Diy ax photo

Note!

Note!

In different countries, different materials are chosen for the hatchet. Maple, birch, beech, oak, ash are considered to be the most frequently used woods. For example, in the southern part of Europe, most often the instrument is made from white acacia. In Russia and the CIS countries, the most popular material is birch. Oak and maple are considered to be reliable woods. Different countries choose different materials for the ax. Maple, birch, beech, oak, ash are commonly used wood. For example, in the southern part of Europe, the instrument is most often made from white acacia. In Russian realities and the CIS countries, the most popular material is birch. Oak and maple are considered reliable timber.

It is easy to work with birch - basic processing and grinding. Strong impact and fatigue are not felt. The wood can withstand heavy loads and impacts. A serious drawback is rotting due to the ability to absorb moisture, which leads to a loss of strength. The birch dries up, but the shrinkage becomes too great. There is no way to somehow protect the birch from moisture.

With a birch ax, you can go to the forest for a couple of days, then dry it. And everything seems to be fine, but after 1-2 months you will notice that the ax is very loose. A temporary solution to the problem is an additional wedge. You can also soak the ax in water. However, now you have to constantly soak the ax to work with it. A birch ax is not a reliable tool if you are not ready to make or buy a new one every month.

On hikes, most often the tool is needed for cutting across the fibers. As a result, the ax receives a heavy load, if it is made of birch, it can loosen.

Maple ax

The maple ax is not very loose. Even if the instrument is exposed to varying humidity. The handle gets a clean and even surface, there are no problems with its processing. Maple does not rot as quickly as birch. Maple is better than oak and birch in strength, but birch is in the first place in toughness.

Ash is considered by many to be the ideal option. This is confirmed by the production of hockey sticks, baseball bats, oars, skis and so on from ash. Strength, reliability, however, wood is more rigid in comparison with birch, but ash has more advantages.

Ax made of oak and beech

Among the advantages - the elementary processing, long service life, high strength, elegant structure. But there are serious drawbacks - it is inconvenient to work with oak, as it dries your hand. If you make the handle long enough, there will be no strong recoil, but physical activity will increase. The beech is easy to work with - it has a pleasant surface. The downside is hygroscopicity. You can soak the material with oil, but the procedure will not give significant results.

Excellent impact resistance, as evidenced by the production of sports equipment from this type of wood, the manufacture of furniture. Viscosity, hardness, strength. In terms of strength, jatoba is better than oak. Outwardly, a tool made of jato will look solid (which must be taken into account when making a gift).

Advice

To make a hawk, you need chipped headers. Do not use boards, because in this case, the strength of the ax will be minimal.

It is important to achieve a high flexural strength of the handle. If you choose a birch, then be sure to clean the bark from the chocks and heat them on the chopping blocks so that the inner layers dry out as quickly as possible - otherwise the birch can rot

You cannot use only cut wood for the ax for a number of reasons:

Minimum strength;

Too much shrinkage after drying;

The wood will crack and warp.

An ax forged by a blacksmith must be planted on the ax. The ax attachment is not such a simple process as it seems at first glance and has many subtleties.

Varieties of axes

The ax is a tool that appeared at the dawn of civilization, but people still use it to this day. Over time, different types of these tools have appeared. They will come in handy at home, hunting, hiking, etc. These tools are sold in stores, but you can make them yourself. Our simple instructions show you how to make an ax. To do this, you need reliable and durable materials, strict adherence to instructions.

First, let's figure out what types of axes are:

- Tourist. The dimensions and weight of the tool are small: 350 mm / 0.5 kg. It is suitable for simple work.

- Household and catering. This tool is used at home, in the country or in cafes and restaurants for butchering meat and chopping bones. An ax with a wide steel blade will last a long time.

- For firewood. The blade of the ax is made of hardened steel (sharpened 40-60 °), the ax is made of wood. The tool is simple and convenient to use.

- Taiga. This device has a shape and size that differs from the parameters of a conventional ax. It is on a hike and other harsh conditions.

- Plotnitsky. This ax has a sharp blade and a comfortable grip. It is not used for cutting firewood.

- Cleaver. Such a hatchet easily splits logs.

- Combat. Battle axes are edged weapons. They are bought only as collectibles with documents.

How to store an ax?

The order in the workshop, when each instrument is in its place, characterizes a good owner. Any ax - marching or carpentry, needs proper storage. It is impossible to forget that this is a dangerous piercing weapon. In order to ensure the safety of pets, it is worth taking care of the place where the ax will be located. It is impossible to leave the tool stuck in a log or any wooden surface, because of this it quickly becomes blunt. The right place for him is a shelf or stand, from where he cannot fall.

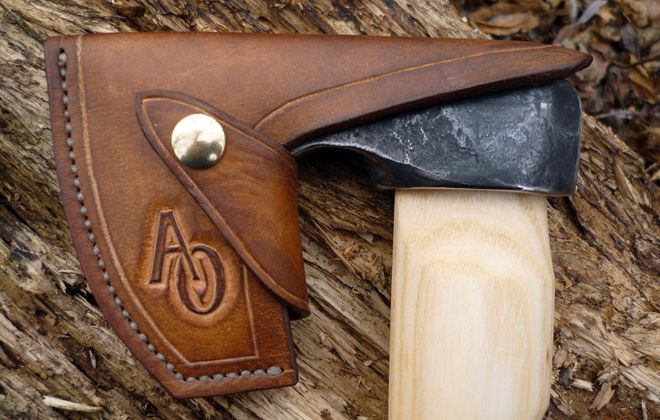

Ax case

In order to provide the ax with a long service life, during storage it is necessary to put on a cover or special sheath on it. It is convenient to carry a hunting ax in a holster, which is attached to a belt. It is best if the cover is genuine leatherso that the metal blade is protected from moisture and negative influences environment. You can sew such a cover yourself using skin scraps, tracing the blade along the contour and leaving a couple of centimeters as an allowance. The edges of the cover can be sewn or glued together with special glue.