or made by yourself. Professional carpenters are of the opinion that the best wedge is the one made from dried birch. The metal element is made from a piece of a shovel.

Wedge driving

After preparing the hatchet and wedges, you can start wedging. First, the longitudinal elements are hammered, light blows are applied with a hammer or the butt of another ax. It is not necessary to hit hard, as the wood can deform. Then the transverse wedges are driven in. The protruding parts are carefully cut off with a hacksaw and are convinced of the reliability of the ax head. The procedure can be considered successful if the handle cannot be removed from the ax, and the space of the grooves is completely filled with wedges.

It so happens that it is not possible to completely get rid of the gaps. In this case, you can use regular gauze soaked in epoxy. To do this, the upper part of the ax is wrapped with soaked gauze before the ax is inserted. Epoxy resin allows you to eliminate any gap or crack, thereby forming a reliable fixation of the hatchet.

Varieties of axes

Axes are of several types, and each has its own purpose. Professionals distinguish this tool by the width of the butt, which can be wide, medium and narrow. At the same time, some use it for universal work, others for logging, and some varieties are used for neat carpentry work.

The main types of axes:

- cleavers;

- for felling timber;

- construction;

- tourist.

Within each of these groups, there are various tool options designed for narrow-profile or other special jobs.

Handle differences

Hatchet - this is the name of the handle for an ax. There are many varieties of them, made from various materials. Plastic and metal copies are not in widespread demand, and their practicality can be confidently questioned. The most common wooden components of the tool are capable of damping inertial vibrations during operation.

Axes classification by handle:

- Lumberjack. When using this tool, you must hold it with both hands. Although this ax can quite successfully chop wood, its main purpose is to chop trees.

- Woodcutter. The ax is widely used in the household on the personal backyard. It is suitable for some types of carpentry work, chopping wood and cutting small trees, branches.

- A carpenter. It is mainly used for processing logs and various wood blanks. They can chop wood and cut down small bushes. The handle allows you to conveniently use the tool with one or two hands.

- Srednerus. This ax is designed to be gripped with both hands, usually equipped with a powerful sharp blade and is used for butchering animal carcasses. It is noteworthy that the second name of this tool is the taiga ax. On long-distance expeditions, it is very convenient to cut through glades with its help.

- Ermak. It is of medium size, and the small handle, held with one hand, offers a higher load when working with the tool. It is convenient to carry it with you. It is mainly used for domestic needs and for splitting firewood.

- Strong guy. Small size allows you to take it with you on hiking trips. With its help, you can put up a hut, cut small tree trunks, chop wood or cut a hunting trophy.

There are a number of other varieties, but they are professional, designed for special work that requires specific skills.

Firewood chopping

For the preparation of firewood, an ax is most often required in country houses and rural farmsteads, since even for frying a shish kebab, wood will serve as the best fuel.

The wood ax blade is sharpened at an angle of about 40-60 degrees for better chopping.

The handle is most often made of wood, but it can also be metal, the blade is made of hardened carbon steel

When asking which steel to choose, always pay attention to the manufacturer's seal installed on the handle.

You can start the list of the advantages of an ax with the ease of working with it, since a beginner can also cope here. The second plus is affordability for the buyer in the sense that finding such an ax is easier than ever in any store.

Also, there is a wide price range for these axes, from which everyone will choose something for themselves.

The disadvantage of an ax of this format is that it is intended only for one type of work and cannot be used in other areas.

They cannot cut down a tree, and it is quite unsuitable for a butcher, since it is not so sharp. The disadvantages include the easy opportunity to get a fake of low quality, which the market is full of.

How to properly and permanently plant an ax on an ax

Many of us are familiar with the situation when a perfectly planted ax suddenly starts jumping off the ax. Few for whom this phenomenon is inexplicable.

Each of us understands that the wood drying process is to blame.

But you should know that this can be completely avoided if the insertion is technologically correct and if, at the end of it, a couple of simple, but very reliable actions are performed. This is what I will tell you about in order.

There are two sequential stages in this process:

- Selection and preparation of the hatchet.

- Actually putting the ax.

It is this logic that I will follow in my story.

Which side to plant the ax? Many craftsmen know that the input eye of the ax is less than the output. Why is this done? Yes, so that the hatchet can be wedged in it and securely fastened. Given this fact, you should choose the right ax for a specific ax.

First you need to remove the size of the exit hole (larger in size), outlining its inner outline on a piece of paper.

Then a template is cut out along the drawn contour of paper, on the basis of which a search for a suitable hatchet in the market will be conducted.

The picked up ax must be given a couple of days in order for it to completely dry out. To do this, you just need to put it on the heating radiator and occasionally turn it over there.

Do you want to know how to equip your workshop so that it is very convenient to work in it? Then read this article by my colleague!

Planting an ax

Planting an ax begins by placing it on the edge of the ax, 5-7 millimeters from its edge, and then marking the border of the part that will be processed, i.e. the border of insertion.

- Then the outline of the template must be transferred to the butt of the ax.

- Having completed the markup and armed with a large rasp on a tree, they process the end of the hatchet up to the boundary mark so that at the end it goes to the outline of the template.

- As a result, the end of the workpiece should coincide with the contour applied to it.

After that, you can start trying on. Moreover, you need to try on at the exit (large) hole of the ax. If necessary, it should be sharpened more. The processing should be finished when the ax starts to lightly "bite" the tree of the ax.

Having achieved such a "bite", the very edge of the piece of wood is sharpened so that it goes into the ax by about 1 cm.

Can you sharpen an ax? If not, click here!

After that, you need to take a caliper and measure the size of the ax inlet.

By further processing, this size should be achieved on the hatchet in the area of the initially applied boundary mark.Moreover, the processing is carried out along the entire perimeter of the workpiece so that it completely fits into the outlet of the ax.

Further processing should lead to the fact that the end of the piece of wood should resemble in its shape a champagne cork with a thickening downward.

As in the beginning, the workpiece is machined using a rasp.

The control of the dimensions of the workpiece for their correspondence to the dimensions of the holes of the ax should be constantly carried out using a vernier caliper. Having achieved full compliance, a small chamfer is removed at the very edge of the ax to facilitate the process of entering the workpiece into the ax.

- After finishing processing, markings are made for two slots on the processed end.

- The marked slots are made to a depth not reaching about 1 cm to the border of the ax's insertion.

- Having inserted the sawn end of the ax into the inlet, they begin to tap on its opposite end in order to plant the ax on a wooden blank.

Then 3 wedges are installed on the glue in the cuts: one large longitudinal and two wedges on the sides. After inserting the wedges, the butt of the hand should be machined to give it perfect evenness.

The ax is now very securely attached to the ax. But if the ax is left in this state, the wood will inevitably dry out, and the tool may become unusable.

What needs to be done so that the ax is securely fixed on the ax handle forever

To prevent drying out of the hatchet, its end should be preserved by soaking it, for example, with linseed oil, any oil paint, PVA glue or epoxy, etc. This is the secret of keeping the ax on the ax forever.

It also makes sense to process the rest of the hatchet with something. The choice of material depends only on the preferences of its owner. This will both preserve the wood and make it more pleasant to the hands.

These are all the secrets to properly plant an ax on a hatchet and ensure that it stays in working order forever.

I like it! 304

I don't like it! 39

Useful tips from the "handy" owner

Wood splitters and their varieties