How to do it yourself?

In this part of the article, we will look at how to make a homemade ski module.

Tools and materials

Materials can be purchased in the store or taken from old unnecessary equipment:

- profile pipe;

- saddle;

- plastic skis;

- steering wheel;

- shock absorbers.

Instruments:

- welding machine;

- Bulgarian;

- drill;

- spanners;

- small consumables (fasteners).

Manufacturing scheme

The main part of the design of the ski module is the skeleton frame, it is recommended to start assembly from it, in accordance with the previously selected drawing. The main design feature is the distance between the skis (about 90 cm).

The control system of the motorized towing vehicle is transferred to the steering wheel of the future module. The last step is to attach the seat and ski springs.

Choice

When choosing a pusher, it is necessary to take into account that the width of the sleds should be slightly larger than the width of the tracks of the motorized towing vehicle. The trough should be made of high-strength plastic - this material reduces the weight of the structure and will not create unnecessary stress on the equipment.

The driver's seat should be soft and adjustable for the user's height. Riding in a hard and uncomfortable chair is very difficult and uncomfortable, especially over bumps. It will be good if the pusher design includes a headlight and protective glass. The frame must be painted with an anti-corrosion coating.

The pusher can be attached either from the front or from the back. A pusher model with both of these options is ideal, as the attachment behind the towing vehicle can be used to carry additional cargo.

As for the height of the sides, they can be low or high. The opinion is erroneous that high sides better protect against snow getting inside the module. On the contrary, the low sides are much more convenient, and the snow does not fall into the trough, since it is already rammed by the front part of the device, which has a beveled appearance.

What are they?

You can make a vehicle resembling a snowmobile out of a motorized tug with the help of a ski-wheel module. With it, the ease of use is increased several times. The driver is no longer on the sleigh, but in front of the motorized dog, and he himself makes the turns of the steering wheel. The most convenient device for driving on snow, in the summer it can be replaced with a similar wheel module.

The entire system weighs about 20 kilograms and also does not take up much space during transportation. You can use a single ski module or with two skis in the front.

The advantages obtained by installing the steering module are an increase in the capacity of the drag sleds:

- the driver no longer controls the vehicle from them;

- the speed of the towing vehicle increases, because the weight is evenly distributed;

- ease of management;

- also due to the correct distribution of the load, the contact of skis and tracks with the surface increases, and fuel consumption is reduced;

- stability of the system due to the wide arrangement of skis, that is, the towing vehicle will not turn over at an unexpected moment.

In addition to the pluses, there are also a number of minuses:

- you will have to obtain a license to drive a vehicle, since the new design is comparable to a mini-snowmobile;

- difficult to drive through loose snow;

- frequent breakdowns due to heavy loads on the frame and chassis of the motorized dog.

The pusher module looks like a sled with metal runners and a plywood bottom. Its main function is to compact the snow in front of the tracks. The transformer pusher can be located both in front of the motorized towing vehicle and behind it.

Their name comes from the old construction - "drag".Conventional sleds move through the snow using two skids, and sleds do it using the bottom. They can be divided into 2 subspecies - transport and fishing, the differences are only in size. In addition to the bottom of the sled, you can attach special pads 8 mm thick, which will protect the plastic from abrasion.

Appointment

A motorized pusher can significantly improve the cross-country ability and controllability of a motorized towing vehicle in shaky and deep snow, since the peculiarity of its design and a sitting person create a large load on the snow surface, crushing the snowdrifts underneath. In this case, the snow layer is compacted along the path of movement to the width of the tower's tracks, which facilitates its movement.

Thanks to such a module, the performance of the motorized dog increases during the climb, and the weight of the driver sitting in it contributes to additional compaction of the snow mass, and subsequently to better grip of the tracks of the machine with its surface.

And also the turning angle is much reduced, which increases the maneuverability and speed of the vehicle. All the advantages of a pusher are usually felt when traveling long distances.

Of course, clutching to the module significantly increases the load on the towing frame, which reduces its durability. In summer, the pusher can only be used in swampy areas, so as not to disable it.

Popular brands

To develop and produce equipment with the best cross-country ability and very powerful motors, you need a lot of experience in mechanical engineering. The following firms have recommended themselves from the best side:

- Lebedev Motors is a young company from Russia, since 2008 it has been producing off-road vehicles with one or two tracks;

- Omela Group - became famous thanks to the Pomor brand, produces motorized towing vehicles and equipment for them;

- "Baltmotors" is a production in Russia, closely cooperating with partners from China, their main goal is customer focus and affordable prices;

- "Paxus" - all-terrain vehicles of this company are distinguished by low fuel consumption, high maneuverability and ease of operation;

- Irbis - the company started its activity in 2001, now the main office is located in Moscow and has more than 2000 service centers throughout the country.

The best models from manufacturers

We will provide an overview of the most purchased models of pushers that have found application in the snowy regions of our country.

For motorized towing vehicles "Koira"

This module comes complete with a sled and a fender, and is installed in the front of the towing vehicle. The driver is in a sitting position, which greatly eases the hardships of a long road on snowy terrain, for example, to the place of hunting or fishing. The pusher increases the speed of the track, significantly compacting the snow underneath. The device is manufactured with a high level of quality: the frame, steering wheel and all components for control are made of a thick profile pipe with a section of 40x25 mm and a wall thickness of 2 mm. The steering section rotates smoothly and quietly thanks to rubber bushings.

Dimensions:

-

length - 165 cm;

-

width - 60 cm;

-

height - 26 cm.

The dimensions at the extreme points of the bump stop are 160x82x46 cm. The steering wheel is equipped with a 56 W halogen headlight. The soft convertible seat can be adjusted to suit the height of the driver. On the steering wheel there is a trigger for switching on the gas and a button for adjusting the lighting. For safety reasons, an emergency stop check is provided.

Pusher for a motorized towing vehicle "Muzhik"

This version of the pusher is also mounted in front of the motorized towing vehicle, and, like the previous one, allows the driver to move long distances in a sitting position. The trough of the fixture is made of high-strength plastic. The frame is welded from a profile with a size of 20x40 mm and a wall thickness of 2 mm. The dimensions of the structure are the same as for the module for the "Koira": 165x60x20 cm.Sledges with a bump stop have the following dimensional parameters: length - 145, width - 60, height - 26 cm.

The model has a soft and moisture resistant seat. There is a lever and a throttle cable, there is an 18 W LED headlight. There is an engine control on the steering wheel. The handlebars have a comfortable rubber base.

BTS towing module

It weighs 25 kg and has the following parameters when assembled:

-

length-185 cm;

-

width-78 cm;

-

height-63 cm.

The set includes sledges, the length of which is 1.5 m. The design is equipped with a spacious, durable and moisture resistant seat. There are rubberized handles on the steering wheel, there is a headlight for lighting and a gas cable.

Exploitation

Before using the pusher, it is necessary to check all fasteners, the operation of the stop and gas levers, the performance of the headlight, the fastening of the cables and wires. The pusher should be securely attached to the towing vehicle.

After the first ride, check the tightness of all threaded connections, and after each use, clean the module from dirt, snow, ice, lubricate the articulated joints with oil. If it is heavily soiled, it is necessary to wash the module. It is necessary to use detergent for washing.

The pusher should be stored in a dry, well-ventilated room or in a special small building. You can also leave it outdoors under a canopy, but so that direct sunlight does not fall on it during the warm season.

Before turning on the engine of the motorized towing vehicle, make sure that the throttle lever of the pusher module has free play and is not blocked. In addition, the parking brake must be applied.

Changing the design of the module is strictly prohibited.

Its use is permitted exclusively for hitching with a motorized towing vehicle or sled in the front or rear. Not intended for use on sandy soils and water.

An overview of the Hurricane model in the video below.

How to choose?

The first thing you should pay attention to when choosing a motorized towing vehicle and accessories for it is the dimensions. Compact models can be placed in a car, while standard-sized units are moved in a trailer.

Goose and its passability

Given the size, do not forget that the larger the tracked conveyor of the motorized towing vehicle, the better.

The engine and its power. The more people move on a motorized dog, the more horsepower the engine should have. It is worth remembering that the Chinese manufacturers actually have "horses" not as powerful as those of the Americans. That is, an American engine of 13 liters. with. will work more productively than the Chinese 15 hp. with.

Workmanship. It is necessary to immediately carefully inspect the accuracy and evenness of the seams, the uniformity of the coating of parts.

Drive - front or rear. With rear-wheel drive, control of a laden motorized towing vehicle is easier, since the center of gravity is located near the steering wheel, but an empty unit will rears up or bury itself in the snow instead of moving. In front-wheel drive, the contact of the goose with the surface is better and maneuverability does not depend on the load.

CVT or gearbox, as well as the type of suspension.

Convenience of systems adjustment. Any motorized towing vehicle requires periodic inspection of structural units, an important criterion is the simplicity and convenience of these operations. When choosing, you should pay attention to the casing - it can be plastic and can be removed without problems or made of special material, with fastening valves.

Accessories. Here you can do without restrictions, according to the principle "the more the better" thanks to all kinds of modules, track planners, wheeled carts. The motorized towing vehicle will become an indispensable assistant with many options for any time of the year.

Manufacturing

Before making a homemade pusher for a motorized towing vehicle with your own hands, you need to accurately select the main characteristics of the product

Particular attention is paid to:

-

sizes;

-

carrying capacity;

-

engine power;

-

the execution of the transmission;

-

starting method (manually or from an electric starter);

-

additional equipment.

A properly designed pusher guarantees a very high cross-country ability even in deep snow. The sled must be oriented in such a way that it passes any part of the path before the ATV enters it. A typical pusher module is therefore placed at the front. It performs the tasks of conventional steering. The optimal profile dimensions for the drawbar are 20x40 mm.

Such a part must be welded to the profile and a new silent block must be pressed in. The bolt must be taken 12x80 with a medium-sized thread; some experts advise using Volga stirrup bolts.

If everything is done correctly, the part devoid of threads will definitely be inside the silent block. Next, you yourself need to weld the nut for this bolt and the ear of the slip suspension. The bolt is counterbalanced from the opposite side of the ear using an automatically locking nut. The drawbar is attached to 4 bolts and auto-locking nuts are used in the same way.

When this is done, the wiring connector can be connected. After it, the throttle cable is attached for the pusher. The seats are selected quickly removable, which are placed and removed in one motion. The best seats, according to experts, are made of PCB. The steering wheel and the column for it are taken from Ural motorcycles, the fork is boiled from their own frame.

You can attach the pusher to the drag using a pair of bed corners. They are welded, measured exactly in the allotted place. A larger nut is placed at the bottom, which acts as a bolt centralizer.

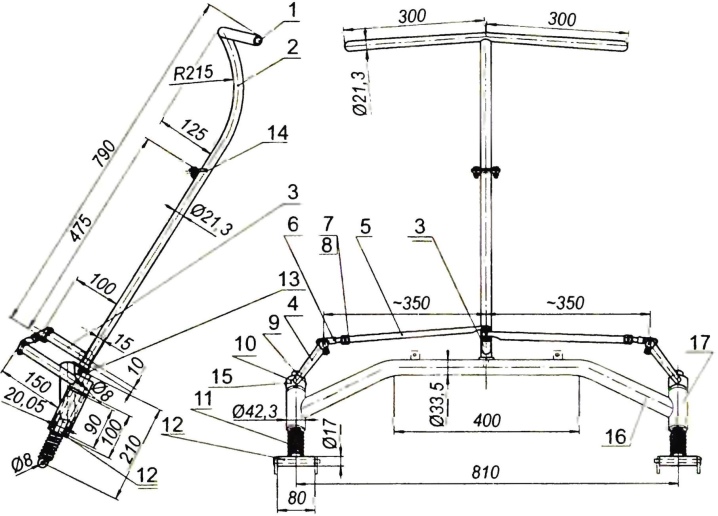

Speaking about the drawings of the pushers, it is worth mentioning the schematic diagram of such a device. Shown here are the axle box geometric center, general mounting arrangement and assembly as a whole. Sorry, no dimensions are specified.

And here are all the necessary dimensions for a motorized towing vehicle as a whole. The attachment points of the main parts are also indicated.